Will’sMods Part 2

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Will’sMods Part 2

- This topic has 15 replies, 7 voices, and was last updated 03/30/2014 at 9:32 pm by

Eamon Mc Gowan.

-

AuthorPosts

-

03/24/2014 at 10:16 pm #17919

Will came up with some neat mods for the WEPS. From my perspective they are valuable because they make adjusting angles easier and faster for my arthritic hands, but in truth for any hands.

In the first part I illustrated the over-sized adjusting handles/screws that make locking in the angle a breeze. They work beautifully. There is however one drawback in having them and that is that the black-handled hex driver for tightening the vise screws is very awkward to get in and out of its slot because of the large metal levers that you see for locking down the angle are in the way…awkward enough that I now have found somewhere else to keep it.

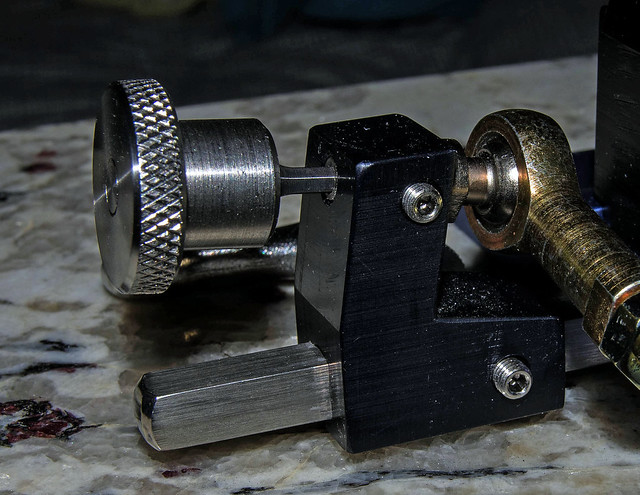

On to the micro-adjuster. This is also easier to work with because of the unique screws Will uses to do the work. Once again, very neat mod. Take a look at the whole assembly on the right hand side.

You can see the configuration of the micro-adjuster changes with the addition of the larger knurled adjuster that fits into the end of the block. Set screws are provided for the front and the back. These are tightened then backed off a quarter turn…they provide enough grip on the initial setting until it can be locked down with the large knurled knob.You can see the back set screw in place and as well one Will provided for the angle setter for the same reason i.e.to hold the chosen angle steady while you get around to locking it in. Are there any cons for this mod…not really unless you don’t like the change in the symmetry of the WEPS.

OK, two down and one to go. I will do the thin blade support so you can see how it fits on and then go over the Pros and Cons of the mods from my perspective.You may have other observations to add to what I have said, please add your thoughts.

Leo

03/25/2014 at 12:19 am #17920I should add here, that making a micro-adjustment with the larger knurled knob delivers a very positive action because its circumference is bigger and so, once you get used to it, you can more accurately get the adjustment you want…of course easier too.

By the way Leo the Nav, I still haven’t vacuumed my stuffand won’t until I do a complete wobbly knife or two with this modified rig to see how well it can stabilize a blade for sharpening.

Cheers

Leo the ancient03/25/2014 at 1:11 am #17927Looks like it is going to be an absolute pleasure to use.

Leo Nav

03/25/2014 at 11:44 pm #17948I have been using this “new” system for about three months now? I got to tell you once you get used to it there is no turning back! One more thing I did (and it’s free) is turn the angle bar around so the little divits are on the back side. This makes for much faster angle setting. The down side is you can not use the pre-marked settings, but I cheated and used a sharpie and made a line for 20°. This gets me really close and with the angle cube attached it is quick to get the angle desired.

My blade stabilizer shows up today and then I will add my 1.5 cents.03/26/2014 at 1:16 am #17949I think these mods should in an ideal situation become standardised for the WE ; having spent a small fortune over the last few months on both bench stones diamond plates,and the WE I can not justify much more outlay just yet since I still have to get the SWATS , the DMTs and films for ceramics and possible a jig for scissors these little tweaks will have to wait .

I think they are a great shall we say Pimp for the WE and anything that cuts down time setting up is a real asset for either power users or people whose dexterity is perhaps not what it was .

Adding say Will’s mods and the SWATS is like race tuning the WE.

I think it is proof how the WE is such a good product in that it keeps evolving which is great to think that it is likely to see a lot of evolution ensuring its presence in years to come .03/26/2014 at 11:56 am #17950I can honestly say since I have them, these are very useful mods Leo, but to standardize them and stay to the quality of material and workmanship now found in both the WEPS and these mods might drive the retail price prohibitively high. As you would see if you had Will’s stuff in your hands, they are heavy duty,very high-quality items. We already know that about Clay’s original rig.

So to your point if I interpret it correctly, it would be very nice indeed to have these and the WEPS as standard, but is it possible to do and stay reasonably competitive, I would hazard not.I see them as add ons. Clay could say better than I for sure.Cheers

Leo03/26/2014 at 11:58 am #17952I have a similar system, using an Allan screwdriver I bought from McMaster-Carr. I suppose I could cut the length down, but it feels fine as it is. I’m not absolutely sure, but I recall calculating that one turn of the screw equals about 0.4 degrees, so one quarter turn works out to about 0.1 degrees.

BTW, I clipped a small bit of wire insulation and put it under the locking set screw. With a little pressure on it, the adjustment screw stays put, doesn’t bugger up the threads.

Attachments:03/26/2014 at 12:10 pm #17953Yes I think you are right although it would be good if WE sold these as tweak up kits amongst the accessories like the SWATS , chisel sharpener etc.

Leo Nav

03/27/2014 at 11:35 am #17958I agree, Leo. It would be nice if WE offered more of the little enhancement tools as accessories and the knurled knob is an excellent candidate.

Having nothing better to do with my time, I checked and can confirm that one turn of the micro-adjust screw does produce a hair under 0.4 degrees of change. There is enough range of adjustability to go +/- 1 degree or so.

03/27/2014 at 7:43 pm #17962I’ll talk to Will and see if he has time and wants to make these mods available for sale. I’d be happy to carry them. If not, I’ll see if he objects to us having them produced.

-Clay

03/27/2014 at 10:10 pm #17964Good idea Clay! Makes sense.

If you do end up manufacturing them, check and see if the Allen head shaft on the knurled micro-adjuster knob can be shortened a bit. They are a mite too long as they are for the symmetry of the whole rig…purely for the look though, so if it is difficult that can be ignored I guess.Cheers

Leo03/27/2014 at 10:19 pm #17965I’ll talk to Will and see if he has time and wants to make these mods available for sale. I’d be happy to carry them. If not, I’ll see if he objects to us having them produced.

Way to go Clay! Also what is VERY nice that he has is the ratcheting lever locks for the degree bar. I just love mine! It makes it so much easier and faster!! B)

03/29/2014 at 2:02 am #17992Installed Will’s mods today. Very easy and quick process. I did spend the time to flip the angle bar as Eamon McGowan did, and it makes for a very smooth angle setting process; although the slack adapters included in the mod kit weren’t as effective in this configuration. With the secure lockdowns provided by the mods the indentations are no longer a requirement. I did do something that I hope I don’t regret later… dabbed a tiny amount of super glue on the tips of the micro adjusters and they seem very secure now. I believe that I could get them out if it ever became necessary.

03/29/2014 at 4:59 am #17994“I hope I don’t regret later… dabbed a tiny amount of super glue on the tips of the micro adjusters and they seem very secure now. I believe that I could get them out if it ever became necessary.”

I hope you don’t regret it too! :ohmy:

Actually the large micro-adjusters will fit snugly I discovered when I e-mailled Will, but they just need to be given a bit of a push in so the retaining ring grabs the end of it. The glue shouldn’t be necessary…at least not with my set.Cheers

Leo03/29/2014 at 7:26 am #17998Acetone will dissolve a superglue problem.

-

AuthorPosts

- You must be logged in to reply to this topic.