Why convex isn’t a “stronger” edge…

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Advanced Techniques and Sharpening Strategies › Why convex isn’t a “stronger” edge…

- This topic has 18 replies, 5 voices, and was last updated 08/05/2014 at 12:41 am by

Josh.

Josh.

-

AuthorPosts

-

05/13/2014 at 2:23 am #18691

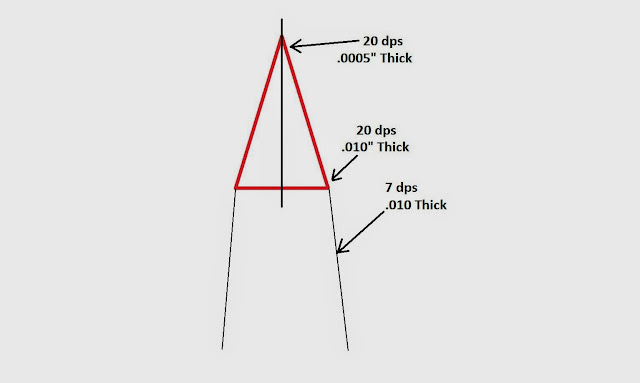

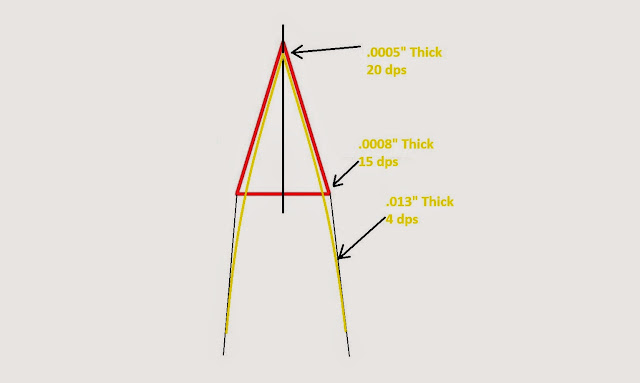

so I got to thinking about it and drawing it up and this is how it makes sense to me… I don’t think a convex edge is any stronger IF you are still having the same edge angle at the edge of the edge. Convexing your edge will somewhat help with binding and make it a little thinner at the shoulders (which may help slightly with cutting ability). The reason why people say it is stronger is because typically they actually make the very edge bevel wider instead of simply removing the shoulders. This is my theory anyway, what do you think?

05/13/2014 at 10:33 am #18699

05/13/2014 at 10:33 am #18699Hey Josh,

You’re my mate!

I was thinking exactly the same some time ago and wrote a blog post about it. What is the use of a convex edge?[/url] It’s based on an an earlier discussion here.

I think there are some myths and some truths preserved in the knife community about convex edges. One of them is that a convex edge is stronger. I think this is a rather meaningless phrase: stronger than what? Exactly what you say.

The blog post was rather controversial when I wrote it and resulted in quite a row in a certain community, but I still think it is completely right. Everyone should make up their own mind, but I think we think exactly the same.

Molecule Polishing: my blog about sharpening with the Wicked Edge

05/13/2014 at 6:07 pm #18700I mentioned elsewhere a brief conversation about sharpening I had with Adam & Haley DesRosiers. Murray Carter joined for the last couple of minutes of the conversation.

He didn’t disagree with Haley about convex edges being the “true” edge. (Neither did I, for that matter.)

Since then, I’ve found an electronic version of one of Murray’s books on knife design I was able to download to my Kindle. In it he definitively states, from his perspective, that the simple, true triangle is the strongest blade.

Hmmmmmm.

Thanks for the links to articles & blogs….

I am in need of more education and, especially, more experience.

~~~~

For Now,Gib

Φ

"Everyday edge for the bevel headed"

"Things work out best for those who make the best out of the way things work out."

05/14/2014 at 11:09 am #18714I generally agree with each of you but I do think there is some merit to each claim.

We look at convex edges as a means of strengthening what would otherwise be a fragile, slender, low-degree edge. Edges get dull for three reasons: first there is simple wear at the apex; second, there are chips caused by excess pressure applied to an overly-hard and brittle edge; and third, there are dings (or dents if you will) caused by excess pressure applied to a relative soft edge. A Wyoming cowboy, when viewing these dents with a microscope, would call them “saddles” along a ridge line.

Convex profiling and micro-bevels address all three modes of failure. They remove what would otherwise be a fragile edge and replace it with an edge with a more durable profile.

I don’t think it’s correct to compare the two in terms of their relative strength. The object is not really to make a stronger edge, it’s to produce an edge which acts like an edge with a more acute angle – a durable edge which cuts better. The claim of added strength is just a bonus, not the purpose.

I’ve just done my first batch of convex edges (all 8″ chef’s knives), which clearly weren’t my best work, but each knife, finished with 1000-grit diamond – then 3 and 1 micron diamond film, with the progressive bevels all polished. After taking each knife to the cutting table and whizzing through some carrots, celery and tomatoes, I was stunned by the improvement over my earlier, single bevel attempts. I think the curvature of the shoulders just behaves better when separating slices of vegetable matter. A disclaimer: this was also my first attempt at microbevels, after which I proceeded to add more bevels to approximate a convex edge. I don’t really know that my microbevel edges wouldn’t have cut just as well.

An edge with narrow shoulders seems intuitively to me to cut better than the same edge with wide shoulders. Profiling those shoulders to a convex form also seems intuitively to me to be an improvement.

05/14/2014 at 11:40 am #18715Having said all that, here’s a slightly different perspective about blade strength.

Last week, I begged my brother to let me sharpen his wife’s IKEA damascus chef’s knife, promising to bring it back having done no harm. Relevant why? Because it was my intent to try putting on a convex edge.

After clamping the blade in my WE vise, I ran my microscope down the edge, recording the video as I went. Kind of a before and after demonstration. Within an inch, I was shocked to find a serious crack in the core material ( VG10 ). I found at least two more cracks further down the blade. The cracks run perpendicular to the edge and extend back into the next layer of steel. The cracks are barely visible with the naked eye.

Here are some photos for your enjoyment:

This is non-magnified view of the first crack:

This is the microscope view of the the first crack:

This is the microscope view of the second crack, just beyond the belly of the blade:

This is the third crack, perhaps an inch or so from the tip:

There is no further identification on the blade other than: IKEA VG10 Chromium Steel. Other than the damage above, this is a lovely knife, especially after sharpening. Lord knows what abuse this poor bugger has seen, but I know it’s a treasured item in the lady’s kitchen. In sharpening it, I didn’t get the sense that the edge material was overly hardened. What do you think caused the damage? Maybe flexing the blade beyond its limits? But so close to the heel?

05/14/2014 at 2:19 pm #18718The convex for say potatoes slicing is better because there is not an angled shoulder to catch so for many cutting purposes convex is desirable( the whole side is good to convex having maximum girth about 2/3rds up then tapering to the spine the this really cuts well so there will be a curved shoulder near the bevel first slow down point then the one 2/3rds up this makes for an awesome profile no definite stopping points.

Murray Carter may well say a v edge is stronger but he admits that certainly with using bench stones there is a tendency for a bevel to have a slight convex even when the intention is to do a V edge mostly he does two bevels when sharpening a secondary followed by a primary it is probable that the secondary will be flat since it has more real estate but the aim is to have a very small primary so this will have a very slight convex to it .

Some knives like a bush knife is best with a complete convex profile from spine to edge since these feather stick best the convex helps to stop the edge steering to deep into the stick05/14/2014 at 2:30 pm #18719I was not aware Ikea did a damascus blade is it made in China like the rest of their knives?

The cracking in the VG10 may be that it has nor been tempered properly after hardening since the tempering lowers the Rockwell Hardness making it more durable and less brittle if someone is going to cut corners on production costs then not tempering enough is a good moneysaving shortcut.

I would hazard a guess that this is the cause of the cracks and I would expect more will follow overtime .

05/14/2014 at 6:06 pm #18720I generally agree with each of you but I do think there is some merit to each claim.

We look at convex edges as a means of strengthening what would otherwise be a fragile, slender, low-degree edge.

That is my point though… it doesn’t strengthen anything unless you are increasing the angle at the edge of the edge somehow

as seen in the photo above, if you are keeping the angles the same the convexing adds absolutely no strength but rather removes some of the shoulders of the edge. As a matter of fact, it would yield less lateral strength on the edge than the V edge would.

Convex profiling and micro-bevels address all three modes of failure. They remove what would otherwise be a fragile edge and replace it with an edge with a more durable profile.

I agree, the increased angle adds strength to the edge.

I don’t think it’s correct to compare the two in terms of their relative strength. The object is not really to make a stronger edge, it’s to produce an edge which acts like an edge with a more acute angle – a durable edge which cuts better. The claim of added strength is just a bonus, not the purpose.

Well people all over different forums seem to make this one of their main objects!

So is this what you are saying: “due to the shoulders being “removed” you can actually increase the angle by a couple of dps and still have the same cutting efficiency”? I would think this *may* be true, but I don’t know how much of a difference it actually would make in real world applications.

I’ve just done my first batch of convex edges (all 8″ chef’s knives), which clearly weren’t my best work, but each knife, finished with 1000-grit diamond – then 3 and 1 micron diamond film, with the progressive bevels all polished. After taking each knife to the cutting table and whizzing through some carrots, celery and tomatoes, I was stunned by the improvement over my earlier, single bevel attempts. I think the curvature of the shoulders just behaves better when separating slices of vegetable matter. A disclaimer: this was also my first attempt at microbevels, after which I proceeded to add more bevels to approximate a convex edge. I don’t really know that my microbevel edges wouldn’t have cut just as well.

So if I got this straight, you put (for example) a 15 dps bevel on your knives, then a 20 dps micro bevel, and another bevel or two in between this range to convex it? if so then this will not benefit you at all with removing the shoulders… because the 15 dps shoulder is still there, unless you stropped a TON

so to see a benefit of convexing, you would actually need to drop your 15 dps down to about 8-10 dps imho, to truly remove the shoulders.

An edge with narrow shoulders seems intuitively to me to cut better than the same edge with wide shoulders. Profiling those shoulders to a convex form also seems intuitively to me to be an improvement.

Since we are on the topic (lol) I will say what I think most people do and actually mis-interpret the results. I have mounted mouse pads to my WEPS paddle and then used psa lapping film stuck to them. I have sharpened a knife on my weps with this set up… know what I found? that even if I set my angles to the lowest possible (where the vise is the limiting factor), to around 14-15 dps, the final edge of the edge angle is >20 dps!!! this was stunning to me. the mouse pad actually wrapped around my edge THAT MUCH. So what I think most people do is use the “mouse pad trick” and sharpen at the same angle (using a mouse pad and sandpaper) and don’t even realize that they are actually GREATLY increasing their angle – which yields to greater edge strength. They are not realizing that they are sacrificing cutting performance. This is why the WEPS is great, beacause it can be precise!

05/14/2014 at 6:08 pm #18721Having said all that, here’s a slightly different perspective about blade strength.

Last week, I begged my brother to let me sharpen his wife’s IKEA damascus chef’s knife, promising to bring it back having done no harm. Relevant why? Because it was my intent to try putting on a convex edge. ….

The pics aren’t coming through… are they for you Leo?

05/14/2014 at 6:12 pm #18722No unfortunately not 1

05/14/2014 at 6:25 pm #18723I did some Globals on an Edge pro and the way I did it was thinned at 10˚ to the edge then beveled the edge at 15˚just a couple of passes to put the bevel on and each subsequent bevel at -1˚ through to 11˚ the work was done with 1200 grit then I stropped out the transitions . Globals unlike Shuns come with a convex and in their literature they claim it goes from 10-15˚ .

I imagine the Shuns are sharpened on a wheel and the Globals on a belt .05/14/2014 at 6:27 pm #18724I did some Globals on an Edge pro and the way I did it was thinned at 10˚ to the edge then beveled the edge at 15˚just a couple of passes to put the bevel on and each subsequent bevel at -1˚ through to 11˚ the work was done with 1200 grit then I stropped out the transitions . Globals unlike Shuns come with a convex and in their literature they claim it goes from 10-15˚ .

I imagine the Shuns are sharpened on a wheel and the Globals on a belt .sweet! I bet that was super sharp and efficient!

05/14/2014 at 7:10 pm #18725I was very happy with the result I did this whist waiting for the WE and having read about a method to convex decided to do it would be a little quicker on the WE probable with the low angle adapter.

05/14/2014 at 7:23 pm #18727I just looked it up on the Ikea website it is the Slitbar series it is 36.48€ but interesting enough it carries a – 25-year Limited Warranty. Read about the terms in the Limited Warranty brochure. So it would be worthwhile seeing if they will exchange it.

I think at the rock bottom price they are made in China .- Core of hard steel that gives a very sharp edge,surrounded by softer steel that makes the blade durable.

For this price it has to be made in China or India I could not find any reference to VG10 steel like a Shun and it comes in a box with a weight of 1Lb so quite a heavy knife unless the box is heavy.

So the cracks could be due to lack of tempering or simple bad tempering.

Still damascus brings out the Magpie in us I admit I have 2 damascus Laguiole 1 Theirs ,a Shun and a Seki cut camping Deba now I actually prefer the look of plain steel especially when laminated so a hard carbon steel laminated with Iron I like seeing the line between the two different metals.Attachments:05/14/2014 at 9:47 pm #18732I should have stayed online to make sure the photos loaded. Strange that they didn’t, as I compressed them quite a bit. Even cropped them. Here I’ll try again. Since Leo already got the right overall, I’ll skip it.

Non-magnified view of the heel area:

Microscope pic of the same crack:

Yes, the knife is heavy. That bolster is a solid chunk of stainless, forged with the blade. The handle looks to be a micarta, maybe of ironwood. Again, I didn’t sense that the edge was overly hard (untempered) but clearly, something’s wrong.

Thanks for looking it up, Leo. I’ll tell her to take it back and ask for a warranty replacement.

Josh, I completely agree with you that the convex cannot be stronger than a normal v-edge of the same angle. I’m simply offering that maybe the claim originally was made as compared to a knife which has an edge angle continued from the same primary grind planes. For example, if the 15-degree grinds had been continued out to the apex.

Attachments: -

AuthorPosts

- You must be logged in to reply to this topic.