Edge retention as a function of edge angle / steel

Recent › Forums › Main Forum › Knife Specific Discussion › Steel › Edge retention as a function of edge angle / steel

- This topic has 46 replies, 10 voices, and was last updated 02/07/2015 at 8:40 pm by

tcmeyer.

tcmeyer.

-

AuthorPosts

-

09/29/2014 at 8:03 pm #20509

I am not where where this should go, this seemed like the best fit.

This is a piece of work which intends to look at the edge retention as a function of micro-bevel angle, steel type and possibly grit finish in an exhaustive manner using the Wicked Edge to set the micro-bevels.

It will be part of the Mule-Library program I have started a test run which I will do on two Spyderco knives. The procedure is basically this :

-sharpen a knife on a Wicked Edge/1000 grit diamond with a specific angle micro-bevel

-cut 1/2″ hemp and periodically measure the sharpness

-determine the edge retention statistics

-repeat a few runs until stable

-then repeat this whole thing across a range of micro-bevel angles

-then repeat this whole thing again across a range of steels

-possibly repeat this whole thing across multiple grit finishesNote the work is blinded to prevent bias.

The results of this comparison when finished allow you to answer some very interesting questions such as :

-At what angle/grit do I need to sharpen 420J2 to have the same edge retention as as 21 dps – 1000 grit WE edge on S110V cutting half inch manilla hemp?

This question in fact many people don’t even realize has an answer at all. In fact the more dramatic question :

-At what angle/grit do I need to sharpen 420J2 to have twice the edge retention as as 21 dps – 1000 grit WE edge on S110V cutting half inch manilla hemp?

also likely has an answer as well because the influence of edge angle / grit on edge retention is very large.

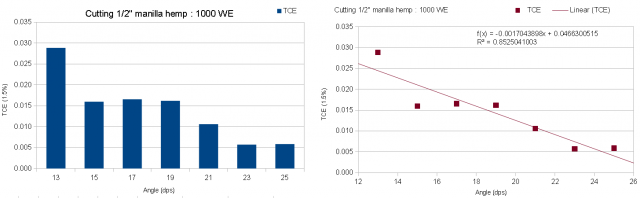

Here is one run only on a VG-10 blade from Spyderco (Lum Chinese) :

-primary grind full zero

-edge bevel is approx. 6.5 dps in the final sweep (slop from stone wear, not intentional)I would like to get 11 dps, but it is not possible easily with the WE, I am going to play with this a little. In fact very low angles would be interesting because at some point the strength would be compromised and the apex would fail by lack of strength. However hemp is so soft that this takes very low angles, less than 5 dps.

Now before anyone reaches any dramatic conclusions from the particular shapes or relationship between one angle and another, again this is one run only I can not even bound the performance with error bars at this point. However there are still some obvious observations :

-the edge retention appears to depend critically on the edge angle

-further it decreases significantly as the micro-bevel angle is increased

-this change is so large that angle could be as critical (or more) than the steelsA lot of this I have discussed before, however the point to this is to move from these general statements to doing the work in enough volume to allow answering some very specific questions about steels and angles and at what point one can compensate for another.

It will take 3-5 runs before the measurements will stabilize and I think it should be a smooth trend. That large difference between 13 and 15 dps is likely just amplified by random scatter. This is a lot of work, just to compare two steels will take about 100 runs of cutting hemp with just one grit and multiply that by any grit changes (so almost 500 runs if you wanted five grit finishes) so do not expect it completed any time soon.

As a final caveat, you can not generalize from this to edge retention in general. Hemp is so weak (compressible) that it can easily be cut with ultra-low angles in contrast hard wood cutting (plywood etc.) can easily turn edges at 10 dps on weaker steels. Thus if you ask the same question :

-At what angle do I need to sharpen 420J2 to have twice the edge retention as as 21 dps – 1000 grit WE edge on S110V cutting half inch plywood?

The answer might be that it is not possible as you can not reduce the angle on the 420J2 enough to compensate as it would be so low it would not have the strength to cut the plywood and would just deform.

09/29/2014 at 8:48 pm #20511Great! I was just asking about this.

So I am curious why you choose hemp rope? If it is soft and easier on a blade it will take longer. And not many people are into cutting hemp rope all day. If you made cuts in cardboard or something it seems like that could speed up the process and also give some added benefit of edge durability since the cardboard is harder. It may cause the edge to fail sooner and would be a way more real world helpful data point than hemp. Everyone I know cuts cardboard these days. Or at least cuts boxes open.

Thanks for doing this! Just a question to maybe help speed things up!

09/29/2014 at 8:59 pm #20512Those are valid points, the simple reason why I used 1/2″ hemp is because I just don’t have enough cardboard to do it. It would take about 250-500 m of cardboard to do one run. That means I would need to cut about 50 km for this comparison on just two knives with one grit. I do cardboard edge retention runs, and carpet and wood and other materials as I get them.

09/29/2014 at 9:03 pm #20514I have tons of cardboard all the time.. Wish you were close to me! I would get you a truck load!

Makes sense though Cliff. Thanks!

What information are you starting from? I have 0 idea of what angle to start with and what micro bevel angle to use on the various types of steel. Is there a chart somewhere? The Knife data base is a little thin. I hope to help add to that in the near future.

09/29/2014 at 9:10 pm #20515I have been doing this for awhile so I know what the curves will look like in general, but here I am aiming to get exact numbers for how the edge retention depends on angle, grit, steel and so on.

I picked VG-10 as it is very common steel, almost a benchmark for Spyderco. I am still considering what to use for the other one; 8Cr13MoV, S30V or something like S110V/10V . I have one of the new Spyderco’s / Farid’s and I might use that.

09/30/2014 at 6:04 am #20516awesome! Thanks for posting here Cliff… i’ve been away from the forums over vacation, but I did see your thread on your forum. I will be following there as well.

10/03/2014 at 10:37 pm #2060710/03/2014 at 10:57 pm #20608Cliff, will you explain your process and what we’re seeing on the graph? I think covering the basics would be really helpful e.g. started with angle x, made n number of cuts, required how much force etc…

-Clay

10/03/2014 at 11:04 pm #20609Clay :

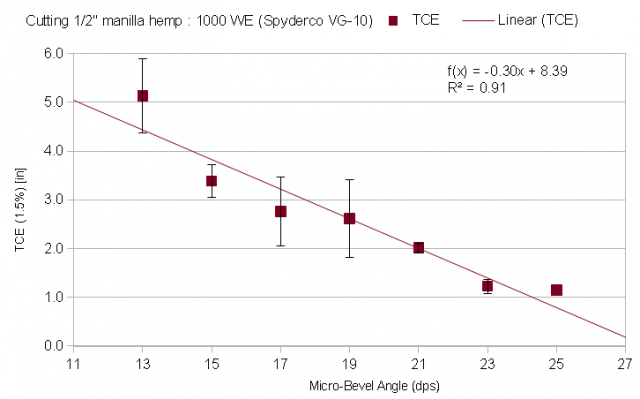

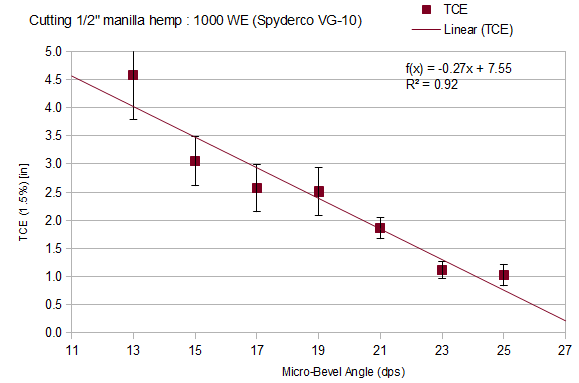

-Paramilitary in S30V from Spyderco, zero ground

-final edge angle of 6.5 dps

-micro-bevels set at angles from 13 to 25 dps with the WE/1000 diamondThe procedure :

-set a micro-bevel angle

-cut 1/2″ hemp (unsupported) on a 2″ draw

-measure the sharpness periodically

-calculate edge retention statisticsThis is then repeated multiple times with each micro-bevel angle (the blade is zero ground between each round)to produce an average result.

The sharpness is measured by the amount of length to cut Bergia spinning thread on a 35 gram load, and confirmed on jute with a 500 gram load.

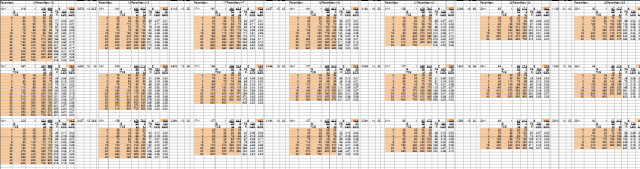

The edge retention statistic is the TCE which is just the sum of :

-amount of material cut (in inches) * sharpness (as a percent)

added in every interval. This basically is a piecewise integral.

Now you might ask, why not just cut until Y amount of sharpness and stop? The reason is that statistic will have a lot more scatter. The TCE is more stable as it uses the performance of the blade throughout the entire cutting.

10/03/2014 at 11:11 pm #20610For further details :

-sharpness is inspected under 50X linear magnification

-also confirmed with basic checks (shaving, paper)

-the work is always partially blinded

-the cutting is always done though random samplingThis means for example I bought a full spool of 1/2″ hemp, I then take from that ten runs of 10 feet and I cut from those by generating random numbers from 1-10 and then making cuts based on that. The reason for this is that it essentially averages the properties of the hemp through the entire roll and prevents a bias from the hemp being different from one run to the next.

By partial blinding I mean that the person doing the sharpening or doing the cutting and doing the measuring are not always the same person. This prevents what you expect to happen from controlling the results. This is really critical as it stops even a subconscious bias from being an issue because you don’t “know” what should happen until everything is revealed and that is only done after all measurements are completed.

In even more detail, I also (always) use some measure of robust statistical analysis. In this case I use weighed averaging, in some other cases (where I collect more data) I use median based statistics. I am a severe numbers gear and an actual experimentalist (physics) by trade so I can drown anyone in details if they want.

10/03/2014 at 11:20 pm #20612Thank you. How are you performing the sharpness testing? Do you have a jig set to draw cut with specific weights placed on it or are you using the sharpness testing jig that you posted plans for?

-Clay

10/04/2014 at 12:41 pm #20618I’d I also like to know that, Cliff. I think I sort-of understand what you are doing. But I’d really appreciate it if you could elaborate a little more on your method. What is shown on the Y-axis? And what exactly is a run in relation to what the graphics show?

Molecule Polishing: my blog about sharpening with the Wicked Edge

10/05/2014 at 2:24 am #20627What is shown on the Y-axis?

TCE which is an edge retention statistic, it is calculated by taking a sum of :

(sharpness) * (amount of material cut)

For example, if you cut 10 pieces of 1/2″ thick rope at 50% optimal sharpness (0.5 as a decimal) then that gives you :

(0.5) * (10 cuts * 1/2 in) = 0.25 in

if you cut another 10 pieces but the sharpness has decreased to 40% then you have :

(0.4) * (10 * 1/2″) = 0.20 in

and you continue until some stopping point, measuring the sharpness and calculating the product and then at the end you add up all the bits to get the TCE.

I use 1.5% as the stopping point in the above which is very dull, the knife has little fine cutting ability and the edge is even starting to reflect light and be visible.

And what exactly is a run in relation to what the graphics show?

It shows the edge retention as a function of micro-bevel angle with a fixed edge angle (6.5 dps) and a fixed grit (1000 diamond/WE). The edge retention decreases as the angle increases.

10/05/2014 at 2:35 am #20628… are you using the sharpness testing jig that you posted plans for?

I think you are referring to Dan’s jig which is a push cutting device.

The simplest way to do it is hang a weight from piece of cord, have a clamp which can catch the other end and then you can put the knife under it, lift the knife and then draw it.

It can be all machine recorded as well. At one point I actually did it with a stand/clamp to hold the knife at a specific height, 1mm above the cord attachment, and had it move on a fixed track and measured the tension in the cord electronically. The problem was that the extra precision wasn’t of benefit as I found there is too much scatter in the results due to random and systematic error.

Consider for example when you are cutting the material you are using to dull the knife, even if you do it very controlled, then all the things that can change :

-the material itself isn’t going to be overly consistent (unless you get ISO rated material)

-speed, force, angle of the cut

-temperature, humidity of the environment

-dirt, dust, debris

-initial sharpness, angle, gritThe you have things like the actual steel itself which is a big mish mash of micro-structures :

-tempered and untempered martensite

-pearlite

-cementite

-alloy carbides

-retained austeniteand the edge is just a random selection of all of that, hence it blunts in a very random manner. Parts of it will wear smooth (well tempered martensite + cementite), parts of it are very weak and roll/deform (austenite, pearlite) and parts of it just chip/fracture (around or through the alloy carbides).

In general, as controlled as I can be, from one run to the next, the most confident I am is about 50% in any run hence I always do at least 3-5 to make sure I have reasonable scatter estimates. Now once you stop doing the controlled comparisons and just do real work, the variability goes through the roof and the performance can change by a factor of ten easily. Hence outside of the “lab” you really want to average over a long time before judging a knife as good, bad or ugly as a knife can easily “fail” simply because it hit a rough patch of material or you were not the best technique wise so you need to find a consistent patter.

Here is a full three runs, the scatter is starting to calm down now and the trend is fairly clear :

This is all the jazz behind it which generates that little graph :

10/08/2014 at 2:07 pm #20684Thanks a lot for your extensive explanation, Cliff. And for the interesting experiment of course. I am really curious about the results of the next ones.

And what exactly is a run in relation to what the graphics show?

It shows the edge retention as a function of micro-bevel angle with a fixed edge angle (6.5 dps) and a fixed grit (1000 diamond/WE). The edge retention decreases as the angle increases.[/quote]

What I meant is simply: does this graphic show the results of one run? Because you emphasized “one run” in your first post. (And, if so, did you plan to do multiple runs of every knife in order to minimize statistical errors, or did you mean something else?)

Molecule Polishing: my blog about sharpening with the Wicked Edge

-

AuthorPosts

- You must be logged in to reply to this topic.