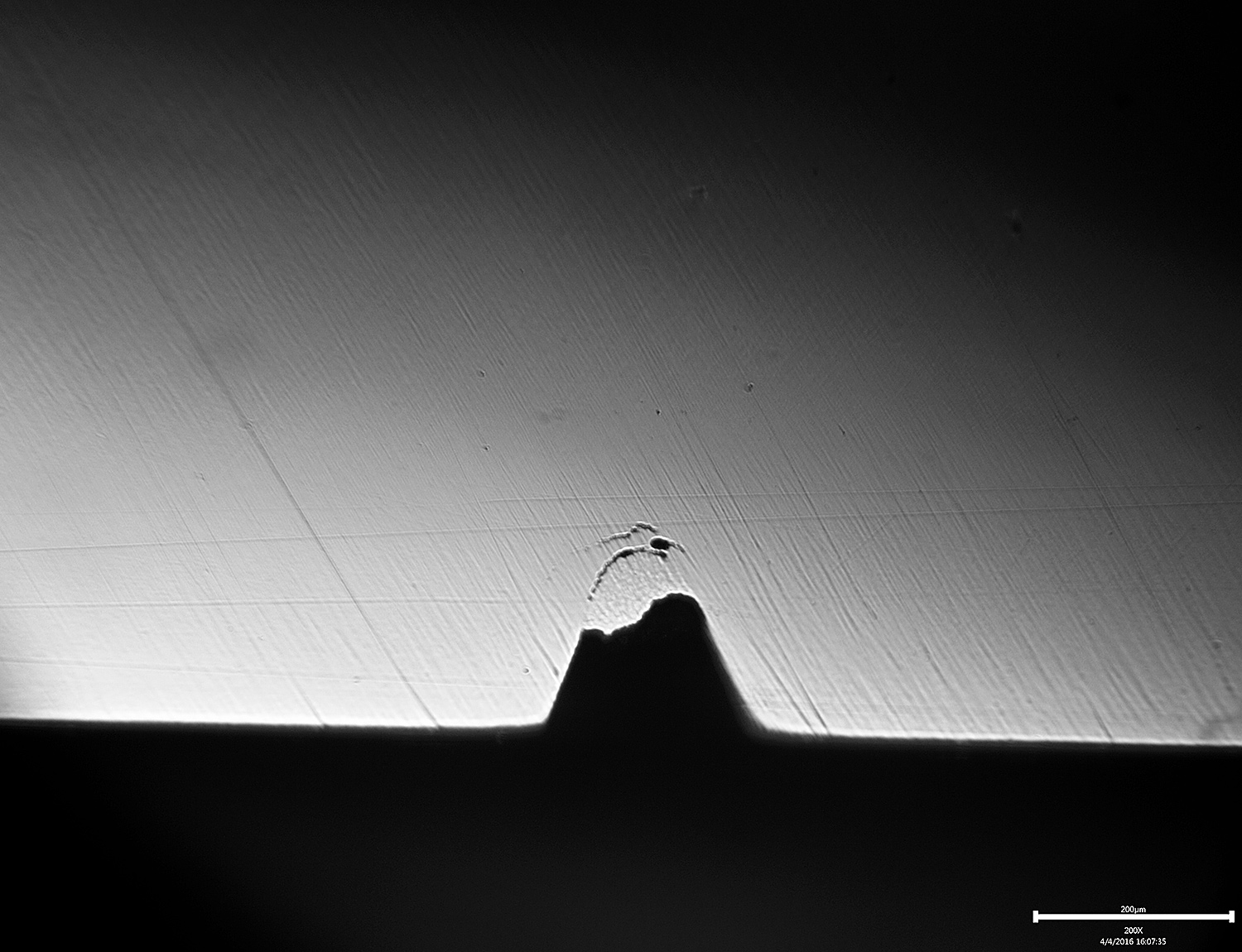

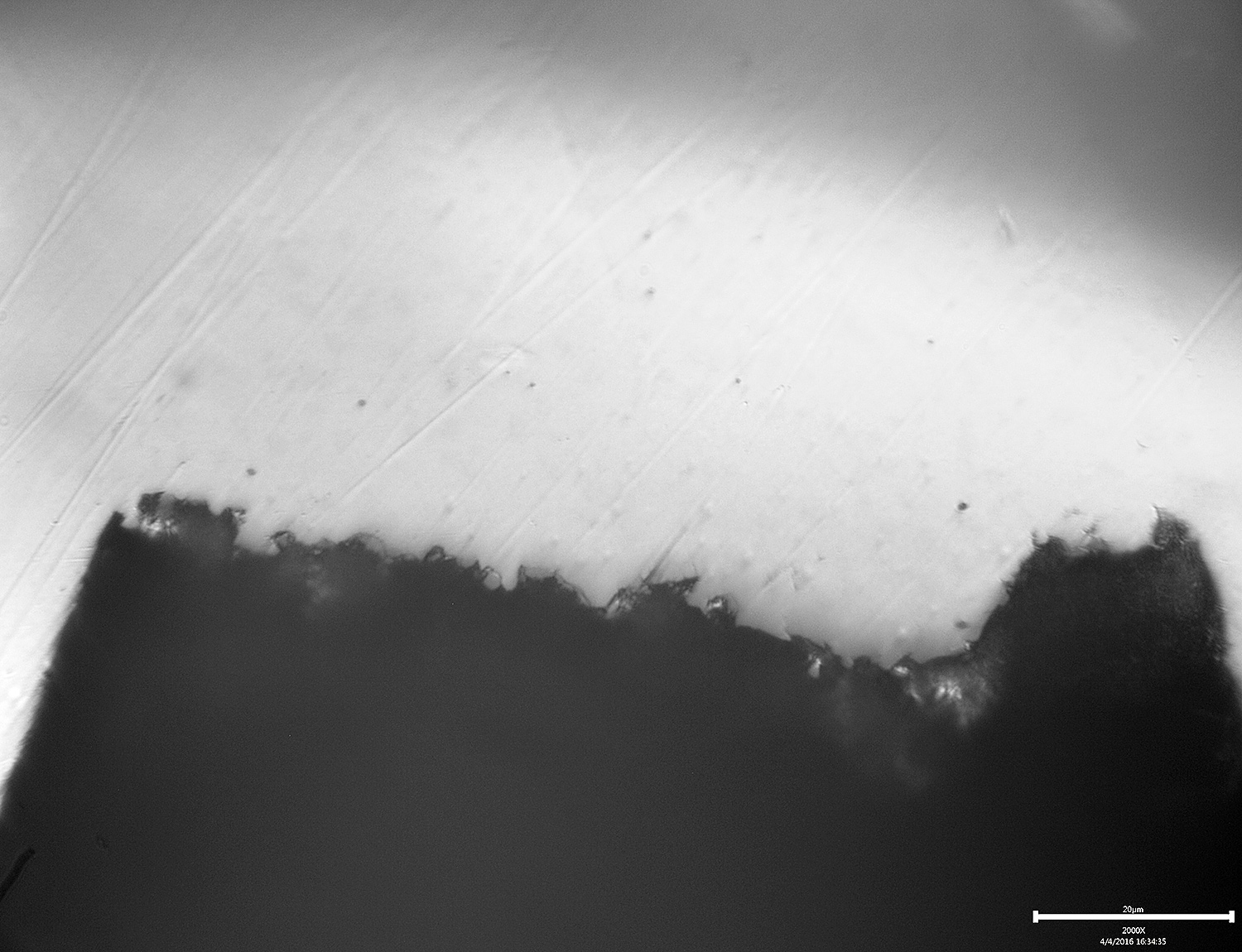

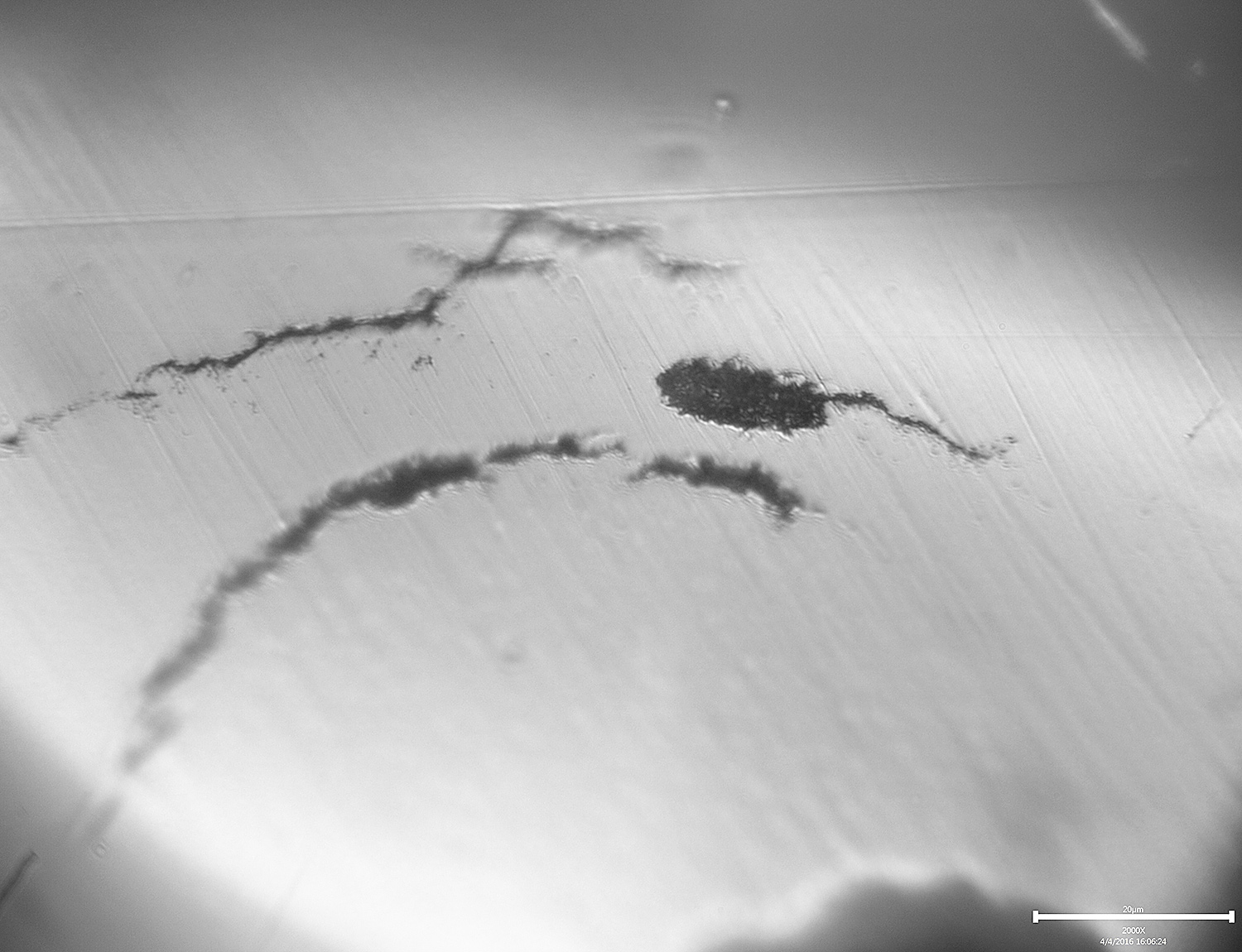

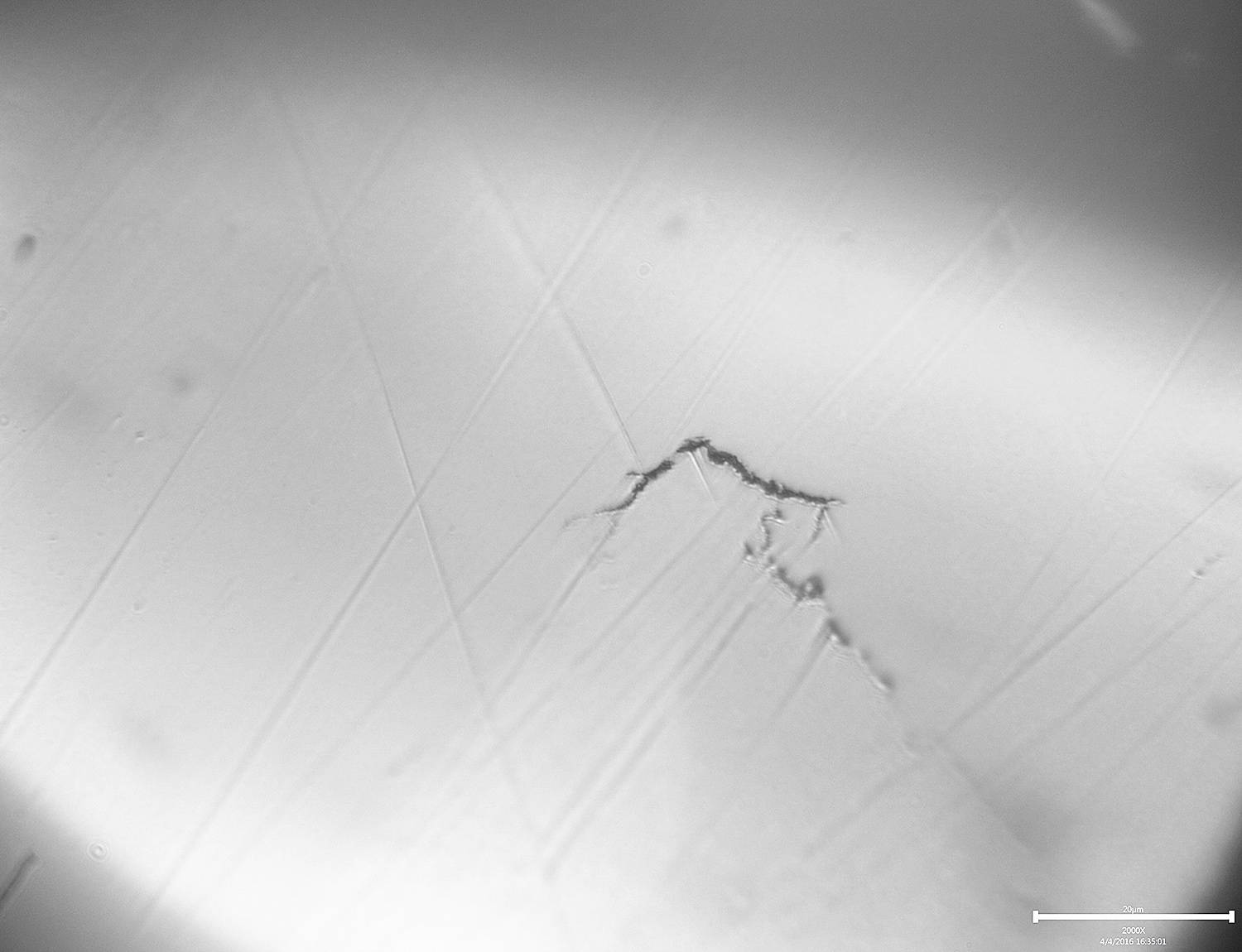

I just can’t see why some people do not finding taking the time to stop and observe is important. I have been studying Todds blog at scienceofsharp.workpress.com lately and I am all screwed up now. Their is a little world going on at the micro level that we are just now starting to understand. Not only am I convinced that micro fractures are causing some of our problems but that these problems are variables found in each step of the blade forging processes. When we start looking you start seeing these issues everywhere.

I have started rethinking the way I see a metal blade. We perceive it as this “indestructible thing” used to carve other things when in reality it is more like a gelatin fluid at the microscopic level. As we are sharpening and then looking under a microscope we are only seeing the pattern left behind in a moment of time, however, after each pass of the stone, the metal is moving.

Sorry to go esoteric on you but I share your intrigue Clay. These blades are much more fragile than we once thought. I am starting to believe that more is not better, after all, especially at the microscopic level. Todds SEM photos and your careful observation are telling us this.

I have also studied Murray Carters work as well and the Japanese where onto something. I keep hearing him saying that they made blades by forcing “Just a little more” out of it at each step of the forging process with reverse succession of temperature and force. They must have been doing this for a reason. They new something that has been lost over time.

Both of these observations seem to contradict what we are observing or do they? I think we are just missing something somewhere.

Keep up the good work if I can help I will.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-1622