Micro Bevel How To

Recent › Forums › Main Forum › Welcome Mat › Micro Bevel How To

Tagged: micro bevel

- This topic has 24 replies, 9 voices, and was last updated 12/26/2015 at 4:28 pm by

Mark76.

-

AuthorPosts

-

12/26/2015 at 9:04 am #30055

Without getting too much further into it, you’re also looking at the crystalline structure of the elements evolved beyond the sharpening when it comes to the obsidian vs steel argument.

It’s basically the works of ultramicrotomy starting to bridge into surgery. The diamond knives of ultramicrotomy are used to create 2000 radial cross sections of a single hair, or 100 cross sections of a single red blood cell. That’s how fine we’re talking when it comes to the obsidian and diamond knives. The edges are not sharpened, they are made using fracture lines.

The “crystalline elements” – carbide dimensions and grain size are much larger than the edge width of a straight razor or surgical scalpel.

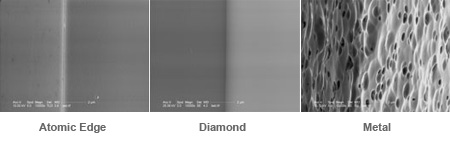

What is more important is whether the blade can make the cut without being chipped or folded. I can make a carbon steel straight razor sharper than a diamond microtome or obsidian scalpel, but the question is whether it will perform better for a particular application. Diamond microtomes are very keen, but the bevel angle is too high to cut anything but thin, flexible sections, and if the bevel angle were lower, they would be even more fragile than they already are.Your image reminds me of another BS marketing photo from http://www.beaver-visitec.com/brands/atomic-edge.cfm

where they show amateurish SEM images of their product vs the competition and where the steel scalpel is coated with teflon, so you can’t even see the apex.Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

12/26/2015 at 9:43 am #30059Thanks for all the great info. Three things I did wrong, I used normal pressure instead of light. I also did edge trailing strokes. And I probably did too many strokes.

I saw Clay’s video and thought it was interesting he used 200 diamonds. I understand the desire for a toothy edge, but this seems extreme (that I why I choose 400 and 600).

1 user thanked author for this post.

12/26/2015 at 11:44 am #30061Josh, maybe I should better ask this question at the guy of Science of Sharp (sorry, forgot his name), but how can you exactly measure the width of an apex? I.e. where do you measure it. For example, if you do it at the exact top you might end up with a few molecules’ width. If you do it just half a millimeter lower, it will already be much thicker. So how can the concept of apex width make sense without saying where you measure the width. (And this is even apart from measurement apparatus – unless you’ve got an electron microscope – and my hands simply not being exact enough to measure consistently at the same location for every knife.) This is the reason that in my Japanese Kitchen knife Reviews blog I measure the edge thickness only at 5 mm above the edge. I simply cannot get it more exact.

I think Todd (that’s his name – below) answered this well. It is my understanding that the apex width itself is what initiates the cut and the initial piercing of the material, but all the metal behind the apex is what determines how well that specific blade will cut. So I agree that the apex width alone isn’t relevant when discussing cutting ability. The cutting ability of a blade basically works like this… for shallow cuts the lower the initial angle the better it cuts, but as you get into deeper cuts in material that is thick, the actual grind geometry of the blade along w/ the stock thickness will be what matters most. So you basically have: the apex width (and everything entailed – wire edge, burr, micro chipping, etc), then the secondary bevel (using this “western terminology” diagram) which is what most people mess with/sharpen, etc, then you have the primary grind, and finally the stock thickness. All are relevant and *should* be fine tuned to task specific cutting.

…..I have seen him say… 1. only a couple strokes with your highest grit stone (when micro-beveling) will lead to a wire edge until you do more and the micro-bevel both establishes and stabilizes.

This specifically refers to low angle primary (less than 10dps) where the apex will bend rather than abrade unless the micro-bevel angle is at least 5 dps higher. For example, micro-beveling a straight razor by adding tape gives inconsistent results because of this.

2. edge leading will give you minimal burr removal but can lead to micro-chipping/irregularities. …

Edge leading almost always prevents a burr on mid- to high-grit stones. Low grit results are quite variable, depending on the stone. The micro-chipping process is what removes the burr, so it is not a negative in this case.

Thanks for the correction Todd. Actually, your microbevel (even with tape) didn’t look all that bad to me hehe. So what you are saying is that increased angles will cause the micro-bevel to be stabilized from the start and not need additional passes (since there won’t be apex deflection w/ most knife blades)? The micro-bevel I applied (on the first page of this thread) was done on the Wicked Edge and was about 20 passes, feather light and edge leading, w/ 1um lapping film. It shaves nicely after the strop progression thanks to your input 😉

12/26/2015 at 2:24 pm #30063Your point is valid, in that softer metals can take a finer bevel due to glass’ brittleness, but you also said yourself – that edge will fold, and if it folds within the first stroke of the blade (such as with hypodermic needles) then all subsequent incisions will be tearing cells instead of cleaving them. There’s a reason glass and diamond blades are used in ultramicrotomy. But as we said, the risk of chips from the inherently sharper, but more brittle glass type blades getting sheared into the wound is why they’re still not fda approved. And like you said, given applications are everything. I am purely arguing surgical instruments and cell histology, where what we would call a toothy edge is not what you want when you’re bisecting tissue. At a 100 micron level, everything is toothy, but it’s not what we’re talking about because at a microscopic level, everything is irregular.

Also not sure why you’re picking on a maker of ophthalmic surgical blades. Ophthalmic surgery is by far the most demanding type of surgery with regards to knives used. I haven’t done any research into them, are they a fraudulent company? Because glass knives are used in ophthalmic surgery, particularly radial keratotomy, one of the only procedures done on the human body using diamond knives.

12/26/2015 at 2:45 pm #30064Thanks, Todd and Josh! That’s insightful.

A practical question, Todd: how can I, who only has a caliper and no electron microscope, measure the thickness directly behind the edge. Maybe my caliber is precise enough to actually measure this thickness, but how do I position it in such a way that it measures the thickness at, say, 10 microns behind the apex? Kind of the most precise I’ve been able to get is about 5 mm behind the edge, with an emphasis on “about”.

Molecule Polishing: my blog about sharpening with the Wicked Edge

12/26/2015 at 3:08 pm #30066Thanks, Todd and Josh! That’s insightful.

A practical question: how can I, who only has a caliper and no electron microscope, measure the thickness directly behind the edge. Maybe my caliber is precise enough to actually measure this thickness, but how do I position it in such a way that it measures the thickness at, say, 10 microns behind the edge. Kind of the most precise I’ve been able to get is about 5 mm behind the edge, with an emhasis on “about”.

If there is no convexity, then the thickness can be determined from the bevel angle and simple trigonometry. In the case of a microbevel, you would need to measure/estimate the width of the microbevel to calculate the thickness behind the microbevel. Light stropping will only convex the bevel very near the apex and will not affect the thickness appreciably 1mm or more back from the edge – again you could calculate it from the angle.

You don’t need to measure edge width – the ability of the shave or cut paper can tell you all you need to know about that.

12/26/2015 at 3:28 pm #30067Your point is valid, in that softer metals can take a finer bevel due to glass’ brittleness, but you also said yourself – that edge will fold, and if it folds within the first stroke of the blade (such as with hypodermic needles) then all subsequent incisions will be tearing cells instead of cleaving them. There’s a reason glass and diamond blades are used in ultramicrotomy. But as we said, the risk of chips from the inherently sharper, but more brittle glass type blades getting sheared into the wound is why they’re still not fda approved. And like you said, given applications are everything. I am purely arguing surgical instruments and cell histology, where what we would call a toothy edge is not what you want when you’re bisecting tissue. At a 100 micron level, everything is toothy, but it’s not what we’re talking about because at a microscopic level, everything is irregular.

You may find this link interesting:

https://scienceofsharp.wordpress.com/2015/03/24/sharp-and-keen-part-2/I believe that in days long past, the lab technician responsible for microtomy could hone his carbon steel blade to a level surpassing that of a modern diamond microtome blade.

Also not sure why you’re picking on a maker of ophthalmic surgical blades. Ophthalmic surgery is by far the most demanding type of surgery with regards to knives used. I haven’t done any research into them, are they a fraudulent company? Because glass knives are used in ophthalmic surgery, particularly radial keratotomy, one of the only procedures done on the human body using diamond knives.

I am not picking on them, I am pointing out that they make a blatantly false claim that metal knives have an edge radius of 600nm. Gillete razor patents explicitly state that they have an edge radius less than 1/10 of that dimension – and I have measured such blades to confirm this to be true. Even cheap, disposable scalpels are nearly as keen as Gillette Fusion blades.

12/26/2015 at 4:05 pm #30071Thanks, Todd and Josh! That’s insightful. A practical question: how can I, who only has a caliper and no electron microscope, measure the thickness directly behind the edge. Maybe my caliber is precise enough to actually measure this thickness, but how do I position it in such a way that it measures the thickness at, say, 10 microns behind the edge. Kind of the most precise I’ve been able to get is about 5 mm behind the edge, with an emhasis on “about”.

If there is no convexity, then the thickness can be determined from the bevel angle and simple trigonometry. In the case of a microbevel, you would need to measure/estimate the width of the microbevel to calculate the thickness behind the microbevel. Light stropping will only convex the bevel very near the apex and will not affect the thickness appreciably 1mm or more back from the edge – again you could calculate it from the angle. You don’t need to measure edge width – the ability of the shave or cut paper can tell you all you need to know about that.

Todd, is that true? I’m indeed talking about the case without convexity and without a microbevel. But don’t you need to know both the angle of the edge and the length of the edge? I can easily find out the angle of the edge (particularly if I sharpened the knife myself), but how do I find out the length of one of the triangles of the edge? For example, if the edge is 15 degrees per side and the edge runs for 1 mm on every side of the blade, the thickness directly after the edge will be different than when the edge runs for 2 mms on every side.

Molecule Polishing: my blog about sharpening with the Wicked Edge

12/26/2015 at 4:19 pm #30072..

Todd, is that true? I’m indeed talking about the case without convexity and without a microbevel. But don’t you need to know both the angle of the edge and the length of the edge? I can easily find out the angle of the edge (particularly if I sharpened the knife myself), but how do I find out the length of one of the triangles of the edge? For example, if the edge is 15 degrees per side and the edge runs for 1 mm on every side of the blade, the thickness directly after the edge will be different than when the edge runs for 2 mms on every side.You would need to measure the length of the edge with some modest magnification – a USB microscope with scale function, or laying your calipers across the bevel.

12/26/2015 at 4:28 pm #30074You would need to measure the length of the edge with some modest magnification – a USB microscope with scale function, or laying your calipers across the bevel.

Thanks again, Todd. But that was the original problem 😉 : my caliper and/or my hands are simply too fiddly to measure such small distances. But your USB-microscope idea seems indeed doable. I’m gonna try it!

Molecule Polishing: my blog about sharpening with the Wicked Edge

-

AuthorPosts

- You must be logged in to reply to this topic.