Ever wanted to measure and view a Edge Profile? Check this out!

Recent › Forums › Main Forum › Welcome Mat › Ever wanted to measure and view a Edge Profile? Check this out!

- This topic has 83 replies, 10 voices, and was last updated 04/29/2016 at 10:11 am by

M1rrorEdge.

M1rrorEdge.

-

AuthorPosts

-

04/24/2016 at 1:44 am #33679

Thermo plastic is brilliant. I knew there was something fairly common around these days that could fit the bill.

My kid has a clump of the stuff here that they were using to make little things with…or he did until I just swiped it!

04/24/2016 at 2:04 am #33681

04/24/2016 at 2:04 am #33681Well, after a few hours of working with the thermoplastic and two or three different blades, I have learned two important things. One, you must figure out a way to mark the direction of the impression so you can identify the sides after it is removed. Now that I have multiple impressions from multiple blades, I am getting them confused. You may have seen me change the images on my earlier post if you are on my side of the world or where up late last night. The reason was because I lost track of which mold I was looking at. What it did do, is show me the power of the data we are getting. I know my knives from sharpening them and the ZT is thinner behind the edge than the Kershaw 7100BW. When I identified my error, I fixed it as fast as I could. I will try not to do it again. It might be a good idea to find a tackle box holder for the mold impressions that you can label and we may need to mark the mold impression sides L or R. so they can be properly identified in the image

Cheers!

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-1622Attachments:

You must be logged in to access attached files.

04/24/2016 at 3:22 am #33683I also have recognized this. With this new tool, we can check not only the angles of the edge and face of the knife from the spine but with intersecting lines generated by the software we can also see when something is off. In this image, it appears that one bevel is wider than the other from the shoulder and it’s possible the cutting edge is off center ” just a tad” as well.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/24/2016 at 8:48 am #33684It is important to cut across thermoplastic impession strictly perpendicular to edge line. Otherwise angle value will be wrong.

04/24/2016 at 9:19 am #33685Anyone else having trouble getting a clean cut? I was thinking about using a cigar cutter but I don’t have one at the moment. This would allow us to cleanly cut with the force required with out collapsing the impression. The Thermoplastic holds the shape really well even after all the abuse I have put it through to trim it down. We lost a little flexibility in the Trimming. Any Ideas?

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-1622Attachments:

You must be logged in to access attached files.

04/24/2016 at 11:30 am #33690I just cut it with a break off type box cutter. Works perfectly for me.

1 user thanked author for this post.

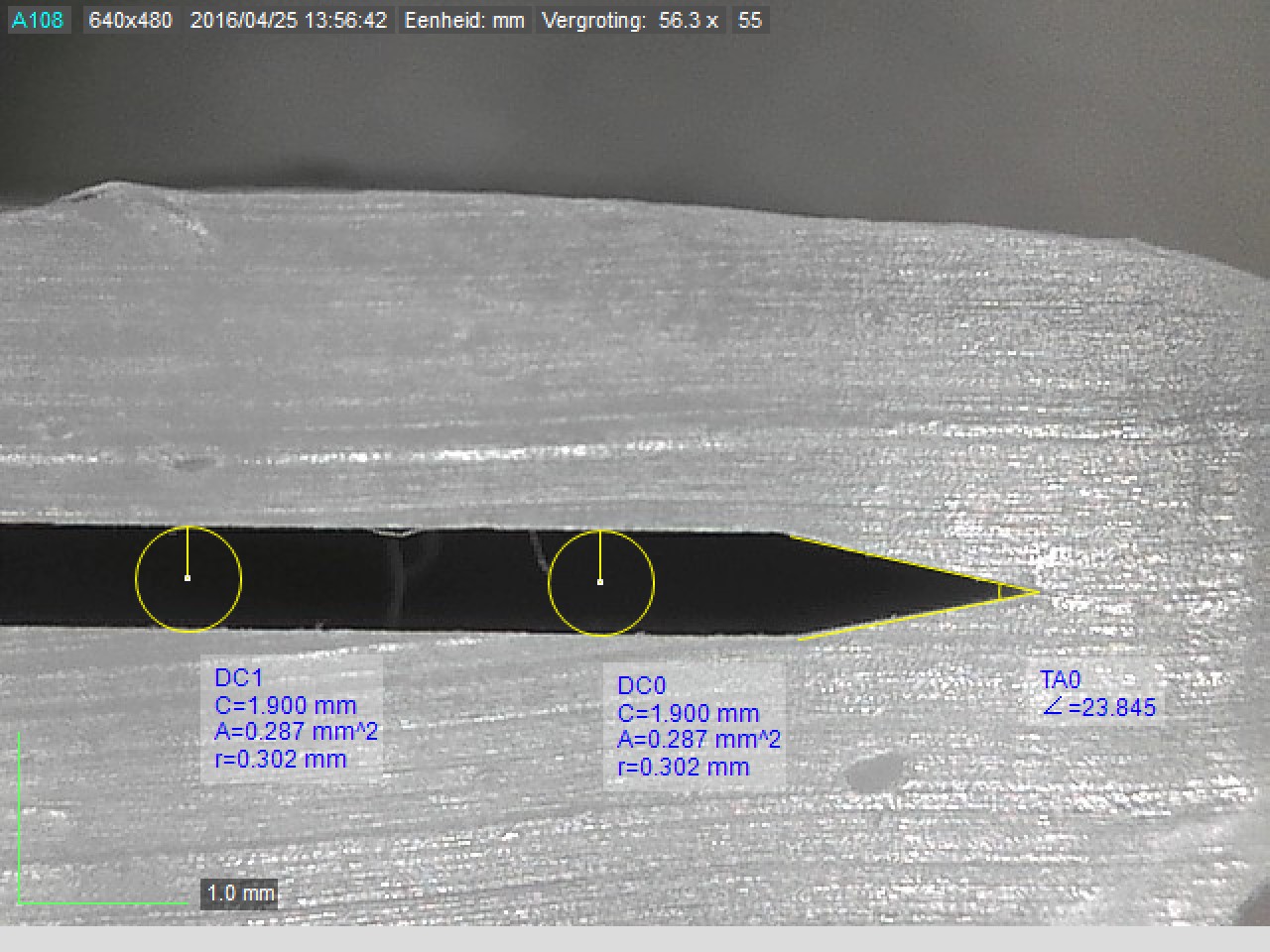

04/24/2016 at 1:00 pm #33691O.K., as promised, I cut a micro bevel onto the same ZT0770CF and molded the results with our new thermoplastic molding method. I captured it with Dino-lite Capture 2.0 and my Dino Lite AM4815ZTL USB Microscope and drew the angles. Does this seem like a “realistic” diagnostic and documentation tool and something of value? I would loved to see what you guys have done with this….Do you see room for improvement?

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/24/2016 at 1:33 pm #33693My box cutter blade is dull, I will get another. Do you think a small plane would help? Maybe, I just need to find a holder in the first place.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/25/2016 at 1:08 am #33696This is all very interesting, but I’m not sure what we’re trying to prove. I wouldn’t expect to measure bevel angles which are significantly different from what I’m setting up for with my AngleCube and WEPS. And what if it were? What would you do next? Is the intent to show a customer what you’ve done for him/her? Or is the intent to measure the factory angle before sharpening? I’d think most of them aren’t particularly flat bevels. Most I’ve seen are sharpened on a belt and probably polished on a wheel.

04/25/2016 at 2:08 am #33697Great question;

I envision the blade edge molding procedure being used several ways. Yes, a sharpie will do most of these things too, however, as soon as you start “scrubbing” the information is gone.

Yes, we have invented many different creative ways to determine these things as well, “heck”, how long has man be sharpening steel? In this modern age, we have a unique tool called the computer. If we leverage its power we can see things we just couldn’t before. By modeling the edge and loading it in a computer we can now see it and document it and share it with others. It becomes more tangible.

- It could be used by anyone to verify the angles on an edge bevel of a knife prior to sharpening it and after.

- You can also determine if the cutting edge is centered on the knife prior to grinding away at the bevel. Anyone could identify what needs to be done before you even start sharpening.

- You can document your own knives and customer knives (Before and after shots- Who doesn’t like doing that (Added Value)?

- You can see and measure the bevel widths to ensure they are even on both sides of the knife and if not you can determine what needs to be done to correct it.

- You can measure the width behind the edge much like you can with a digital caliper if the microscope you use is calibrated.

- Before the advent of the computer we had to use a digital caliper and trigonometry to figure out the angles now anyone can leverage the power of the computer and advanced software to do it with a few “clicks”.

- This simple tool can help to bring real “precision” to the process of sharpening a knife.

- Best but not least, at least for some of us, tinkering with “play dough”, wax, and now thermoplastic is fun to do!

If you are unsure of any of these measurements, this process could help both the “new guy” and the professional get a better understanding of the geometry on the knife he has in his hand, at a moment in time. I am sure there are many other things that this can be used for. The beauty of all of it is anyone can do it or simply choose not to.

Yes, I am sure there are people just “rolling their eyes” saying WHY? My knife is Sharp (“It shaves arm hair”), why should I care. I would suggest that if you are reading this post, this is probably not the case for you. More than likely you are eagerly trying to make it sharper or understand the process better. For each person the reasons to use this could be wildly different. This is why it is so cool.

Respectfully- Mirror Edge

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/25/2016 at 3:27 am #33699O.K., as promised, I cut a micro bevel onto the same ZT0770CF and molded the results with our new thermoplastic molding method. I captured it with Dino-lite Capture 2.0 and my Dino Lite AM4815ZTL USB Microscope and drew the angles. Does this seem like a “realistic” diagnostic and documentation tool and something of value? I would loved to see what you guys have done with this….Do you see room for improvement?

Did you make this pic with the Dini-Lito software?

Molecule Polishing: my blog about sharpening with the Wicked Edge

04/25/2016 at 3:46 am #33700yes

O.K., as promised, I cut a micro bevel onto the same ZT0770CF and molded the results with our new thermoplastic molding method. I captured it with Dino-lite Capture 2.0 and my Dino Lite AM4815ZTL USB Microscope and drew the angles. Does this seem like a “realistic” diagnostic and documentation tool and something of value? I would loved to see what you guys have done with this….Do you see room for improvement?

Did you make this pic with the Dini-Lito software?

Yes

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/25/2016 at 4:41 am #33701Frans, your impressions look cleaner than mine. Is it possible that the polymorph is a little different chemistry then the thermal plastic that I purchased? Mine is real hard too, I’m guessing that they aren’t all the same. Doesn’t polymorph come in two different types? Just a observation from the privided photos.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/25/2016 at 7:07 am #33702No, last week I also received the HEA-500 thermoplastic from teachersource and as far as I can determine, it is the same material.

As far as precision goes, I also found that it doesn’t matter if you use a holder for the plastic or just take a small amount and fold it over the edge. Here are two photos that illustrate it. The first one with a piece as folded over a 0.6mm thick utility blade and cut once hardened. The second one as viewed with the Dino-lite AM3113T at 55x This is with the Teachersource HEA-500 thermoplastic.

This is all very interesting, but I’m not sure what we’re trying to prove

For me it is not about proving anything but just another tool and something that I find interesting. When sharpening, I use an angle cube to set my angles and a loupe to check the edge. This is another way to check if my bevels are even and centered or to measure the primary grind of a blade.

Attachments:

You must be logged in to access attached files.

04/25/2016 at 7:14 am #33705I think I’ll open a new topic on USB microscopes soon. I hardly use my cheap VEHO microscope anymore due to its limitations. And I think that HDR and perhaps a better depth of field, perhaps using image stacking (as well as a higher magnification) could greatly improve its use.

I’m inclined to a Dino-Lite microscope, since they have these options and also seem to have pretty good software. The main problem for me is that when browsing the Dino-Lite site, it was pretty scarce with information. Any ideas about getting more information?

And any other considerations I should take into account?

Molecule Polishing: my blog about sharpening with the Wicked Edge

-

AuthorPosts

- You must be logged in to reply to this topic.