Fixing uneven bevels

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Fixing uneven bevels

- This topic has 17 replies, 6 voices, and was last updated 08/19/2017 at 2:35 pm by

sksharp.

-

AuthorPosts

-

08/04/2017 at 12:44 pm #40455

Happy Friday all!

I’ve had my WE for a few weeks now and I’m getting better results than I could have ever imagined. Really happy with it.

One area where I’m a little uncertain is fixing uneven factory bevels. A few of the cheap knives I plan to practice on have a very thin bevel on one side and a much wider / thicker bevel on the other side.

My plan was to set the desired angle and work the 100 grit stone on the thin beveled side until the bevels are about even (and I’ve got a burr), then work the other side until the burr is pushed back over.

Before implementing this plan I’d like to get feedback from more seasoned reprofiling experts. If you have any additional tips or procedural tricks for evening out the bevels, I’d appreciate it.

Thanks!

08/04/2017 at 12:57 pm #40457I’d adjust the thinner side over multiple sharpenings rather than all at once. It will be just as sharp, and you won’t be wasting metal just for symmetry’s sake.

2 users thanked author for this post.

08/04/2017 at 2:24 pm #40459I’d adjust the thinner side over multiple sharpenings rather than all at once. It will be just as sharp, and you won’t be wasting metal just for symmetry’s sake.

In all honesty I will never use or carry these knives. They’re cheap Kershaws I plan to give away as gifts. The people receiving them aren’t knife people, so they probably won’t use them very often. The aesthetics of these particular edges are more important to me than saving steel. 🙂

I’d like to learn how to reprofile properly regardless. Any tips you may have would be great.

08/04/2017 at 2:31 pm #40460Mikedoh is correct to mention that there will be some superfluous metal removal if you decide to even things out all in one go. However, I would only consider that to be a significant concern if it’s an expensive or emotionally significant knife. For knives that you described as cheap and for practice, I’d say have at it!

Knives with uneven bevels will exhibit a steering effect when cutting. This can be desirable for some applications and if you research kitchen knives you will find that many are intentionally sold with 70/30, 80/20, 95/5 and 100/0 (single bevel or chisel) grinds.

I think you have the correct idea about how to accomplish even bevels; sharpen on the narrow side until the bevels look even and then carry on as usual through the progression.

3 users thanked author for this post.

08/04/2017 at 3:09 pm #40461Not to interject negativity, for me it’s been easier said than done to even out the bevels from side to side. There are a few issues I deal with:

- The knife may not be forged or ground symmetrically by the maker, intentionally or unintentionally. So it may have an inherent shape aberration you’re trying to correct.

- I find my technique needs to be very close to perfect to make even bevels. The difference between my right dominant hand and left hand affects the bevel, in my technique, stone grip and pressure applied, to mention a couple ways.

- I also find it hard to keep the bevels even down the entire length of the bevel, heel to tip, on one side alone let alone to keep it matching from side to side.

- Unless the bevel is very different in width from side to side, when properly sharpened and polished nicely, the only one that ever notices it is me.

Like Organic said, it may be intentionally ground as an uneven bevel. These can have many implications more than just the width of the bevel being different from side to side. An uneven bevel knife can be intentionally ground uneven from side to side so when you even it out the knife doesn’t cut correctly any longer.

Marc

(MarcH's Rack-Its)3 users thanked author for this post.

08/05/2017 at 8:30 am #40466…Like Organic said, it may be intentionally ground as an uneven bevel. These can have many implications more than just the width of the bevel being different from side to side. An uneven bevel knife can be intentionally ground uneven from side to side so when you even it out the knife doesn’t cut correctly any longer.

I have on several occasions sharpened kitchen knives to move the edge off-center to improve cutting of certain solid foods. The narrow bevel goes to the side of the knife opposite the user’s hand. For instance, if the user is right-handed, I’ll put the narrow bevel on the left side of the knife as seen when looking down at the spine.

This method is practically worthless if the edge is that of a very thin knife, but for thicker edges, the differences can be profound. Imagine cutting with a chisel-grind edge. When cutting very thin slices from a radish, the straight side will cut perfectly, while the broad bevel will slide off to that side

4 users thanked author for this post.

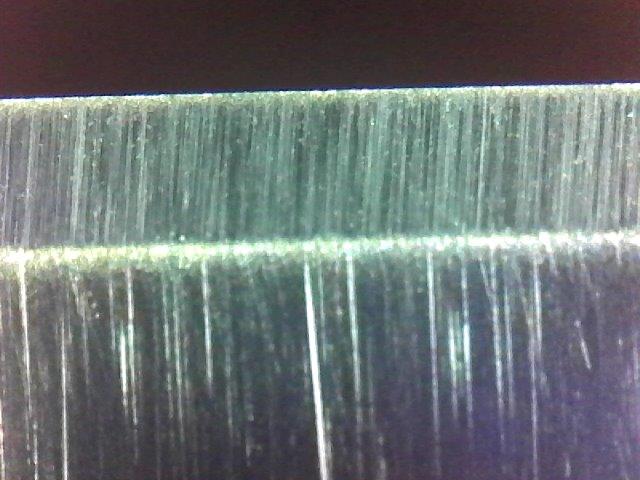

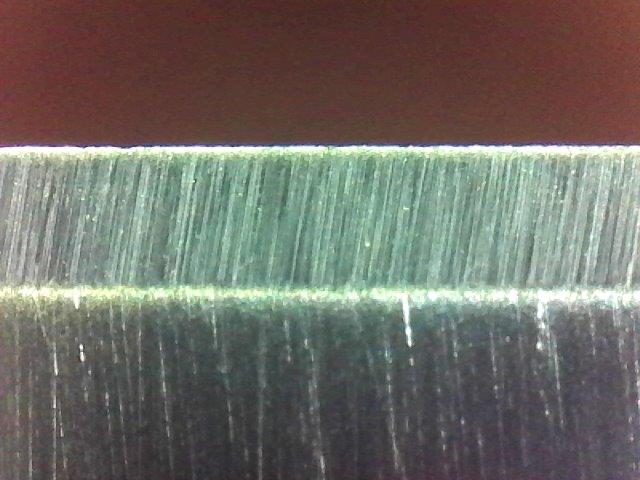

08/06/2017 at 2:58 pm #40482I just received this knife today. I took these USB Microscope Photos (250X) of the bevel of this new knife, “right out-of-the-box” just to see what I bought. Since we’re the ones that’ll be sharpening these knives, I think it’s helpful to know what the new edge looked like and what we’re starting with.

What I saw fits right in with the theme of this thread: Fixing uneven bevels.

Here’s a couple photos of the bevel from similar positions on opposite sides of the knife and the tip on both sides also:

The tip appears very similar. The bevels are completely different. The left bevel is so much taller then the right bevel at the same distance back from the tip on opposite sides. The right bevel is very narrow, where-as the left looks like it could be an uneven grind knife and there may be a micro bevel on top of it. Further back down the bevel closer to the heel the bevel width has evened out and there’s no evidence of a microbevel.I’ll show those photos and continue this in the next post.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

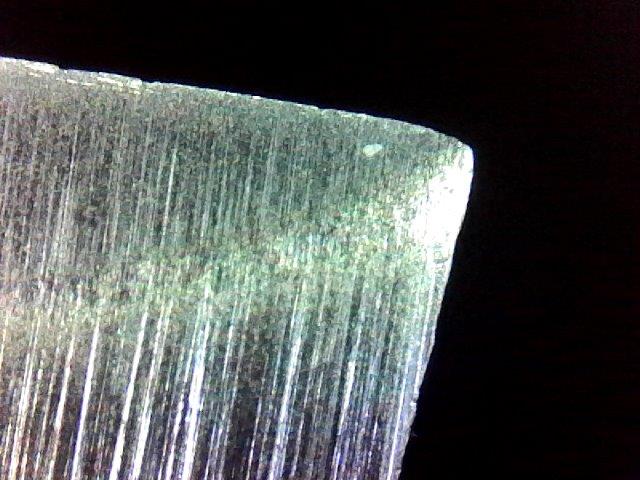

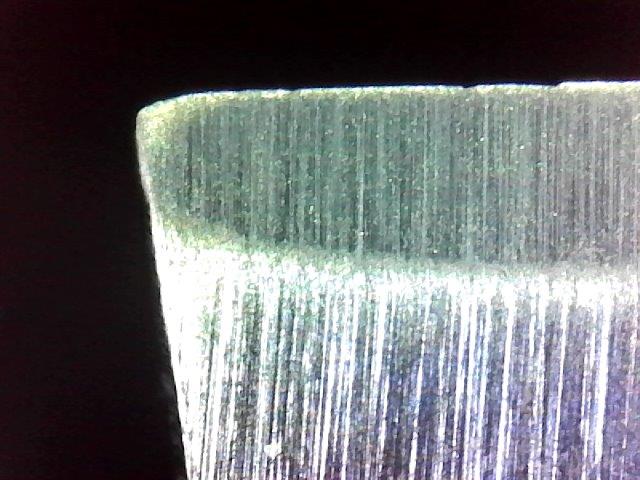

08/06/2017 at 3:16 pm #40488Here’s the bevel further back towards the heel in a relatively similar place but on opposite sides of the knife:

From all the photos, considering the entire grind it’s hard to know what to make of this knife. I researched the web pretty thoroughly and can’t find anything anywhere suggesting this is an uneven or asymmetrical grind knife. There’s nothing that says it has a micro-bevel and there’s nothing that says it’s a 50/50 even grind. As you look over the entire bevel around the complete knife the only conclusion I can make is it’s not a consistent grind.

It is sharp. It’s not a “stand-out” cutter but it’s sharp. It did slice newspaper and push-cut it very easily. I plan to use it a while before I sharpen it to get a good feel for it’s behavior and edge retention. I’ll probably strop it with a paddle strop after using it some. That usually seems to improve it’s cutting ability.

This knife being a “Japanese Super Stainless Steel” (HRc 68-69) will be discussed further in my Thread. I’ve been putting together some good information and photos as I have gained experience using these steels.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

08/06/2017 at 4:57 pm #40492Great observations, Marc. The matched bevels near the heel tells me that the manufacturer intended for the bevels to be the same. The fact that they are quite different near the tip tells me that the fellow putting the final edge on was a little sloppy at the belt sander. If a manufacturer in fact wanted an uneven bevel, I think they’d have done so for the entire length.

I assume that the left/right orientation in your photos are as looking at the blade while clamped in the vise. If not, then they set the bevels for a left-handed person. Even wackier. Ooh! Wait a minute – I’m left-handed. We’re not wacky. We’re not. Really.

3 users thanked author for this post.

08/13/2017 at 7:55 am #40591My plan was to set the desired angle and work the 100 grit stone on the thin beveled side until the bevels are about even (and I’ve got a burr), then work the other side until the burr is pushed back over

Having done quite a few inexpensive EDC’s I wouldn’t totally ignore the wide side while trying to even the other side first. I color both sides with the sharpie and remove all traces of marker on both sides first, then see what it looks like. By doing this you have the wide side even and then you can match the thinner side by working it a little more. Sometimes it surprised me that after doing the above that the bevels were a lot closer to even and you don’t have to remove as much metal. Then after you get both sides relatively even work both sides, 1 pass right then left side, 10 or so strokes or until your happy with the scratch pattern then move on. I like to work the burr back and forth after establishing it on both sides, this seems to reduce it a bit before I move on. I do start re-profiles generally with 100 grit.

Have used the 50 to start some but those were “special” cases and you don’t need those stones very often and with those you don’t draw a burr because they’ll damage the edge and cause more problems than they help.

Please let us know how it turns out and sorry for jumping in so late in the game.

1 user thanked author for this post.

08/13/2017 at 8:16 am #40592Anarchy84, I have found that sometimes when working the shorter bevel side I have shortened the wider bevel side. As I corrected the profile angle on the short bevel and I apex the edge it sometimes removes steel at the tip which shortens the bevel width of the wider opposite side. So keep an eye on both sides like sksharp said above and work a little on one side then switch to the other side, then back again. I have on several occasions pretty much corrected a bad uneven bevel simply by profiling the knife to matching even angles on both sides. One side shrinks as the other side grows as the apex slides to the center. If the knife is ground properly and symmetrical it should even out.

Marc

(MarcH's Rack-Its)08/13/2017 at 9:48 am #40593Might need to clarify a bit.

I almost never work one side of the knife more than the other. By removing the marker from both sides of the bevel first (with the stones not by wiping off) most of the time the bevel is pretty even side to side. There are some extreme cases where I have to work one side “a little” more but not very often.

Sorry if I wasn’t clear enough on the prior post.

1 user thanked author for this post.

08/14/2017 at 12:05 am #40610Have used the 50 to start some but those were “special” cases and you don’t need those stones very often and with those you don’t draw a burr because they’ll damage the edge and cause more problems than they help.

I recently acquired the 50/80 grit stones and have used them to reprofile 3 knives. I apexed the edge and formed a burr with the 50 grit stones and then progressed all the way to 1500, into diamond lapping film and strops.

I’ve seen several recommendations not to apex with the ultra coarse stones, but my results thus far have been very good. Interesting.

Thank you all for the tips. I appreciate it.

08/17/2017 at 7:44 am #40676Have used the 50 to start some but those were “special” cases and you don’t need those stones very often and with those you don’t draw a burr because they’ll damage the edge and cause more problems than they help.

I recently acquired the 50/80 grit stones and have used them to reprofile 3 knives. I apexed the edge and formed a burr with the 50 grit stones and then progressed all the way to 1500, into diamond lapping film and strops. I’ve seen several recommendations not to apex with the ultra coarse stones, but my results thus far have been very good. Interesting. Thank you all for the tips. I appreciate it.

Here’s the only problem I see with that, at least as far as I see it. By drawing a burr with the 50/80 stones I believe you have to remove more metal than necessary. First just to draw the burr with such a course stone and second to get back down to the bottom of the scratches that those leave behind. The harder the steel the more of a problem those stones can create, at least for me. I do however think they have there place. I try not to remove any more metal from the knife than absolutely necessary. Please remember that these are opinions and totally subjective to my experience and observations. If what you are doing is working for you then by all means stick with it and thank you for sharing it.

1 user thanked author for this post.

08/17/2017 at 8:58 am #40680You bring up a good point, sksharp. I was under the impression that the amount of steel that needs to be removed to form a burr was the same regardless of which stone is used. Coarser stones just get me there quicker. Is this incorrect?

Either way, my limited experience tells me you are right about the scratches being much deeper. Starting at 200 grit makes the progression much smoother than starting at 50. I definitely try to avoid using coarser stones unless a knife needs a good amount of reprofiling.

I appreciate all of your feedback on this.

-

AuthorPosts

- You must be logged in to reply to this topic.