Adding a second dimension to base rod

Recent › Forums › Main Forum › Suggestion Box › Adding a second dimension to base rod

- This topic has 17 replies, 13 voices, and was last updated 11/30/2015 at 6:23 pm by

kpromero.

-

AuthorPosts

-

07/20/2013 at 7:46 pm #13468

Hello all.

I’ve owned my WE for over two years, yet, this is my first post. I love my WE and it is the most precise piece of sharpening equipment I own.

However, there are two primary inconveniences the I find (again, this my opinion):

1. Finding the sweet-spot: Yes, I do use the Sharpie method.

2. When sharpening long knives (>8″) I find that I need to take the knife out and reset it, in order to accomodate for the length.So, I was wondering if I might spark any interest (or not) in the following:

At this time the base rod allows the arms to move horizontally. I, personally, feel that somehow allowing the arms to move in a vertical direction as well would be great. Allowing the arms to slide along the base rod in a vertical and horizontal direction, I believe, would eliminate the need to move the knife once it’s set, regardless of length or position; of course one could still use quality control methods via the angle cube and Sharpie.

I apologize for not posting a pic or outline (although, I do have one in mind).

Again, just trying to make an already great product better.

-CM

07/20/2013 at 10:26 pm #13472Wow! Such a simple idea? I wonder if it would be affordable to mass produce? Sound like a great idea to me?

07/21/2013 at 3:13 am #13487It is a good idea and we’ve been working on something similar, essentially putting the base rod on a sliding platform on a track.

-Clay

07/21/2013 at 5:48 pm #13508I’ve owned my WE for over two years, yet, this is my first post.

Welcome to the forum!

Great idea.

Thought I’d mention on this point…

2. When sharpening long knives (>8″) I find that I need to take the knife out and reset it, in order to accomodate for the length.

You shouldn’t have to reset an 8″ knife. For example, this knife…

… that I used as an example in this thread on securing flexible knives, the blade is almost 11 in. long, and I was able to sharpen the entire edge without moving the knife.

Feel free to post your ideas on what you have in mind.

07/21/2013 at 7:16 pm #13509It is a good idea and we’ve been working on something similar, essentially putting the base rod on a sliding platform on a track.

OMG wow that sounds really cool! I swear I will end up in the poor house with all your new great ideas!!!! :woohoo:

11/11/2014 at 2:01 pm #21192The EZE Sharp Blade Sharpener has a rail that allows the rod to move horizontally. I can’t wait for a prototype from Clay

.

11/20/2014 at 1:34 pm #21354The EZE Sharp is the first thing that came to mind while reading the opening post. For those not familiar with that system:

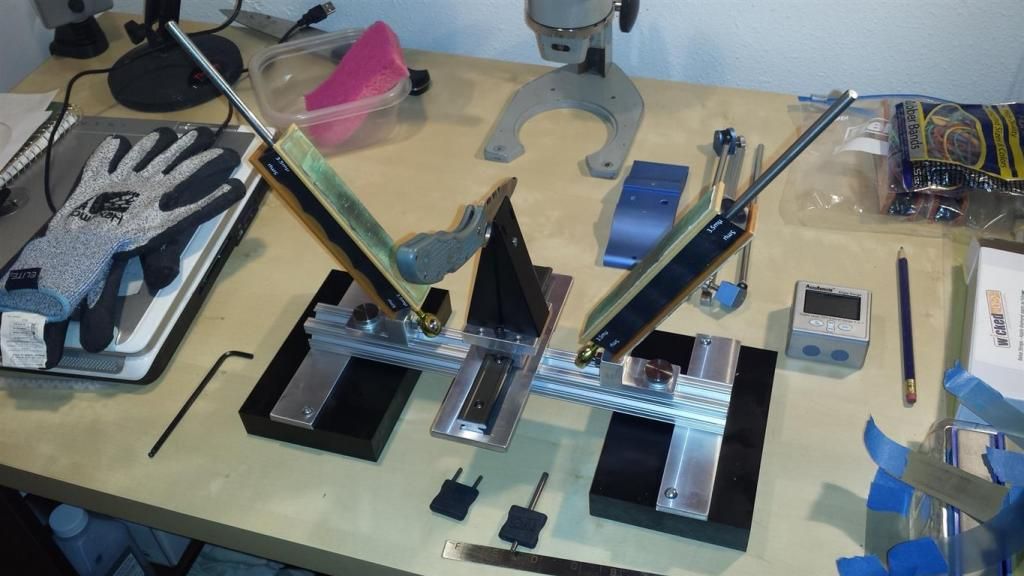

Attachments:12/06/2014 at 10:05 am #21831Hi all,

After playing around for a good while with my WE I wanted a few modifications. One was adding that second moving dimension to the blade.

The other was greatly reduce the play in the arms. I am still refining it but any suggestions would be welcome.

Maybe the modifying got out of hand…The WE certainly is a great system.The other question is what shapton stone to use after the 1600 ceramic. I want to get away from tapes. They work great but are a hassle.

The diamond sandpapers in particular work wonders but they are just too expensive.Oh and lastly, please use gloves. About 2 weeks ago I was sharpening my Sebenza, which of course was already plenty sharp… :S ., in a moment of

being clumsy my hand caught on the blade, a cut severe enough to require an emergency room visit and stitches,

I nearly cut the tendon that controls my thumb, the hand out of commission for 6 weeks. So, be careful.12/06/2014 at 3:31 pm #21834Hi Arne,

Welcome to the forum! Great to see you enjoy your WEPS so much that you’ve already made some modifications.

That said, I cannot make out from the picture what exactly you’ve done. Could you elaborate a bit on this?

Personally I use the 5000 grit Shaptons after the 1200/1600 stones. However, most people would probably give you a different advice and say you should go back to 2000 grit or so. That’s certainly safer, but I find it a bit overkill.

And the gloves… I wrote a blog post on them: http://moleculepolishing.wordpress.com/2012/08/12/554/ . Your injury sounds pretty serious. I hope it’s healing well.

Thanks for joining and get well soon!

Molecule Polishing: my blog about sharpening with the Wicked Edge

12/07/2014 at 12:59 am #21836Mark, it looks like the center vise slides forward and to the rear to be able to adjust it. What a brilliant idea! I have only ever thought about moving the arms themselves!

12/07/2014 at 3:30 am #21837You are right. The vise is on a, of the shelf carriage that moves on a of the shelf rail. I use two nylon tipped bolts to keep the vise in place.

It works but the position of those bolts is not optimal so I need to think about that a little more. The carriage looks tilted in the picture, it isnt, just the way

the light falls.I used ball joints and a larger diameter rod to eliminate slop in the arms. Essentially a home made version of the Pro Pack II upgrade arms but a little cheaper.

The horizontal bar is just aluminium extrusion you can buy, the rest of it I made from aluminium scrap. I might move the ball joints up a little higher. I still need to make a low angle adapter.

12/07/2014 at 4:02 am #21838That looks great. I made something similar earlier this year using a picatinny rail. It was cool looking but wasn’t very useful haha. I like the rods and rail you made for them.

12/07/2014 at 4:19 am #21839Thanks Arne, now I understand. It looks very good! But what do you use this second dimension for? Do you sharpen very long knives or is there another purpose?

Molecule Polishing: my blog about sharpening with the Wicked Edge

12/07/2014 at 9:01 am #21853Very elegant solution. Thanks for sharing. Very nice.

12/07/2014 at 9:44 am #21854Thanks Arne, now I understand. It looks very good! But what do you use this second dimension for? Do you sharpen very long knives or is there another purpose?

It would be used for longer knives or doing serrations with a triangle or other shaped ceramics or stones. I am with Josh. I only thought of moving the arms rather than the vise. Nice idea! Thanks for sharing!

-

AuthorPosts

- You must be logged in to reply to this topic.