Abrasives in Micron Scale

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Abrasives in Micron Scale

- This topic has 39 replies, 1 voice, and was last updated 02/05/2025 at 2:40 pm by

Mr.Wizard.

-

AuthorPosts

-

11/14/2014 at 3:23 pm #21235

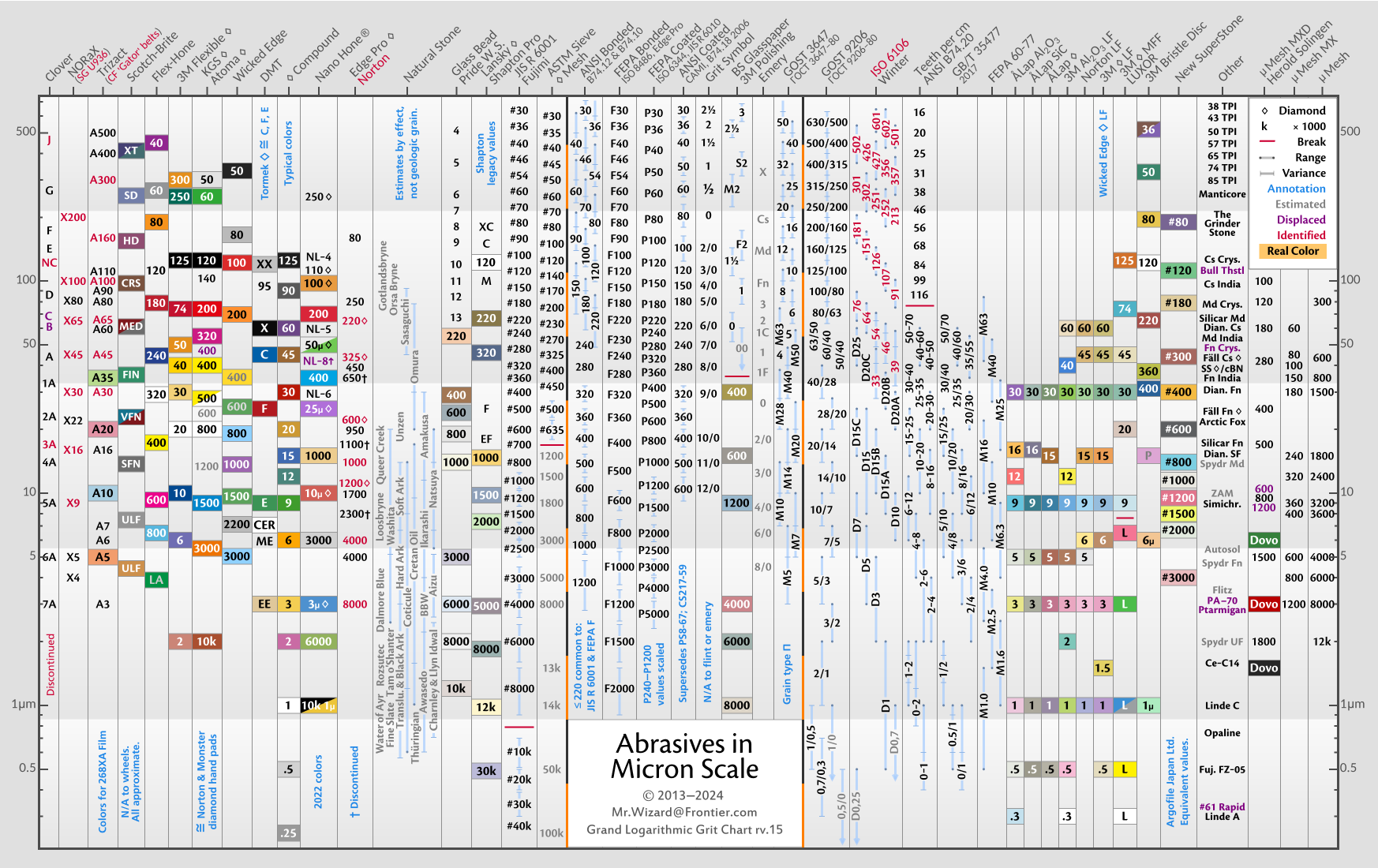

Abrasives in Micron Scale: Grand Logarithmic Grit Chart

I would like to present a new format of grit comparison chart. In the chart I seek to display the information as compactly and intelligibly as possible. Since abrasive particles sizes cover several orders of magnitude a logarithmic scale is most appropriate. A logarithmic scale also has the property of equidistant spacing for any geometric progression, meaning that a theoretically ideal stone series will be uniformly spaced in the chart. Stated another way, two grits that differ by a specific ratio will be a specific distance apart on the vertical axis of the chart whether they are 1.0 and 1.5 micron or 200 and 300 micron.

I give tribute those before me who created unified grit charts which were my inspiration for creating this one. Please see the README for ongoing acknowledgements.

I spent considerable time assembling this chart therefore I am not releasing it into the public domain. I retain control over its distribution and use as detailed in the README and LICENSE files. I ask that it only be shared by linking to the original source: http://myplace.frontier.com/~mr.wizard/GLGC/%5B/url%5D

Please see http://myplace.frontier.com/~mr.wizard/GLGC/README.txt for important details about the chart including how to interpret it and what it does and does not represent.

The chart and README will be updated if and when corrections or improvements are appropriate. Previous versions as well as additional charts may be made available in the /GLGC/ directory.

I am soliciting feedback on the chart presented above. Any corrections and all suggestions are welcome.

Please ask any questions you have regarding the chart and its interpretation. Anything that is unclear shall be additionally explained in the README, and potentially modified in future revisions.

As explained in the README file I chose to limit the range of the chart to keep it compact. A format I considered is to include additional scales to cover the macrogit and submicron ranges. Please see the file “GLGC RC2.png” in the directory linked above. I request feedback on this layout as well.

-

This topic was modified 6 years, 5 months ago by

developer (ChrisB).

-

This topic was modified 6 years, 5 months ago by

developer (ChrisB).

11/14/2014 at 3:32 pm #21236Hey Mr. Wizard,

Welcome to the forum!

I already responded to your chart on KKF, so I’ll keep it brief here. But praise again :cheer: .

On KKF you wrote that Clay provided you the figures for the WEPS stones. Is there a reason the WEPS diamond stones are at about their expected micron rating, but not exactly? (E.g. 1000 grit stones at around 7.)

And how did you arrive at the ratings for the 1200 and 1600 ceramic stones? I know this is pretty hard to do and wrote a blog post about it: http://moleculepolishing.wordpress.com/2013/08/08/the-mystery-of-the-spyderco-and-the-wicked-edge-ceramic-stones/ .

Molecule Polishing: my blog about sharpening with the Wicked Edge

11/14/2014 at 3:45 pm #21237Thanks for the welcome!

I am using the data https://www.wickededgeusa.com/grits-comparison-chart-for-the-wicked-edge-sharpener/%5Dpresented">. This table shows the 1000 WEPS plate as 7 micron, the “1,200 Ceramic” as 5 micron, and the “1,600 Ceramic” as 2.85 micron — assuming I am not reading it entirely incorrectly.

Thanks for the blog link; I hadn’t seen that and it looks very interesting. I suppose ceramic values are always approximate/equivalent based on what I read (elsewhere) about that Spyderco rods. I should note that in the README with the next revision.

Any other questions/comments/improvements?

11/15/2014 at 12:10 pm #21246Thanks for the post Mr Wiz:

Have you looked into how these equivalents compare to a standard mesh size? Or is the ANSI value the equivalent of a standard mesh size? One of the others?

I use a chart on http://www.advancedabrasives.com/index.cfm?page=sap-diamond-powders From this, I extrapolate a simple, not-so-sophisticated formula: Divide 20,300 by micron size or grit size to get the opposite value: (Micron size = 20,300/grit) or (Grit = 20,300/Micron size). Am I plucking daisies in right field?

Thanks again for the very interesting data.

Tom

11/15/2014 at 12:44 pm #21247Thank you for your interest. “Mesh” is a bit confusing and ambiguous, at least from what I have seen. It is a specification for a wire sieve, not abrasive grit. (And there is more than one.) If you have a spec of x wires per inch you also have to ask how thick the wires are if you want to know how big the holes are; it is not simply a fixed ratio. Additionally it becomes mechanically infeasible to use mesh grading for very fine grits therefore the high mesh numbers are merely theoretical. A summary of some different mesh types from Wikipedia: Mesh (scale). Note that none of them extend beyond 500.

Then you have to ask what you mean by a mesh number applied to a grit. Does it mean all of the grit passes through that mesh (sieve)? Or the grit will caught on that mesh? How much of it will be caught? Essentially mesh (sieve) is used in the grading and testing of grits, specifically macrogrits, but it is not itself a grit standard. (And individual macrogrit standards use mesh differently.) For coarse grits it may be used that way in a highly approximate sense or simply as jargon (e.g. referring to ANSI 120 grit as “120 mesh”). With finer grits it seems to be used in marketing to give extremely high numbers that look impressive; I suppose “100,000 mesh” looks more impressive than 0.25 micron to uneducated eyes. (I believe the page you referenced is simply using 25,400 microns per inch divided by “mesh” for their equivalents.)

I chose to include U.S. Mesh up to 400 in my chart because it physically exists and therefore serves a purpose. As is the case with all of the data in the chart (please see the README) you cannot directly convert from one column to another. (Or as is the case with a dual-family column like US Mesh / Chosera, from one family to another.)

By the way do you find the alternate form with extended scales shown here of value?

11/15/2014 at 1:13 pm #21248Clay Allison, I note that you have seen my chart. I hope you like it.

I used the values from your chart for the Chosera stones. Could you tell me more about these numbers? While neither 5000 nor 10000 is part of the JIS standard these two Chosera values do not match an extrapolation from JIS 1998. If the values were provided to you was their nature further specified or merely “micron?”

11/15/2014 at 5:23 pm #21249Hey Mr Wizard,

I was thinking again about the grit rating for ceramic stones. You’ve read my blog post, so you know about the difficulties.

What we want to measure (I think) is abrasiveness of stones. For diamond stones and water stones we have found a measurement for this: the size of the abrasive particles.

However, for ceramic stones this doesn’t work. Still, we try to plot them on the particle size scale in order to denote their abrasiveness. This seems like a methodological problem to me.

What do you think about this? (I have no solution at hand…)

Molecule Polishing: my blog about sharpening with the Wicked Edge

11/15/2014 at 6:37 pm #21251Yes, I did read your blog post. It’s the best treatment of the issue I have yet seen; well done.

I decided early in the process that my chart would not attempt to make absolute comparisons if abrasive performance. This is clearly explained in the README.

- As you well know diamond compound on leather cuts much more slowly and produces a much higher surface finish than the same diamonds on a metal plate. This means that even if the abrasive and the work piece are identical results can be very different.

- If the type of abrasive is different the results with further diverge; a soft but sharp abrasive may work very fast on soft metal yet be ineffective on high hardness steel.

- Abrasive roughness (sharpness) plays a large role in performance that particle size distributions do not quantify.

- The shape (aspect ratio) of abrasive particles is not well addressed in the standards, yet again can have a large impact on performance.

- Even for a specific abrasive material of a specific particle shape and roughness and a specific median particle size by weight (D50) performance may be different. This is because a single number cannot describe the entire distribution including maximum particle size etc. An abrasive may be more tightly graded than a given standard and yet still comply with it.

So where does that leave us? In my opinion there is still value in a chart like this or I wouldn’t have spent so long putting it together. However I think that is is more useful for considering spacing within a family of products than absolute comparison between them.

Generally I have avoided inclusion of abrasive products that have to be quantified by approximate performance rather than actual PSD values. There are only a couple of exceptions, one of them being the Wicked Edge ceramic rods. I included them partly because a rough micron grade had already been assigned to them (on Clay Allison’s chart) and partly because they were part of a series. If their relative performance to each other, and to a limited degree their performance relative to the WEPS stock plates, can be reasonably approximated then I think their inclusion will be of service to WEPS users.

I am open to other ideas for how this chart may be further developed but I hope the concerns outlined above sufficiently explain my current position on the matter.

11/15/2014 at 8:49 pm #21253Mr. Wiz…

My background come from the paper industry, but I think the same principles apply. Mesh size has to do with the size of the openings or perforations. The size of the wire or other intermediate material is not considered. Screens are rated by opening size and the total percent of opening. You could have a screen with an array of 1/4″ holes and a total open area of only 20%. I don’t know how or if abrasive particles can be sieved down to micron size, but the equivalents would apply. Running the particles through a series of attrition mills, each with an eventual exit opening dimension would take them down to the target diameter – that which would pass through an equivalent sieve. The sequence and mill type would also contribute to particle roughness.

I’m sure that grit size is extrapolated from the particle size, which can be measured by microscopic and ESM methods. A batch of particles measured to have a median size of 0.5 microns would be assumed to pass through a sieve opening 1/50,000 of an inch wide, for 50,000 grit. Grit size is apparently the inverse of the particle size in inches.

Edit: To be correct, from the chart at the Advanced Abrasives site, particle size is the metric inverse of “mesh”, which I read to be particle diameters per inch.

1 user thanked author for this post.

11/16/2014 at 11:49 am #21257Hey Mr Wizard,

The readme file indeed provides a good list of reasons why particle size does not equal abrasiveness. One thing you might want to add to that is the speed at which the abrasive particles break down. For example, these particles seem to break down pretty fast in Chosera stones, which produces a mud. I think this is why Choseras have much more of a polishing effect than, for example, Shaptons.

Molecule Polishing: my blog about sharpening with the Wicked Edge

11/16/2014 at 2:28 pm #21262The Chart and README have been updated to v0.81 and I incorporated your suggestion.

11/18/2014 at 1:20 am #21292Clay Allison, I note that you have seen my chart. I hope you like it.

I used the values from your chart for the Chosera stones. Could you tell me more about these numbers? While neither 5000 nor 10000 is part of the JIS standard these two Chosera values do not match an extrapolation from JIS 1998. If the values were provided to you was their nature further specified or merely “micron?”

Hi Wiz,

The numbers for the Chosera stones are “as stated” by the manufacturer. I’ll see if I can collect some more information about them.

-Clay

11/18/2014 at 5:35 pm #21321Great thread, everyone!

This idea of the unified grit comparison chart has definitely taken a more serious turn! :woohoo: Nice job, Mr. Wizard!

The Chosera grit to micron ratings were modeled after the JIS new chart, IIRC. which, in my experience, lines up pretty well with the way they are situated here. Komit also did one on Knife Forums a while back, too.

One of the things to remember -which has already diligently been addressed here- is that the micron ratings, while the most tangible of all the variables, are really only a loose quantification of abrasive size. I love that Mr. Wizard has addressed the idea that particle size does not correlate to the depth of its scratches, something we touched on a couple of years ago on this forum with the 14 micron diamond paste vs. a 1K diamond – and warrants more discussion. B) I also love that PSD, shape, density, and friability are also mentioned as variables. Time, pressure and effects of the binders are also worth mentioning, too! It is all these entropic forces that make us fall back on the micron or grit rating. So, in that respect, everything looks to be in good relative order on the chart. B)

On a personal level, I think these charts are important, but can quickly become overwhelming since the grit range has been greatly expanded to 0.025 microns now. One thing I would like to address based on my own findings is that the 5K Chosera should be rated slightly below the 5K Shapton Pro…

Top is a 5K Chosera, and below is a 5K Shapton Pro, but even then, in the hands of other users, the results will inevitably vary!

11/18/2014 at 6:38 pm #21322

11/18/2014 at 6:38 pm #21322Tom, I’m glad you like it, and thank you. Please make sure to look at the linked README file. I gave specific acknowledgement to Komitadjie as his chart was the primary inspiration for mine. With the v0.81 update the README mentions these factors of abrasive performance, among others:

– backing or bonding characteristics

– cutting point density (open vs. closed coat, binder proportion etc.)

– workpiece composition and hardness

– pressure and speed of application (affecting grit penetration depth)I appreciate the pragmatic note regarding Shapton vs Chosera 5K performance, but as explained I will not be modifying item placement in my chart based on that kind of observation unless it amounts to overwhelming evidence that the datum is false.

I would love to see a chart comparing the absolute performance of many different abrasive products but such an endeavor would be far beyond my budget, if nothing else. I have given it thought however. My best idea is creating several standard steel samples, cutting them into pieces, and sending them to the four corners of the sharpening world. Contributors would then perform specific operations under instrumentation (spring scale, chronometer, etc.) and mail the samples to a lab for surface roughness measurements. Somewhere in the process the samples would need to be weighed on a calibrated lab balance to measure total metal removed. This is probably far too involved and costly to be worth it to most people.

11/23/2014 at 11:05 am #21420Thank you very much for putting this together!!!

My questions are in the area of the high grit sandpapers. I am using a combination of papers from 3M that I guess are ANSI, and I found some 2500/3000 grit paper from an auto detail supply company locally. My results are good and consistent and the progression is smooth but on the charts it seems there is now way it could line up.

For example my P2500 paper is much much finer then a 600-800 ANSI paper from 3M. The 3000 grit is so smooth it feels like vellum or something…any help greatly appreciated.

Also did the Wicked Edge 5u/3.5u pastes make the chart? I usually follow up the 3000 grit paper with these and have had near mirror polish results to the naked eye.

Thanks again for all you work on compiling this!!! B)

1 user thanked author for this post.

-

This topic was modified 6 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.