Snecx

Forum Replies Created

-

AuthorPosts

-

08/12/2017 at 7:09 am #40572

I finally had the time to use the new Gen 3 and all the DLF. I used 6, 3, 1.5, 1.0, 0.5 and 0.1 micron films.

I’m here to report that the 0.5um DLF specifically has issues and it creates deeper scratches than the 1.0um film. Happens to 2 new strips, consistently, on two knives.

I’ve also redid the progression and it’s very consistent down to 1.0um, but once I hit 0.5um it gives me a lot of stray scratches that are not supposed to be 0.5um. The 0.1um DLF does not show such behavior.

At this point I think I will be skipping the 0.5um until I get the chance to experiment again.

07/29/2017 at 6:31 am #40388I’ll add something that wasn’t mentioned already, maybe a counter intuitive one.

I know for the more expensive knives it is tempting to tape the blade or the jaws. But I’ve learned it is best not to use anything between the vise and the blade, as anything used will compromise the grip of the blade. So if you must protect the blade from scratches, I found that the best option is to use thin sheet of paper.

3 users thanked author for this post.

07/26/2017 at 8:16 am #40344So, that’s a good win. I’m glad Curtis saw it and thanks Snecx for your awesome video. I think I’ll try to recreate it and add some animations in to show it off. For now, do you mind if I add your video to the Knowledge Base about the subject?

Feel free to put it on the Knowledge Base. I’m glad the video can be of good use for now.

And it’s great to hear about the outcome. Definitely a win for everybody!

1 user thanked author for this post.

07/25/2017 at 11:49 am #40335Snecx- that video is pretty brilliant. Unfortunately, the guy still thinks that the plane represented by the sheet of glass is imaginary and that the stone travels on some other plane…

NO kidding! I think the challenge is more difficult than we’ve all expected. I hope you’ll be able to bust this myth once and for all. Good luck!

07/25/2017 at 11:44 am #40334It is most likely Simple Green. I had no issue with any of my stones, until I wash them with SG. Upon washing my 1500/glass paddles, I had the glass come off. Once it’s dry, I just stick the glass back onto the double sided tape on the paddle and it’s good as new.

Using soapy water is a common trick used in the application of stickers. It allows the sticky side to slide freely until you squeeze the soapy water off.

Given the application I think it’s behaving properly, but I could be wrong.

07/22/2017 at 2:38 am #40286He’s a visual guy, so I doubt he’ll bother to read so deep about it. It’s also sad to see how many people got it wrong, the same way he did.

Here’s my attempt to illustrate the angle issue as simple as I can possibly do.

7 users thanked author for this post.

07/21/2017 at 10:02 pm #40283So much misinformation on this video. The angle from the pivot changes but the angle in the edge is constant. He failed to understand the difference.

I’ll try do something.

1 user thanked author for this post.

07/21/2017 at 12:53 pm #40263Very nice! Was that done with the diamond pastes on cereal box cardboard or did you use the Edge Pro polishing tapes?

You remember! It was done mostly on the white thin cereal box with diamond paste. IIRC I maybe only changed the angle by 0.5dps to prevent overpolishing of the primary bevel.

I’m hoping to try the new lapping films soon. I forgot to order the 1/4″ jaws and the blade I need to sharpen can’t fit the stock jaws. So it’s just a matter of waiting for the jaws to arrive.

1 user thanked author for this post.

07/21/2017 at 12:47 am #40249It has been a while since I whipped out this knife. Here is one of my best mirrored edge. Is this considered “scratchless”? I’m sure under extreme magnification this would appear scratched up too. When do we stop?

Finally I’m gonna be trying diamond lapping films next, so hopefully they will give me better results without the slight edge rounding.

4 users thanked author for this post.

07/20/2017 at 5:16 pm #40243Yes Clay, I got the 2017 Gen 3 Pro, and I haven’t used it yet! All new and I’m just going through the entire system, preparing it for upcoming work. I’ve oiled mine so I think it should stay rust free.

It’s just that I have experience with machine shop settings where even SS316/304 can rust after glass bead blasting. It doesn’t even have to be really wet for it to happen.

07/20/2017 at 11:39 am #40238Hi Clay, I took mine apart to oil it today. It seemed that half of the cam has the bead blasted finish and I think that could be the culprit. Only half of the cam is polished.

It is just a guess based on what I’ve observed, I could be wrong. But I’ve had stainless parts rust on me once bead blasted and it’s a very common problem in finishing.

07/19/2017 at 9:30 pm #40228Wow, I think I’m gonna coat mine with grease as a preventative measure. Glad you solved the clicking!

07/19/2017 at 11:36 am #40211I was having the same issue with the click but was told it was normal. Glad you found a resolution. I will try the repair as soon as I find time. Also, I am having a problem with the jaws not wanting to open on their own with the spring force. I have to push the bottom of the jaws to get them to open every time after they are closed. I will evaluate when disassembled and see if I can tell what the issue is. Given the issues I am having, I still love this new clamp!!

I had the same issue! And it’s the same issue. It was that plastic/polymer contact piece rubbing in between the clamp holders. It made a click when clamped because of the tight fit, then it wouldn’t come down on its own at certain times. The moment I sanded it, it fixed both the clicking and the “jammed” jaws.

Now the jaws open smoothly upon unlocking. It’s about as perfect as it can be!

3 users thanked author for this post.

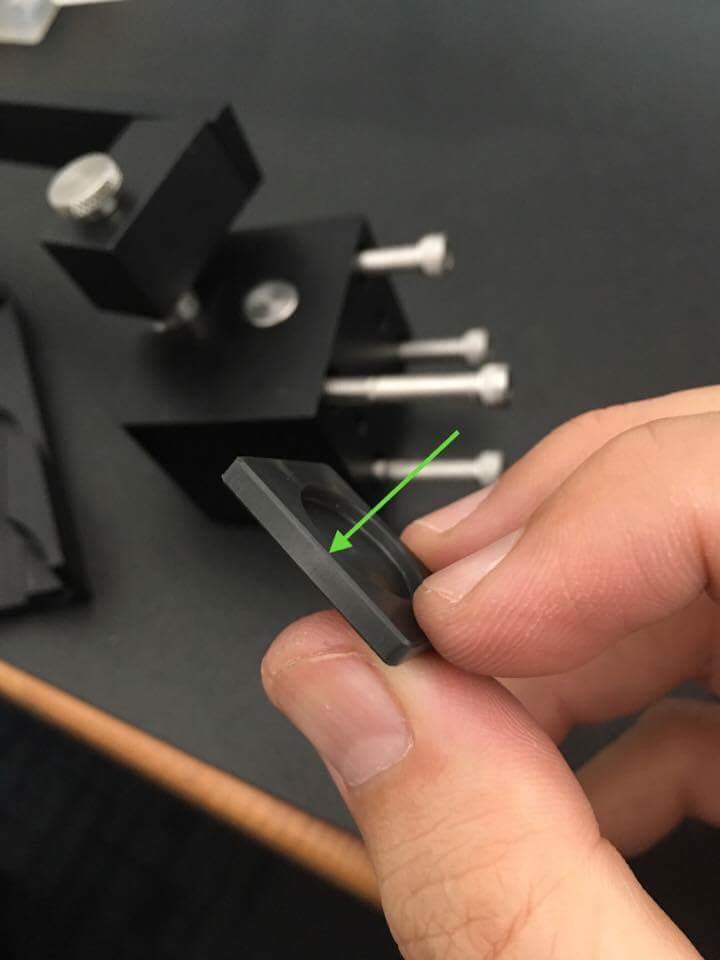

07/19/2017 at 4:51 am #40202Well I fixed the clicking issue. It’s a minor one. I took everything apart, and found the offending piece. I simply sanded off the corner of this edge (on both sides) and it’s now smooth.

It’s a simple fix

Attachments:

You must be logged in to access attached files.

5 users thanked author for this post.

07/18/2017 at 3:52 am #40198Your clamp looks smoother than mine. Mine is pretty strong and makes a click when near full engagement. Is that normal?

-

AuthorPosts