Ever wanted to measure and view a Edge Profile? Check this out!

Recent › Forums › Main Forum › Welcome Mat › Ever wanted to measure and view a Edge Profile? Check this out!

- This topic has 83 replies, 10 voices, and was last updated 04/29/2016 at 10:11 am by

M1rrorEdge.

M1rrorEdge.

-

AuthorPosts

-

04/20/2016 at 4:53 am #33500

Has anyone seen this? http://edgeonup.com/eou_new_2016_005.htm

Does anyone know why the sharpening community is ignoring this?

They are not ignoring it, there is a pretty long thread about it on bladeforums http://www.bladeforums.com/forums/showthread.php/1285538-Edge-Sharpness-Tester?highlight=edgeonup but even among knife enthusiasts, there probably is not all that much interest in going this deep.You only have to look at my sharpening equipment (and that is not all of it) to see that I have a bit of an obsession with sharpening but I don’t need equipment to know when a knife is sharp and do I really need to know more than “is it sharp enough to do the job I want it to do”?For now, I think I stick with my familiar paper cutting and hanging hair tests but that can always change

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

04/20/2016 at 8:30 am #33508MirrorEdge – I have one of these as well though I don’t use it much, maybe because I’d already built mine and got used to it. I know a couple guys on here also have one but I don’t see much posted about it.

-Clay

04/20/2016 at 2:42 pm #33516Wow, great collection Frans! One of the observations I made in the video seems to indicate that the pure act of cutting paper removes the keenness of the blade. It is proved in the video by the additional water added to the cup after he cut the razor wrapper with the edge (Loss of Keenness maybe?). I have seen countless videos where the sharpener after spending 30 minutes on the blade immediately pulls out a piece of printer paper and slices off a corner. Wouldn’t it be in our interest knowing this information to give that honor to the owner of the blade? The test described would only effect the portion of the blade being tested I assume the width of the test medium. The site says it’s non destructive. The smallest model they sell is pretty cheap at $59.00 which is affordable. The system described indicates that it provides measurement like a thermometer measures temperature. I believe that many people think he is trying to measure sharpness which would be the equivalent of trying to measure weather with a thermometer. I don’t think that is the case at all. It appears to be a repeatable scientific test that would be worth doing but it doesn’t seem to be catching on. Is it simply because the shaving hair or plucking a strand of hair from our wives head is easier, free and occasionally fun to do (LOL),? Wouldn’t this test allow us to test our edges and circulate those results to others for replication and validation (All other variables being equal of course- Manufacturer, Blade Model, Steel Type and angle geometry)? I realize that many in the knife community think this is all just nonsense. However, I believe that we should seek improvement in any way we can. I think I found this on the blade forum initially and they where just “blasting” it or maybe they where “blasting” the guy you called Mike. I am not sure. Is their no value to be gained from this? Do you know where the posts are that objectively look at what this thing is doing?

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/21/2016 at 8:47 am #33556One of the observations I made in the video seems to indicate that the pure act of cutting paper removes the keenness of the blade. It is proved in the video by the additional water added to the cup after he cut the razor wrapper with the edge

That was something that surprised me. I would not have thought that it would have such an impact.

It appears to be a repeatable scientific test that would be worth doing but it doesn’t seem to be catching on. Is it simply because the shaving hair or plucking a strand of hair from our wives head is easier, free and occasionally fun to do (LOL),?

I am not 100% sure yet but I think it also convinced me that I do not need a tester like that because I usually test the edge for sharpness and nicks by cutting paper and I never noticed that the blade lost sharpness because of that and I see no need to measure anything that I would not notice in real use.

Wouldn’t this test allow us to test our edges and circulate those results to others for replication and validation (All other variables being equal of course- Manufacturer, Blade Model, Steel Type and angle geometry)

I think the purpose is exactly that but I wonder if it does that. I think the crux lies in the “all other variables being equal” part.

i.e. if you and I sharpen the same type of knife with the same equipment but get slightly different results. Would that be because my stones are a bit more worn, did I use slightly less or more pressure, etc….I believe that we should seek improvement in any way we can.

Yes I think so too and I think devices like that have their use like for a manufacturer of razor-blades to check if their production quality is constant and if their blades meet industry standard. I see no practical use for myself but I can see that others may think differently.

The smallest model they sell is pretty cheap at $59.00 which is affordable.

Yes that is affordable but as usual it is not the US price that makes it expensive for us Europeans but the high shipping cost and import /clearing charges.

I have a scale with a hold function and 1 gram precision so I can make something very similar to their basic model and give it a try. Perhaps that will change my mind04/21/2016 at 10:16 am #33557Has anyone seen this? http://edgeonup.com/eou_new_2016_005.htm I had found this about a year ago and was wondering why I didn’t see it being used. I will create a new topic post for this here: Measuring sharpening progress without the Loss of Arm Hair!. For what it’s worth, it’s inexpensive and the science appears sound if you use it to compare the blade to itself (Before and After Sharpening). It gets a little tricky to try to use this test to measure one blade with another, but why not the same blade before and after sharpening? Clay, can you post your rig to the new topic as a example of how to custom make something like this? I really want to know what you all think about this… Does anyone know why the sharpening community is ignoring this?

<!– [if lt IE 9]><script>document.createElement(‘video’);</script>< ![endif]–> <span class=”mejs-offscreen”>Video Player</span><span style=”line-height: 1.5;”></span>

I have one of the edge on up EST’s and as seen in the bladeforums thread I was having less than reliable results and didn’t trust it to test my edges for customers when completed. I’ve got one if you are interested ?1 user thanked author for this post.

04/21/2016 at 11:47 am #33558Can you provide the blade forum posts with objective criticism of the device ? All I see is criticism of the man trying to sell the device on blade forum. I want to hear or read what people have observed tested or failed to verify in testing. I guess I am the only one who is asking for this kind is empirical evidence of fraud or pure bunk. I can’t seem to find any posts where people have tried it and reported their findings ( peer observations). Can you share what you saw while using it? How did you determine reliability or failure of the test results. At what point did you say this is a piece of junk? Why could you not “trust” it for testing improvement of the blade from customer receipt to final stropping? Did it fail to perform what is advertised? If it doesn’t, how is he still selling it? I am assuming that you use the telephone paper cut test, the Murray carter three finger test and the hanging hair test and that these indicate one of two things. Sharp or not sharp. Are these not subjective sharpness tests or have I missed something completely?

I am not trying to be a pain. This is something I have been trying to wrap my head around with a new found since of wonder. I showed someone the test in the below video and they where amazed. However, it’s more of a trick than a test. The speed and velocity of the blade split the paper not the sharpness of the knife. I realize people are very passionate about this issue and many have just given in . One day I may surrender to the idea myself but I am not convinced that we are proving anything concrete with those tests.

Does anyne know or have a copy of ISO document for standard commercial blades? ISO 8442-5 Part 5 http://www.catra.org/pages/products/kniveslevel1/slt.htm Does anyone know why this standard isn’t being discussed? Or, has it and I just keep missing it?

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/21/2016 at 1:10 pm #33564I haven’t been using my BESS machine because I find it fiddly to use compared to the I built. You have to load a new piece of filament with the BESS for each iteration whereas you can get up to 20 tests from the same piece of tape before having to reset and reload. I also didn’t like the experience of having to slowly add lead shot until the filament was cut and then weigh the shot afterward to determine the value. It is important information and we’re still working on building a robotic version of it with XYZ axis motion as well as rotational motion for the knife and auto-capture of the force data, both angular and straight. It’s a big project on our back burner right now, but will be awesome once we get it up and running. We should be able to cycle through a lot of tests very quickly and get some very meaningful data to study.

-Clay

1 user thanked author for this post.

04/21/2016 at 1:34 pm #33565Can you provide the blade forum posts with objective criticism of the device ? All I see is criticism of the man trying to sell the device on blade forum. I want to hear or read what people have observed tested or failed to verify in testing. I guess I am the only one who is asking for this kind is imperical evidence of fraud or pure bunk. I can’t seem to find any posts where people have tried it and reported their findings ( peer observations). Can you share what you saw while using it? How did you determine reliability or failure of the test results. At what point did you say this is a piece of junk? Why could you not “trust” it for testing improvement of the blade from customer receipt to final stropping? Did it fail to perform what is advertised? If it doesn’t, how is he still selling it? I am assuming that you use the telephone paper cut test, the Murray carter three finger test and the hanging hair test and that these indicate one of two things. Sharp or not sharp. Are these not subjective sharpness tests or have I missed something completely? I am not trying to be a pain. This is something I have been trying to wrap my head around with a new found since of wonder. I showed someone the test in the below video and they where amazed. However, it’s more of a trick than a test. The speed and velocity of the blade split the paper not the sharpness of the knife. I realize people are very passionate about this issue and many have just given in . One day I may surrender to the idea myself but I am not convinced that we are proving anything concrete with those tests. Does anyne know or have a copy of ISO document for standard commercial blades? ISO 8442-5 Part 5 http://www.catra.org/pages/products/kniveslevel1/slt.htm Does anyone know why this standard isn’t being discussed? Or, has it and I just keep missing it?

You might not have read far enough into that bladeforums thread… Here, here, and here are my results, and I seemed to be the only one getting them (i.e. a hair whittling/hht3-4 edge scoring worse than a 200 grit edge that would barely shave). I don’t know what the issue was, but I do know that it only tests push cutting sharpness, not slicing aggression/sharpness which is one thing Cliff Stamp has compared in the past and it playes a huge roll… I think Clay’s does this which will be sweet. A few things pointed out that could be affecting the reading were: steel type/carbide content, peaks of the ”teeth”, etc (you can read through the thread.

One thing about the test media that was pointed out is that it depends how gently you set the media down on the edge and how long it takes to “cut” (sometimes a delayed response was observed).

I’m not saying it doesn’t work, or that I did everything correctly. I’m just saying that at this point I don’t have any more time to mess with it to see if I can deduct/troubleshoot what was going on. I simply don’t trust it for my uses at this point.

edit: currently to test sharpness I: examine the edge with the naked eye to ensure all looks good, then make sure it will pop arm hairs on both sides equally (if you do this after repeated stropping on your pant leg on one side of the edge and it will still shave well on both sides this indicates to me I don’t have a weak wire edge), and then see how it bites into my finger/thumb sometimes. It’s sharp enough and good enough for me =) I think often times we over-evaluate sharpening instead of just sharpening and using a knife, like Cliff here.

This can also be seen by Todd’s most recent post on his blog that you pointed out above… even sharpening a straight razor is way over though/theorized most of the time, although it does take skill and technique.

1 user thanked author for this post.

04/21/2016 at 1:49 pm #33567Josh, I have a strong hunch that the peaks of the teeth, time to cut and force with which the media is set down are all huge factors. If improving keenness is a matter of reducing the surface area of the cutting edge to as small an area as possible in order to magnify the force applied, then having all the force concentrated on a single micro-tooth would require less overall force required to cut the media. It’s like a bed of nails sort of. If all the nails are the same height, then you can safely lay down on them and not get punctured because all of your weight (force) is distributed over all the nails. If you have a few nails that are sticking up higher, all your weight will be concentrated on those and you’re definitely getting punctured. I’ve observed with both my system and the BESS system that you can leave an amount of weight pushing the media into the blade that is normally not enough to cut the media and it will still rupture the media if left long enough. I’ve also set the tool head down to hard and cut through the media, which indicates that you can set it down hard enough to start the rupture but not enough to go all the way through. In that scenario, a much lesser amount of weight will be enough to finish the job and give you a lower reading. With my triple beam style system, I can balance the load so that the tool head starts just above the blade, but not making contact. Then I can add very small increments to avoid a sudden drop onto the blade. Thinking about that now, I realize that the velocity you’re moving the media is a big factor too. Even if you’re only lightly setting the media against the blade, if you’re doing it quickly it will have the effect of much more force.

-Clay

1 user thanked author for this post.

04/21/2016 at 1:54 pm #33568Clay, have you posted anywhere on the forum videos or details on the testing systems you have at WIckedEdge labs? I know your familiar with CATRA and believe you have some of of their systems. I think it would be awesome if you could give us a tour of your toys.

Just a cool thought. I think others would be interested too.

Just a cool thought. I think others would be interested too.Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/21/2016 at 2:21 pm #33571Clay, have you posted anywhere on the forum videos or details on the testing systems you have at WIckedEdge labs? I know your familiar with CATRA and believe you have some of of their systems. I think it would be awesome if you could give us a tour of your toys.

Just a cool thought. I think others would be interested too.

Just a cool thought. I think others would be interested too. I don’t think I’ve posted videos before. I’d have to do a lot of work in the R&D room to remove projects we’re working on that haven’t reached the market yet but otherwise could do it. We don’t use any CATRA machines here though I’ve sent things off to them before. Our testing machine is home built as is the next generation though that one is being done in consultation with Los Alamos National Labs.

-Clay

1 user thanked author for this post.

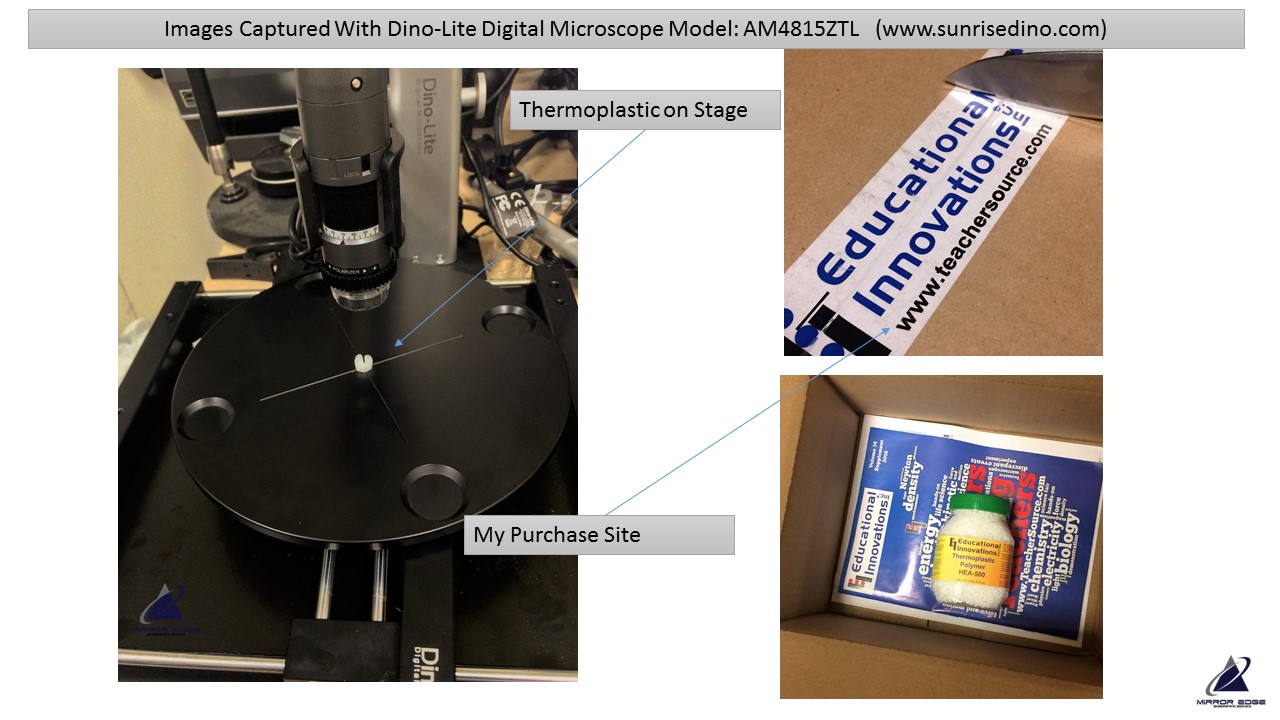

04/23/2016 at 1:39 am #33645My military orderly room just notified me that I have a package that just arrived. Woo hoo! I may finally get to try the thermal plastic. More to come.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-16221 user thanked author for this post.

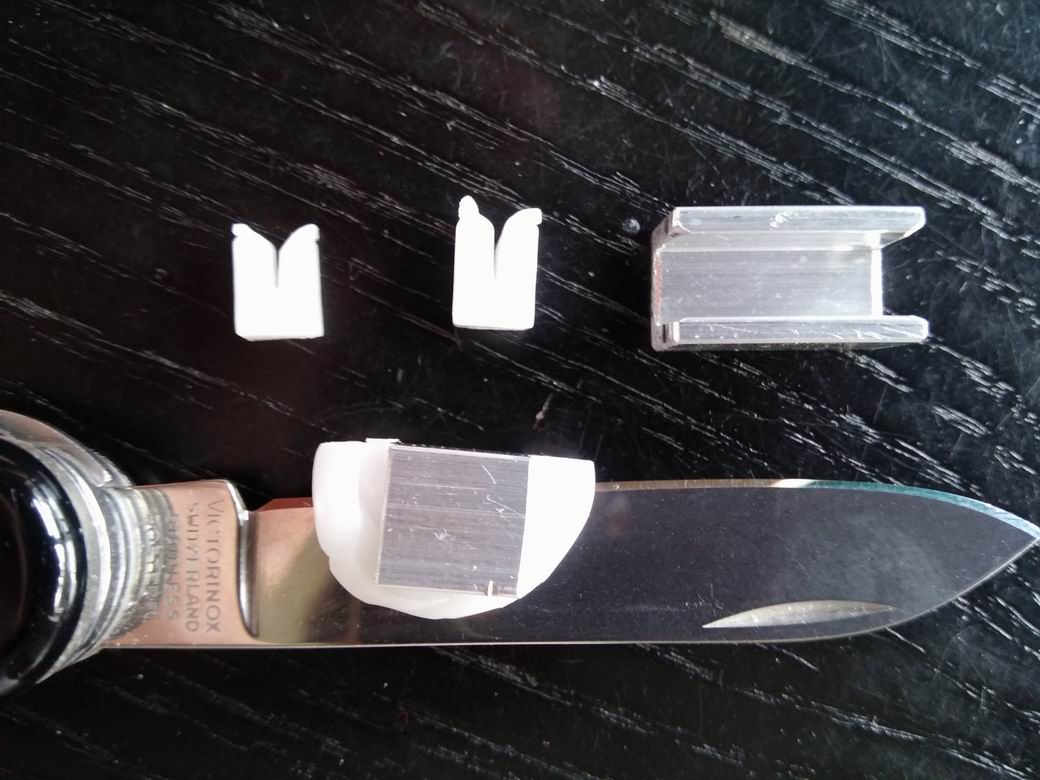

04/23/2016 at 5:16 am #33651My military orderly room just notified me that I have a package that just arrived. Woo hoo! I may finally get to try the thermal plastic. More to come.

Great, taking your idea of using a holder for the medium, I now use a small piece of aluminum U-bar. This gives it nice flat sides making it easier to cut once hardened. Just to give you an idea, I made a few quick photos as pressed on the knife, once it is cut and under the microscope.

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

04/23/2016 at 7:33 am #33656Great job Frans… looks like you’ve got it dialed in!

1 user thanked author for this post.

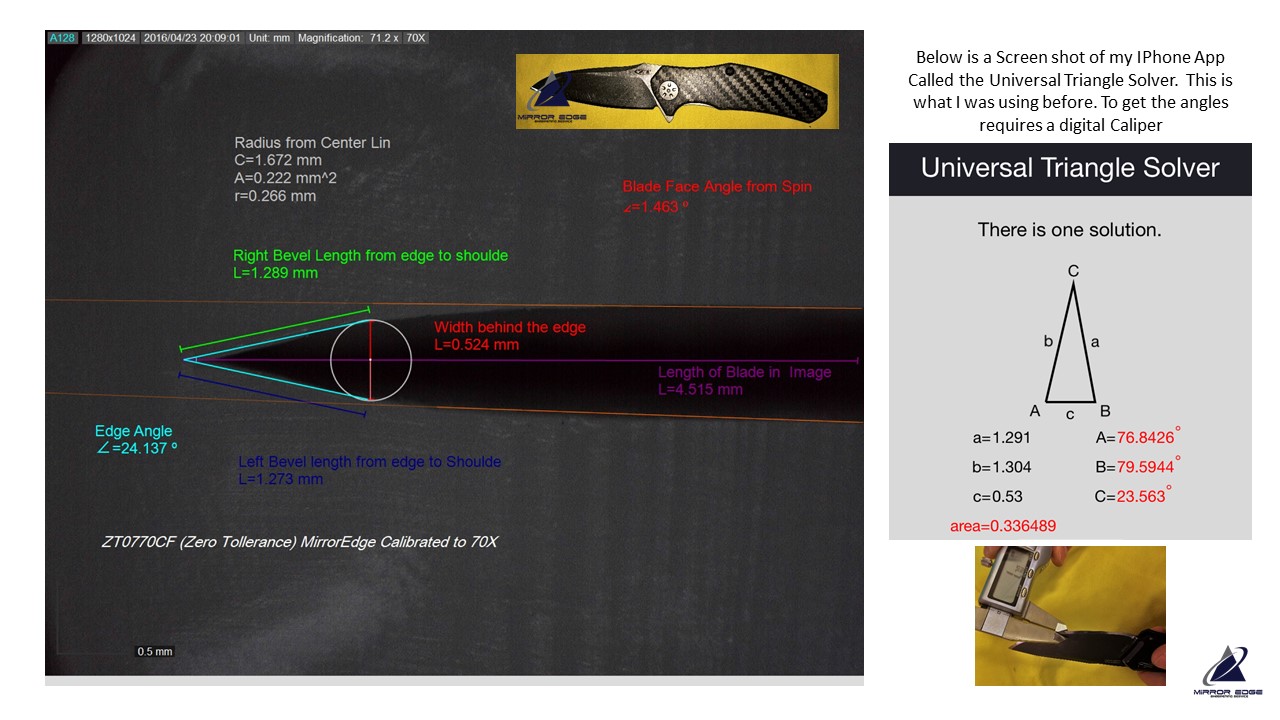

04/23/2016 at 11:52 am #33660Well Guys, I got the Thermoplastic to Work and It works very well at holding it’s shape. It’s very easy to use and in my opinion the perfect reusable medium for this application. I like the holder Frans. I am going to have to make something similar. My observation is the once hardened it’s a little hard to cut without reasonable force. So we have moved a little from one extreme to another. Fortunately for us, we all have sharp knives.

I think the holder that Frans found will be perfect, now, I just need to find something like he has. I provided additional details in the slides below. I am amazed at how much information this process can generate.

I think the holder that Frans found will be perfect, now, I just need to find something like he has. I provided additional details in the slides below. I am amazed at how much information this process can generate.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-1622Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.