Using a Sharpening Steel

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Advanced Techniques and Sharpening Strategies › Using a Sharpening Steel

Tagged: diamond stones, diamonds plates, knife sharpener, sharpener maintenance, sharpening, sharpening steel, wicked edge

- This topic has 10 replies, 5 voices, and was last updated 10/05/2016 at 5:54 pm by

phillyjudge.

-

AuthorPosts

-

04/29/2016 at 9:05 am #33813

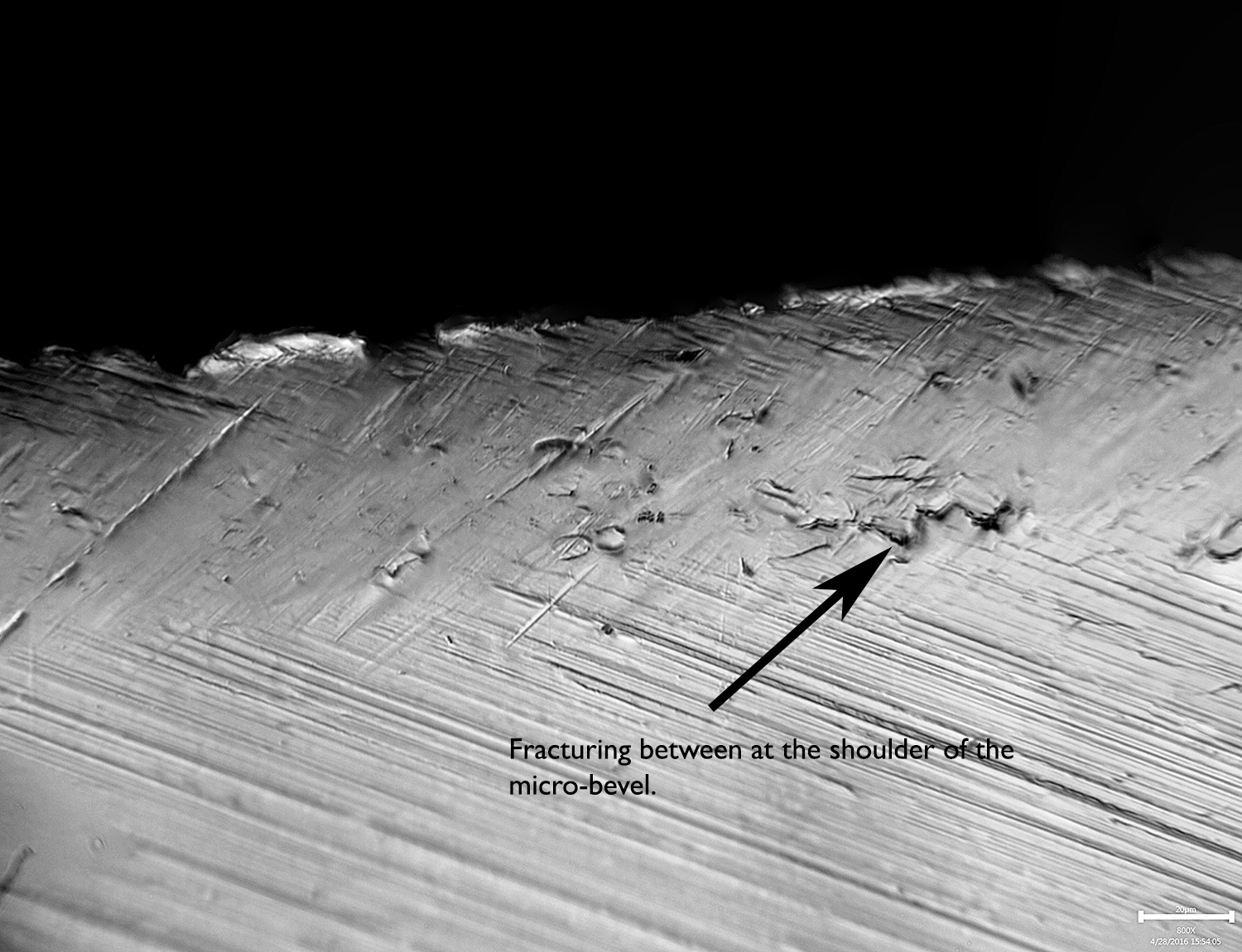

I just had the pleasure of spending the afternoon with Mingjia Liu, principal oboist of the San Francisco Opera (http://sfopera.com/about…/people/bios/orchestra/mingjia-liu/). He uses the Wicked Edge to sharpen his reed knives, which is a big part of the skill set needed for playing the oboe because each musician creates their own reeds. Mingjia has a very good video on the process here: https://www.youtube.com/watch?v=zbdFPepEHL0. Part of his sharpening technique is to use a steel after sharpening to establish a burr that cants to one side. Reed musicians like have the burr as in aid in scraping very minute amounts of material from the reed as they’re shaping it. We worked on some knives together while he was here and later I took a look at the edges under the scope. What I found was pretty interesting – the micro-bevel/burr that was formed with the steel comes at the expense of a certain amount of steel. There is a noticeable fracture line between the original apex and the bit of metal that is pulled up into the wire edge. In this case, it was about 30µ. What that means is that the knife will lose about 30µ (0.03mm) of metal every tme it’s sharpened. Check out the image here:

You can see the scratch pattern from the 3µ lapping films going in one direction and then the scratches of the micro-bevel/burr going the other direction and the fracture lines along the shoulder. Those fractures were present throughout the entire length of the blade I examined.

It may be that the burr is so essential in reed carving that the metal has to be sacrificial but it makes me wonder about using a steel on a good kitchen knife and if the potential metal loss is a concern. It would be easy enough to measure with a micrometer, you wouldn’t even need a microscope. You would just measure the width of the blade before and after steeling for a number of times and track the loss of metal. If anyone wants to study it and report back, that would be awesome.

-Clay

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

04/29/2016 at 9:36 am #33816Wow Clay!!! That is super interesting and the first time I’ve seen it visually documented, thanks!

What kind of steel was he using? Was it smooth or grooved, steel or ceramic? I use a round ceramic honing steel that is very very similar to the white rods on the sharpmaker. I have been a proponent of this vs. a smooth steel because the ceramic actually removes a minute amount of metal at the same time as realigning the edge. The key is to use it with very light force. I wonder what the results would be from this? Interesting study topic =)

04/29/2016 at 9:43 am #33817Great photos and good topic.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/29/2016 at 9:44 am #33818Reed-making is a process I’ve never known about. Really interesting video.

The reed knives appear to be straight-razors. Good straight razors are sharpened at such a low angle that the edge is little more than steel foil and quite flexible. It would seem that when subjecting that foil edge to the abuse of a sharpening steel, fractures are likely to occur. Maybe they should use something more gentle – like a ceramic stick?

Or maybe they need that abuse to produce the burr they want.

04/29/2016 at 10:44 am #33822Wow Clay!!! That is super interesting and the first time I’ve seen it visually documented, thanks! What kind of steel was he using? Was it smooth or grooved, steel or ceramic? I use a round ceramic honing steel that is very very similar to the white rods on the sharpmaker. I have been a proponent of this vs. a smooth steel because the ceramic actually removes a minute amount of metal at the same time as realigning the edge. The key is to use it with very light force. I wonder what the results would be from this? Interesting study topic =)

He’s using a steel that he’s been having manufactured to his spec. I don’t know the material but I do know that it’s hardened to HRC 63 and one portion is smooth and another has very tiny little ribs or flutes.

-Clay

04/29/2016 at 10:45 am #33823The reed knives appear to be straight-razors.

They’re thicker than straight razors, both at the spine and through the grind. He’s sharpening them at 24° on one side and 22° on the other. I’ll try to take an impression of the metal to measure the geometry.

-Clay

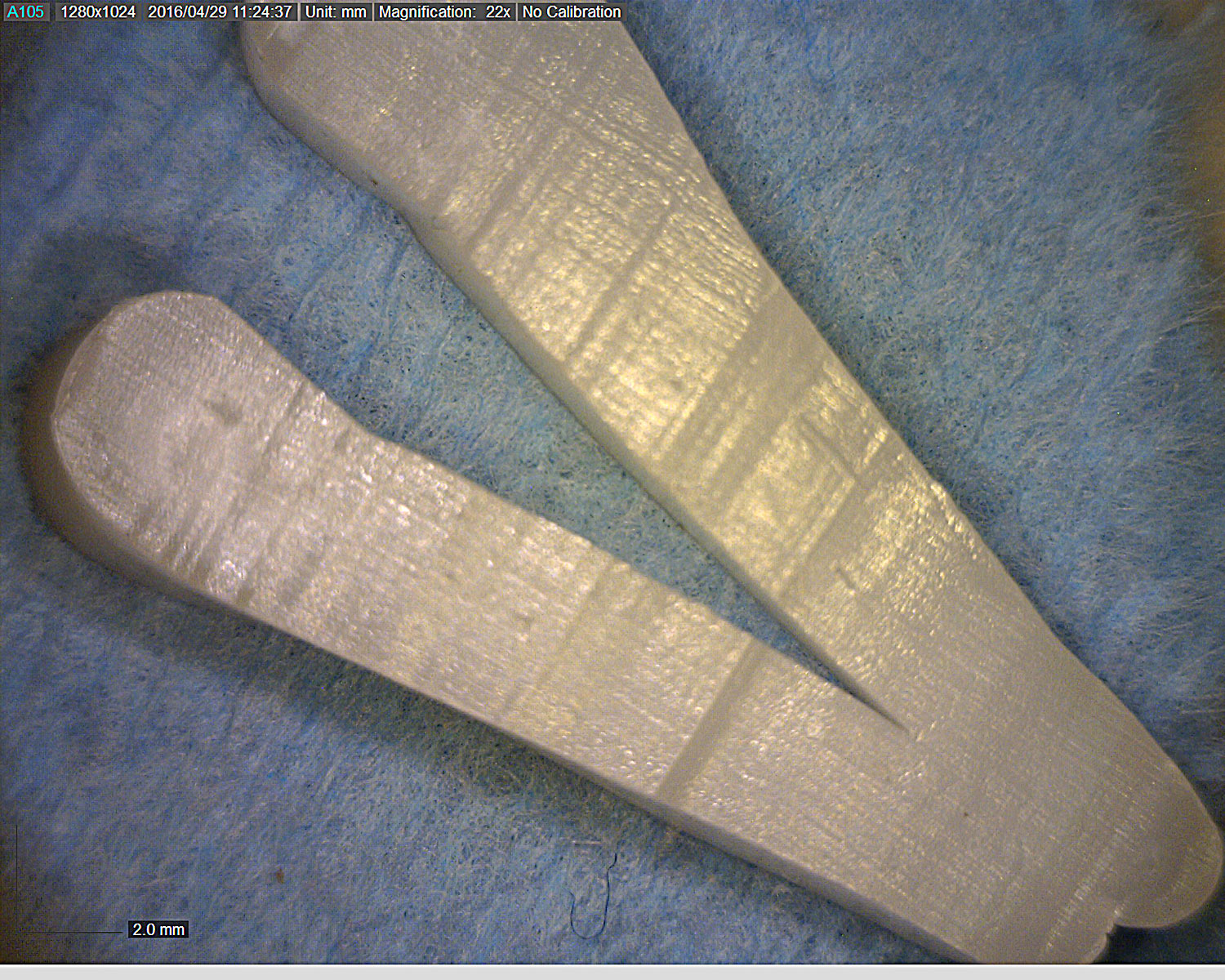

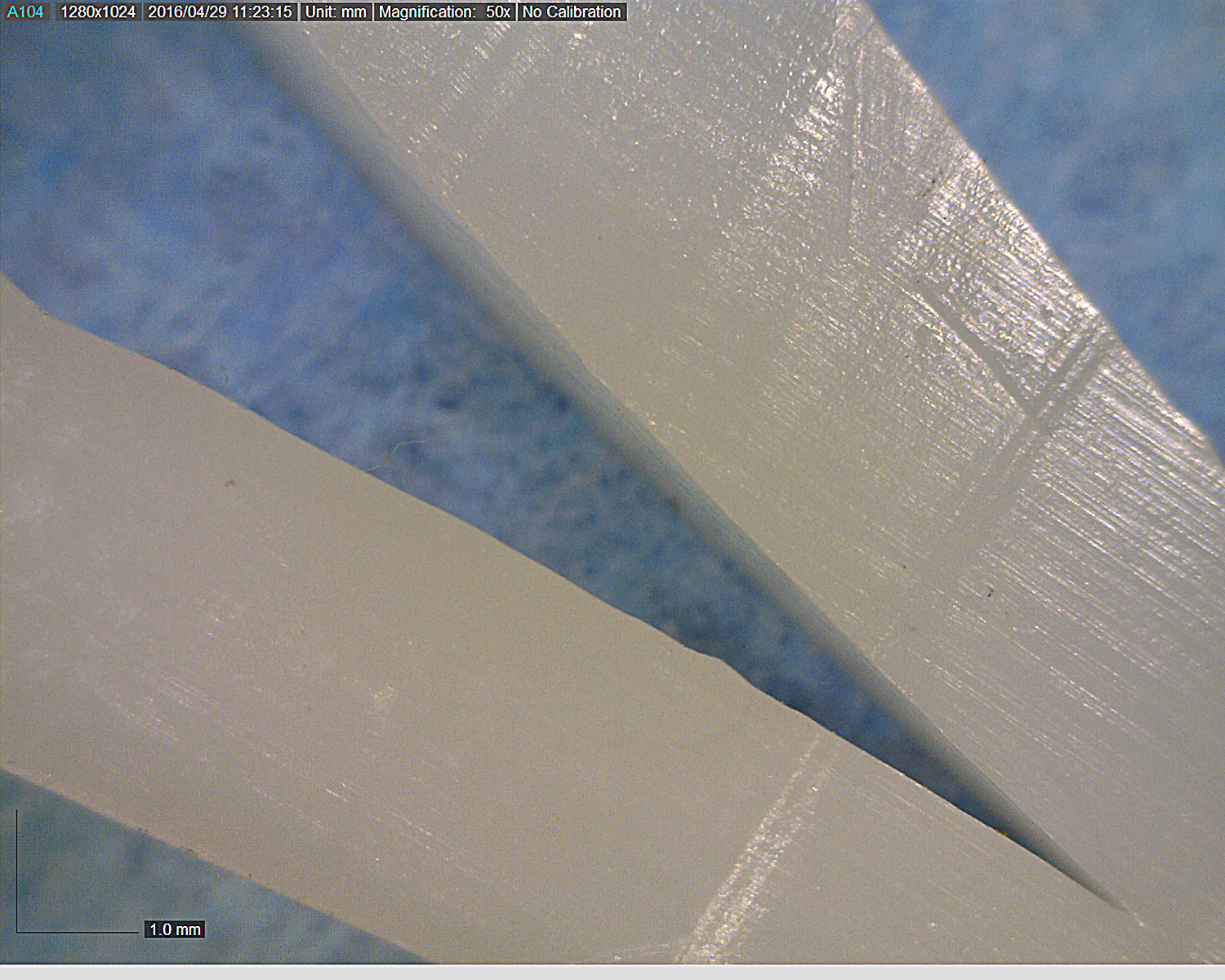

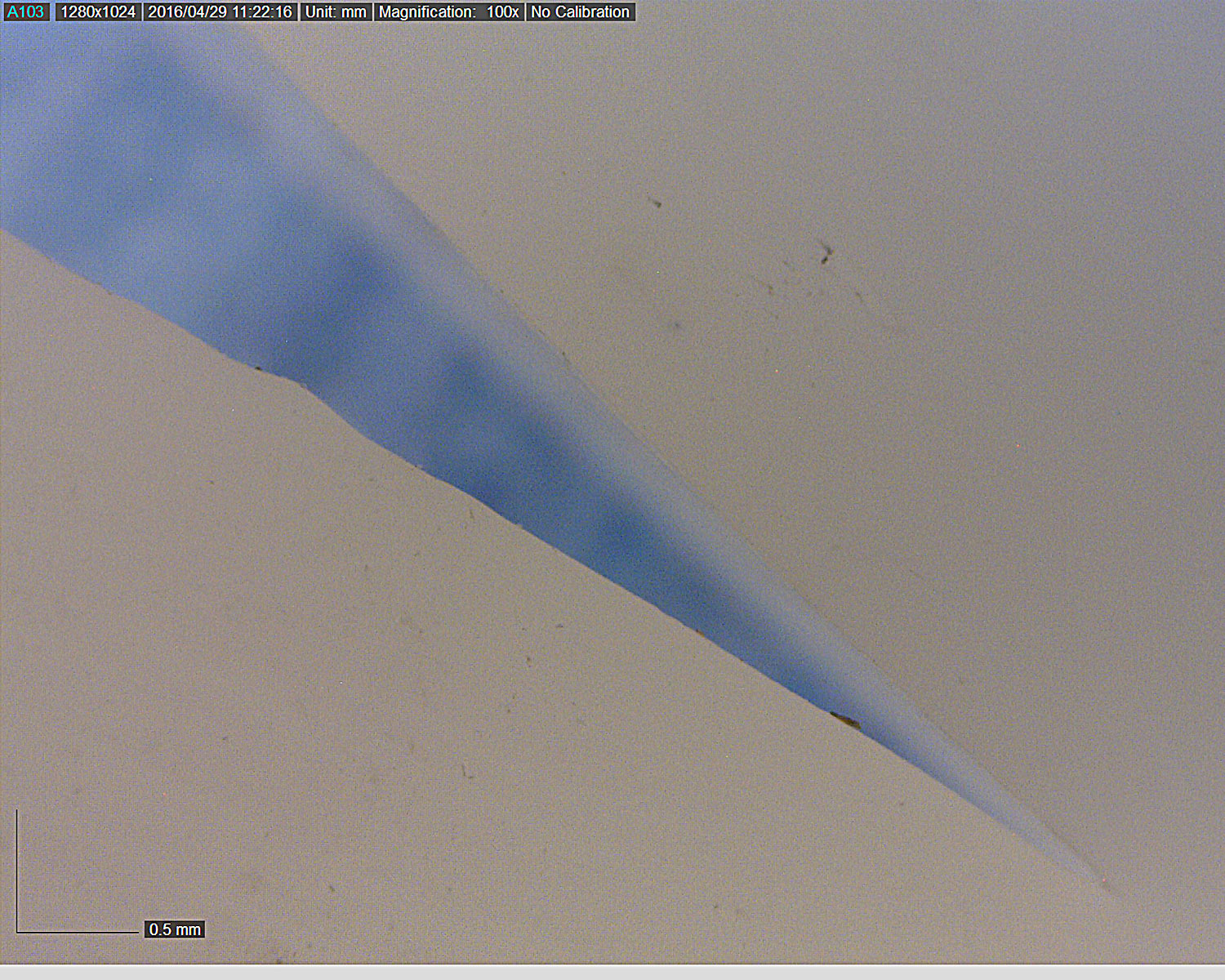

04/29/2016 at 11:48 am #33824Tom, here are some images at various magnifications that I took of the ThermoMorph impression I made of the knife blade:

You can see in the lower magnification images that the blade face is parallel from the spine to where the grind begins, and then it’s hollow ground to the bevel. It’s asymmetrically ground overall, leaning to left when mounted in the Wicked Edge. This slight bias is for right handed users and creates a sort of scooping action when the blade is drawn across the reed. Incidentally, the knife is held roughly perpendicular to the reed both in terms of the face of the blade and the spine of the blade so that the knife is nearly vertical and forms a cross with the reed. Although Mingjia sets the sharpener at 24°/22°, the actual included angle is closer to 15°. This is because he’s built a special holder for his blades that sits up much higher than the regular position and clamps the knife by the handle, a little like the Tormek adapter.

-Clay

Attachments:

You must be logged in to access attached files.

04/29/2016 at 12:32 pm #33829So they normally use the knife as a scraper, huh? It’s really neat that this opportunity comes along right after the development of the thermoplastic casts.

Woodworkers and gunsmiths often use scrapers when they want to remove tiny amounts of wood. Generally, they use a strip of spring steel, grind one edge to a bevel, then roll the tip of the bevel over so as to form a scraper with a burr. Their burr is only about fifty or a hundred times as big as with the reed knife.

What grit level does Mingjia finish his edge to? Does he take it to a mirror?

04/29/2016 at 1:03 pm #33830I was able to use ImageJ to measure the angles, however, the the image wasn’t calibrated so believe the length measurements are off. It is a pretty neat opportunity regardless. Thanks for sharing it.

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/29/2016 at 1:17 pm #33832So they normally use the knife as a scraper, huh? It’s really neat that this opportunity comes along right after the development of the thermoplastic casts. Woodworkers and gunsmiths often use scrapers when they want to remove tiny amounts of wood. Generally, they use a strip of spring steel, grind one edge to a bevel, then roll the tip of the bevel over so as to form a scraper with a burr. Their burr is only about fifty or a hundred times as big as with the reed knife. What grit level does Mingjia finish his edge to? Does he take it to a mirror?

Exactly, a scraper. It seems very similar to what you describe that gunsmiths and woodworkers use. He has been finishing his with the 3000k Chosera stones but he fell in love with the 6µ and 3µ films and will probably switch to those now. The edge after the 3µ looked great, but then was a lot rougher after he finished with the sharpening steel. He seems to like that results, so I’m not sure if a slightly rougher finish is actually better of if he just likes the burr he creates.

-Clay

10/05/2016 at 5:54 pm #35285I am going to go lowbrow, here. Way to hobnob!

-

AuthorPosts

- You must be logged in to reply to this topic.