Is stropping just for show?

Recent › Forums › Main Forum › Stropping › Is stropping just for show?

- This topic has 27 replies, 10 voices, and was last updated 09/23/2015 at 2:57 pm by

Ravenbrook.

-

AuthorPosts

-

09/13/2015 at 9:24 am #28856

Does stropping improve the edge sharpness? I’ve sure I’ve rolled a few edges a bit by stropping. Last week I did my Manix 2 with S110V on the WEPS. I was finished with the 1600 ceramics and keeping the knife in the clamp, I ran my arm along both sides of the blade to see if it would shave. ( I watched it in one of Josh’s videos!) It shaved great. I stropped it and while the knife is sharp and has a great working edge and bit of polish it doesn’t seem as sharp as it was before I stropped it. Other than making it look pretty, does stropping improve the edge quality that much?

09/13/2015 at 10:22 am #28857I think it is a complicated issue and I think it depends heavily on the state of the apex before the stropping. There is a wonderful blog called scienceofsharp[/url] in which the author is exploring this and other problems with the skillful aid of advanced electron microscopy. I encourage you to read every article posted yourself.

One of the things I took away from his work is that he was able to get an extremely sharp edge directly from a DMT 325 stone (somewhere between the WEPS 200 and 400 plate). “10000x magnification of the apex cross-section after honing on the DMT Coarse (325). Edge width is less than 100nm.” This is in the same range as the edge he got from a Shapton 16,000 grit stone.[/url] “Edge-on view images after Shapton16k, showing an apex width in the range of 0.1 microns.” I found this highly surprising and it wrecks any notion of a finer abrasive always producing a sharper edge.

The author specifically explores the effects of pasted strops in a three part article:

The Pasted Strop – part 1[/url]

The Pasted Strop – part 2[/url]

The Pasted Strop – part 3[/url]

I hope you find this as challenging and enlightening as I do.

09/13/2015 at 12:51 pm #28859I wrote a couple of blogs on this, too. https://moleculepolishing.wordpress.com/category/stropping/page/2/

Basically stropping allows you to refine your edges beyond what most stones can do by abrasion. (And note, more refined edges don’t necessarily equate sharper edges. There is a whole lot of topics on “what is sharp”.) There are stropping compounds of 0.10 microns. Secondly, some strops/stropping compounds also have a burnishing effect that can further refine the edge.

But if you’re happy with your edges after the ceramics, I see no need to strop. Unless some little OCD-devil creeps in somewhere 😆

Molecule Polishing: my blog about sharpening with the Wicked Edge

09/13/2015 at 8:22 pm #28863And I should have re-read the Science of Sharp blog. Here it almost literally answers your question, a bit more extensively than I did: https://scienceofsharp.wordpress.com/2014/08/13/what-does-stropping-do/

Molecule Polishing: my blog about sharpening with the Wicked Edge

09/15/2015 at 7:24 pm #28879We find a measurable improvement in our testing after we use the strops. A fun experiment to run is the Hanging Hair Test (HHT) and it doesn’t require specialized equipment. Try sharpening a knife at an acute angle, like 15 degrees per side, with your stones and then run the HHT. Record your results. Then lower the angle by a degree or two, or mount the knife higher in the clamp if you can’t go lower on the degree bar, and then strop the edge using light strokes. Re-run the HHT and compare your results. I don’t want to give away exactly what we’ve seen here until you’ve had a chance to try it for yourself. Good luck! A knife that passes HHT at a high level transcends most nuances of “what is sharp?” because it push cuts and slices well, does great shaving but also on tomatoes etc… It’s not all that durable for chopping or carving wood where the forces the edge is subjected to are high.

-Clay

09/16/2015 at 12:56 am #28882I agree wholeheartedly… I’ve been able to get the edges of ALL of my knives so sharp that they literally can whittle hairs and they perform better in the kitchen than any kitchen knives I’ve ever used.

The level of sharpness that I’m seeing is beyond what I ever thought possible with the WE system and I love it.

My neighbors, and a large majority of my friends leave their kitchen knives here at the house when they visit and I keep them in a box in on a shelf in my closet for them to get next time they visit.

09/16/2015 at 2:19 am #28883I think it is a complicated issue and I think it depends heavily on the state of the apex before the stropping. There is a wonderful blog called scienceofsharp[/url] in which the author is exploring this and other problems with the skillful aid of advanced electron microscopy. I encourage you to read every article posted yourself.

One of the things I took away from his work is that he was able to get an extremely sharp edge directly from a DMT 325 stone (somewhere between the WEPS 200 and 400 plate). “10000x magnification of the apex cross-section after honing on the DMT Coarse (325). Edge width is less than 100nm.” This is in the same range as the edge he got from a Shapton 16,000 grit stone.[/url] “Edge-on view images after Shapton16k, showing an apex width in the range of 0.1 microns.” I found this highly surprising and it wrecks any notion of a finer abrasive always producing a sharper edge.

The author specifically explores the effects of pasted strops in a three part article:

The Pasted Strop – part 1[/url]

The Pasted Strop – part 2[/url]

The Pasted Strop – part 3[/url]

I hope you find this as challenging and enlightening as I do.

The question is… have you taken the straight razor challenge yet and honed a razor off of a 325 and shaved your face w/ it? I really wanna try it after my dmt wears in =)

09/16/2015 at 7:46 am #28884We find a measurable improvement in our testing after we use the strops. A fun experiment to run is the Hanging Hair Test (HHT) and it doesn’t require specialized equipment. Try sharpening a knife at an acute angle, like 15 degrees per side, with your stones and then run the HHT. Record your results. Then lower the angle by a degree or two, or mount the knife higher in the clamp if you can’t go lower on the degree bar, and then strop the edge using light strokes. Re-run the HHT and compare your results. I don’t want to give away exactly what we’ve seen here until you’ve had a chance to try it for yourself. Good luck! A knife that passes HHT at a high level transcends most nuances of “what is sharp?” because it push cuts and slices well, does great shaving but also on tomatoes etc… It’s not all that durable for chopping or carving wood where the forces the edge is subjected to are high.

What exactly is the HHT that you mentioned?

09/16/2015 at 9:21 am #2888709/16/2015 at 9:31 am #28888The question is… have you taken the straight razor challenge yet and honed a razor off of a 325 and shaved your face w/ it? I really wanna try it after my dmt wears in =)

I some would have me “turn in my man card” for this but I completely suck at shaving. I can tear up my face with a cartridge razor let alone an experimentally sharpened straight razor. I’ve actually shaved with a straight, including one I honed myself. (Maybe I get to keep the card?) I found it difficult to get the razor back to the professionally honed state and after a couple of tries I decided my face wasn’t up for the learning process. I suppose I should get that Dovo professionally honed so I can try it again.

Do you shave with straight razors?

09/16/2015 at 9:20 pm #28896…

One of the things I took away from his work is that he was able to get an extremely sharp edge directly from a DMT 325 stone (somewhere between the WEPS 200 and 400 plate). “10000x magnification of the apex cross-section after honing on the DMT Coarse (325). Edge width is less than 100nm.” This is in the same range as the edge he got from a Shapton 16,000 grit stone.[/url] “Edge-on view images after Shapton16k, showing an apex width in the range of 0.1 microns.” I found this highly surprising and it wrecks any notion of a finer abrasive always producing a sharper edge.….

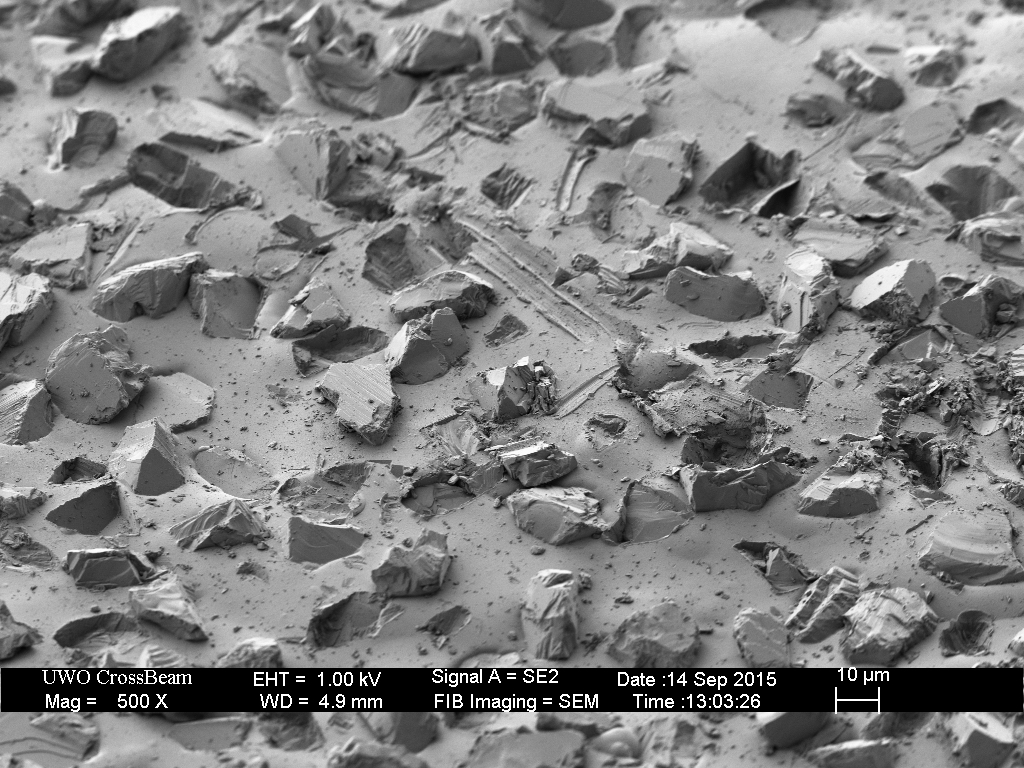

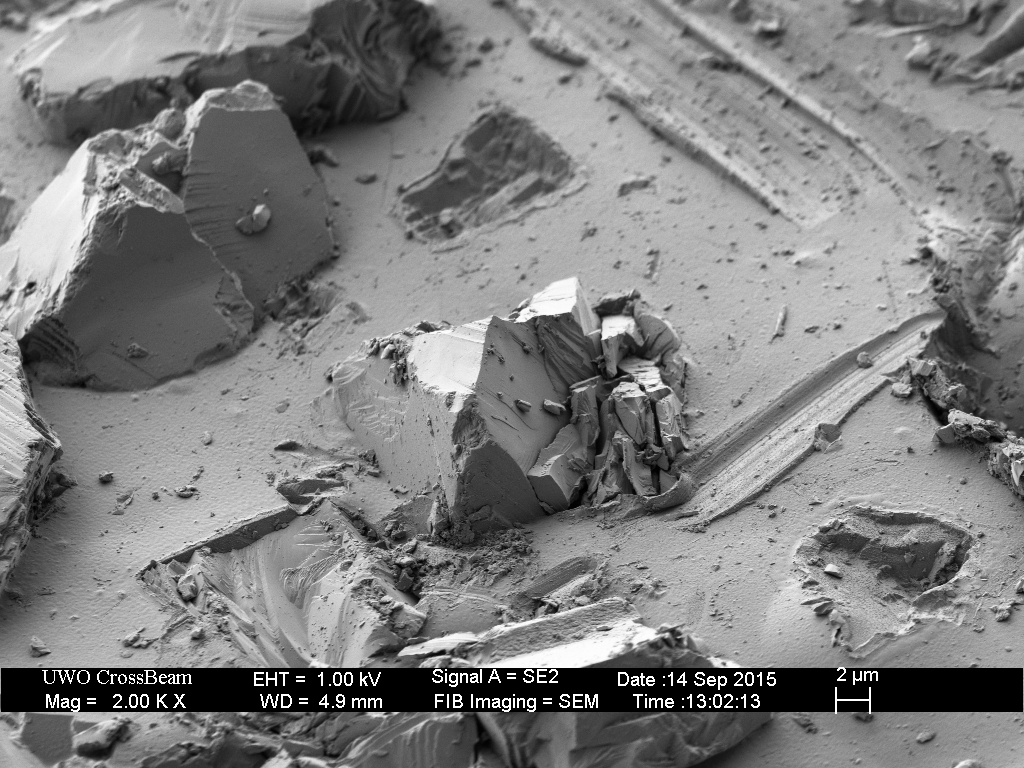

This is a set of images from a DMT fine hone – how do we assign a “grit rating” to this?

Maybe this helps to explain how a highly refined apex can be formed on 25 micron hone.

09/16/2015 at 11:32 pm #28906

09/16/2015 at 11:32 pm #28906Great SEM photos! It looks to me that the particles are between 15 and 20 microns across, which, depending on whose chart you are using could be anywhere from 900 to 1700 grit. Looks really, really coarse in the photos, but the scratch depth would be pretty reasonable as a toothy finish.

What I find interesting is the way the particles are attached to the substrate. It doesn’t seem to be a plating process, which I think would look more like paint poured over the particles. These look like they were sprinkled onto an adhesive substrate. Mr Wizard: Am I interpreting this correctly?

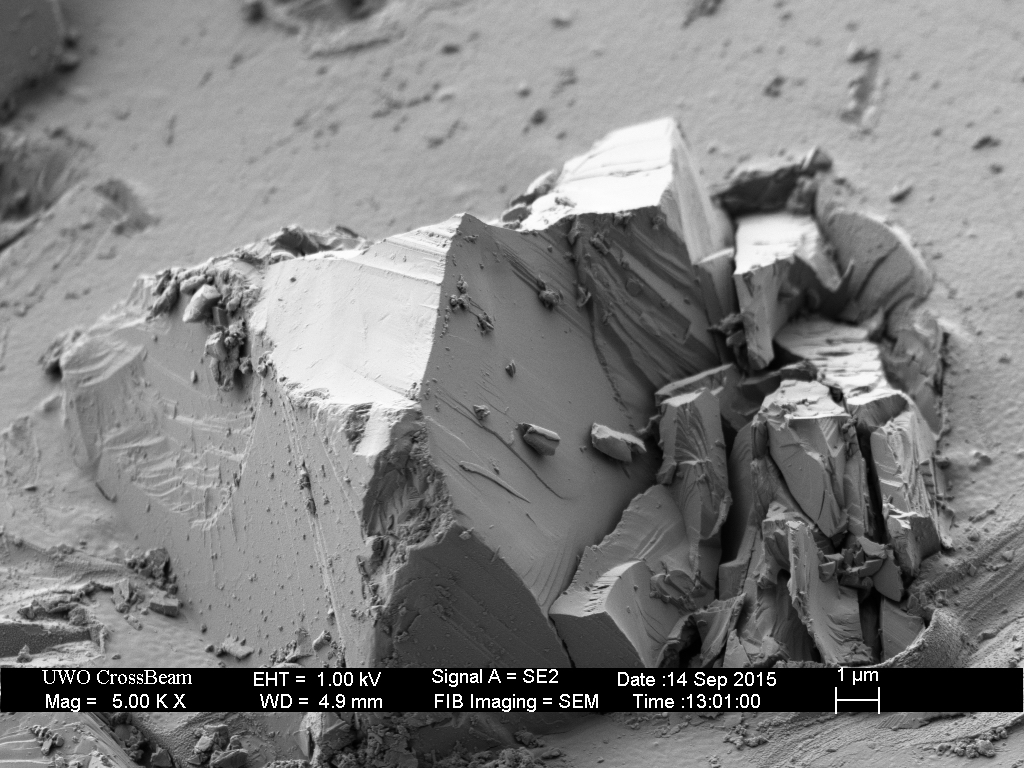

09/16/2015 at 11:42 pm #28908It appears that the nickel is plated up around the diamonds. If I were making one, I would try to stick the diamonds to the surface prior to plating.

My question is whether we use the size of the entire diamond, or the size of the sharp tips to assign an effective grit.

09/17/2015 at 12:34 am #28914What I find interesting is the way the particles are attached to the substrate. It doesn’t seem to be a plating process, which I think would look more like paint poured over the particles. These look like they were sprinkled onto an adhesive substrate. Mr Wizard: Am I interpreting this correctly?

I’m not sure it’s possible to know from the images alone how the diamonds are attached. The magnification is very high and the structures take on a strange appearance under the electron beam. Diamonds don’t look like gems, just geometric structures. If you Google “SEM diamonds” you’ll see what I mean. It becomes difficult to visually separate the stones from the substrate. Here is a picture of a 100# diamond plate at 500x with an optical microscope:

You can see the stones very clearly above the substrate. I’m guessing that the same plate would look very different in an SEM image at 20kx and may even appear as though there were a metallic coating over the diamonds.

Here is picture of a DMT 3 micron plate at 2000x:

The image is only focused on one feature in the entire plate that is significantly raised above the surrounding area. The area in question is an agglomeration of diamonds that have clumped together due to electromagnetic fields that are produced during the plating process. What’s interesting is that the diamonds do appear to be coated over with metal, even in this optical image, so it is possible that DMT’s process does involve a layer of nickel or other metal deposition on top of the diamonds. As a side note, when I talked to the head engineer at DMT, he told me that the 3 micron plate is exceptionally difficult to produce because of the tendency toward agglomeration which is why we don’t see diamond plates finer than 1000 grit from other manufacturers. They at DMT feel like they’ve got it fairly well dialed in though all of the plates we’ve examined do have some degree of agglomeration issues. Depositing small diamonds on an adhesive is obviously easier to do since the diamond films seem fairly common.

Attachments:-Clay

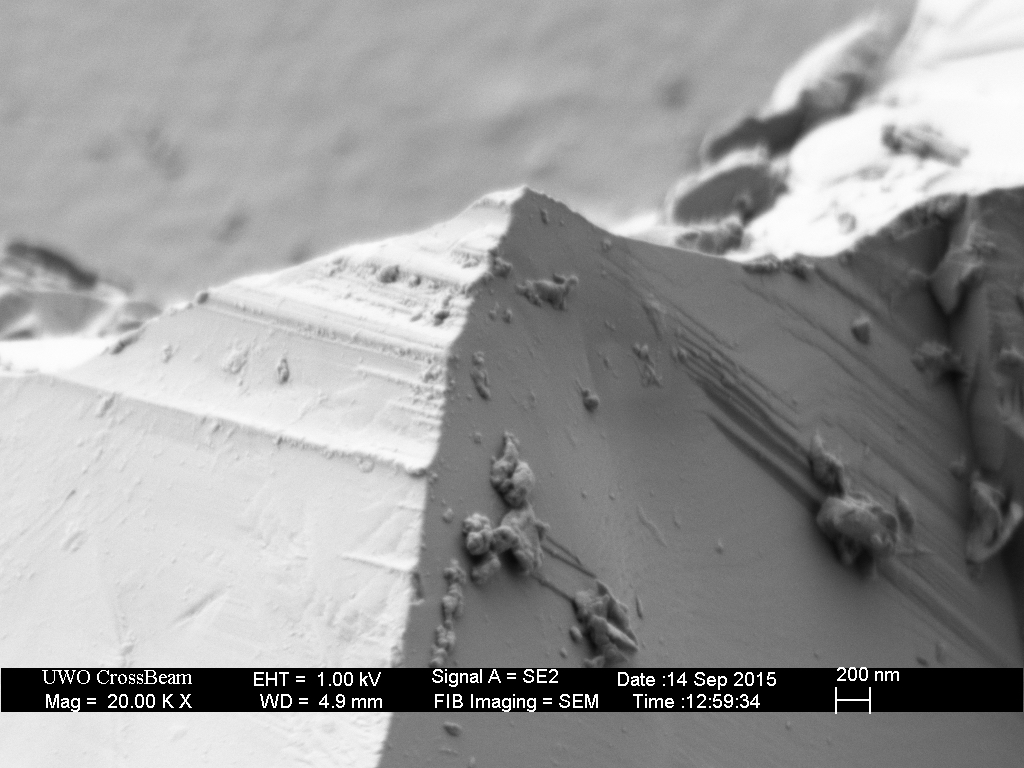

09/17/2015 at 1:07 am #28915Maybe it is easier to visualize from an image of a new plate:

There is no metal on the surface of the diamond – the nickel is plated up around them. You can see a couple of shallow depressions where diamonds that were not deeply covered and have fallen out prior to packaging.

-

AuthorPosts

- You must be logged in to reply to this topic.