Edge retention as a function of edge angle / steel

Recent › Forums › Main Forum › Knife Specific Discussion › Steel › Edge retention as a function of edge angle / steel

- This topic has 46 replies, 10 voices, and was last updated 02/07/2015 at 8:40 pm by

tcmeyer.

tcmeyer.

-

AuthorPosts

-

10/10/2014 at 9:30 am #20753

I wrote about this some time ago here : http://www.cliffstamp.com/knives/articles/sharpness_review.html .

Very interesting read, Cliff! I’d visited your site before, but I’ve now also begun to read the longer articles. Very educational.

Molecule Polishing: my blog about sharpening with the Wicked Edge

10/10/2014 at 6:33 pm #20763Clay,

I wrote about this some time ago here : http://www.cliffstamp.com/knives/articles/sharpness_review.html . I will put up some pictures/film later.

I would also be very interested in seeing a video on how you do this… seems simple, cheap, and effective, something that basically anyone can replicate. Thanks cliff!

01/16/2015 at 11:48 am #22724I’ve mentioned my Spyderco Delica in ZDP-189 quite often here and I’ve extolled its virtues whenever I could. Up until this week, resharpenings have been touch-up, using 800s and 1000s. This week, I had cause to sharpen it when a chip appeared near the tip. I can’t recall what I hit with it, but I do recall thinking “Uh-oh. That’s gonna leave a mark.”

I took some micro photos of it, but haven’t yet transferred them to my main computer. I’ll do that soon, but for now, let me say that the chip was not especially severe – more inline with what I routinely see on my other knives. The problem lies with the hardness of the steel. I’ve seen comments in posted reviews where people have mentioned being put off by the difficulty in sharpening the ZDP-189 with normal equipment. Shoot. I’ve got diamonds, ain’t I?

I’ve become acclimated to the feel of the ZDP stuff when using my diamond stones, and so I no longer sense that the steel is anything but normal. I do recall saying that with the first sharpening, I sensed that the knife may have had a grandmother who was ceramic.

Anyhoo, this little chip took me about 400 strokes of my 400-grit diamond stones on each side to eliminate it.

01/17/2015 at 1:20 am #22735So here’s some photos of the subject chip(s). This first one shows the depth measurement of the chip and the bevel width. Not being sure of the angle of the bevel relative to the camera, the measurements could be off by a small amount, but not enough to buy lunch with.

The second and third photos are different views of the same chip(s):

The fourth photo is of the edge after sharpening. Not necessarily the same area that the chip had been. It shows the width of the bevel as less than one millimeter.

A few final notes: All four photos were cropped identically, so their fields and images are all the same width and height. The chip, as measured in the first photo, is 0.182 mm deep, which is only 0.007″ deep :ohmy: . Think about it. It took 400+ strokes with 400 grit stones to take the edge down about eight thousandths of an inch. Tuff stuff. B)

Someone’s sure to ask… The angle is 20 dps. The finished bevel is at 1000 grit diamond stones. The last photo was taken with the camera held perpendicular to the bevel.

01/17/2015 at 1:54 am #22740Those are serious chips do you recall how these were formed.

I would treat this steel as a Japanese knife so slicing movements rather than chopping movements avoid anything as hard as bone or frozen food if you are careful with its use and it still micro chips perhaps it was poorly tempered and I would consider asking Spyderco to replace it since if the tempering was not correct perhaps the steel is harder and more brittle than it should be.01/17/2015 at 2:21 am #22744Leo:

this is a Spyderco Delica I use as my EDC. The blade is less than 3″ long and is not used for kitchen work, except to open packages. the chips are actually quite small; the largest was only 0.007″ deep and barely visible to the unaided eye. As I stated above, I don’t recall what I hit, but the chips were not unexpected. This ZDP-189 steel is hardened to RC64 – 65. It stays sharp a long time and the trade-off for that is being brittle. I love it and wouldn’t give it up.

Tom

01/17/2015 at 2:48 am #22747Those are some very detailed shots, what exactly did you take them with?

01/17/2015 at 3:06 am #22748I have a Rockstead Un ZDP 189 with VG10 hardened to 67 RC although I admit that I do not use this I have it both as an investment and to enjoy for its looks.

I only mention keeping an eye on the micro chipping since it is high tech steel and it is possible that there was a possible fault with tempering I know that your knife is not a cheap knife but in comparison to a Rockstead it is so ; it could be possible that certain aspects of the production standards are not quite what they should be.

I think it is an attractive knife and I have even considered getting one myself or a chefs knife made with this ZDP 189 there are quite a few laminated knives of this type I think on the cktg website.

When I mentioned kitchen work I was referring more to the density and hardness of certain things that should be avoided copper staples for instance are probable about the same hardness as bone and are often imbedded in cardboard boxes.

A lot of people have found that VG10 found in Shuns is prone to chipping but many cooks & chefs abuse their knives and I think that this can be the cause of the chips more than faults in the metal.

As someone that both sharpens and collects knives I would not expect chips due to missuse to be the cause on your knife which is why I would keep an eye on the situation I am sure that if it turns out that the tempering was not correct that they would gladly replace it especially since you sharpen knives and therefore deal with people I would expect that they would wish to keep you sweet.01/17/2015 at 4:05 am #22749I hope to dig into my zdp stretch this weekend again now that I have my usb microscope to use. I hope mine does not chip easy..I got mine at the seconds sale and will just have to live with it..lol.

Great pictures.. Amazing how big a mm is. I thought at first holy crap only a mm of bevel! Then I looked at mine..which is 17dps while yours is at 20 and mine is just shy of over 1mm.

Cliff, if I am not mistaken he has the celestron 5MP usb microscope. Obviously I need to play with mine some more because my pictures do not turn out that nice just yet. But I just put mine on my starett Flex-O-Post Assembly so I can try and get shots while the blade is still mounted in the vise and take all wiggle out of my pictures.

01/17/2015 at 5:44 am #22750Eric”s right, I use the Celestron 5MP. Those pictures, however, are taken at the lowest resolution setting; 1280 X 960, or 1.3 MP. On a computer monitor, there is nothing to be gained in the image at higher res.

The difference is the magnification setting. Like most, if not all of these “barrel type” microscopes, it will focus on a given distance at two different magnifications. Since I use the end of the shroud as the focal point (so I can rest the ‘scope on the edge) the two magnifications are 58X and 179X on my monitor. I’ve pretty much abandoned the high setting as too difficult to keep in focus and the depth of field being too narrow. So I use the lower setting and it shows me virtually everything I need to see, and makes it easy to hold steady.

if you think about the geometry of a simple magnifier, you’ll have a lens which you move relative to the object and your eye. Consider the distance between eye and object as fixed. The closer the lens if to the object, the larger the image. The closer the lens is to the eye, the smaller the image. In the case of these microscopes, the “eye” is a small sensor on a circuit board at the top of the barrel. In my case, the ‘scope focuses at some point near the sensor (low mag) and again with the lens away from the sensor (just past the LED ring) for higher mag.

Try moving your ‘scope down in magnification to see if there is another focal point. Solved my problems.

01/20/2015 at 5:48 am #22780As I’ve mentioned here many times before, the “shaving sharp” edge that so many folks rave about simply won’t really cut things like foam rubber, meat, and rope very well. It’s one of the modern myths that persistantly bug the knife world that an edge capable of shaving a small section of soft arm hair, is really capable of doing significantly better on items cut more frequently than will an edge that won’t feel as polished. The type of edge that I’m trying to talk about will be a lousy shaver. It’ll probably cut you if you try to make it shave, but for exactly that reason it will be significantly better for cutting meat, rubber and twisted fibers. — Mike Swaim7

The above was on Cliff’s website about Measures of Cutlery Sharpness. This is easy to prove…just sharpen your knife with edge leading strokes from heel to tip using each grit paddle up to as high as you want, then you will find that your knife will be a very lousy shaver, but will cut mason line or something else with ease. I test slicing sharp on my finger…yeah, my finger. I hold the knife against my finger tip, where I have the most callous, then begin drawing the knife ever so lightly and softly and if it bites immediately, then it is slicing sharp ready!

02/03/2015 at 6:14 am #23083cliff you wrote an article/paper recently using this picture in it… would you mind posting it here? can’t find it but it was very helpful and well written.

… in other words, are you saying that the more you raise the angle of the micro-bevel the lower the edge retention?

Yes, and most people say the opposite. Here is why it is wrong :

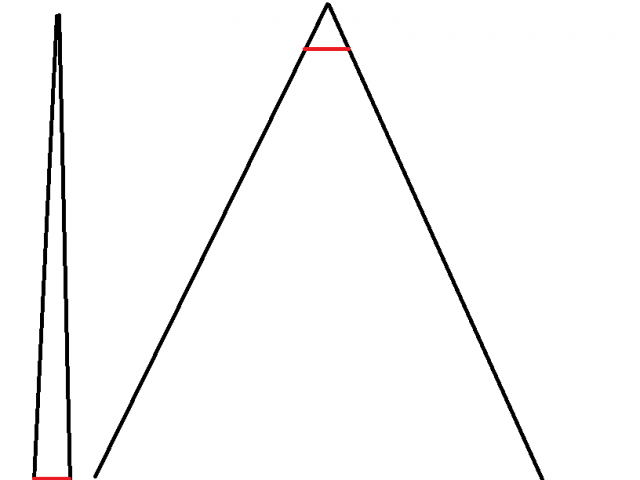

These two crudely drawn triangles reflect a very low edge angle and a very high edge angle. Note the red lines represent the same thickness of a worn apex. The thickness of the apex is a very strong influence on the sharpness (it isn’t the only thing, but it is a heavy factor).

Which one do you think will happen sooner, which knife will reach the red line faster, the one on the left with the very low angle or the one on the right with the very high angle?

—

Now there is where you might jump to “Hey, doesn’t this just say we should sharpen at zero degrees for ultimate performance – that is obviously wrong.”

Yes, this is true, the relationship in the above graph will not just continue beyond 13 dps in a straight line, at some point a very dramatic change will be made and the performance will decrease rapidly and at some further point the edge retention will fall to zero. This happens because at some point the micro-bevel will be so low that the apex is no longer strong and/or durable enough and it will just grossly deform/fracture. The trick then is to find the lowest angle this doesn’t happen as that give the optimal performance. This will depend on the steel, the material being cut and operator skill/experience.

—

As a bit of math, the reason this happens is because the edge retention behavior in total has not only the affect I have noted in the above which is just a linear relationship it also includes step functions on strength and toughness. Step functions are particular functions because the basically do nothing until a certain limit is reached but at that point they can cause dramatic effects. The math is a bit wonky as step functions are written similar to this for the effect of angle on the stiffness of the edge which is related to it deforming to failure :

s(x) = (1 if x > Ao; 1/x^3 for X < Ao; 0 for x < Ac)

Thus the edge retention would be written as :

E(x) = l(x) * s(x)

Where l(x) is that linear equation and s(x) is the step function. This jibberish translates to :

-if the angle is above some angle (Ao) then the edge won't really deform/fracture significantly and just slowly wears, deforms and chips at a very small micro-level

-however if you go below that angle then the strength/toughness is no longer there to keep the micro-bevel stable and it will just deform/fracture beyond the apex, the entire micro-bevel will start to take damage and the blunting will be very rapid

-if you go beyond that point further and reach a critical angle, Ac, then the strength/toughness is so low that the micro-bevel will just crack of the first time you try to cut with it

—

Now the math is a bit complicated and the language possibly foreign, but it is easy to understand as we see things like that every day. For example the life of tires on your car has a number of step functions. If you drive on the highway you get tire life which is a very slow process of small wear and little rips/tears. If you go off road at some point the rocks can be jagged enough that they will start to damage the tires beyond the normal tread wear. But if the rocks are not jagged enough this doesn't happen and you just see slow wear. If you hit a nail there is sudden and catastrophic failure.[/quote]

02/03/2015 at 6:25 am #2308402/03/2015 at 6:50 am #23086Awesome thanks Cliff!

02/03/2015 at 10:36 am #23090The article that changed my thinking and opened the door to much better edge performance for me. Cant thank you enough! It was this research that inspired me to try and take the angles on the WEPS lower(and lower(and lower)). :whistle:

The real world testing on your youtube channel where you talk about practical use and results based on different steels and angles is some of my absolute favorite stuff to watch.

Aloha

-

AuthorPosts

- You must be logged in to reply to this topic.