Knife clamping position questions

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Tips for Specific Knife Grinds and Styles › Knife clamping position questions

- This topic has 14 replies, 5 voices, and was last updated 12/12/2017 at 1:42 am by

tcmeyer.

tcmeyer.

-

AuthorPosts

-

12/07/2017 at 5:57 pm #42524

Rather than start several different threads as I try different knives, I figured I’d just start one and add to it.

My first question is about a Wharncliffe blade:

For a knife like this, if you were to ensure contact between the spine and the 2 depth key prongs, the perfectly straight edge of this particular knife would not be parallel to the top of the jaws, resulting in an uneven bevel width as you grind away.

So in this case, is it correct that what you want to do is mount the knife’s edge so it is parallel to the top of the jaws, which would mean the spine would only contact one prong of the depth key?

And for this particular knife, is it correct that you can basically clamp it anywhere along the blade since the edge is perfectly straight? There’s no reason not to clamp it in middle, but I just want to be sure I’m understanding correctly that in this special case, it doesn’t matter where you clamp it because the edge is perfectly straight.

1 user thanked author for this post.

12/07/2017 at 6:52 pm #42526I often have to clamp knives only resting on one of the two pins. Some thin knives like fish filet knives I clamp all the way up at the tip of the jaws well above the pins. As long as you use the advanced alignment guide or employ some method to document the position for repeatability of clamping it doesn’t matter in my book. Secure clamping is the number one priority for me.

I try to clamp knives centered forward and backwards so the stones are used equally towards the tip and towards the heel. I have not examined or scrutinized the bevel height or uniformity to determine if the clamping position for a knife like your example will effect the bevel size and shape or the angle consistency along the apex. It may well vary if you clamp it with the bolster or handle up against the vice with the blade all the way forward of the jaws. Consistency in the bevel, from one sharpening to the next time sharpened with repeated clamping is what I strive for.

I wouldn’t just clamp that knife anywhere. I would clamp it where I could get the most ability to adjust it up and down above the jaw line to maximize the angle variety available so as to avoid hitting the vice and jaws with the stones. That way with subsequent sharpenings if I choose to lower the bevel angle I can do so without having to determine a different clamping position or bumping the jaws with the stones.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

12/07/2017 at 8:17 pm #42527Thanks Marc. That makes sense.

I wouldn’t just clamp that knife anywhere. I would clamp it where I could get the most ability to adjust it up and down above the jaw line to maximize the angle variety available so as to avoid hitting the vice and jaws with the stones. That way with subsequent sharpenings if I choose to lower the bevel angle I can do so without having to determine a different clamping position or bumping the jaws with the stones.

Yes, I’ve noticed in nearly every video of a WE with some use on it, there is always bare aluminum on the tips of the clamp jaws where the jaws were abraded by the stones. So it must be fairly hard to avoid that, unless you only do large, tall knives.

I did a quick test to see how far above the top of the jaws a straight blade has to be (at a few different angle settings) so you have some small clearance to avoid grinding the top of the vise jaws.

With the angle set at 13 degrees (and 2.67 mm of threads visible on the fine adjust screw), the blade edge has to be 13mm above the top of the jaws to avoid hitting it.

at 15 degrees, 10mm above.

at 17 degrees, 9mm above

at 20 degrees, 6mm above

and you probably can’t sharpen a knife if it’s under ~3mm above the top of the jaws, or you’ll grind the jaws.

These may be off +/- a millimeter or so. I just did a quick test. But it’s good to know what ball park these numbers are in, for future reference.

Taking bets on how long I can go before I accidentally grind the vise tips…

(and I guess I could cover the jaw with a layer of tape for a little protection, not that a few scrapes affects the function or anything)

2 users thanked author for this post.

12/08/2017 at 1:34 am #42533I agree with Marc. But to answer your question directly: if you clamp the knife very near the handle, can’t you get the edge horizontal?

That said, in general (but probably not with this knife) I try to clamp my knives resting on both pins, simply to ease repeatability. Then I only have to record the distance from the clamp to the tip of the knife, with the ruler WE includes with some models or with a normal ruler.

Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

12/09/2017 at 9:09 pm #42564Mark76, re: “if you clamp the knife very near the handle, can’t you get the edge horizontal?”

Yes, good call.

But let me take a step back and post some photos. This first photo (not in the position you’d use to sharpen) is just showing that the clamp can exert force lower in the jaw than just at the top of the jaw, depending on the shape of the knife. The feeler gauge I inserted shows that at the tip end, it is clamping at the top of the jaw, while at the heel end the feeler gauge (.003” thick) could only be inserted up to about the left-hand depth key pin holes, so it’s exerting clamping force from the spine of the knife upward (toward the knife’s edge in the photo).

Here’s a backside view of the same, to show it clamping the spine at the fingerhole.

Next…this seems like the likely clamp position for sharpening (not much choice, really). The edge of the blade is parallel to the top of the jaws, and I had to slide the knife in up to the ricasso to secure the front of the blade. While it may look like the clamp is barely engaging on the tip end, in this position the knife felt solidly clamped and when I jiggled the knife handle it held solidly. I had the spine resting only on the left-hand depth key pin when I closed the clamp.

I suppose I could try lowering the knife to the bottom depth key position to engage more of the knife at the tip, but this was secure. In general, would you say that (if you have a choice) it’s better to get the edge as far above the top of the jaws as possible while still giving a secure grip?

1 user thanked author for this post.

12/09/2017 at 9:51 pm #42565 I suppose I could try lowering the knife to the bottom depth key position to engage more of the knife at the tip, but this was secure. In general, would you say that (if you have a choice) it’s better to get the edge as far above the top of the jaws as possible while still giving a secure grip?

I suppose I could try lowering the knife to the bottom depth key position to engage more of the knife at the tip, but this was secure. In general, would you say that (if you have a choice) it’s better to get the edge as far above the top of the jaws as possible while still giving a secure grip? If it’s relatively easy to (re)clamp, this seems like the ideal position.

Molecule Polishing: my blog about sharpening with the Wicked Edge

12/10/2017 at 1:56 am #42566When I mount either of my two Spyderco knive in the Gen 3 vise, I try to not have the corner pad of the vise fall into the thumbhole,, thinking that it’s not an ideal set-up.

I would mount the knife shown as high in the vise as I could, making sure to clamp the spine at both corners. The edge does not need to be horizontal to achieve a constant angle if the edge is relatively straight (Wharncliffe blades are about as straight as you can get), so you can mount it with the edge on a diagonal (spine horizontal). Even though the angle seen at the stone may appear to change, the bevel angle, relative to the knife’s centerline, will be constant. It’s not intuitive, but it’s the truth.

Since I went to using aluminum foil tape (the kind used on HVAC ducting) I haven’t had any clamping problems, regardless of the tension adjustment on my Gen 3 Pro vise. The pads on the vise jaws bite into the foil beautifully and the tape is never going to move on you. A little harder to remove than masking tape, but it leaves no adhesive residue

5 users thanked author for this post.

12/10/2017 at 9:55 pm #42571The edge does not need to be horizontal to achieve a constant angle if the edge is relatively straight (Wharncliffe blades are about as straight as you can get), so you can mount it with the edge on a diagonal (spine horizontal). Even though the angle seen at the stone may appear to change, the bevel angle, relative to the knife’s centerline, will be constant. It’s not intuitive, but it’s the truth.

I’m not sure I understand your point above.

Let’s say I have the blade edge parallel to the jaws, but I lower it down in the jaws like the yellow outline in the graphic below:

That new yellow position will increase the bevel angle relative to the old position, right?

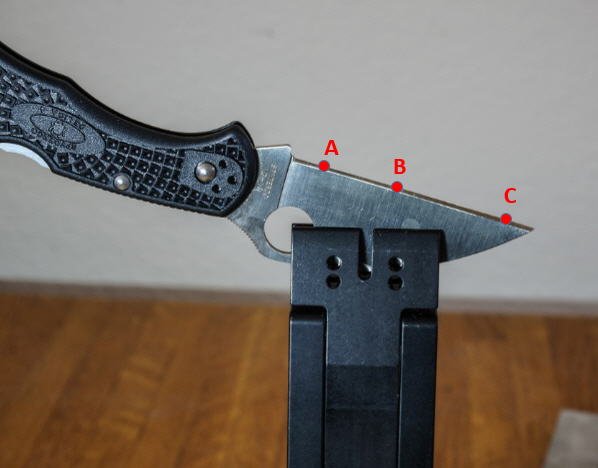

But if I understand what you’re saying, regardless of whether the Stone is at A, B, or C (where B is lower than A, and C is lower than B) in the below graphic, you’re saying the sharpening angle is the same?

And even if the blade edge were to be tilted at a much steeper angle (by rotating the handle clockwise), and let’s also say we extend the length of the blade by a foot (but centered in the clamp) just to exaggerate the point, the sharpening angle still doesn’t change? You’re right it’s not intuitive. I’m not seeing how the sharpening angle could remain the same.

12/11/2017 at 1:52 am #42574On youtube, there’s a fellow who had posted a video insisting that the angle changes. A week or so later, he posted a second video, explaining how he was wrong. He does a pretty fair explanation and demonstration of why the angle doesn’t change, even on very long blades. You are looking at the angle of the stone, where you should be looking at the angle of the bevel – perpendicular to the edge. The same principle applies to blades which are not held horizontally. If they’re straight, the angle stays the same.

Clay once posted about a long chef’s knife he mounted at about 45 degrees, relative to the vise. The heel of the blade must have been five or six inches above the vise. When he checked the resulting bevels with his goniometer, it showed the same angle for the entire length of the blade. I was dumbfounded and couldn’t understand how it was possible, until another forum member showed how and why, using the same string method used in the fellow’s video. Bingo! Enlightenment!

Curtis? Do you still have those photos?

2 users thanked author for this post.

12/11/2017 at 6:03 am #42576Hi tcmeyer, I do recall watching the video and subsequent correction that I think you’re talking about, by Simple Life or something like that. But I thought that was limited to the blade being straight, AND the edge had to be parallel to the jaws.

I even think I recall the explanation from curtis, but I thought that was similarly limited to the blade’s edge being horizontal in the WE clamp jaws.

If “The same principle applies to blades which are not held horizontally. If they’re straight, the angle stays the same” then that’s an additional level of 3-dimensional geometry that I’d like to try to understand. It’s a real brain teaser.

At the moment, I’m not seeing the geometric distinction between, on the one hand, a perfectly straight blade mounted at an arbitrary angle in the clamp, and on the other hand an otherwise identical shape/size blade but with (for example) a slight convex curve in the edge, mounted at basically the same angle in the clamp.

Seeking enlightenment!

12/11/2017 at 8:14 am #42581Hopefully, the enlightenment you seek will be found here…

(Page 6 about 1/2 way down, if the link doesn’t take you there directly).

p.s. Page 12 has the pictures and info I believe tcmeyer is referencing (info actually starts on p.11).

(That whole thread is worth a careful read).

2 users thanked author for this post.

12/11/2017 at 8:48 am #42585I’ve said it before, but that’s a great post, Curtis. It makes it insightful why straight blades not mounted horizontally are sharpened at the same angle.

Yet I often choose to mount a blade with its spine on both clamps, simply to ease repeatability. (I only have the “old” ruler and not the newer plastic measurement device. This will, however, be in my kit soon

.)

Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

12/11/2017 at 10:35 am #42592Thanks Curtis. There’s a gallimaufry of different but related topics intermingled in that 13 page thread so it’s going to take some time to get through and digest it. There are separate discussions of o-rings and wedge clips and concentric circles and string setups, not to mention the original topic of the angle guide.

A question:

Does anyone have (access to) a sheet metal bender? If you took a piece of say 6″x 12″ sheet metal, and maybe in the middle lengthwise, bend it so the final piece is bent at around a 160 degree angle (replicating a 20* bevel angle) and mount the straight part in the WE vise, with the bent part simulating a 3″ wide bevel that is 12″ long.

Then set your stone angle and fine adjust so the face of the stone is fully in contact with the bent portion of the sheet metal “bevel” at the centerline of the vise (similar to the concept of setting the stone thickness compensator).

Then with the sheet metal first mounted horizontally in the vice, sweep the stone and note that the stone stays fully in contact with the beveled part of the sheet metal regardless of how far you sweep it right or left. No gaps in the contact areas as you sweep the stone.

Then try various angles of the sheet metal in the vise (i.e. rotate the sheet metal within the vise), and do the same test with sweeping the stone across the “bevel” and noting that it retains full contact on the sheet metal bevel regardless of the sweep of the stone.

That would fully account for the pivot of the stone on the rod as you sweep, which is something that the strings pulled from a common pivot point don’t convey very well.

Anyone have a way to easily do this?

1 user thanked author for this post.

12/11/2017 at 4:18 pm #42606Thanks Curtis. There’s a gallimaufry of different but related topics intermingled in that 13 page thread so it’s going to take some time to get through and digest it.

If you click on the link Curtis gave you, you arrive directly at the correct topic. No need to scroll through the entire discussion.

Unfortunately I think I don’t fully understand your metal bender idea.

Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

12/12/2017 at 1:42 am #42667This has my juices flowing, as I wonder how best to describe the principles at work here. Here’s my latest attempt at a proof:

When the edge of the blade is straight, the sweep of the stones/rods goes from being more or less cone-shaped to that of a plane. The plane lies on the edge at some angle above the vise. It also lies on that edge for its entire length, and since the plane is flat, it does not (and cannot) change angle and since the angle of the blade doesn’t change (it remains vertical), the angle of the bevel must stay the same. If you sight down the edge of the blade, you’ll see that the angle of that plane, relative to the edge of the blade, does not change.

Given this, you have to accept that the angle between the pivot point and the base is irrelevant. The angle of the bevel is normally set where the pivot point is perpendicular to the vertical plane of the blade, directly above the vise. With straight blades, you can set the angle anywhere along the edge, but directly above the vise is the most repeatable point.

2 users thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.