Chef’s knife w/ convex factory grind (Mac Mighty)

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Tips for Specific Knife Grinds and Styles › Chef’s knife w/ convex factory grind (Mac Mighty)

- This topic has 31 replies, 6 voices, and was last updated 01/20/2018 at 8:48 pm by

sksharp.

-

AuthorPosts

-

12/31/2017 at 1:54 pm #44294

I have a Mac Mighty 8” chef’s knife that came with a convex factory grind, but the bevel is teeny—barely visible to the naked eye. From what I’ve found online, the factory edge is 15 degrees (although I’m not quite sure how you translate a convex grind into dps since it’s rounded). I’ve seen different claims online about the steel, either AUS8 or VG10.

Do you think starting around 600 grit will be enough, or will I need to start coarser than that? Given how small the bevel is, it doesn’t seem like there will be extensive metal removal required even considering it starts out convex. I’m considering using Trizact instead of diamond, and my coarsest Trizact is A35 which is supposed to be very slightly coarser than P600, so call it P550.

This is the knife (although mine is several years old, it looks the same visually): https://www.amazon.com/Mac-Knife-Professional-Hollow-8-Inch/dp/B000N5H2XU

1 user thanked author for this post.

12/31/2017 at 5:31 pm #44297Convex edges are usually applied by a slack belt, and maintained with leather. If you want to use leather on the WE, that will work but will be a lot of strokes. Strop progression.

Or put stones to it and profile it with a flat edge.

3 users thanked author for this post.

12/31/2017 at 6:23 pm #44301Graphite to maintain the narrow bevel takes light touch with minimal metal removal. I suggest you use your finest diamond stone, 1500 if you have one and your sharpie to match the bevel angle. Then I would step down grit by grit, (1500>1000>800>600) till you find the grit level that is touching the edge with the least amount of metal loss. Your better off taking more time and taking less metal if you want to maintain the fine narrow bevel. The steel may be a MAC proprietary alloy. Also it may be and uneven grind bevel.

It would be helpful if you’d use that Dino-Lite USB Microscope to photograph your edge. We’d love to see just what your dealing with. It may help you to get better help from us to share that visual info with us. After all you have that super microscope we’re anxious to see in action!

Marc

(MarcH's Rack-Its)12/31/2017 at 6:49 pm #44303You can always sharpen it as a convex again if that’s how you like it. Check out the knowledge base article.

1 user thanked author for this post.

01/01/2018 at 12:35 pm #44314I have never sharpened this blade, but I do run it across a fine ceramic rod now and then. As you will see in the photos, there are a number of tiny chips in the edge (mostly less than a thousandth of an inch deep) visible under magnification, but in spite of that, this blade still swipe-cuts paper easily with no snagging. I’ve had the knife about 5 years I think, so all things considered, it has held up well with just using the ceramic rod to maintain it.

My microscope has 3 choices of image size to save to (640×512, 1280×1024, 2560×2048). I saved these all at 1280×1024 (the native sensor size), but the forum software might reduce that.

I used different end caps (clear, translucent, white, black etc), different magnification, and different exposure settings just to see what differences they can make in the photos.

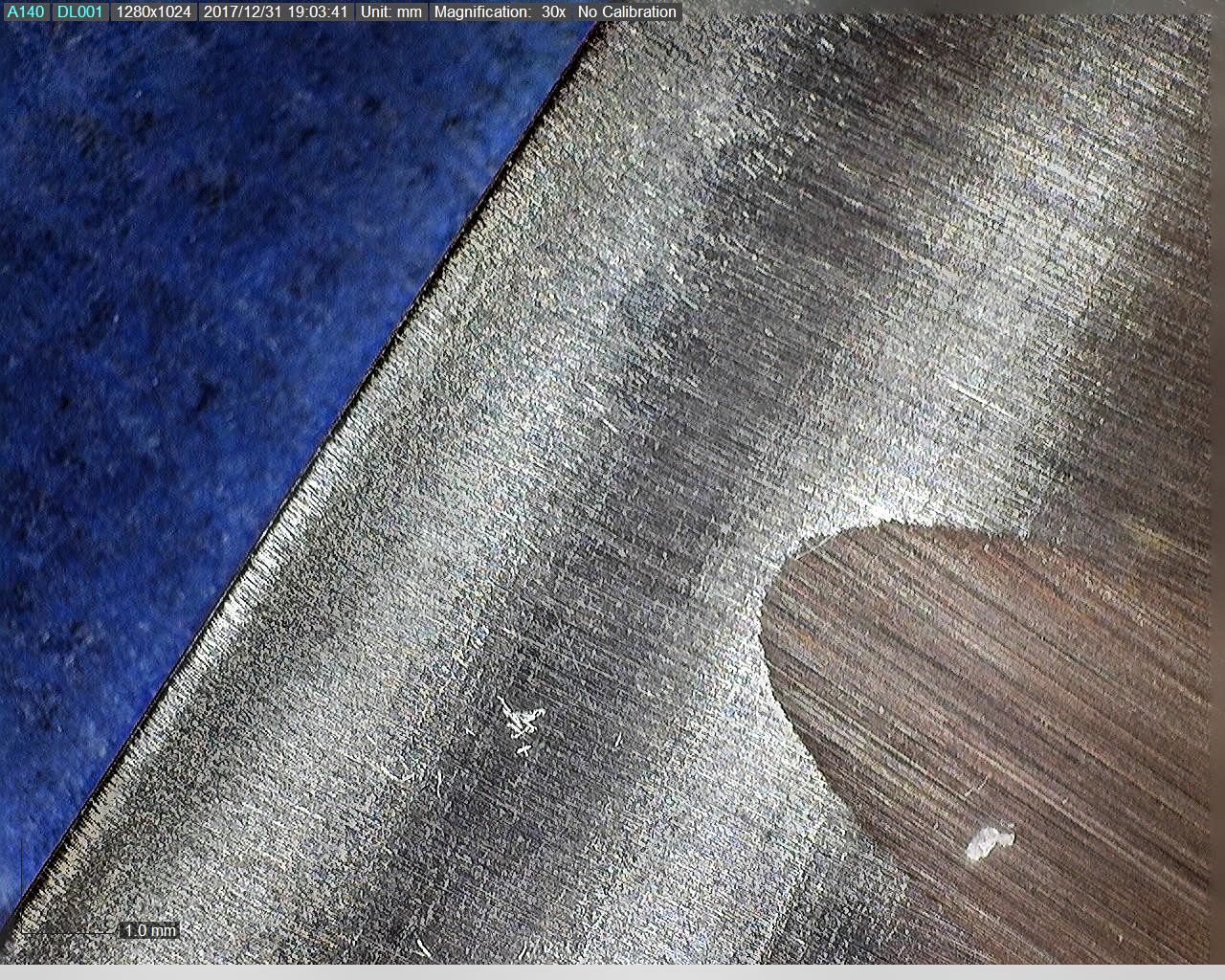

The first two photos are 30x magnification but using different end caps.

Compare those to this one at 40x and using the EDR (extended dymanic range), and the convex grind is more visible in this one. The bevel here is about .05 mm (about 2 thousandths of an inch).

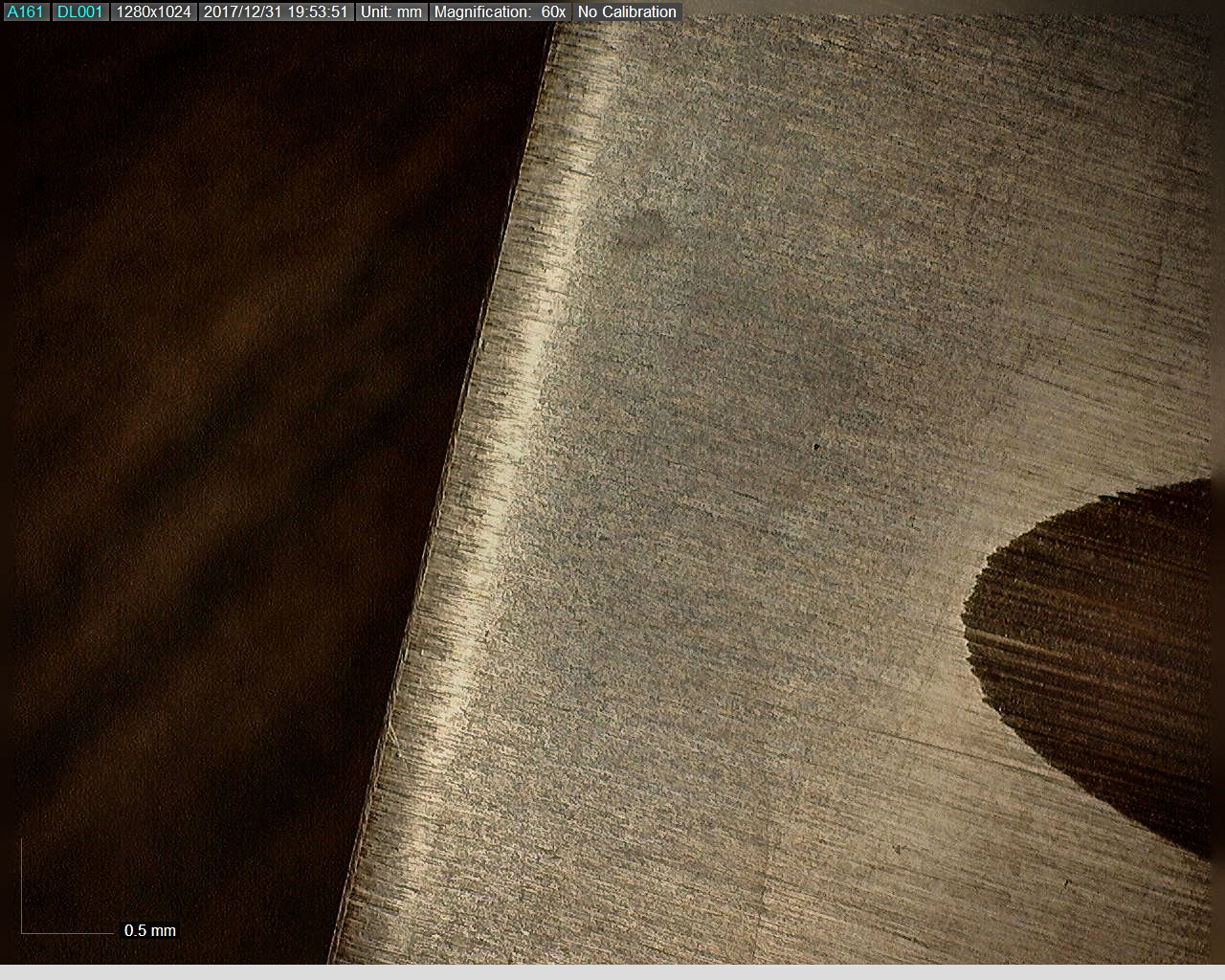

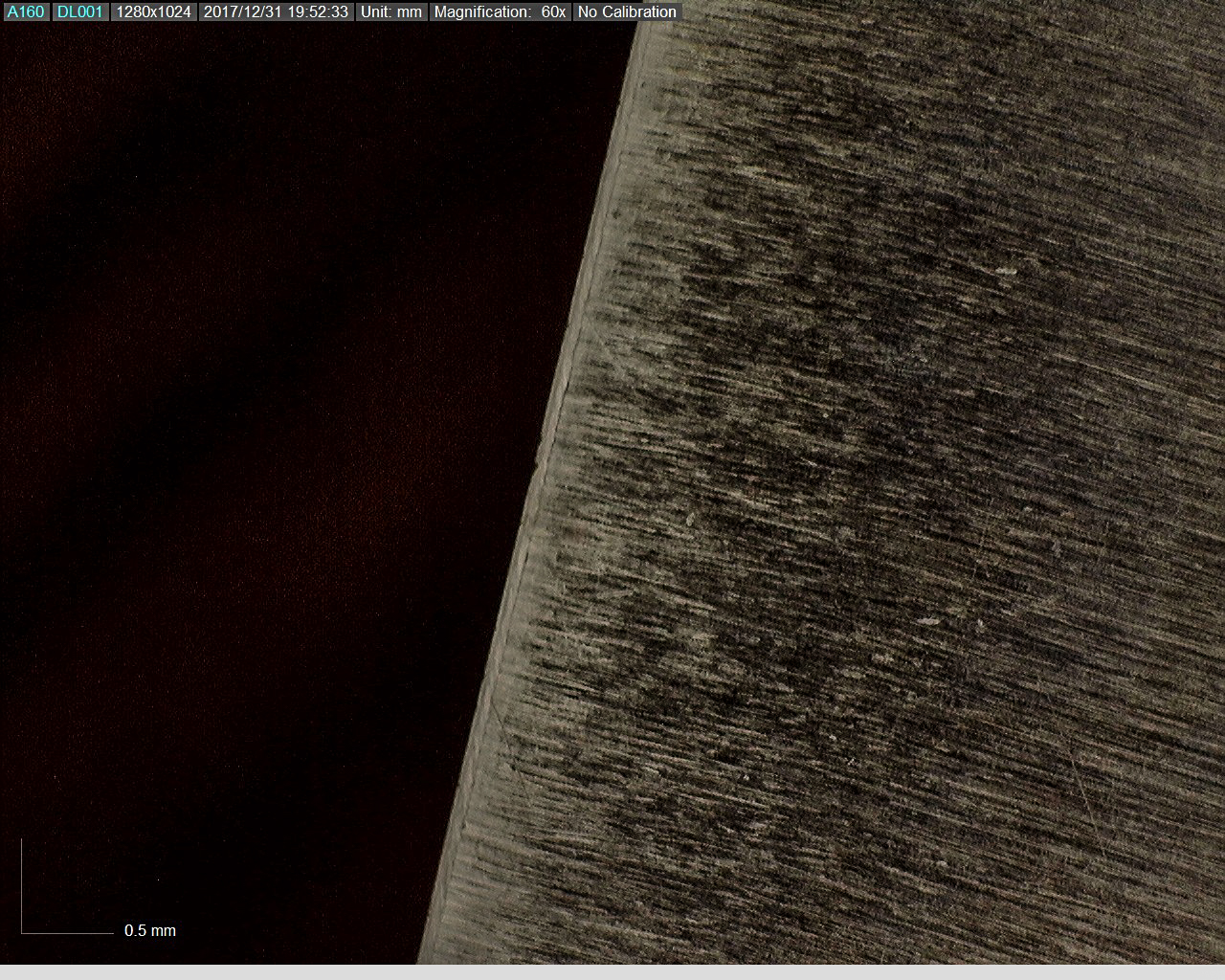

This next one is at 60x and a different end cap. Either I slightly moved the knife or I missed the focus slightly since they edge focus isn’t super crisp.

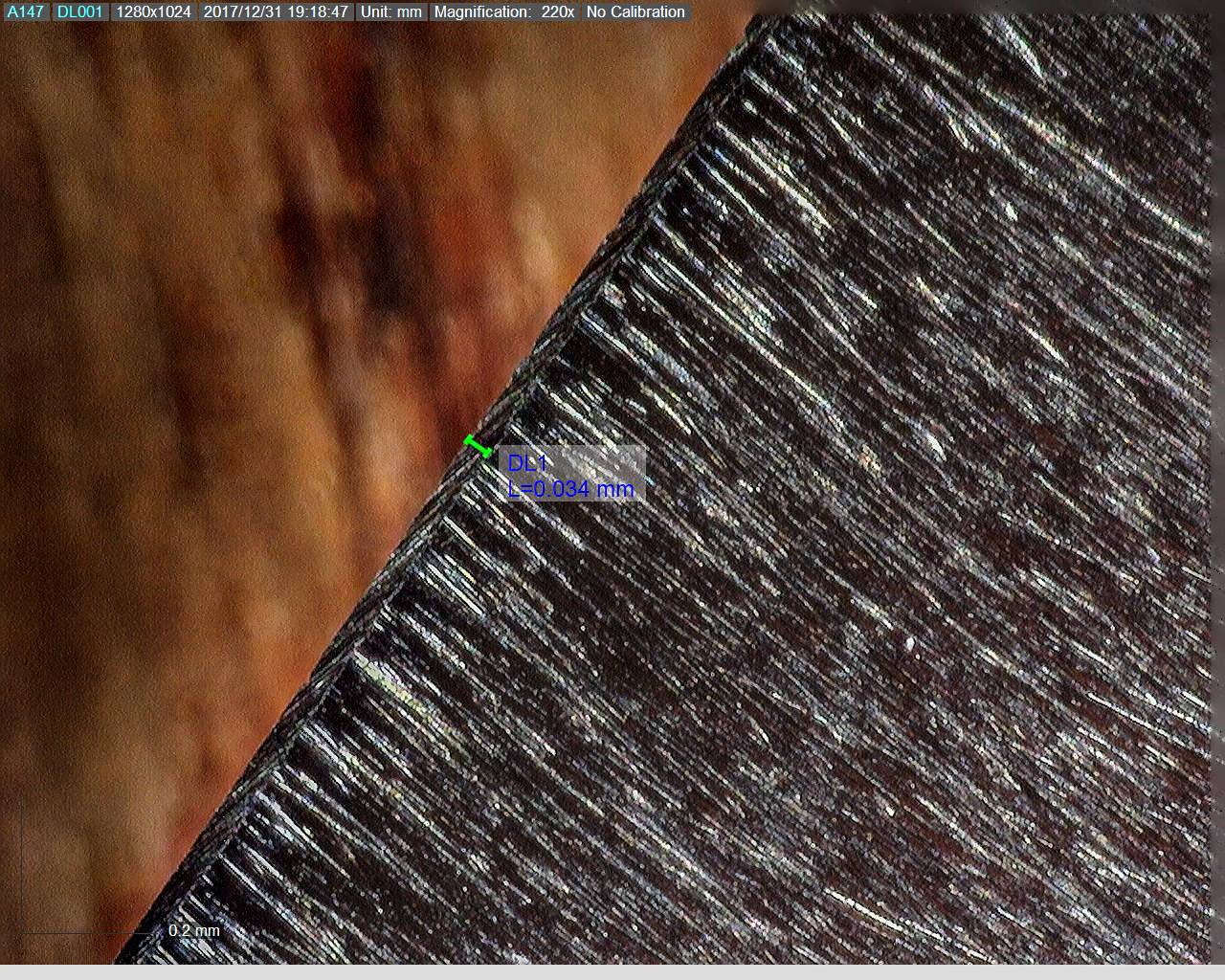

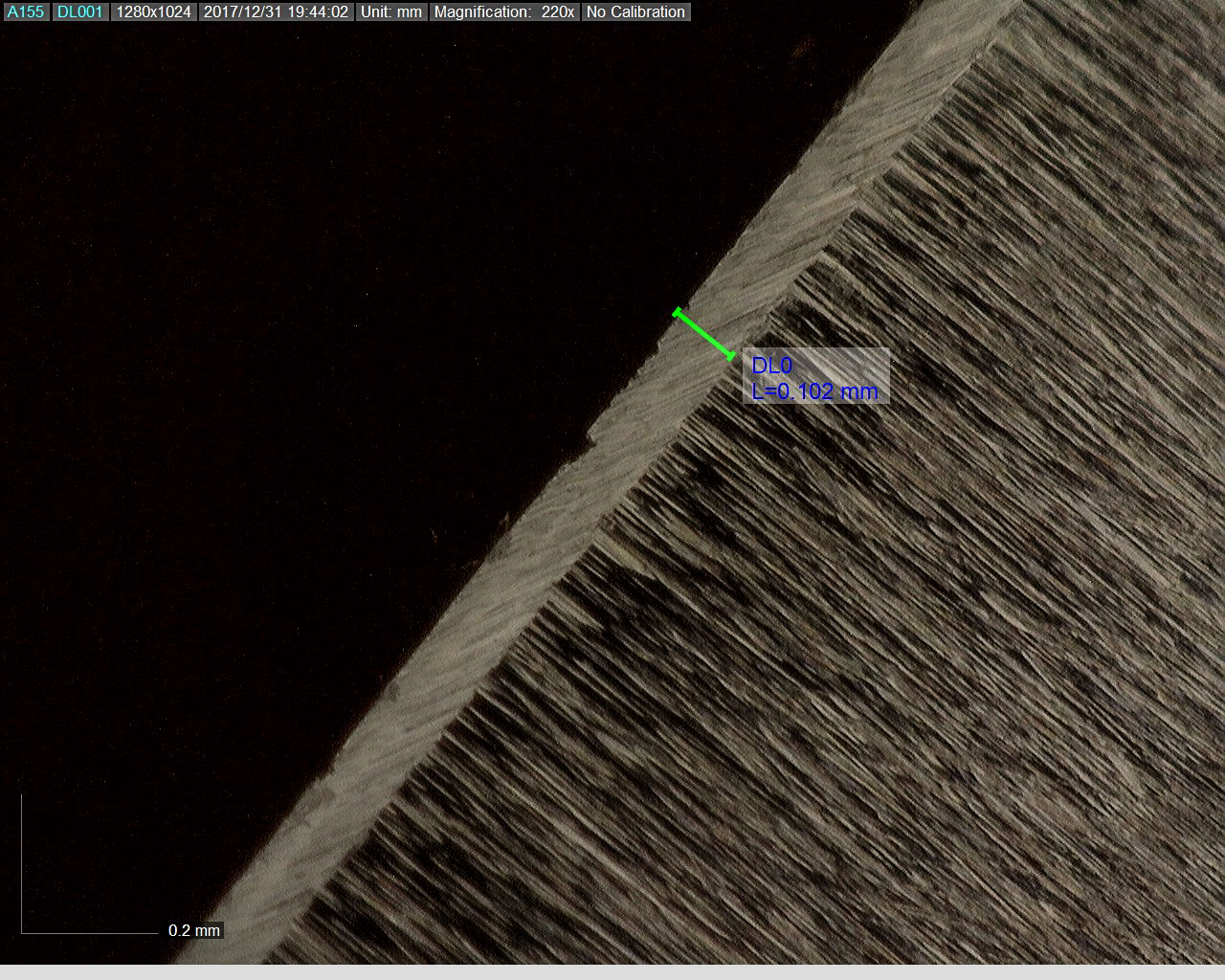

The next one is at 220x using the black cap. Here the bevel is about .03mm. The bevel on this knife varies quite a bit over the length (.102mm is the largest, in a later photo). That might be partly due to my use of the ceramic rod manually.

Here the bevel is .012mm with a couple chips visible and using either the translucent or the white end cap (I forget).

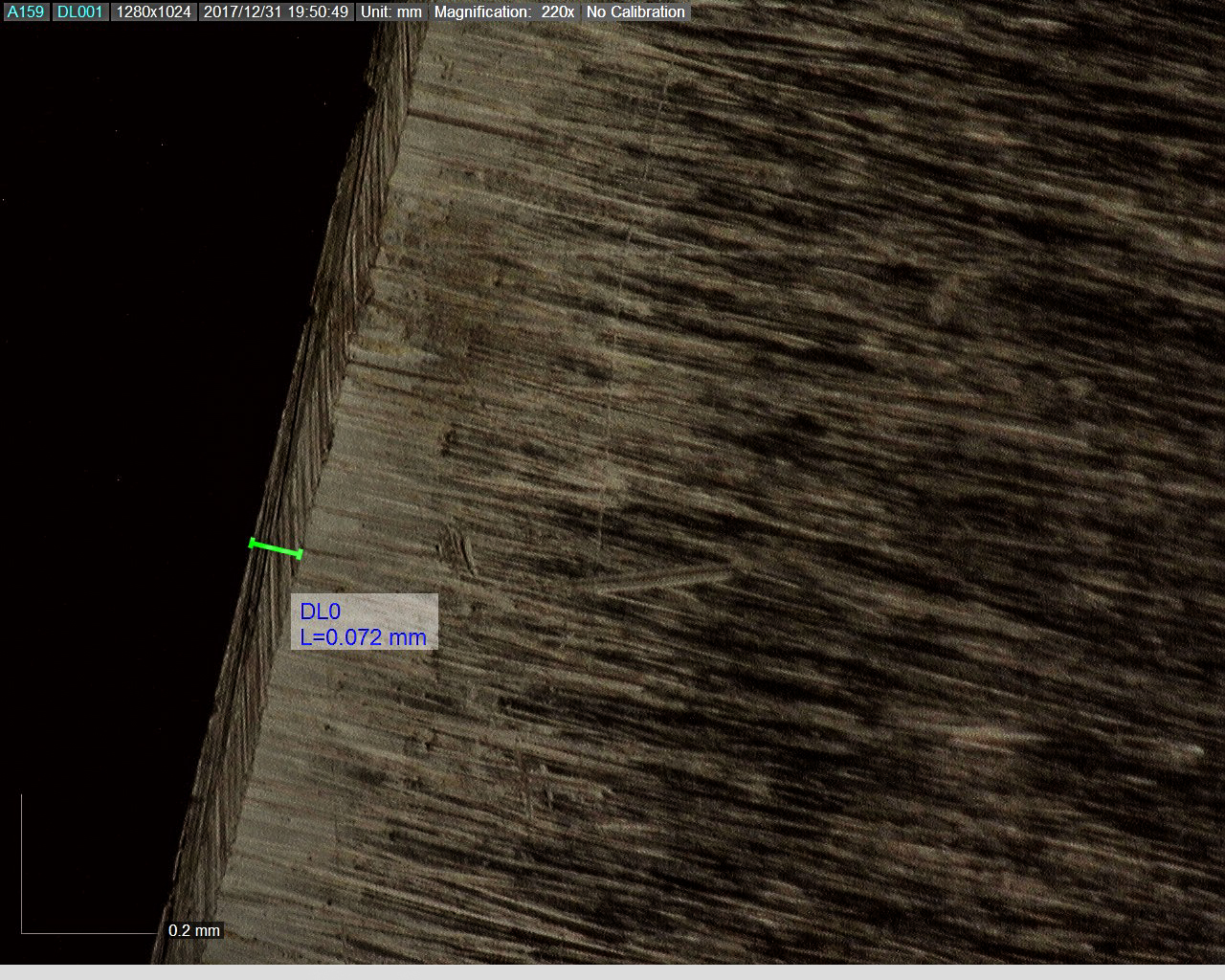

This next one is also 220x but here the bevel is .07mm, and you can see a couple different levels of bevel, with the one closest to the edge having scratch marks that run along the blade (the ceramic rod I presume).

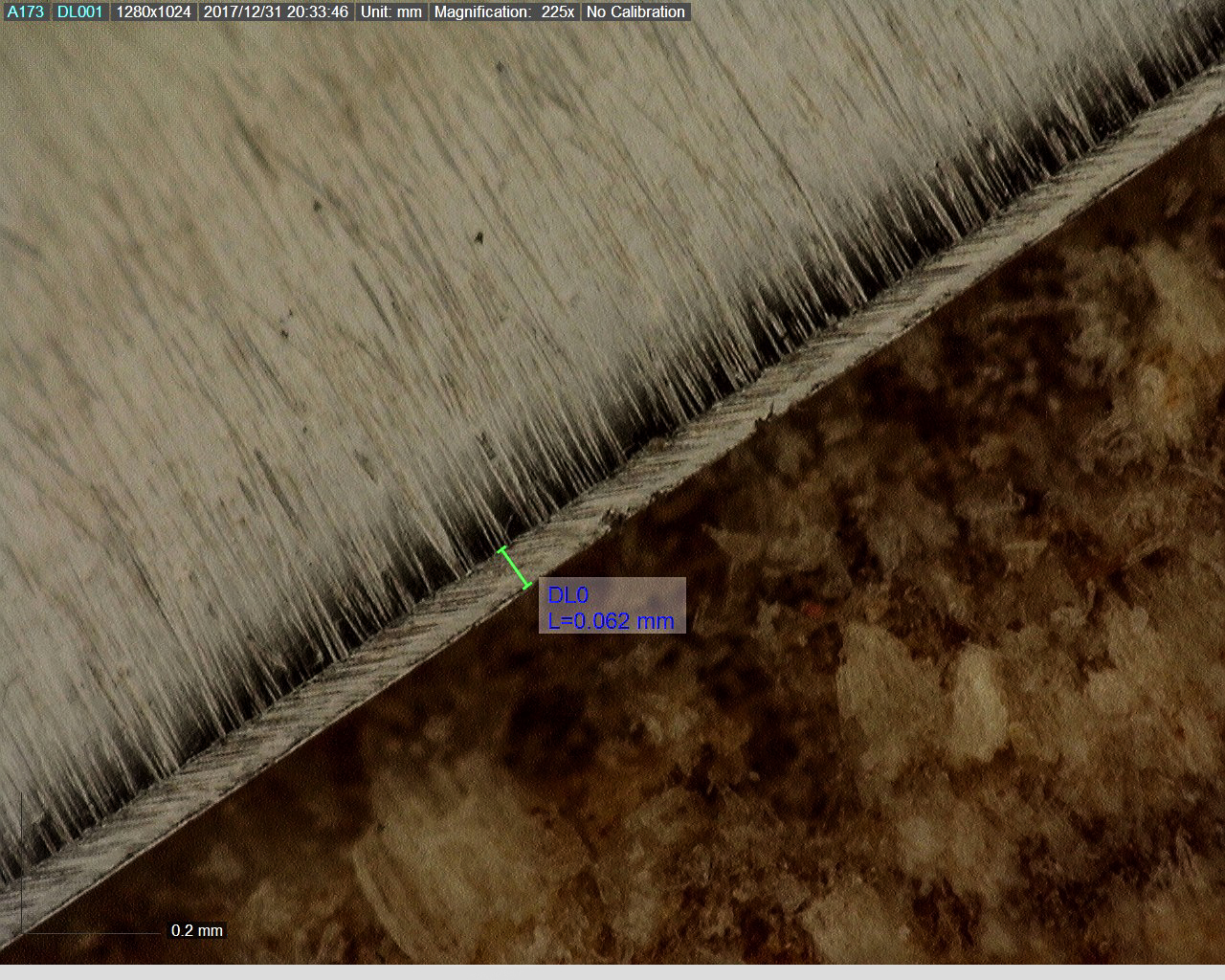

This one is 225x (no particular reason I used 225 instead of 220) and a different end cap, with a .06mm bevel (about 2 thousandths of an inch).

Any advice for going about sharpening it appreciated. I think I’ll use Trizact instead of diamonds, unless you guys think I need to start coarser than that. I have Trizact A35 green (approx. equivalent to P550), A20 red (approx. P1000), A10 blue (approx. P1500) and A5 (slightly finer than P2500). Here’s a photo of the Trizact PSA abrasive on the WE aluminum blanks:

2 users thanked author for this post.

01/01/2018 at 1:05 pm #44317Graphite how are you cutting the Trizact to the strips for the aluminum blanks. Are you using a paper cutter or does it come in rolls that narrow? Also why are you thinking the Trizact is more appropriate for this knife then going the normal route and using WE diamond stones. Certainly it’s more work and expense, (being consumable), to use the sandpaper than the diamond stones. Also with sandpaper you have to be more selective in the stroke direction and pressure. Also I think the consistency of the scratch pattern will fall off as the Trizact paper wears much more quickly and the difference will appear more noticeably as compared to the consistent scratch pattern of a broken in diamond paddle.

Marc

(MarcH's Rack-Its)01/01/2018 at 1:22 pm #44318Looks to me like that edge was ground (sharpened with a belt sander) and then micro beveled. I would do exactly as MarcH suggested, mark the micro bevel, verify the angle and use a 1000 or 1500 stone and if it’s taking to long back up a grit until you get it where you want it then strop.

1 user thanked author for this post.

01/01/2018 at 2:13 pm #44323I don’t think this is a convex edge. The knife was ground down on a slack belt by the looks of it, then a standard edge was applied.

When you see a true convex edge, it is curved right to the apex.

I wouldn’t treat this knife any different than any other standard knife. As I’ve mentioned to expect before, the bevel varies greatly, doesn’t matter if that is your ceramic rod (though I would bet it’s not, as I can’t use a knife for a couple weeks with out causing way more wear than this knife has and you can see some scratch marks running tip to heel-ish rather than spine to edge) so if you want to put a proper profile on it, go ahead. a WE is excellent for just that.

If you want to use sandpaper rather than stones, is that because you are worried your stones are not broken in? I see no reason to use sand paper personally. In fact, if you do plan to re-profile (I would that edge is terrible) the sand paper will be way less consistent that the diamond stones.

I think you are making this knife way more complicated that it should be. I think quite honestly you will finish this up quickly, that is a very easy edge to deal with. Figure out how you want it to look, and get it spotted up right. Check the edge angle a couple times to make sure it’s going to be profiled how you want it to be, get a good record of the spot. You can move it slightly to get the tip in the easiest spot to recreate later, mark it down using the advanced alignment guide and get to it. That part will take longer than sharpening it because of how much attention to detail you will give it. I could have sharpened that knife start to finish in less time that it took me to write this post. It’s that easy.

Careful to not miss the forest for the trees.

3 users thanked author for this post.

01/01/2018 at 4:40 pm #44333Justin, I’m not sure what you’re reference to complexity is about. I asked a question about whether 600 grit would be coarse enough to start sharpening a knife with an edge I’ve not encountered before, which is the purpose of this forum. If you’re referring to all the microscope photos as implying I’m adding complexity, I posted those only because Marc and you asked for them, and I spent a fair amount of my time trying to get photos to show you the varying results using different end caps and settings. The photos did turn out to have value in getting guidance, but I certainly didn’t need to take that many.

01/01/2018 at 4:49 pm #44334The pics are great actually. I think you did a great job there. They give a ton of insight into what is going on at the apex and I’m really happy you shared them. I do believe you are correct when you say they were of value in getting guidance.

The complexity I mean is adding the sandpaper and blanks, all that. It’s extra cost, extra time and energy and I’m not sure I see any benefit. Would you mind sharing the reason you went that way?

I’m encouraging you to tackle this one, and don’t see any reason diamond stones wouldn’t serve you well here.

Edit: When you get into rare abrasives, things most people don’t use etc you add more and more potential points of failure or complication. When you do that, you make it harder and harder to predict the outcome of your effort, and the experience of the people around you is less and less valuable. You add more factors to consider why things went wrong if they do, and less meaningful input from people if you need it.

I would strongly suggest getting going with as standard of a setup as you can till you nail down your technique and get good results. As you add in complexity, you will be adding in a bunch of experience behind it.

Certainly some cases will call for it, but I do not think this knife is one of them.

1 user thanked author for this post.

01/01/2018 at 5:20 pm #44341Graphite you gave me the exact same impression, That’s why I questioned why you were going that route in my post above:

Also why are you thinking the Trizact is more appropriate for this knife then going the normal route and using WE diamond stones. Certainly it’s more work and expense, (being consumable), to use the sandpaper than the diamond stones. Also with sandpaper you have to be more selective in the stroke direction and pressure. Also I think the consistency of the scratch pattern will fall off as the Trizact paper wears much more quickly and the difference will appear more noticeably as compared to the consistent scratch pattern of a broken in diamond paddle.

I was questioning you because your route of attack is certainly more complicated then is required. I also gave reasons why I didn’t think it was necessary. Justin and I read it exactly the same. Your plan of attack was certainly making it more complex then it is! For me the WEPS is a very simple tool. Easy to use and gives great results exactly as it comes. I haven’t needed to go outside-the-box of WEPS stones and accessories to achieve a super sharp shinny edge on all of the most hard and difficult metals to sharpen. Let it work for you and keep it simple, (KISS).

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

01/01/2018 at 7:15 pm #44346Graphite, I have some questions on your excellent photos. Were these posted knife edge pictures just as taken by the Dino-lite? Or are they stacked photos enhanced with the software to give that focused depth of field? Is 220X or 225X the high/highest power for this microscope? Were the photos taken with the microscope plastic shroud in direct contact with the knife’s steel, while being hand held or are they taken while backed off at some distance using the microscope stand to hold and steady the scope?

Marc

(MarcH's Rack-Its)01/01/2018 at 8:21 pm #44351Justin and Marc, thanks for explaining your perspective. Trizact isn’t new to me (I’ve used it more than I’ve used diamonds, but never by hand). I used Trizact for years on powered sharpeners for woodworking tools back when I was doing that a lot. There are 4 different lines of Trizact and this particular line is designed specifically for tool blade finishing, cutlery, etc. It’s not a foreign abrasive for this application (I’ve seen several youtube videos where knifemakers use Trizact, albeit in a powered system).

The finish, longevity, consistency, and price are all great in my past experience. So I think you probably have some mistaken impressions in equating it to sandpaper. The only reason I can think of that it might not work here would be if it doesn’t work for hand sharpening (i.e. maybe it cuts too slow compared to powered applications, and that’s just a time issue, not a complexity issue).

I only have diamond stones 100-1000, and not planning to buy more. I bought the aluminum blanks specifically for using Trizact in cases where I want a finer finish. But I’m not interested in mirror edges on my knives, so I’ll take what these give me.

Each of these Trizact strips cost under a buck, even considering tax, shipping, and waste when cut to size. I doubt I’ll spend more on Trizact in my lifetime than one set of fine-grit diamonds cost (let alone dozens of them), so it is actually significantly cheaper than an elaborate collection of fine diamond stuff.

I don’t have the giant collection of WE stones you guys have, so my situation is different from yours. It seems that maybe you are assessing whether it would be complicated for you, given all you already have, but I wasn’t trying to ‘sell’ it. For me, it’s all I have for finer grits. I truly didn’t expect it to be controversial.

Having said all that, I’ll just stick to the diamond stones thru 1000 on this particular knife for now, in case I run into any issue and have further questions. Then if all goes well I’ll try the Trizact on it next time (the angle settings I log will probably be different so I’ll need thickness compensation). I’ll use the Trizact initially for knives where I don’t have any questions, or that are expendable. But since I already have it, have used it before, and have already cut strips (paper cutter) and have the aluminum blanks there’s no extra cost or other complication for me.

3 users thanked author for this post.

01/01/2018 at 8:39 pm #44352Marc, this particular set of photos is single images only (no stacked) since they were mostly straight-on, and 220x is the maximum claimed magnification but tic marks go to 230x and it seems to work there.

Depending on which end cap (it came with 7 different ones), some were in contact, and some were with the endcap spaced above the knife, held by a clamp. I had to do some tilting and propping of the handle and edge of the knife to get a good angle for a few of them, so in those cases I had to hold still while I snapped the photo or it would have blurred. At 220x the focus is at .46″ from the main rim of the scope with no cap, and the smaller end caps are about .35″ thick so it ends up just a hair above the surface. Oddly, all the end caps they included are too long to focus in the 70x-180x range so in that range you have to go without the cap, or cut one down. On the polarization control, I find that for knives I can just leave it on full +, without having to mess with the setting, but it’s pretty challenging to avoid oversaturated areas due to metal reflections without it so I’m glad it has it.

1 user thanked author for this post.

01/01/2018 at 9:54 pm #44357Thanks for the insight on the photos.

I’ll just stick to the diamond stones thru 1000 on this particular knife for now, in case I run into any issue and have further questions. Then if all goes well I’ll try the Trizact on it next time (the angle settings I log will probably be different so I’ll need thickness compensation)

I don’t follow your statement about the logged angle may be different? The angle is an angle. It doesn’t matter how thick the stone or medium is if the measured angle while the stone is leaning against the knife at a similar position as originally recorded is the same angle, that you logged. The thickness compensator is used to allow the change of different thickness stones or medium with out the need to measure the angle with a digital angle device between stone changes…. Or did I misunderstand what you were saying?

Marc

(MarcH's Rack-Its) -

AuthorPosts

- You must be logged in to reply to this topic.