Cliff Stamp

Forum Replies Created

-

AuthorPosts

-

02/03/2015 at 6:25 am #2308401/17/2015 at 2:48 am #22747

Those are some very detailed shots, what exactly did you take them with?

12/05/2014 at 11:04 pm #21811Have you make a comparison of the performance between the flat (perpendicular) grind and the steep micro-bevel?

Note a steep micro-bevel will turn into a flat as you increase the angle, a flat is just an apex ground at 90 dps. I have not looked into the question which may be of interest which is what is the exact apex thickness required to prevent that initial early edge loss. This isn’t because it isn’t an interesting question, in fact for many people it might be the exact question they are interested in – however it isn’t of critical importance to me due to how I use knives in general.

Personally for example I would rather sharpen a knife which can cut 1/2″ hemp with 5 lbs on a draw and sharpen it after say 100 cuts so it never gets more than 10 lbs. I would not sharpen it so it starts at 10 lbs but can do 1000 cuts before hitting 20 lbs. Now I am using hemp more or less as an example here as the numbers are straightforward and everyone can cut a piece of hemp. But in general I prefer knives which are ground to cut very well and sharpened for the same.

When I sharpen garden tools for digging, depending on who I am sharpening them for, I will either run a light flat (20 microns thick) or a visible flat (50 microns thick). It mainly depends on how much force they use and the kind of ground. If I don’t know anything about them I just do the 20 micron flat first and when I sharpen them again I just look at the edge and then ask them a few questions. If they note they saw early degradation and there is visible damage I will thicken it. By they way the reason I pick 20 microns is that is how thick an apex gets when I can see it.

For sod knives and similar I do xx-coarse finishes and cut the edge bevel as low as it can get and not deform and thin out the primary the same. Again this depends on the individual but if you make an effort here you can really see large practical gains in cutting ability which will keep the blade cutting a long time. If the cutting is light and the soil is not so rocky I have gone as low as :

-0.015″/5 dps

With a 36 grit microbevel at 16 dps, this stays very aggressive for a long time and is so easy to sharpen that a lot of people will do it themselves. When I get it back normally the knives have thickened so that much of the 5 dps edge bevel has been consumed by the repeated applications of the 15 dps / 36 grit edge.

Now if the weeder is a lot more aggressive I have gone up to :

-0.025″/10 dps

and I don’t run a true micro-bevel but another bevel at 20 dps (again at 36 grit) which is big enough to see. The trick as always is just set the thickness at the point where it stops deformation. This maximizes cutting ability and maximizes the amount of wear it takes to reduce sharpness to a specific level.

[…]

Based upon this reasoning, could we not say that, when it comes to push cutting through hard objects, a 17 dps mirror finished edge would theoretically have the same edge retention as a 15 dps coarse edge?

If the apex isn’t deforming, then the 15 dps edge will have higher edge retention, if the apex is deforming then it will be the 17 dps edge. The reason this happens is that a lower angle will require more material to be worn away to reach a given apex thickness (which is what determines dullness).

12/05/2014 at 6:00 pm #21802Why would the steel be too weak at a high grit higher angle micro bevel thanks low grit lower angle?

A low grit finish will generate a much thicker apex than a high grit edge which is one reason why a low grit apex will be stronger (resist lateral deformation) more than a high grit edge at the same micro-bevel angle. However the main issue is the type of cutting which is why I started with “If they are slicing soft materials (cardboard, ropes, foods, etc.) …” . In this case the apex will typically not be under high loads to deform it, it will dull mainly from slow abrasion. To combat that, use a low grit edge to make an irregular surface which will take a lot of abrasion before it is worn smooth and stops cutting and use a low angle apex to both enhance the roughness and maximize the amount of wear required. Because the loads are small the angle you can use can be very low and there is no real risk of deformation.

However if they are push cutting hard materials this type of finish won’t work because the apex will come under heavy loads to try to deform it and if you use a low angle and finish the apex with a low grit finish it is very likely to collapse almost immediately. For example that finish in the above which easily slices though ~2000 piece of 1/2″ hemp will fail dramatically in less than 10 cuts if you try to push cut because the forces will be so high that the apex will just deform and can crack right off. In order to make the apex perform well under cutting that type of material you have to raise the polish and then increase the angle to prevent it from deforming. Now of course continuing to increase the angle past the point it stops deforming doesn’t help. It is just that this point will be a lot higher in push cutting a hard material vs slicing a soft one.

Now there is a sort of semi-trick you can use which is to pre-dull the edge, this creates a not-sharp edge which stays not-sharp for a long time. What you do is sharpen as normal to a high polish, this will form an apex of < 1 micron and be very sharp. You then take the knife and very carefully, grind the apex back to a small flat. This can be done by making a small pass against a very fine stone, cutting light sandpaper etc. . The critical part is you want to grind the apex into a small flat. This flat is very durable and resistant to deformation and fracture and will just dull by slow wear. Now it won't be super sharp, but it will stay not-sharp for a long time before it gets super dull. What you are trying to do here is avoid the early fast lost of sharpness as that < 1 micron apex will deform/fracture and turn into an irregular surface. Another way to approach this is to apply an extremely high micro-bevel which is very light, say 1-2 pps only at say 45 dps.

If you sharpen knives for yourself, if you have decent steels, well you are not going to want not-sharp knives which are semi-dull for a long time, you want actually sharp knives which cut very well for a long time. But if you look at knives a lot of people use they are mainly used in extremely dull states and thus how to sharpen them for optimal performance for them is a bit of a different process.

12/04/2014 at 10:22 pm #21781Why doesn’t the very muddy stone result in a rounded or widened apex, or if it does why is that an ideal platform?

Good question, I didn’t actually discover that intentionally, it was more or less an accident. I often experiment with stones that do something poorly to try to understand what they can do well. I was working with stones like the Naniwa Aotoshi which is a very muddy 2000X stone :

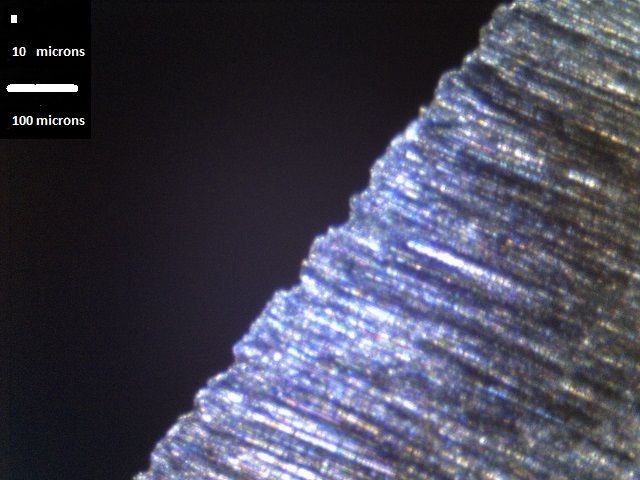

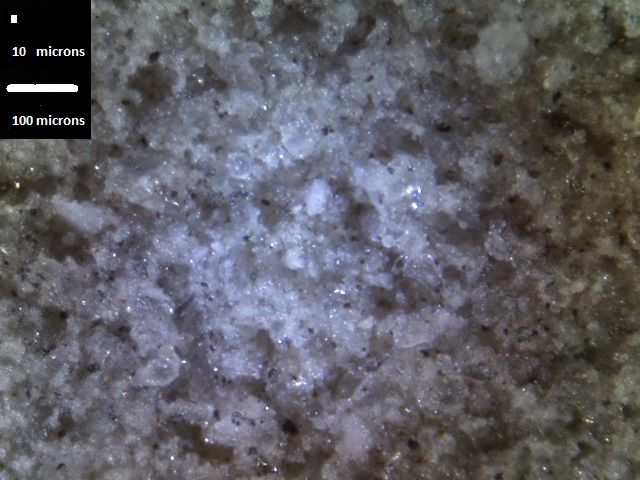

and while it produced a very nice finish to look at and was very smooth to touch, actually getting the apex to form sharp was not at all trivial. I ended up retreating to just flushing the stone, removing the mud and running it almost like a DMT plate. However in a few cases, where I was not fooling around and was actually sharpening for practical purposes I was using the Naniwa to bring the edge bevel up a set in polish from say a Bester 700 so get it ready for a micro-bevel with a Spyderco plate. I started to notice that the micro-bevel was setting much cleaner, meaning that few passes produced a higher sharpness. I then started looking at the prep edges from the muddy stones and they would go from this (Bester 700) :

to this :

That is a < 10 dps bevel on Maxamet, 250 pps on the Naniwa. But here is the curious thing, the Naniwa bevel is significantly duller, thus the apex is thicker -but- it is much more consistent. I then started to realize that the ideal platform I would want to set a micro-bevel would be one which was perfectly consistent and ideally just a few microns-thick at the apex.

Now at this point you could ask – well would it not be easier to set the micro-bevel if the apex was perfectly consistent and 1 micron thick (which would actually be sharp) vs 10 microns thick (which is fairly dull). Well yes, but practically that is very difficult to do, especially when you are trying to be efficient. I thus developed a slight modification to the normal three step method I use :

1) cut the apex off

2) do all necessary shaping, form an apex

3) micro-bevel

to

1) cut the apex off

2) do all necessary shaping, almost form an apex (light starts to disappear from the apex in reflection)

2.5) apex on a very muddy stone

What this does is prevent a burr from forming, keeps the apex from being damaged, and makes a small flat, ideally < 10 microns thick which is then ground away by the next step which is :

3) micro-bevel

Now to be clear here the micro-bevel I am setting is semi-coarse meaning it is typically in the ~5-10 micron range. If you want to produce a very high finish micro-bevel with ~1 micron style hones this won't work because it would take forever to actually set a micro-bevel with a 8k stone if the apex was ~10 microns thick. If I want to end up with a very high polish I use a slightly more complicated process again :

1) cut the apex off

2) do all necessary shaping, almost form an apex (light starts to disappear from the apex in reflection)

2.5) apex on a very muddy stone

2.5a) bring the sharpness up to ideally just below push cutting newsprint with a only sightly muddy stone

3) micro-bevel

For example I have some very nice semi-hard waterstones in the 2-4k range which work well for that and allow a micro-bevel with an 8k stone. How much/involved you have to be here really depends on the steel. Doing this with AEB-l/62 HRC can be trivial, 70 HRC MaxaMet, not nearly so as it is MUCH harder to grind and thus you have to have a much thinner apex to allow the micro-bevel to form.

How do you keep the blade in even contact with only 5-10gf on a coarse stone?

Easy, I just did it a million times.

Initially as you drop down in force it is hard to make constant passes because you are used to feedback from the stone/knife. If you jump from ~1 lbs to five grams it will likely make the passes very erratic, just keep reducing them gradually.

Is it the case for such a steel that it will not hold a truly sharp edge no matter what grit it is formed on? What is the most practical way to finish such a knife?

If they are slicing soft materials (cardboard, ropes, foods, etc.) it isn't hard, just do this (low angle, low grit) :

The apex is so coarse that it takes tremendous amounts of material to wear it down and the "teeth" are so big they are strong enough not to deform/break. This is the same edge after 1000 slices through 1/2" hemp at ~10 lbs of load :

I did ~1750 slices and could not get it to stop slicing newsprint. This was on a $1 "surgical stainless" kitchen knife.

If they want high push cutting performance then you can apply a very high apex angle (still need a low edge angle) but even that will only go so far because the steel will simply be too weak and the apex will both deform/wear/fracture on poor steels.

The only real option you have is to try to optomize the primary grind to reduce cutting loads and try to expand the life of the edge both directly (reduced loads = less strain on the apex) and indirectly (the knife will cut better when duller if it simply cuts more efficiently due to geometry).

12/04/2014 at 7:55 pm #21779what grit is that stone?

That is a Naniwa Superstone 400 but the grit ratings on those are a bit misleading hence why you always hear the same two things about them – they cut very slow and they produce a very high finish. This is not because of the abrasive specifically but what I assume is the binder because the stone breaks down to form a very thick mud which is like a colloid in that it doesn’t settle (or does it very slowly). It thus produces a very different scratch pattern if you use it dry or if you use it with just enough water to build up a thick slurry. The difference is very dramatic compared to something like a Bester 700 which doesn’t have this kind of behavior unless you really force it by using say a diamond stone to grind down the stone and generate a mud, the Naniwa will do it as you sharpen.

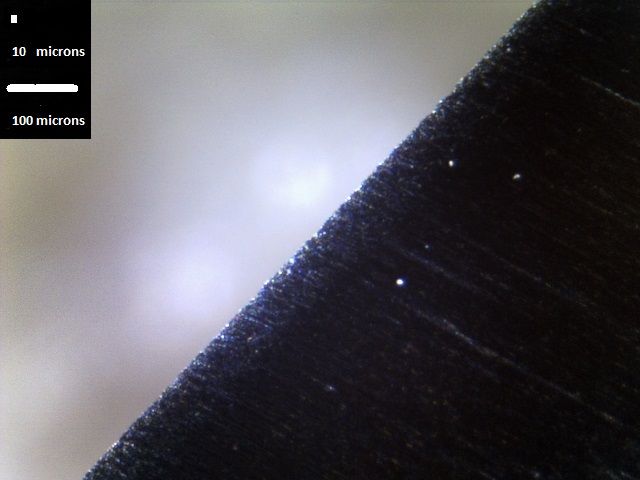

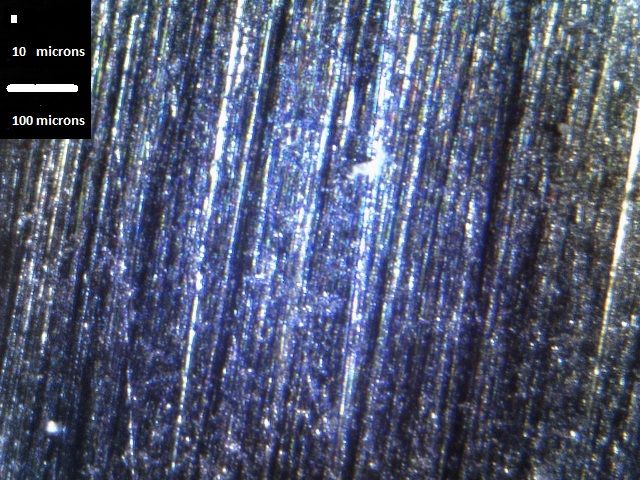

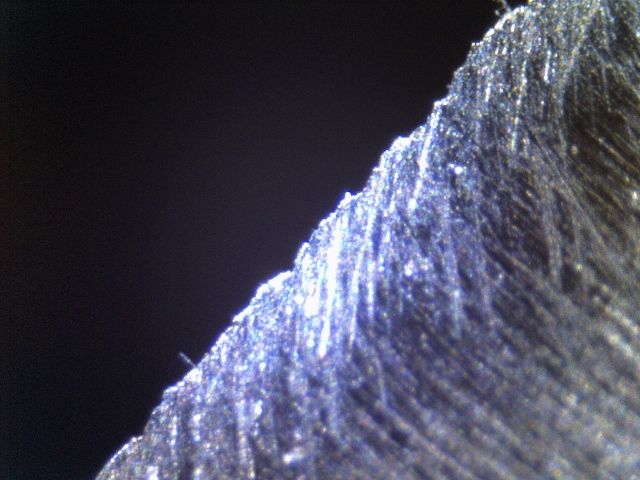

That is the Naniwa 400 and this is the Bester 700 :

They look similar and when use freshly surfaced and clean they produce very similar scratch patterns. Here are 50 passes done on a mirror polished piece of 1095 (the black background is the mirror polish, the white lines are the scratches from the abrasive) :

vs

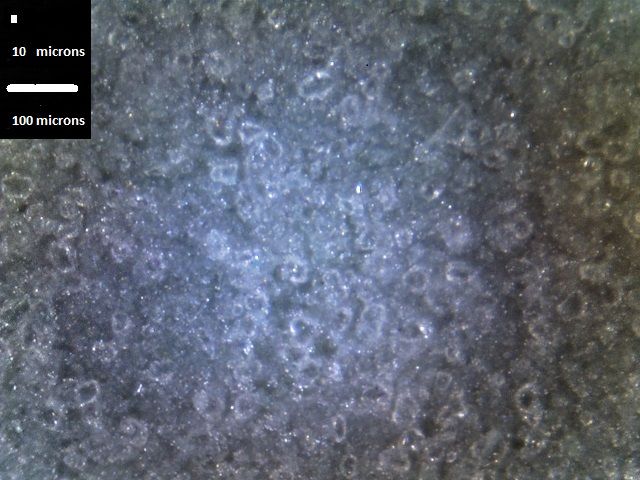

However if you just use the Naniwa a little the surface looks like this :

Note how the abrasive is starting to get masked. This produces a dramatically different type of finish :

I assume this is because of the random honing action of the very thick/consistent slurry mud. This is why that type of stone is really praised by the guys who do Japanese style sharpening as even in low grits it produces a very smooth almost satin like feel to the large and wide grinds they use and it is a non-reflective, very subdued surface, no harsh glares.

With water stones one of the benefits is that you have slurry/mud that you can work with and actually use to produce a higher finish than what the stone actually is if you know what you are doing.

When I am shaping I can and often do use the stone with a thick slurry/mud to prevent burr formation as I approach the apex, or to simply generate a smoother primary grind. But when I am setting the apex I flush the slurry off. It is possible to set the apex with a thick slurry but you have to play a game of grinding down the sides of it at the same time the apex is ploughing through that slurry which is dulling it. It can be done, edge trailing is one way, but I prefer to just flush the slurry off when I am working on the apex itself.

It can be done with some pretty coarse grits, this is one of the more involved ones :

That is a 36 grit aluminum oxide grinding belt, the abrasive is so large I can’t even get it in focus at 50X magnification. It should not be much of an issue once you go above that. By the time you get to finishes like x-coarse DMT, coarse India, etc. it should easily be possible.

[…]

What is the easiest way to reliably get that result?There are two main issues, aside from rare issues such as problems with the steel or obvious problems such as the stones are loaded/damaged :

-the apex isn’t formed

-it is formed but is damaged and/or irregular

It is pretty easy to know if the first is true or not as the edge will reflect light, depending on your eyesight, at a thickness of 10-20 microns. If you can’t see any light reflecting you have either formed the apex or are very close to it, a little more work will ensure it in any case.

The most common problem is that the apex is formed but it is irregular and/or damaged. On steels which are hard to form a clean apex, I resort to focusing on burr minimization which includes things like :

-forming the edge in shaping with a very muddy stone, this ensures the micro-bevel has an ideal platform to start from

-alternate passes

-flush the stone

-go very light (as in down to 5-10 grams of force being applied)

-very sort strokes (as in an inch of travel)

-cross the scratch patten/strokes

-increase the angle dramatically (double it) to cut off any damage

It is only in rare cases that you would have to do all of these and quite frankly when you do it likely isn’t practical because if you have to do that to form an edge which is really sharp it is likely it won’t hold it anyway.

The biggest thing though, which sounds silly, is just accepting it can be done. If you think it can’t, or if you think it is very difficult, then it is very likely your brain will make exactly that happen.

11/30/2014 at 2:47 am #21647…. The results are interesting. I love the teeth from the 140 but I get the polished sensation when I feel the edge.

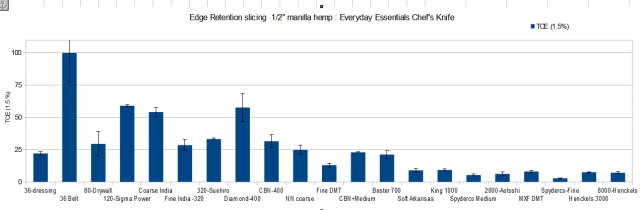

I think that is an interesting way to approach getting a medium coarseness edge. I recently did a little work with it while looking at the edge retention of various grit finishes with a 3Cr13 knife :

If I took the CBN finish for example (Sharpmaker rod) and then started working it with the medium grit rods then the initial sharpness and edge retention would move from the CBN directly towards the medium rod finish. It is a way to basically get an “effective” grit from a a narrow range. However I am not sure that if you had the grits it would not be simpler just to micro-bevel at the intermediate grit. But the two would not be expected to be identical.

11/30/2014 at 2:42 am #21646[…]

But if you use a stone properly, is there any way in which a higher grit stone can dull an edge sharpened at a less high grit?If you use a stone properly then almost by definition it can’t happen, but “proper” use of some stones is not trivial at all.

If a stone is very muddy for example then that slurry tends to make it very difficult to prevent an apex from rounding. If you want to see this happen fairly easily then take a King 1000 and try to get an edge which push cuts newsprint. The stone will put a very high finish on the sides of the edge but it can be really difficult to actually refine the apex as the stone is so soft and muddy. I like a King 1000 to preset an apex before a micro-bevel, but would never pick it to actually apply one unless I wanted some kind of challenge or amusement.

11/28/2014 at 11:13 pm #21623… I went to cut some paracord to see how it would perform and though it will easily push through it, the cord would slick along the length of the edge. This was extremely sharp but not aggressive enough though you could feel the ‘grab’ when you felt the edge with your finger.

As an honest question, why would you call the edge sharp if it just slid along the paracord? Put it another way, if you left an edge really coarse, and after use it had dulled it would likely do the same. Both edges can’t cut the paracord, why is one dull and the other one sharp when they both physically behave the same way if you try to slice the rope?

Here is a simple experiment :

-take a piece of rope (or something similar)

-sharpen a knife with a very coarse grit, say 36

-make a slice for a specific length and record the amount of force usedNow increase the grit and repeat until very high grits (8k+) or you become bored. The force should keep decreasing until it hits some point at which a draw isn’t needed as it will just sink through the rope once that force is applied.

If at any time it slips then the knife didn’t get sharper, for some reason it was dulled by the higher grit, often through apex rounding. Now a lower grit finish in some cases may (will) produce higher edge retention, but it can’t produce higher initial sharpness.

The main reason it is often argued that it does is because there is an over reliance of strops/buffers to produce polishes which tend to rounding apexes. Often was is being compared then is a coarse edge with a V-formed apex vs a polished edge with a rounded one.

As a point of interest/reference, with 1/2″ hemp you should be able to do a cut with a 2″ draw with a load of 4-5 lbs with a very sharp edge (with a thin cross section). With a very coarse edge the force will by higher, ~10 lbs with a 36 grit edge.

11/26/2014 at 11:33 pm #21567In addition to the comments above consider that the factory edge bevel isn’t necessarily uniform in angle along the length of the blade, therefore establishing a uniform angle may widen it in places.

Yes and even worse the primary isn’t likely even either especially on more inexpensive knives.

11/26/2014 at 5:34 am #21528On the other hand the J knife might cut cardboard more easily, depending on just how blunted “dull” is. And the J knife would be a much better choice as a cheese knife.

Exactly.

Think of cutting ability as that which measures how much force a blade requires to make a cut. It all gets pretty simple then as there are three basic forces :

-the force right against the apex, some materials are very hard to start a cut (sharpness)

-the force to push material apart, some materials are very rigid (blade cross section)

-frictional losses, some materials are very sticky (this is related to but not equal to the second term)

A carrot does not take much to start a cut, you can even just push your thumbnail into it, thus a blade doesn’t need to be very sharp to cut it well. But a carrot is very rigid and thus a thick blade will break the carrot and requires more force. A carrot in general isn’t very sticky and thus there are no frictional concerns.

A piece of rope is very hard to start a cut, you will not be able to push your thumbnail into it (unless you emit gamma radiation). A knife has to be decently sharp to cut rope well. However rope tends to fall apart much more so than a carrot and thus cross section isn’t as critical. Rope isn’t very sticky at all.

A wet potato also isn’t hard to start a cut, but is very rigid and also sticky (starch is used to make glues). Thus a very thin convex profile works very well (or a relief hollow ).

Ideally you want a knife which is sharp, doesn’t bind and is resistant to sticking to cut a broad spectrum of materials well. But specialty knives can ignore 1 or even 2 factors if they just cut very few materials.

—

As an aside, those properties of the materials are actually measured by the rupture pressure, Young’s modulus and coefficient of kinetic friction.

11/25/2014 at 4:35 pm #21510If so it would be helpful to think of sharpness (rather than over-all cutting ability due to geometry) as experienced by cutting something infinitesimally thin as there only the very edge (apex) is contacting the material.

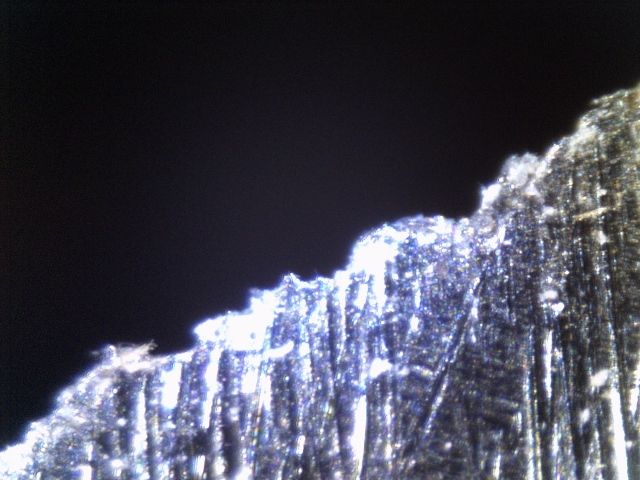

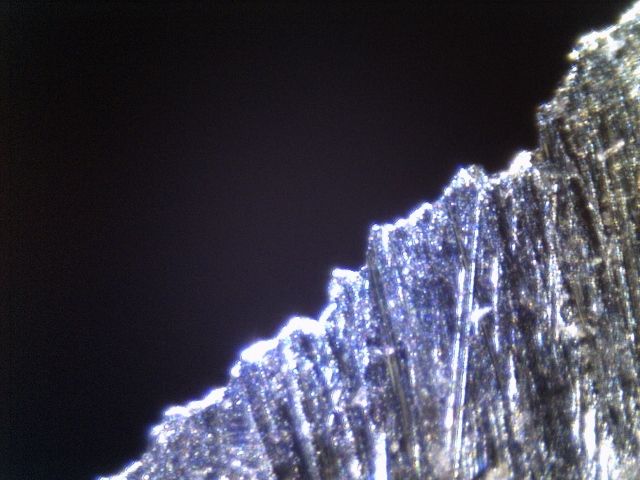

Exactly right, and that is why this is sharp :

and this is not :

But everything is the same geometry wise except for the condition of the very apex.

The first picture is the apex at 15 dps off of a new fine india stone (edge is at 5 dps). The second picture is ~500 slices through 1/2″ hemp later. The knife is much more dull (sharpness, < 1.5% of optimal) but the only thing which has changed is the apex itself.

11/25/2014 at 5:30 am #21490This is confusing.

The main reason people get confused is because they meld sharpness and cutting ability together which leads into odd places when they start talking about things like edge retention which is how the sharpness changes, not the cutting ability.

…some steels could easily be made razor sharp but during use, the razor edge would go away fast but the edge would settle down and still have a very sharp “working edge” for a very long time.

All steels behave like this, it is just the math of how they wear. It comes out of the physics which at a basic level is due to the fact that the more blunt a blade is the harder it is to blunt it further. This when wrote as an equation has a solution which looks like this :

Sharpness (at material cut of length X) = Initial Sharpness / (1 + C * amount of material cut ^1/2)

In reality the power isn’t exactly 1/2 because of things like damage which are pseudo random in nature. I wrote an article on it a long time ago : http://www.cliffstamp.com/knives/articles/model_edge_retention.html .

11/25/2014 at 5:24 am #21489[…]

Will a lower angle have better edge retention?

It is critical here that you differentiate between push cutting and slicing as they are not dependent on apex angle the same way. Yes at some point the apex angle will be so low it will not have the strength and it will buckle, hence if you start decreasing the apex angle at some point the increase in slicing edge retention will reverse and at some point it will disappear completely. The same relationship is seen to a lesser extent in apex bevel thickness but in this case a lower thickness increases both push and slicing edge retention until the point it is too thin and it again collapses.

11/25/2014 at 2:51 am #21470But for all intents and purposes when you lower the apex angle (as long as you have a true burr free apex) then it will feel much sharper when cutting through any given medium…no?

It may cut better, it depends on what and how you are cutting, but that isn’t really what you take sharpness to mean. I can prove that to you with a few simple questions.

Lets say you looked at me and I was cleaning some pine pitch off of a blade and you asked what I was doing and I said I was sharpening it would you agree with me? It is likely you would not, but what about if I said “Well the knife will cut wood much better with the pine pitch off of it so therefore it is sharper.” Just like for example if I modified the handle so I had better control it would also allow me to cut deeper/easier but again would you agree that I sharpened the blade by doing that?

The actual meaning most people think about is actually the same as the actual definition in the literature, most people just have a hard time putting what they think into words. But that isn’t just about sharpness it is a problem with trying to go from how we think about things to some kind of rigid definition because we don’t actually think in those terms.

If I gave you a knife where the apex was rounded and you could easily move your finger up and down it you would likely call it dull. If I showed you that it could cut a carrot much better than a big bowie which was razor sharp you would not accept that the bowie was not in fact sharper you would likely say something like “well even a dull knife could cut a carrot”.

Here is the most simple illustration :

-grind an edge at 25 dps to the highest standard of sharpness you can achieve

-grind an edge at 10 dps to the highest standard of sharpness you can achieve, now make one cut right into a 1000 grit stone

Which edge is sharper, everyone will jump and say the first one.

Sharpness is a property of the apex, specifically a sharper blade produces a higher contact pressure at a given force. To look at it mechanically, when you cut there are a number of forces you have to over come :

-frictional losses

-direct mechanical losses (you have to compress or move some material)

-rupture (you have to break the material)The last one is what sharpness controls. That is the technical term, but that is really what everyone means, the problem is when they try to make a definition they end up saying something that they don’t really mean. But again this is actually really hard to do. If you want to see how hard then try to define a game. It is pretty easy to keep listing things which are games but don’t fall into your definition. This problem is so hard because we don’t think the way we talk, if you try to talk the way we think it gets much easier.

-

AuthorPosts