Ever wanted to measure and view a Edge Profile? Check this out!

Recent › Forums › Main Forum › Welcome Mat › Ever wanted to measure and view a Edge Profile? Check this out!

- This topic has 83 replies, 10 voices, and was last updated 04/29/2016 at 10:11 am by

M1rrorEdge.

M1rrorEdge.

-

AuthorPosts

-

04/05/2016 at 1:14 pm #32994

I got permission from Pavol Sandor to republish his idea in English on the Wickededgeusa forum. CATRA is selling a device for $8000.00 called a Blade Edge Profile Microscope (http://www.catra.org/pages/products/kniveslevel1/bet.htm) which is awesome but way out of reach for most of us on this forum. After days of searching, I found Pavol Sandor on YouTube who figured out how to do it with a candle, play dough, lighter, and camera/microscope. You have got to see this…I recommend that you use a Dino-Lite USB microscope to measure the blade edge angles, capture, and save before and after images of blade profiles. See a video of the DinoCapture 2.0 software here (https://www.youtube.com/watch?v=C-hfl-Vkq3Q)

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-16225 users thanked author for this post.

04/06/2016 at 7:22 am #33024Cool idea!

It would be interesting, if someone had this setup, to do a catalog of factory sharpenings from some of the major manufacturers. Bet it would be a real eye opener!

2 users thanked author for this post.

04/06/2016 at 12:00 pm #33032I am working to do that very thing one knife at a time. The WickedEdge database is a good start. At the moment it’s implementation has anyone listing what others have done not what the knife was designed to be. It’s a shame that the manufactures are still putting crappy edges on from the start or they are using the high speed cutting and shaping devices to save overhead. You can pull the same knife from three different distributors and they all would be different. Their are some really cool water cooled professional “edge making” devices, however, these are not sharpening and perfecting tools like the wickededge. They just put a basic edge on the knife that meets ISO 8442-5. It keeps us employed, however, it would be amazing if they came from the factory with symmetrical shiny bevels from the start. I understand the “whys”.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-16222 users thanked author for this post.

04/07/2016 at 11:37 am #33063Very cool! But how would you actually measure the geometry further? Using a USB microscope with a good scale?

Molecule Polishing: my blog about sharpening with the Wicked Edge

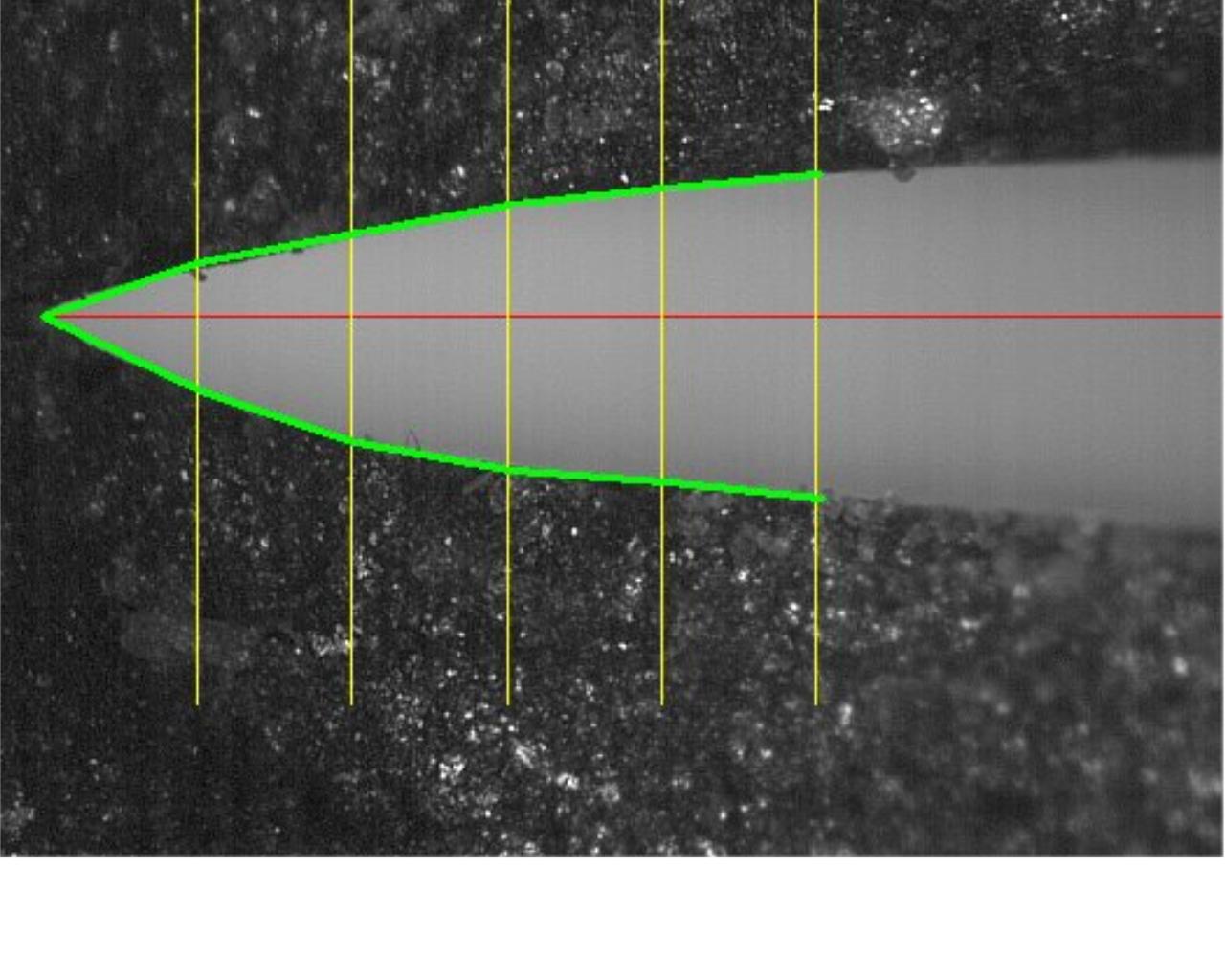

04/07/2016 at 12:42 pm #33068Some of the USB microscope softwares offer measuring tools. After calibrating, you capture an image of the mold cross-section, after which measuring something like the included angle of an edge profile takes only seconds.

1 user thanked author for this post.

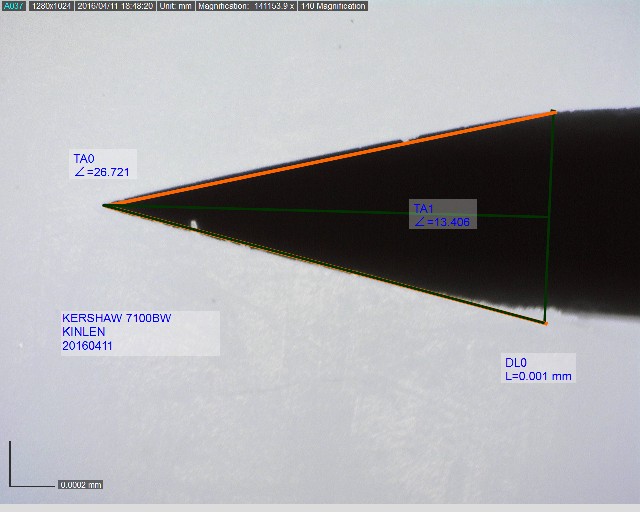

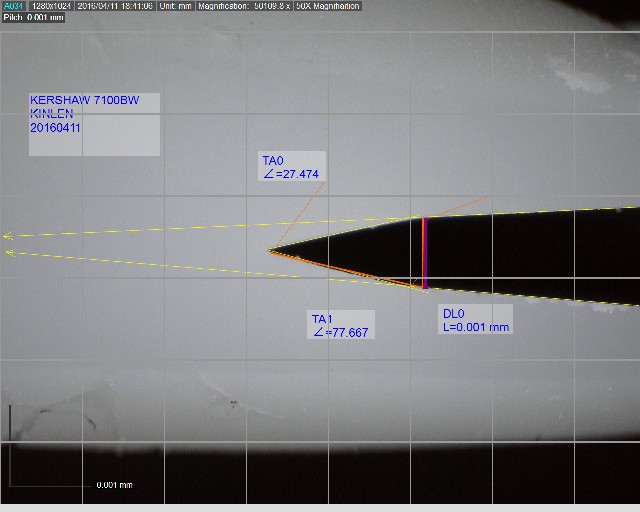

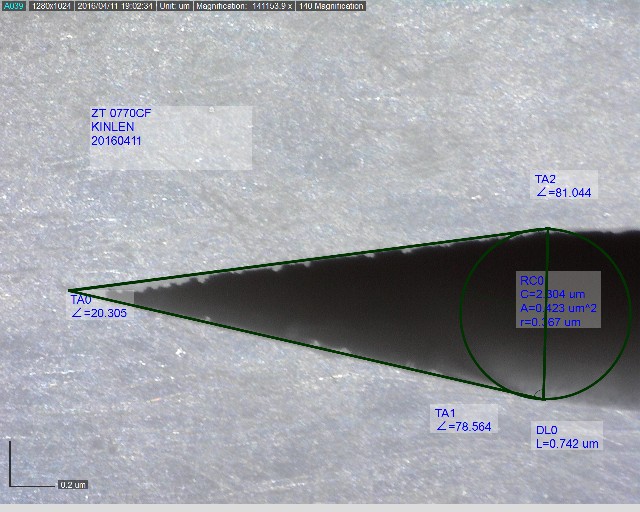

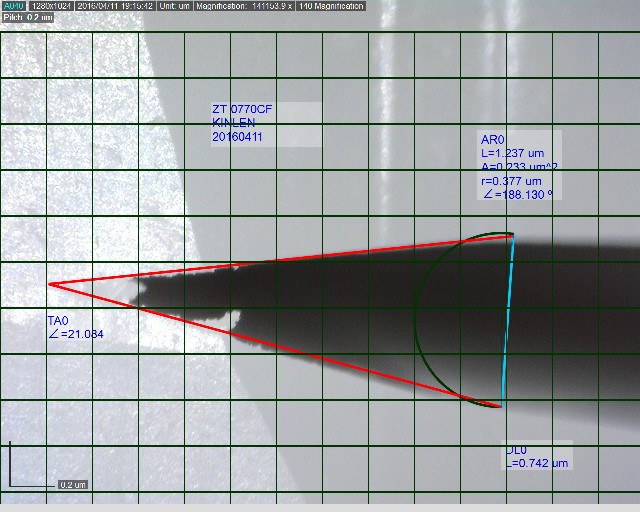

04/11/2016 at 11:52 am #33232I poured the wax mold and prepped it like Pavol. I am using a Dino Lite (AM4815ZT) and the free Capture 2.0 software to measure the inclusive angle and the width behind the edge. You can see and measure all the angles on the edge profile really quickly. If you measure the blade faces out behind the cutting edge, you can see how much metal was removed. It is pretty cool. I tried using just clay to make a impression, however, it shrinks after removing the blade. So, I placed it in the freezer for a few minutes and it improved but not well enough. I recommend the wax mold. It holds its shape much better. After pouring the wax, place it in the freezer for a few minutes to cool faster. Look at some of my results below.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-1622Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

04/11/2016 at 4:26 pm #33254This is interesting. Can the guys with a Dino Lite tell a little more about them?

I have a Veho and thought it was similar to a Dino Lite. But it seems this Dino Lite is, as a microscope, slightly better. But I’m particularly interested in the software that comes with it. Does it run under Windows 7 and Windows 10? And what functionalities does it have?

Molecule Polishing: my blog about sharpening with the Wicked Edge

04/12/2016 at 12:26 am #33276View the DinoCapture 2.0 software here (https://www.youtube.com/watch?v=C-hfl-Vkq3Q) Dinolite has a great YouTube page with more information than you need to make a informed decision. Within the above video you can click a link to all the important info on the software. I have one of the cheap microscopes (from China probably) as well. It states 900X but it just isn’t. The value with Dinolite is in the software. They are not cheap and you can’t use any other camera with the software (I’ve tried). I will also provide Dr. Matts YouTube link here https://www.youtube.com/watch?v=49ERZiDbDj4 . This is the video that got my attention. I am using it under windows 10 and I believe they have a MAC version of the software as well.

Because I have a wicked edge and can sharpen my own blades with perfection, I have been playing with the angles and different steels. If I can accurately measure a 20 degree inclusive angle, I think you can measure just about any angle greater with accuracy after easy calibration of the microscope and at the different powers. I plan to put a “micro bevel” or primary edge angle at between 30-35 inclusive next. I will mold the results and place them here. This will allow me to have a “shiny” bevel that will have a stable edge “in theory”. That is part of the reason I wanted to see the angles. This process allows a lot of clarity that we couldn’t see before. I am working to be able to put a perfect convex angle on a blade next. By molding the stages, I expect to get their soon. I will be able to see the different “facets” and then will be able to see the results of smoothing them out with a leather strop.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-1622Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

04/12/2016 at 1:55 am #33279Thanks a lot! Those are very useful videos. The Dino software also looks quite impressive (much better than my Veho software).

Molecule Polishing: my blog about sharpening with the Wicked Edge

04/12/2016 at 9:17 am #33300Mark, I have a couple of the Dino-Lite scopes and really like them. The software is really good, very easy to use and seems very accurate when it’s calibrated.

-Clay

04/12/2016 at 9:18 am #33302I really like the approach. Have you tried just pressing wax into the edge of the blade to make an impression? Does it truly need to be melted onto the blade to work?

-Clay

04/12/2016 at 2:24 pm #33322You have to melt the candle way. Pressing the edge into the candle will not work, it will break it or just shave flakes off.

My first try was not bad but I want it a bit more refined. This is from a standard 91mm Victorinox as it came from the factory.

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

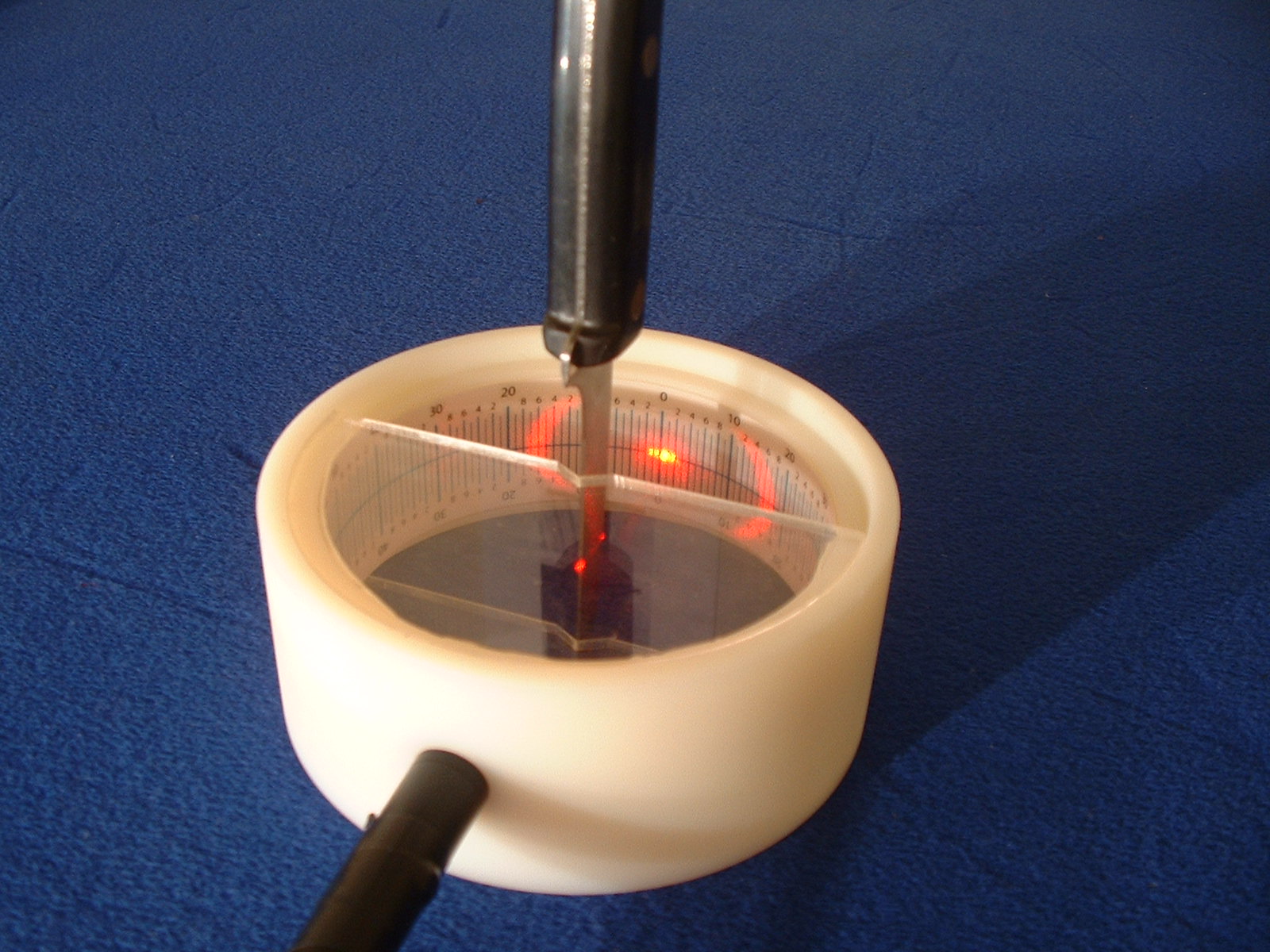

04/12/2016 at 2:29 pm #33325I have tried many different mediums to impress the angles of the blade edge. I’m in the process of building a holder for modeling clay that has a low plasticity (This is the key to a faster method). It’s basically a circle cut into a metal or plastic holder with a V cut into it that is approximately 2 mm in thickness. This Will probably allow me to quickly measure multiple places along the blade without having to melt the wax. I am looking for something which will be completely renewable. I have found that melting the wax, however, provides you a permanent cast of the blade edge for later examination. By putting the wax in the fridge for cooling, I am finding that I’m not getting as clean of a mold as when I let it cool slowly. As you see, I’m refineing the process step by step. Can anyone think of a medium that will hold its shape after removing the blade that isn’t wax? Just pressing the blade into the wax causes it to flake? I have tried putty, play dough,two different types of modeling clay and Silicon Wax used in ear plugs. I think the holder with a little clay may be the trick. If I had a 3D printer I would already have made several different medium holders for experimentation. The wax is a start but believe there may be a better way. This is the reason I am sharing these details. I think the whole community could benefit from using this method. I have used a goniometer (CATRA) as well. I bought one after seeing Clays video. The problem with that tool is recording the results for future review and seeing the multiple facets clearly. It does show a angle quickly, but that is it http://www.catra.org/pages/products/kniveslevel1/lkep.htm . (100.0 U.S. Dollars) There is great value in being able to record your result and being able to share them with others.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-1622Attachments:

You must be logged in to access attached files.

04/12/2016 at 2:47 pm #33327I wonder if some kinds of ball point pens might work as a holder. The ones I’m thinking of are softer tubes that are very simple in design. Cutting them into sections and then cutting a slot for the blade to slide into might work.

-Clay

1 user thanked author for this post.

04/12/2016 at 3:23 pm #33333Would it be possible to warm but not melt the wax in a microwave and then maybe apply either a silicon spray lubricant or a non-stick cooking spray to the blade?

Just a couple random ideas, I did find a page on wax types regarding their softness and melting points which is what got me thinking. Ideally you’d probably want the material hard at room temp but nice n soft for taking the impression.

Great topic!

2 users thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.