Edge retention as a function of edge angle / steel

Recent › Forums › Main Forum › Knife Specific Discussion › Steel › Edge retention as a function of edge angle / steel

- This topic has 46 replies, 10 voices, and was last updated 02/07/2015 at 8:40 pm by

tcmeyer.

tcmeyer.

-

AuthorPosts

-

10/08/2014 at 5:33 pm #20685

What I meant is simply: does this graphic show the results of one run?

The latest one shows three runs, the average is plotted as the points and the standard error is used to generate the error bars. Ideally at least three should be done at a minimum, I like to do 5-7 most times. The problem is just time, ask yourself this – what is more interesting/useful :

-one VG-10 graph with seven runs

-a VG-10 and S30V graph both with three runsIt takes the same time to do both and each run of one data point is about an hour so it takes ~20 hours to do three full runs at all micro-bevels so it is ~40 hours just to look at two steels with three runs. To be frank I am not confident enough in three runs to let that stand and will likely take each to five runs which means it will be ~80 hours for those steels and this is at just ONE grit.

If I wanted to look at five grits as well that would mean it would be ~400 hours. Lets say I wanted to see if there was any difference in the WE diamonds vs the DMT or EZLAP that would mean it would expand to ~1200 hours. If I wanted to add more steels then it would start to climb up to ~10, 000 hours. It should be easy to see that you have to keep perspective in work/time. Often times I get asked “Hey, why don’t you …” . These can be great questions, interesting questions but I simply don’t have the time.

If it isn’t clear, one of the things I have been very vocal about is that I have never intended and never do intend that what I do be used as some kind of ultimate reference. The only thing I am trying to do is at most make people think about things. If you look at this graph and you take from it “I should put a little effort into making sure my micro-bevel angle is optomized” then I consider it a success. What I don’t want to happen is someone look at it and say “Oh, this means XXX is the best angle”. This graph will change if you switch from hemp to plywood to cutting up cod . The general relationship is always there (micro-bevel influences edge retention) but the shape/form will be different. The point is just to realize that micro-bevel can influence edge retention so don’t just default to some standard angle of you care about edge retention.

10/08/2014 at 5:58 pm #20686Just got caught up on this thread! Good stuff!

The only thing I am having trouble with is the TCE, even though you explained it thoroughly Cliff. I am definitely NOT a numbers guy like you and have difficulty understanding how to interpret the TCE in relation to the angle. In otherwords, is it good or bad that the TCE goes down as the micro bevel goes up… what is that saying? Is it saying that you get better edge retention on hemp rope the higher the micro bevel?

sorry for not understanding 🙁

10/08/2014 at 7:08 pm #20688.. how to interpret the TCE

It is a measure of edge retention, the higher the TCE the higher the edge retention.

Now you might ask the following question :

“Why don’t you simply cut material until the sharpness is say 5% (or whatever) and use that amount of material to measure the edge retention?”

This is a very good question and on the surface it seems reasonable to do it that way. But if you try it then you will find that measurement is prone to large variations. What I do is similar to :

-cut material until the knife is say 90% of optimal sharpness

-cut material until the knife is say 80% of optimal sharpness

-cut material until the knife is say 70% of optimal sharpness

-cut material until the knife is say 60% of optimal sharpness

-cut material until the knife is say 50% of optimal sharpnessand so on and from all of those intervals I calculate the edge retention. Because I am using much more data is it a much more stable measurement.

Think of it this way, imagine you have a guy digging a hole and you want to get a feeling for how much dirt he can move in a given time and his fatigue rate. If you just looked at how much dirt he moved at the start and how much dirt he used at the end you are only using two points. What about if he injured his hand half way, or he hit a large rock and had to waste time moving it?

Instead what about if you checked on him at say every 10 minutes and looked at how much dirt he was moving and then used all of those points to make an “average” performance over the entire time. This will be a much more stable or reliable indicator of performance because those points of injury or where he hit a large rock won’t just dominate the entire performance then.

By doing this you can also spot those events and if necessary repeat the experiment to find out what happens if he doesn’t get injured or hit the rock. But if you don’t check in intervals you would never know it happened anyway.

10/08/2014 at 7:47 pm #20691.. how to interpret the TCE

It is a measure of edge retention, the higher the TCE the higher the edge retention.

[/quote]everything you explained makes perfect sense… thanks for breaking it down for me like that!

If what you say is true (above) then your graph would be showing that the lower the microbevel the higher the edge retention, which wouldn’t make sense…. I have always heard that the higher the edge angle the higher the edge retention, is this incorrect? in other words, are you saying that the more you raise the angle of the micro-bevel the lower the edge retention?

10/08/2014 at 8:04 pm #20694My theory is this: Force is the enemy of sharpness and a more obtuse angle requires more force to cut, dulling the knife more quickly. There are limits on both ends based on the steel, heat treatment and the material being cut.

-Clay

10/08/2014 at 8:09 pm #20695-one VG-10 graph with seven runs

-a VG-10 and S30V graph both with three runsI’m challenged by the depth of the math — reawakening old math memory cells I haven’t used in awhile.

That being said, I’ve got a VG-10 Shun in my WE vise right now…..

Excellent, heady stuff.

~~~~

For Now,Gib

Φ

"Everyday edge for the bevel headed"

"Things work out best for those who make the best out of the way things work out."

10/08/2014 at 8:21 pm #20696… in other words, are you saying that the more you raise the angle of the micro-bevel the lower the edge retention?

Yes, and most people say the opposite. Here is why it is wrong :

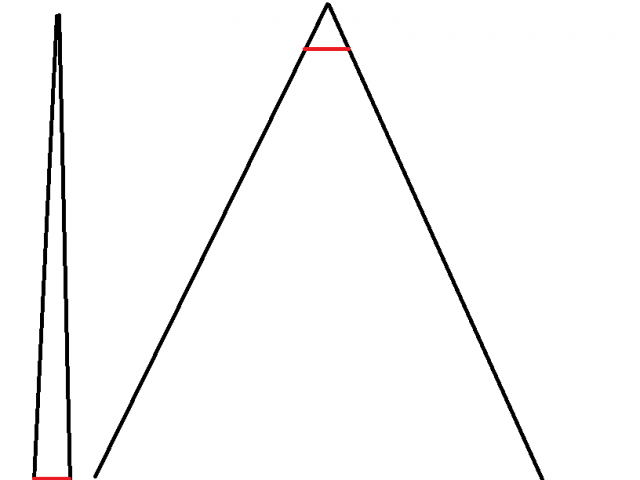

These two crudely drawn triangles reflect a very low edge angle and a very high edge angle. Note the red lines represent the same thickness of a worn apex. The thickness of the apex is a very strong influence on the sharpness (it isn’t the only thing, but it is a heavy factor).

Which one do you think will happen sooner, which knife will reach the red line faster, the one on the left with the very low angle or the one on the right with the very high angle?

—

Now there is where you might jump to “Hey, doesn’t this just say we should sharpen at zero degrees for ultimate performance – that is obviously wrong.”

Yes, this is true, the relationship in the above graph will not just continue beyond 13 dps in a straight line, at some point a very dramatic change will be made and the performance will decrease rapidly and at some further point the edge retention will fall to zero. This happens because at some point the micro-bevel will be so low that the apex is no longer strong and/or durable enough and it will just grossly deform/fracture. The trick then is to find the lowest angle this doesn’t happen as that give the optimal performance. This will depend on the steel, the material being cut and operator skill/experience.

—

As a bit of math, the reason this happens is because the edge retention behavior in total has not only the affect I have noted in the above which is just a linear relationship it also includes step functions on strength and toughness. Step functions are particular functions because the basically do nothing until a certain limit is reached but at that point they can cause dramatic effects. The math is a bit wonky as step functions are written similar to this for the effect of angle on the stiffness of the edge which is related to it deforming to failure :

s(x) = (1 if x > Ao; 1/x^3 for X < Ao; 0 for x < Ac)

Thus the edge retention would be written as :

E(x) = l(x) * s(x)

Where l(x) is that linear equation and s(x) is the step function. This jibberish translates to :

-if the angle is above some angle (Ao) then the edge won't really deform/fracture significantly and just slowly wears, deforms and chips at a very small micro-level

-however if you go below that angle then the strength/toughness is no longer there to keep the micro-bevel stable and it will just deform/fracture beyond the apex, the entire micro-bevel will start to take damage and the blunting will be very rapid

-if you go beyond that point further and reach a critical angle, Ac, then the strength/toughness is so low that the micro-bevel will just crack of the first time you try to cut with it

—

Now the math is a bit complicated and the language possibly foreign, but it is easy to understand as we see things like that every day. For example the life of tires on your car has a number of step functions. If you drive on the highway you get tire life which is a very slow process of small wear and little rips/tears. If you go off road at some point the rocks can be jagged enough that they will start to damage the tires beyond the normal tread wear. But if the rocks are not jagged enough this doesn't happen and you just see slow wear. If you hit a nail there is sudden and catastrophic failure.

10/08/2014 at 8:26 pm #20697… a more obtuse angle requires more force to cut, dulling the knife more quickly.

This is a significant factor, especially if you are doing cutting which requires a lot of force. It is also why things like handle ergonomics can affect cutting. Imagine just filleting a fish with a knife which is slipping in your hand vs one where you have perfect control. Think about the bone contacts, the wasted cuts, etc. that happen in one vs the other. This and many other reasons are why trying to determine the edge retention of steel by looking at one knife to another different one is very hard. It is like taking two people, having them run 100m and deciding based on who won which had better shoes. Unless the guys run very close to each other in general, it likely doesn’t gotta be the shoes.

10/08/2014 at 8:33 pm #20698Cliff,

So, in regular sharpening like most of us do (most of us don’t zero then micro bevel) is there a general guide line such as 15 dps being the highest one would want to go?

Is what you are speaking of (the failure point at a given angle) what marthinus experienced here?

10/08/2014 at 8:36 pm #20699That being said, I’ve got a VG-10 Shun in my WE vise right now…..

VG-10 is an interesting steel . When it first came out there was a little bit of press about how it was a “better” knife steel than ATS-34 . ATS-34 has a lot of Molybdenum as it was designed for high temperature resistance and it needs the molybdenum for that strong secondary hardening. However after makers/manufacturers found out that it actually performed better as a knife steel if you didn’t actually use that and did cold tempering it seemed obvious to make a ATS-34 type steel without all the molybdenum. VG-10 has just enough Molybdenum to give it the crevice corrosion that does and for a very brief period it had some press as a knife steel. However just as people were getting interested the steam roller that was the S30V marketing machine crashed into the knife industry and VG-10 never recovered and isn’t seriously used outside of Japan where it is well regarded.

10/08/2014 at 8:46 pm #20700So, in regular sharpening like most of us do (most of us don’t zero then micro bevel) is there a general guide line such as 15 dps being the highest one would want to go?

It is going to depend on the steel, what is being cut and the person. For example if you cut hemp rope and similar materials it takes a very low angle to make the edge actually fail directly and not just take that slow wear/damage to the very apex. However if you are slicing into plywood and hitting knots and glue you likely need twice the micro-bevel angle and a larger edge angle as well.

The most I would say in general is that for some reason, modern sharpening in the west has produced very high edge angles. If you read for example Cook’s axe book and similar older books you find that 15-18 degrees per side were bevels used on full size felling axes and angles like 18 dps were only used for very hard woods and/or unskilled users (or crappy axes). But yet now these are considered low angles for knives which don’t even do any impact work? What happened to that?

Just think about if you need an angle on you knife similar to a felling axe. If you do then your knife is doing some pretty hard work indeed.

Is what you are speaking of (the failure point at a given angle) what marthinus experienced here?

Yes, he passed it dramatically when the edge took visible damage, he is basically at the zero-edge retention point there.

One of the many benefits of the high apex stability steels (AEB-L, White/Blue) is that they can take very low edge angles and not have that dramatic failure which is why a steel like 1095 properly sharpened can easily have better edge retention than say D2 cutting ropes / cardboard etc. .

This is a sort of secret known to guys like Fikes who would chop / cut up massive amount of ropes with their knives while “factory” knives would go blunt much sooner even with “super” alloys. Fikes however was running much lower angles and more coarse finishes and the two of them amplify each other and thus they can do massive amounts of work.

10/09/2014 at 3:56 pm #20720Excellent graphic, Cliff! It makes something so counterintuitive to many people very clear at a glance. It seems a bit similar to arguments why a convex edge isn’t (necessarily) stronger than a straight edge.

One of the many benefits of the high apex stability steels (AEB-L, White/Blue) is that they can take very low edge angles and not have that dramatic failure

It occurs to me that these are exactly the steels that are popular in Japanese kitchen knives, which are usually sharpened at very low angles…

I have one remaining question. I now understand the TCE, but I don’t understand yet how you measure sharpness (as a percentage of maximum sharpness). You don’t use a jig as I understand it, but how do you measure it? Perhaps I missed something.

Thanks for the great work! I’m really interested when you have any updates.

Molecule Polishing: my blog about sharpening with the Wicked Edge

10/09/2014 at 4:55 pm #20723It seems a bit similar to arguments why a convex edge isn’t (necessarily) stronger than a straight edge.

There are few things in the industry which have the kind of polar discussion about them as convex bevels and you can even find people argue the exact opposites.

The critical aspect of any bevel is the cross section, a very thick/heavy convex bevel will be very durable and won’t cut well unless it is a splitting based tool. But a very thin convex bevel will cut very well but won’t be very durable. Now you can make an argument about optimized cutting ability and durability and how it favors a convex bevel in many cases but this is critical on the cross section in question.

For example if you take a standard 0.035″/20 dps edge and you apply a convex bevel to the edge and increase the apex to ~25 dps or you take a convex bevel by blending the transition line into the primary bevel – both are convex bevels, but they are very different in how they effect the knife.

It occurs to me that these are exactly the steels that are popular in Japanese kitchen knives, which are usually sharpened at very low angles…

There is an odd disconnect that happened in knives. It is hard to pin point when and how it happened but knives and steels have really moved away from all sense of reality in many cases from how steels perform. If you asked a tool maker to make a hot stamping die from O1, or to use D2 to stamp 420 then they would out right note why these are not sensible choices (O1 has very poor hot hardness, D2 will have high adhesive wear against 420). Yet in the knife industry there are knives made out of steels which have no sensible property alignment.

If you look in the literature the properties of steels are clear and even how they are that way and why they are that why. Why is F2 for example a steel used for holding a fine cutting edge / high sharpness but D2 isn’t. But it appears to be in the West that a lot of makers/manufacturers are really opposed almost to applying metallurgy to steel selection in knives. Now not everyone of course, lots of makers are very out spoken about how metallurgy should be used in knife making (Kevin Cashen for example), but at times they seem like a minority.

…but how do you measure it?

Tie a weight to the end of a specific cord, clamp the other end of the cord. Insert knife under the cord, lift the knife to put the cord under tension, draw the knife back – a sharper knife cuts with less draw. This sounds a lot more complicated than it is, just try it directly.

I didn’t used to do it this way, what I used to do originally was much better in that it had more precision and accuracy. I had a electronically controlled tension and I could just adjust the tension so as to make a cut in say 2″ of draw. In this way I varied the force and the lower the force needed to make a cut in 2″ is a higher sharpness. This is the ideal way but it is much more complicated.

Now this is similar to how people make a cut on 3/8″ hemp to measure sharpness. I have done that as well, in fact I started doing that as that is what everyone did (Phil Wilson learned it from Wayne Goddard). The problem is I soon realized that at best I was +/- 0.5 lbs on the cord but this was a huge change in sharpness. It would be like trying to see who won a 100 m dash if your watch was incremented only in seconds. Hence I switched to lighter cords to focus the measurement in on sharpness and not cutting ability as a whole.

—

As of late I have actually been running parallel sharpness measurements, I use 35 grams on bergia spinning thread and 500 grams on 1/8″ jute twine are used for both high/low tension measurements. For awhile I was curious if you could have two edges and one was sharper on the low tension and another sharper on the high tension.

10/09/2014 at 8:52 pm #20724Cliff,

Could you post of photo of the way you do your sharpness testing? Maybe some of us can duplicate it and share results, even by anecdote if all can’t do the same level of data collection and processing, so we’re all talking apples to apples.

-Clay

10/09/2014 at 9:01 pm #20726Clay,

I wrote about this some time ago here : http://www.cliffstamp.com/knives/articles/sharpness_review.html . I will put up some pictures/film later. The thing to keep in mind however is that the method in particular isn’t that critical you can determine sharpness in many ways all you have to be able to do really is put some kind of number on either :

-the force used to make a cut

-the length of edge to make a cut under a given forceRealize further that the more you can concentrate the force at the apex itself the more you will measure sharpness directly. For example if you slice a piece of 1/2″ hemp with a very sharp knife with a high cutting profile you should be able to do it with 4-5 lbs. However only about ~0.25 lbs or less is actually the force due to the sharpness. Thus if you use the knife a little and the force increases by a pound then that shows a blunting which isn’t :

-4.5/5.5 or the knife is at ~80% of optimal .

It shows a blunting of :

-0.25/1.25 or the knife is at ~20% of optimal

Thus while you might want to cut large ropes to blunt the knife, if you want to measure sharpness you want to cut very thin ones as you will more accurately measure the sharpness.

-

AuthorPosts

- You must be logged in to reply to this topic.