Kyle

Forum Replies Created

-

AuthorPosts

-

05/30/2015 at 1:09 am #25703

That’s kind of a difficult question because I don’t have a feel for how well your ceramics are doing for you, or how many film blocks you have. I use four pairs with eight different grades: 15. 9, 6, 3, 1.5, 1.0, 0.5 and 0.1 microns.

The 1200/1600 ceramics are replaced by the 15 and 9 micron films, which are the equivalent of 1200 and 1800 grits. Assuming that you have one pair of blocks for film and that your ceramic stones are performing pretty close to their 1200/1600 and 1.4/0.6 ratings, it would make the most sense to start off by filling in the gap between them with the 6 and 3 micron films.

One thing that hasn’t been talked about much here is that the aluminum platens can also be used with film. You can prepare them by lapping them on a flat plate with a few grades of sandpaper.

Tom

Right now i dont have any blank paddles. I wasnt guna buy any until i know for sure exactly how many different films i plan on using. I didnt really want to replace the films with my ceramics, just replace the leather strops. Im looking to use the ceramics first then continue with lapping film instead of the strops. Just not sure which micron i should start with after the micro fine ceramics.

05/10/2015 at 11:17 pm #25565I would go about it a bit differently. The angle of the stone to the blade edge is the same along that straight line you drew. Yes. But it is also the same angle throughout the arc. Which is what Josh is trying to show in his video. Once the light bulb about the arc line came on (thanks Josh and others) then I started to use my clamp in different ways to take advantage of it on curved blades..or blades that only had a small flat spot on them by the handle (all my Spydercos)

Pardon my quick crap drawings but hopefully they will get the point across.

Here is a good split. Anywhere the blade edge is below the flat line or inside the circle line the angle would be more greater or more obtuse..but not my much I think..Anywhere the blade edge is above the flat line or outside the circle the angle will be lesser or more acute. Depending on what you are doing with the blade this may be desired.

Notice the height of the blade mounted in the clamp determines the circle line..the higher up the larger the circle..the lower the smaller the circle..so you can play around with all kinds of different options. I like to start with mounting my blade..making a sharpie mark on the stone and then adjust the angle of the blade so it is as close the entire length of the blade to the line I drew..sometimes I can see if I lower or raise the height..the circle line will match up better with the shape of my tip curve..

I hope this helps some. I too used to think the same as you KnifeKnerd..until I learned of the circle line of magical same angleness..

The above drawing is what I would do, it is a compromise which would not be visually easy to see at all. BUT with this blade it is so short you would not be able to clamp it this far forward due to the handle..

The above mounting method would result in a very even bevel along most of the blade but the tip portion would be slightly wider.

edit..forgot to raise the flat line of even bevelness..ignore the flat line that is not red!

Great pics. I did end up solving my problem and got my 0900 sharpened and it actually cane out pretty good. I ended up clamping it like your first picture. There is another thread i started and i put some pictures up. I think i may have delted them by accident so i have to put them back up. Got some good tips that helped me get my knife sharpened.

04/29/2015 at 4:41 am #25451As I was inspecting the edge in the two pictures you posted, all based on what I had just previously read, I thought there had to be some mistake. Possibly the wrong photos got uploaded?… Because that edge does indeed look excellent!

I think you wound up doing an excellent job! That edge on your knife looks great to me.

Agreed.

I only hope I can do as well when I get my new WEPS.

And, you will.[/quote]

Nope those would be the correct pictures. Yea i guess i didnt have as much trouble with the 0900 blade shape as i thought. Like i said though up close in person there are a few errors. Especially at the heel on both sides. The scratches dont really show up in the picture that good.

04/29/2015 at 4:13 am #25449I think you wound up doing an excellent job! That edge on your knife looks great to me. I only hope I can do as well when I get my new WEPS.

Thank you. Im pretty happy with how it came out. Pictures make it look a little better then it really is though. Up close in person you can see some mistakes and errors. But overall it came out hair shaving sharp and the bevel was pretty much evan the length of the blade so im happy. The w/e is a great system. Glad i invested the money into it instead of the edge pro. Theres alot to learn though this is only like my 10th knife but each knife i do gets better and better. Youtube and the forums will be your best friend when you get yours.

04/29/2015 at 3:13 am #25447Edit: i fixed my original problem, but now my stone is not hitting the very tip of the blade. How would i go about fixing this? Do i need to tilt the knife down a little?

Can you provide a little more detail?

Also, what was the problem you fixed?[/quote]

My original problem was that my stone was only hitting part of the bevel all the down the length of the blade. I adjusted the knife a little and fixed that problem, but now when i get to the tip the stone isnt hitting the whole tip evenly. If that makes sense. Sorry i dont know all of the sharpening lingo yet. Still new to this. Pretty much the stone isnt completely sharpening the tip. Its missing parts of the bevel on both sides of the tips.[/quote]

Well, if the knife was successfully clamped and vertical in the vise, I assume you fixed the original problem by adjusting the knife either up/down?

Since the tip portion is now an issue, it sounds like you need to move the knife either forward/backward. Best thing to do is use your Sharpie to paint the bevel then make a pass with the 1000. If the Sharpie’s removed at the shoulder right behind of the tip and is not removed from the actual tip itself, the knife needs to be moved towards you. And visa versa. However, this method isn’t a definite solution that guarantees to work on all knives. It’s more for beginners whom are trying get acquainted with the system. There’s a page in the WE user manual that details the basics.

To sum it all up – The exposed path left along the entire bevel after making a swipe with your stone is basically the systems way of telling you where it wants the edge to be. From there all you really need to do is get the apex as parallel as possible to that path.. If that makes any sense at all?[/quote]

So i fixed the issue i was having with the tip. I loostened the vise and moved the knife back a timy bit. Then marked the tip with sharpie and i took the sharpie right off. So thank you. Your idea did work. I finished up the knife. Went 100-1000 diamonds. 1200,1600 coarse, fine. Ceramics then the 5,3.5 strop. The edge came out alright for a rookie. Some spots ate nicely polished and some spots arent as polished. And there is some scratches i missed. Another problem i ran into though was that after i was done with the diamonds and went on to the ceramics. The heel of the blade now wasnt getting completely hit. Some scratches were being left behind at the heel. I just kept going and the knife came out super sharp anyways. I need to get better at removing all the scratches from each previouse grit before moving on. Here are a few pucs of how it came out.

04/29/2015 at 12:37 am #25446

04/29/2015 at 12:37 am #25446Edit: i fixed my original problem, but now my stone is not hitting the very tip of the blade. How would i go about fixing this? Do i need to tilt the knife down a little?

Can you provide a little more detail?

Also, what was the problem you fixed?[/quote]

My original problem was that my stone was only hitting part of the bevel all the down the length of the blade. I adjusted the knife a little and fixed that problem, but now when i get to the tip the stone isnt hitting the whole tip evenly. If that makes sense. Sorry i dont know all of the sharpening lingo yet. Still new to this. Pretty much the stone isnt completely sharpening the tip. Its missing parts of the bevel on both sides of the tips.[/quote]

Well, if the knife was successfully clamped and vertical in the vise, I assume you fixed the original problem by adjusting the knife either up/down?

Since the tip portion is now an issue, it sounds like you need to move the knife either forward/backward. Best thing to do is use your Sharpie to paint the bevel then make a pass with the 1000. If the Sharpie’s removed at the shoulder right behind of the tip and is not removed from the actual tip itself, the knife needs to be moved towards you. And visa versa. However, this method isn’t a definite solution that guarantees to work on all knives. It’s more for beginners whom are trying get acquainted with the system. There’s a page in the WE user manual that details the basics.

To sum it all up – The exposed path left along the entire bevel after making a swipe with your stone is basically the systems way of telling you where it wants the edge to be. From there all you really need to do is get the apex as parallel as possible to that path.. If that makes any sense at all?[/quote]

I fixed my original problem by moving the knife down a little. Ill try exactly what you suggested and let you know how it goes.

04/28/2015 at 9:48 pm #25443Edit: i fixed my original problem, but now my stone is not hitting the very tip of the blade. How would i go about fixing this? Do i need to tilt the knife down a little?

Can you provide a little more detail?

Also, what was the problem you fixed?[/quote]

My original problem was that my stone was only hitting part of the bevel all the down the length of the blade. I adjusted the knife a little and fixed that problem, but now when i get to the tip the stone isnt hitting the whole tip evenly. If that makes sense. Sorry i dont know all of the sharpening lingo yet. Still new to this. Pretty much the stone isnt completely sharpening the tip. Its missing parts of the bevel on both sides of the tips.

04/06/2015 at 5:32 am #25000Yea i have watched alot of his videos on clamping down blades and stuff, and have learned alot but i still dont know what the best way would be about clamping this particular blade because of the weird shape.

03/29/2015 at 11:45 pm #24770It wasnt this forum i heard people saying it. It was a sub forum off usn. Was just looking for an explanation as to why and figured this forum may be better for this question. Looks like mark has a pretty good explanation. Thanks.

03/29/2015 at 1:15 am #24753for this reason, I am considering investing whatever I need to in going completely over to lapping films after the diamond stones. Any thoughts much appreciated![/quote]

What is the difference between using lapping films and leather strops? Do you not have to change the degree when using lapping films like you do with strops?

02/19/2015 at 12:36 am #23564So pretty much i take one measurment and make sure that i stay consistant with that original angle measurement through out the process? So i dont have to take a bunch of different measurements through the length of the blade to make sure both sides are at the same degree? Evan if towards the heel is say 20 degrees and then towards the tip is say 18? As long as that original spot stays consistant on both sides i should get an evan bevel? It just doesnt make sense how if my angle is anywhere from 1-3 degrees off between the heel and the tip how it will come out evan. I just watched his video and that did help me understand how the ffg blades can throw everything off. And that explains why the native 5 i did came out uneven.

02/18/2015 at 7:52 pm #23547The angle cube should not change more than a couple tenths of a degree max, else you may not have the knife well clamped in the vice or your arms are moving or something isn’t tightened down well. Else, your angle cube may be out of sorts and a new one is in order.

When I use the angle cube, if I am within 1 degree total between sides (say L is 20 and R is 20.5), I am good. If a degree or more, than I will move one side in or out, to get it within that degree.

Additionally, I really recommend the extended rods from Oldawan tools, which go with the upgraded ball joint arms. I got 3 inch longer arms and I really have much more flexibility in my strokes without having to be concerned with the paddles coming off the arms on some strokes.

So are you adjusting the angle between every grit? Because it seems to me that on mine the degree is always changing. I just dont get it, why i cannot get this thing to stay at a consistant angle. Wasnt that the whole point of the w/e. How accurate do you find this without the angle cube? I. Just set a knife up set the left side to 20 degrees but the angle cube reads 18.05. I want to do 40 degree inclusive so to get the angle cube to read 20 degree i have it set at 22 on the machine, the right side it is set on 21 and was reading 20.5 but then when i took the stone off and put it back on its reading 19.4, then if i lift it again and place it back its reading 18.5. Maybe i need a new angle cube, this one is brand new though so i dont know how it could have got messed up already. This is very aggravating though, investing hundreds of dollars into this and cant get it to work the right way.

I now have towards the heel of the blade reading 20 degrees but the farther i go to the tip it changes to 19.80,19.50,19.20,19. I tried adjusting how im clamping it and its not changing a thing. It still reads different everytime.

02/18/2015 at 6:55 pm #23541Hey Kyle, welcome to the crazy club. Let me ask you a few questions and try to answer yours at the same time…

The angle cube is not perfect, it has a +/- of a few fractions of a degree. If you measure the angle, say directly in line with the vise(for consistency), then remove it and place it back at approximately the same spot, how much variation are your getting? .05 degrees or so? Thats normal in my experience and I dont think twice about it and you can get exceptional results regardless.

Oh almost forgot there are entire forum threads dedicated to discussion of the wiggle in the joints and the play in the rods, custom brass bushings, and of course where you hold the paddles. :silly: All of this will cause minor variations in the angle cube readout, not counting the inherent limitation of the cube itself.

2nd part of your question regarding the angle changing as you move it along the blade length. The short answer is yes the angle will change. The are posts here on the forum that go into great detail regarding the math, positioning, angles, arc of the rods, etc etc, to minimize the angle variation. Heck Ive even seen a computer simulation to find the sweet spot with graphs and trigonometry I think. :S

Josh has posted the goto quick reference video addressing this and other issues. Im still going back and catching little tidbits each time I watch it:

Hope that helps! I personally adjust the angle of the knife in the vise as shown in the video & lock it down. Then I use the angle cube to adjust the sharpening angle, lift it off and place it back to double check, and then I lock that down and move on with my process.

Yea when i place the stone back on im gettin anywhere from like .5-.8 of a difference. How much wiggle room do you have before you start making a noticeable difference? .5 of a degree? 1 degree? Thank you for the video i will be trying that tape trick next time and update.

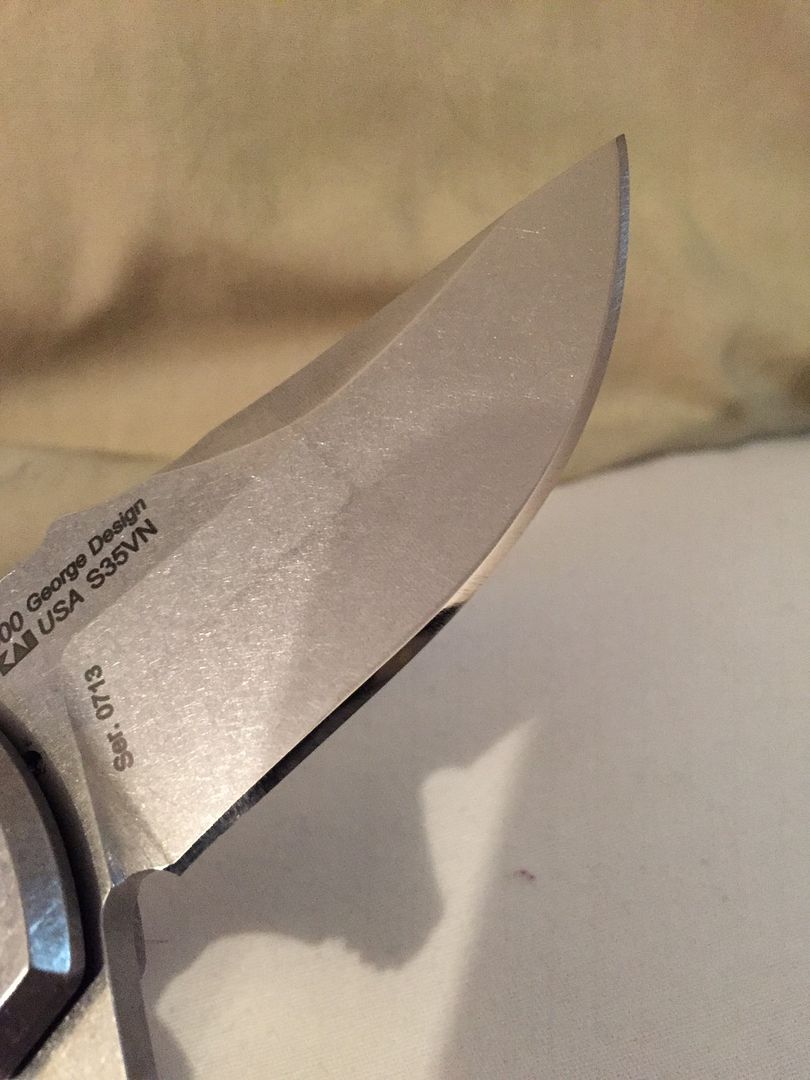

02/18/2015 at 12:50 am #23500I had to lap the micro fines as well as the super fines. The micro fines took forever to lap. They are extremely hard. I also had to start at the 100’s and go up to the 1000’s to smooth them out. But now I get edges like this with them!!

Sent from my iPhone using Tapatalk

So your getting an edge like this by doing diamonds grit 100-1000 then ceramics super and micro fine? Are you using any leather strops after?

02/17/2015 at 11:00 am #23482Nice pictures. Thank you. I think i will probably end up trying the 1200,1600 and go from there.

-

AuthorPosts