Need Help with Basics of Using Lapping Film

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Advanced Techniques and Sharpening Strategies › Need Help with Basics of Using Lapping Film

- This topic has 114 replies, 12 voices, and was last updated 08/27/2017 at 11:32 am by

sksharp.

-

AuthorPosts

-

08/12/2017 at 7:09 am #40572

I finally had the time to use the new Gen 3 and all the DLF. I used 6, 3, 1.5, 1.0, 0.5 and 0.1 micron films.

I’m here to report that the 0.5um DLF specifically has issues and it creates deeper scratches than the 1.0um film. Happens to 2 new strips, consistently, on two knives.

I’ve also redid the progression and it’s very consistent down to 1.0um, but once I hit 0.5um it gives me a lot of stray scratches that are not supposed to be 0.5um. The 0.1um DLF does not show such behavior.

At this point I think I will be skipping the 0.5um until I get the chance to experiment again.

08/12/2017 at 8:25 am #40573Go back to page one of this thread and about 3/4 of the way down, MarcH had a similar problem with 0.5 micron film. Assuming that this film was purchased from WE, maybe Clay could confirm whether or not there’s a problem with the same film. I have film purchased from another source, but I won’t have an opportunity to test it until the weekend’s over. 50th anniversary party today. Whoopie!

1 user thanked author for this post.

08/12/2017 at 9:08 am #40575Quite a mile stone Tom! All my best to you and Mrs Meyer.

08/12/2017 at 9:11 am #40576Snecx, I shared the same experience, exactly. I too am still working on it further. I’ll post my observations when I’m ready.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

08/12/2017 at 11:26 am #40578Congrats, Tom

. Snecx, Clay is working on a new grit comparison chart based on the scratches caused by the different abrasives. Hopefully he will also include the lapping films. Do I understand it correctly you now go from the 1 micron to the 0.1 micron films? Does that work a bit?

Molecule Polishing: my blog about sharpening with the Wicked Edge

08/14/2017 at 12:02 pm #4061508/15/2017 at 6:28 pm #40623Decision Time: I’m continuing my quest with Diamond Lapping Films for a Perfect Polished Bevel. I don’t think I am capable of doing it. It may not be capable of being done. I sharpened a 6″ Japanese Hattori Petty Kitchen knife through 8000 grit with Shapton’s Glass Stones. At that point if I finished it off with a progression of stropping paddles it would probably have been as sharp a knife as any, I ever have sharpened.

Because, I want to see how shiny and sharp I can get using DLFs I continued from there with a progression of films. This time I’m using Jende Industries Film. This brand film is thicker and stiffer than WE brand films. They are the same size and apply and fit just the same as the WE brand DLF. They’re also competitively priced. I started with 16 micron film then followed the progression: 16, 9, 6, then 3 micron. At this point I did used the WE 1.5 micron film, just because the grit fit in the progression, then continued again, with Jende 1.0 micron film.

Now the quandary. The edge is quite thin and very sharp. It is extremely clear and shiny but not totally scratch-less. When visually scanning down the bevel with the USB microscope at 250X, I probably see 10-15 relatively, vertical scratches on either size. I have tried to continue to remove them and others appear as some disappear. Wiping the edge sometimes add scratches. The bevel is quite easily scratched. It’s a balancing act.

Here’s the shiny bevel with an underlying scratch:

Here’s the same scratch under the shine:

With my last few tries at this point I continued in the DLF progression with 0.5 micron then 0.1 micron. I discovered what I suspected were new scratches from the diamond film. The dilemma is do I try to progress again and scratch my progress or switch to my strop progression and refine and continue to polish the edge with stropping. I know from prior experience the strop series will remove some of the fine scratches and smooth the micro-uneven edge and bring up the shine. I know at this point the knife is extremely sharp. It will get even sharper with the strops.

I am curious to see what happens as I continue the DLF progression. After-all that’s the purpose of this exercise so I will keep going. This time I’ll be using Jende 0.5 micron then end with WE 0.1 micron DLF. I’ll photo document the results for a latter post. Either way, what ever the results, after stropping it’ll be incredibly sharp. There may be tiny scratches under the shine, but it’ll be incredibly sharp.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

08/15/2017 at 6:39 pm #40626I’m looking forward to reading about your findings Marc.

08/15/2017 at 7:33 pm #40628Yeah, I’m particularly interested in your 0.5 micron diamond films from Jende and how they compare to the WE films.

Molecule Polishing: my blog about sharpening with the Wicked Edge

08/16/2017 at 2:46 pm #40643Lately I’ve been using a technique suggest by Cliff Curry, which is to make parallel strokes with the lapping films. I rest the paddle on the rod end and just slide the films back and forth along the blade. This is terrible for the actual edge, so it only works if you’ll be adding a micro-bevel later. It works impressively well for getting to a near perfectly polished bevel. From there, I switch to kangaroo strops with fine compound and spend a lot of time polishing.

Here are some of my best efforts, that do not involve lapping films or the technique listed above. These were sharpened w/ diamond stones, then ceramic stones, then lots of leather strops:

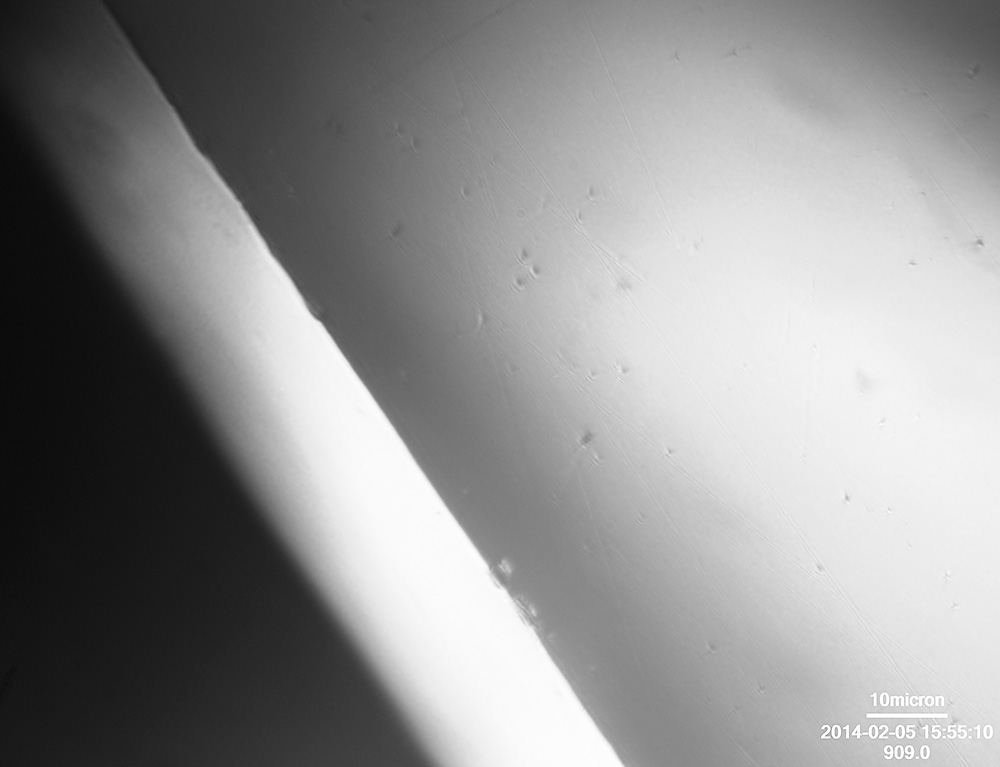

This is also 2000x and shows the edge reflected in the immersion oil. The edge is the line that runs diagonally from left to right.

This is at 800x and with a final step of 1/8µ CBN on kangaroo.-Clay

Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

08/17/2017 at 12:20 pm #40699I continued with my Diamond Lapping Film personal project. Just to reiterate, I am using a progression of finer grit DLF in attempt to produce as clean, scratch free and sharp a polished edge as I can. It is all based strictly on my personal observation, being as objective as I can be. There are no scientific, qualitative or quantitative measurements of sharpness. It’s just my attempt to attain the shiniest, sharpest edge I can with my Wicked Edge and all the Wicked Edge associated sharpening media I have available.

This go-round, I’m sharpening and polishing a 6” Hattori Petty Kitchen Knife made of VG10 steel, rated HRc 60-61. This is a relatively straight flat shaped knife allowing good full access to the bevel. It’s made of a good quality hard stainless steel. I chose this knife, for my task, hoping to get better results than my earlier attempts. It’s not a “show” knife. I regularly use it in my kitchen.

In my last two previous trials I used new, inexpensive folding knives. I believe the beveled edge steel at the apex fell off with the increased thinning process associated with the progression of the Diamond Lapping Films because of the poor quality soft steel used in these cheap EDC’s. This is based only on my guess, because I experienced this same edge fall off, twice, with two same brand, and style, stainless steel knives.

In my prior personal attempts, using Diamond Lapping Films, I experienced an unexplained increase in fine scratches as I used the 0.5 micron WE DLF. Then on my last attempt, I believe, I also saw this with the 0.1 micron WE DLF. I’m repeating my trial this time exercising more care while using the DLF. I’m wiping the knife blade and the DLF paddles with disposable Lens Wiping Towelettes hoping to avoid or prevent scratches from contaminates.

This time I used Diamond Films I obtained from both Jende Industries and Wicked Edge. The Jende Films were: 15µ, 9µ, 6µ, 3µ, 1µ and 0.5µ. I added 1.5µ and 0.1µ DLF from WE to round out the progression.

In my earlier Forum Post I wrote of my progress down through the 1µ DLF. To summarize, up to now I am very pleased with the progress and results. After finishing with the 1.0µ Jende DLF the knife edge is very sharp and relatively clear. There are still some small mostly vertical scratches scattered along the length of the bevel, on both sides of the knife. The knife is extremely sharp and could be stropped and called “finished”, if I chose to.

I’m continuing with 0.5µ Jende DLF, just to see how the DLF performs and the results I can achieve. Here are some Microscope Photos (250X) taken during the polishing process. I have used strictly edge trailing strokes in an alternating bilateral mostly vertical up and away direction:

The photos are shown in a pair with the shiny shot on top and the same view under the shine below it.

This is later in the polishing process as I continue using 0.5 micron Jende DLF:

I’ll continue in the next post.Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

08/17/2017 at 12:37 pm #40705Here at a couple of 250X microscope photos taken at the end of my polishing with the 0.5micron Jende DLF:

I cleaned the bevel and shoulder well with the lens wipes. Then I cleaned the 0.1micron WE DLF paddles prior to using them to hopefully remove any loose diamonds or contaminates. (I verified my set angle with a digital angle device to 20.0 degrees each grit change).

Here are microscope photos take after using the 0.1micron WE DLF for 15 -20 edge trailing strokes:

Again I have paired the photos with the shot showing the smooth shine on top and the shot showing the underlying scratches of the same region, below it. I believe there is a discernable improvement in the scratch pattern showing less and less scratches and finer size scratches as I have continued down through the finer grits. I’ll continue with the next Forum Post.Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

08/17/2017 at 12:46 pm #40710This next pair shows the residue left after wiping with the Lens Wiping Towelettes. I continually wiped the bevel, shoulder and DLF paddle during the polishing process in an attempt to prevent unwanted scratches:

In the second shot you can see residue left from the towelettes.

While trying to wipe the residue I experienced another issue that Clay wrote about in an earlier Forum Post of random scratches just from contaminate on the wiping surface. It became a balancing act of trying to remove fine scratches and not replace them with others caused from wiping. Here’s another photo pair from later in the 0.1 micron WE DLF polishing session:

At this point I decided to call it with the 0.1 micron WE DLF. I didn’t see scratches that were unexpected or unexplained. The films, all of the grits, performed well. It was a point of almost status quo. I gained on it in one area and maybe took a step back at another area. I could tell I wasn’t going to achieve a perfect, scratch free surface using the DLF. I lowered my set angle by 2 degrees per side and began stropping.

I continue with the next Forum Post.Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

08/17/2017 at 1:31 pm #40715Somewhere along the way I came to, not a realization, but for me, a better understanding. The Diamond Lapping Films although the “latest rage” so to speak to hit our sharpening Forum are really, IMO, just what they are called, Diamond Films. They are a relatively inexpensive way to match the very fine grits and close, shallow, evenly spaced, predictable scratch patterns before only seen with more costly fine grit whetstones. The DLF are a continuation of the grit progression of the highly praised 1500 grit WE Diamond Stones. They are diamond stones. The DLF do polish by the nature of smoothing the surface with increasingly smaller grit particles. IMO, I don’t think they polish as well as strops polish.

Here’s a couple more edge photos taken in the stropping process, starting with 4µ, 2µ, 1.0µ then 0.5µ all with cow leather:

They both, DLF and Strops, have their place and value in our sharpening arsenal and don’t replace or substitute for one another…again, IMO. The DLF by the nature of the mounted substrate may have a little give to their abrasion. That probably places their behavior somewhere between whetstones and strops. They do have their place.

I achieved more then I set out to do with my little trial. I think I gained an understanding I hadn’t had before. There is a place for all these media. It’s up to us to decide where it fits our needs. For me there’s still nothing like an edge leading fine sharp bevel that’s been stropped to a fairly fine polish.Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

08/17/2017 at 2:55 pm #40721Great posts Marc! You should put a photo of the finished knife in the super polished edges thread. Is it still your belief that there is a problem with the 0.5 micron WE lapping film, or do you think the erroneous scratches you were seeing previously can be explained by contaminants introduced in the sharpening and wiping process?

-

AuthorPosts

- You must be logged in to reply to this topic.