John Harms

Forum Replies Created

-

AuthorPosts

-

03/21/2020 at 10:34 am #53789

Here’s another shout out for Ed’s (NotSharpEnuff) upgraded micro adjustment kit.

I recently bought a WE130. Used it for a while and noted the items that I personally wasn’t that satisfied with. They fell in three primary areas – fine angle adjustment; ease of adjusting angles; angle accuracy.

Most of my sharpening is on kitchen knives and pocket knives. I also knew that I wanted to re-profile most of my knives with different angles as I’m not hard on the kitchen knives and I use them constantly.

The first thing I did was flip the angle bar so I had infinite angle adjustability and no visual aids when setting the angle. That also forced me to use the angle cube all the time – even when changing grits.

Recently I bought Ed’s micro angle adjustment kit with the “L” arms and the RC dust covers – one for each arm and one for the center tension arm. Wow, Ed supplies a great kit! There are lots of pics already here, so I won’t post mine as they’d just look similar to everyone else’s.

During Ed’s and my email exchange we chatted about longer adjusters. He included them with my kit and I gotta say, I really like the extra room to dial back the stanchion jam knob, fine tune with the longer bolt, then tighten the jam knob. Easy peasy and lots of room for my fingers.

Though I haven’t done it yet, I could shorten the “L” arm bolts about an inch or so – as supplied, they are ~2.5″ long and don’t really need to be that long. For those that push the arms to the rear, that might be an option.

As a practice, I keep everything running towards the front of the WE. More a safety precaution as I like my fingers and don’t really want any accidents. Plus I keep and return everything to the pelican case that I bought with the WE.

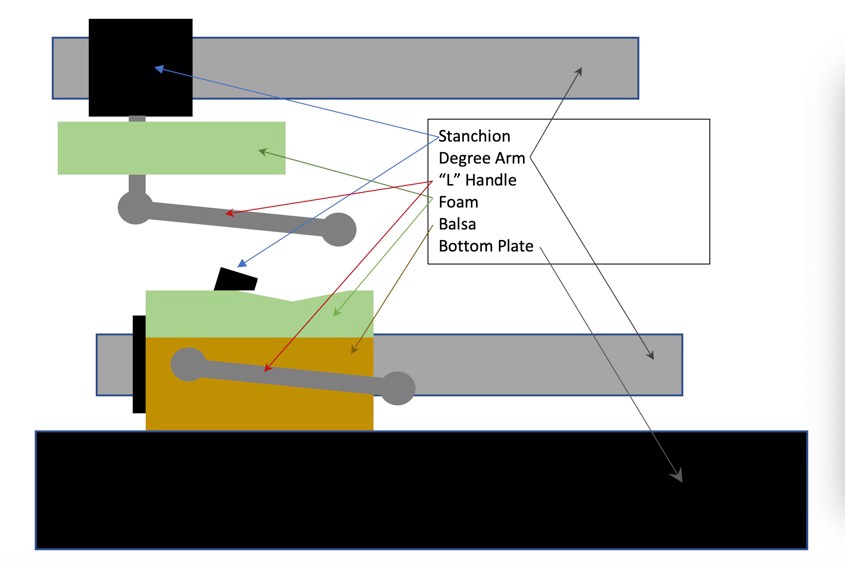

However, I’m working on getting some 1″ x 1.5″ or 1.5″ x 1.5″ closed cell foam blocks and running the “L” arm bolts through the foam, then into the stanchions – thus having the arms rest on the foam as they lean towards me. They can’t rotate because there would only be a thin section below the bolt and the the table, and at 1.5″ tall, the blocks would be at the perfect height to rest the arms on when changing grits or inspecting the blade.

I’ll probably make a couple different versions to try out to see what works best. If it does, I won’t shorten the bolt and I’ll post pics here. I’m thinking a block with a shallow “V” cut in it.

If the screw hole is too close to the bottom, I may buy some 3/8″ balsa for the bolt hole and glue the foam on top as the rest. Depending on the depth of the foam, I may also need to use a standoff from the stanchion to ensure access to the micro adjusters is retained.

Again, pics of the rest once I make it.

John

Here’s what I’m thinking. Looks like a Hobby Lobby run tomorrow – if they’re open that is!

-

This reply was modified 5 years, 1 month ago by

John Harms. Reason: Added a drawing of what I'm thinking for a front arm rest

John Harms. Reason: Added a drawing of what I'm thinking for a front arm rest

-

This reply was modified 5 years, 1 month ago by

John Harms.

John Harms.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

-

This reply was modified 5 years, 1 month ago by

-

AuthorPosts