Interesting video… do you destress your edge?

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Thoughts/Theories/Science Related to Sharpening › Interesting video… do you destress your edge?

- This topic has 51 replies, 17 voices, and was last updated 11/01/2014 at 6:15 am by

Mark76.

-

AuthorPosts

-

08/20/2013 at 1:42 am #14286

Thanks for the input guys!

I had a REALLY interesting conversation with a super smart metallurgist (who primarily works in the scissor industry) about metal. I asked him if powered sharpening equipment (i.e. belt sanders) will indeed damage the last few microns of the edge even if its unseen. He said on a very microscopic level but it would not make any noticeable difference to the user. He said that it isn’t until the edge starts to actually change color that you begin to possibly damage things – light tan means it is still recoverable by making a few more passes but if its blue your done and the temper is ruined.

He gave an analogy of a metal mill… he said that sharpening with a powered stone/belt is the same thing but on a much smaller scale – i.e. a mill carves out chunks of metal whereas a belt sander carves out small pieces of metal. It all has to do with heat transfer… He stated that even under a water cooled system the heat is still being generated, it is just washed away very quickly and transferred into the coolant. Well, in the above scenario when a piece of metal is carved away by the abrasive on a belt, approximately 75% of the heat is transferred away from the blade itself – this is why you have a spark.

Also stated that its not required for you to have time AND heat to damage the temper, but just heat alone can do this. Kevin Cashen (I believe) a few years ago did some scientific research where he measured the head on the sub micron levels of the edge with micro-thermo couples. He found that just moving a piece of metal across dry sandpaper by hand generated around 2000F for a nano-second. So my converstion with this metallurgist was quite interesting =)

08/20/2013 at 6:33 pm #14309Thanks for the input guys!

I had a REALLY interesting conversation with a super smart metallurgist (who primarily works in the scissor industry) about metal. I asked him if powered sharpening equipment (i.e. belt sanders) will indeed damage the last few microns of the edge even if its unseen. He said on a very microscopic level but it would not make any noticeable difference to the user. He said that it isn’t until the edge starts to actually change color that you begin to possibly damage things – light tan means it is still recoverable by making a few more passes but if its blue your done and the temper is ruined.

He gave an analogy of a metal mill… he said that sharpening with a powered stone/belt is the same thing but on a much smaller scale – i.e. a mill carves out chunks of metal whereas a belt sander carves out small pieces of metal. It all has to do with heat transfer… He stated that even under a water cooled system the heat is still being generated, it is just washed away very quickly and transferred into the coolant. Well, in the above scenario when a piece of metal is carved away by the abrasive on a belt, approximately 75% of the heat is transferred away from the blade itself – this is why you have a spark.

Also stated that its not required for you to have time AND heat to damage the temper, but just heat alone can do this. Kevin Cashen (I believe) a few years ago did some scientific research where he measured the head on the sub micron levels of the edge with micro-thermo couples. He found that just moving a piece of metal across dry sandpaper by hand generated around 2000F for a nano-second. So my converstion with this metallurgist was quite interesting =)

So if the blade it gets hot to touch but no color change? your good to go??

08/20/2013 at 8:54 pm #14312So if the blade it gets hot to touch but no color change? your good to go??

Basically! If you can touch your edge immediately after taking it off of the belt and don’t burn yourself you shoudl be good to go.

08/21/2013 at 4:15 am #14315Interesting observation and theory about how the edge can get “burnt” at the factory and have an initial low sharpness/edge holding ability.

He does not offer a theory, but an unsubstantiated guess, that he presents as fact. It sounds somewhat plausible, but without objective evidence, this is just another guy on the Internet saying… something.

Your question about “de-stressing” probably a bad term for what he is doing as Curtis alludes to…

I have never found the need to do it, so I have not.I have sharpened a bunch of knives on my belt grinder. The knives of crappy steel with low edge retention, remain that way. Likewise, the better steels still show the properties that warrant spending the extra money for a knife with good steel. They take a good edge, and stay that way for a long time.

Eamon,

I don’t quench at all when doing a typical sharpening job… minor re-profiling and sharpening.When I do repairs, I will use cold water if I feel heat in the blade. Some may say that this is too late, but I have not seen any problems with those blades. All anecdotal information… but I don’t claim to have any theories on this..

🙂02/05/2014 at 8:01 pm #16868In regards to edges and over heating, as Roman Landes has discussed at length, the apex of a knife is literally < one micron wide so damage to the edge on an order of a micron will affect the properties of the steel in regards to edge holding / durability significantly. Roman has presented data on this as Ashokan (published material sources) on multiple occasions and he is very active on HypeFree and has provided more detail on this topic there.

The reason why intermittent water cooling is not a good idea is because :

a) those steels are not meant to be water quenched

b) the very edge will rapidly contract and if you cycle this over and over it will crack

These are not conjecture or ideas, they are known in metallurgy, and arguing against it is like saying that free chromium in steel doesn't add to corrosion resistance.

As a few points of correction :

-you can not judge the temperature of the apex from feeling the blade because the very apex cools rapidly in air and it has a very low heat capacity because the volume is small

Years ago I (and others) did a simple experiment where we burned blades to black and still kept our hands on the blade, you can not use this as a means of controlling temperature.

In regards to scaling, the colors you see are oxidization, similar to rust and just like rust they are resisted by stainless steels (and other alloy steels) and thus those steels have to get much hotter before they scale.

But again, you are concerned about the last micron of the edge, you can't see that anyway, the visible ability of most people is in the 20-40 micron range, a sharpened edge is on the order of 0.1 micron, if the damage is 10 microns you won't see it but the edge holding/durability is completely obliterated if you are interested in a sharp edge.

In regards to why I called it destressing is because that is what it does, it removes the metal on the edge which was fatigued / stressed in use and ensures that when the knife is sharpened then the apex forms on quality metal. The label is also critical as it promotes the understanding of how a knife blunts and what you need to do to sharpen it (removed the stressed metal).

I started doing this after a series of experiments I did years ago where I compared sharpness by normal "touchup" methods vs what I called full sharpening (which included cutting the edge off). After concluding that the latter was significantly better I did the research to figure out why it happened and it is known in metallurgy that the damage will be beyond the immediate blunting.

I did those experiments when I noticed that edge holding after steeling and stropping was significantly less than the edge holding from the initial sharpening and as well if I extended it for a long time the edge would at some point fail catastrophically by fracture.

As an aside, this destressing also :

-prevents formation of recurves and any uneven edge grinding as the light line will tell you of problems long before you would other wise notice them

(if the light does not reflect in a consistent thickness there are issues which should be resolved)

-is a great visual aid because once it is removed you know you are 20-40 microns away from a sharpened edge and you can switch to your finishing stones and not put coarse shaping scratches to the very apex

In regards to that Benchmade, the loss of steel wasn't because of the destressing, it was because it was in use for seven years and that use/sharpening obviously caused metal loss.

There is a long history to that knife, it was a replacement for a knife which was defective. That one was also found to be defective by the original owner who was told by Benchamde it was his problem as he was newb (that is what he noted they tried to make him feel like). The owner sent it to me and I concluded it was indeed defective, he wasn't.

The problem is :

-lack of initial sharpness

-poor edge holding (for that steel)They are both related to the same problem which is the edge fractures. If you check it under magnificantion you can see that the edge fractures at a size well above the scratch pattern.

It is possible to sharpen it decently, but it requires :

-micro-loading, 5-10 grams of force on the abrasive (which has to be very clean, flat, etc.)

-heavy micro-beveling/back sharpening (burr minimization)

-cross scratching the grits (burr minimization)Of course if it is that fragile in sharpening, it is that fragile in use.

Ironically, my brother doesn't care about that much at all because he uses knives in a semi-dull state (the edge is ~10 microns thick) and at that level of thickness it is stable enough and the high carbide volume keeps it there for a while.

I got it back off him after that long as the edge had thickened and he wanted the primary grind planed down. I did that and confirmed the low edge retention on cardboard was still there : http://www.cliffstamp.com/knives/reviews/cardboard.html . Note how poor it does compared to the other S30V blades, it not only isn't Class III, it isn't even Class II.

02/05/2014 at 8:25 pm #16870Once again Cliff your deep knowledge of steels is much appreciated. My favourite steels for super easy and super sharp edges is Sandvik 12C27 and 13C27. My French folders from Chambriard use the 13C27 razor steel and the edges obtainable with little sweat on those blades are most satisfying. My Helle Temagami knife uses a triple laminate steel with 12C27 at the apex point. Love these very sharp knives.

Once again thanks for the stimulating comments.Cheers

Leo02/05/2014 at 9:03 pm #16872I generally recommend anyone who wants to learn/understanding sharpening get at least one steel which is easy to sharpen simply to see what should be the ideal process. Everything you have listed are examples of that as they are all razor blade steels and when hardened properly they are ideal as they have :

-excellent grindability

-trivial ease of sharpeningIn general there is rarely even an issue with burr formation/removal. While difficult to obtain, if you really want to see something special try to find :

-AEB-L at 62/64 HRC

-1095 at 65/67 HRC

-SuperBlue at 65/67 HRC

-M2 at 64/65 HRCThese steels are so strong that the edge will form very crisp very easily. However the HT is critical and if it isn’t done well then you will likely hate it.

I have a knife from Joe Calton in full hard 1095 which I expect to perform well from a very quick inspection of it. Even with the edge set on a semi-coarse Norton diamond :

-it shaves with no pressure felt on the skin

-true/90 push cuts newsprint at 3/4″ from the point of holdAs boxed it is one of the sharpest knives I have seen in a long time.

02/05/2014 at 9:09 pm #16873I have an ESEE Laser Strike knife of 1095 steel but I don’t know the hardness. I do know it sharpens up beautifully but with more effort necessary than for either of the Sandvik steels. Do you know the ESEE knives at all…they are all 1095 carbon steel.

Leo

02/05/2014 at 9:20 pm #16874Yes, I have a number of them.

They set the hardness at 55-57 HRC so while the steel will grind easily, there are likely to be some issues with edge crispness / burr formation if you are trying to achieve a very high sharpness.

Of course they are promoted for very heavy use and thus the tempering is going to be high, above 450 F to ensure they are outside of the embrittlement range and thus the mid-range hardness.

They are quite durable though and resist fracture strongly.

02/05/2014 at 9:28 pm #16875Thanks very much Cliff! That is exactly what I wanted to know. You are a genuine huge nugget of knowledge that all of us are going to appreciate. I suspect we will be wanting information on steels like this in our Wiki and we will be getting to that fairly soon I hope. Your encyclopedic knowledge will be useful here.

Very best regards

Leo02/05/2014 at 9:41 pm #16876Cliff,

Thanks for jumping on to the conversation and adding your knowledge. I’m really glad you did.

–Clay

-Clay

02/05/2014 at 10:51 pm #16881-AEB-L at 62/64 HRC

-1095 at 65/67 HRC

-SuperBlue at 65/67 HRC

-M2 at 64/65 HRCfor the hardness numbers to be as high as this, these steels should be almost untempered, this is very close to “as quenched” hardness figures for given types of steels. Will it be useful for anything more than paper cutting, wouldn’t it be too brittle?

02/05/2014 at 11:06 pm #16882I have knives in all of those steels and more, the 1095 is actually above the as-quenched hardness due to the strong carbide precipitation it has due to the super saturation of martensite.

In general no, they are not so limited – but again, they have to be done right. Here is just one example of a 1095 paring knife being used in non-paring knife work :

and why not :

and :

The paring knife is ground from 1095 high carbon steel hardened to 66 HRC. The blade is 0.055″ thick, 0.41″ wide, 2.8″ long and weighs 35 g. The edge is 0.010-0.012″ thick, ground at 5.7 +/- 0.4 degrees. At 0.2″ back from the edge the knife is 0.021″ thick. There is a full distal taper to point.

It has a micro-bevel normally, 10-12 dps, usually a very high finishing grit (high for me), which is 4k+ waterstone or similar.

Again though, and I can’t stress this enough – if the HT isn’t there the steel will be horrible as there are many ways to get hardness but only one right way :

-presoak

-soak at the minimum time/temperature to put 0.6% carbon in solution (CRITICAL)

-quench immediately

-cryo immediately

-snap temper

-water quenchrepeat cryo until cost is a factor, water quench after the snap temper, then final temper around 350 F give or take (M2 is a HSS so it tempers hot).

The first part is critical, if you soak too long more than 0.6% carbon goes into solution, plate martensite forms instead of lathe, the steel becomes very brittle, it becomes hard to remove retained austenite, etc. .

02/06/2014 at 2:34 am #16886This is an example of a full hard 1095 blade :

This is Calton’s paring knife :

-0.055″ stock

-ffg (hint of convex, you can’t see it but you can mic it)

-edge is micro-bevel only, not visible

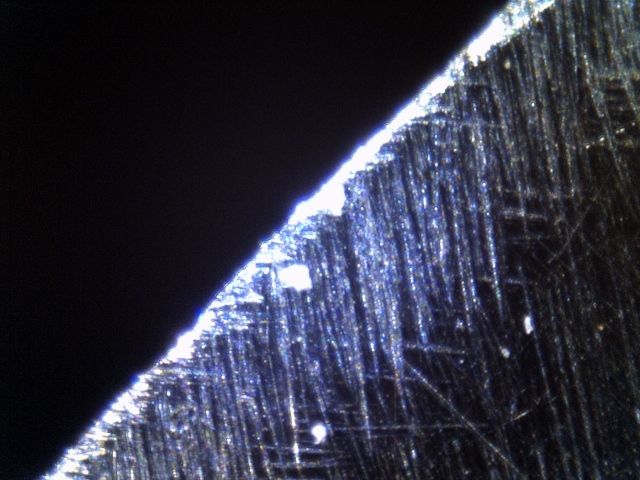

-norton diamond, worn/fineHere is a really horrible picture which I used to think were ok before I started looking at Clay’s pictures :

The scope I am using has a horrible issues with depth of field and reflection hence coarse edges look very blobby, but in any case you can see the very small bevel, this is at 50X linear magnification.

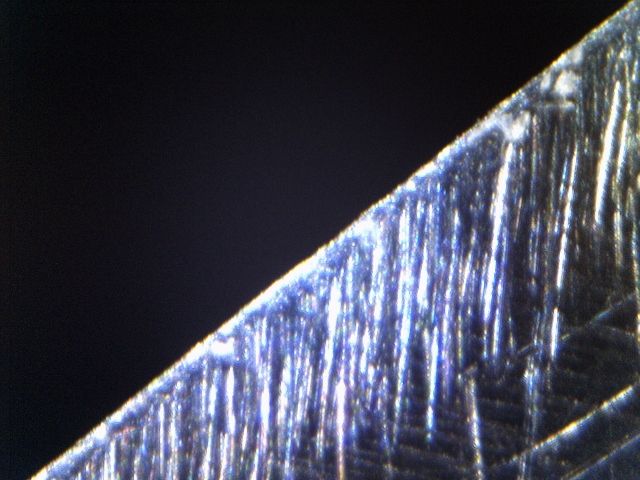

Here is the edge after sixty 2″ slices on that rope, note no chips/rolls, just light wear. The initial performance was :

-6 to 7 lbs

after 60 cuts it was in the plateau and was :

-11 to 12 lbs

If those numbers don’t impress you, just try to cut a piece of 3/8″ hemp with a 2″ draw with less than 6 lbs of vertical force.

In any case, this rope is fairly demanding on edges, more so than most kitchen use anyway and similar to cardboard and other utility work and it does nothing significant to the edge.

The edge only reflects light in one small section of edge which was the peak force position during the slices.

02/06/2014 at 4:00 am #16890It looks deadly sharp the thinness of the taper to the edge is what makes the knife practically sharp high levels of polishing does not necessarily make a sharp knife especially if there are appreciable shoulders on the edge of the final bevel .

I alway s think that big shoulders are like air brakes on a wing the leading edge if fine for cutting processed foods like thin sliced ham or cheese but if the blade it to really cut it needs to have no real shoulders then the knife will cut deep which is what is needed for preparing real food.That paring knife looks and sounds awesome!

-

AuthorPosts

- You must be logged in to reply to this topic.