Today at the Whole Life Market sharpening

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Advanced Techniques and Sharpening Strategies › Today at the Whole Life Market sharpening

- This topic has 22 replies, 8 voices, and was last updated 06/29/2013 at 5:33 am by

Leo Barr.

-

AuthorPosts

-

06/28/2013 at 8:31 pm #12850

i would like to use the WE to sharpen, but i do have a fairly good set of waterstones, but nothing finer than 10,000.

more opinions please

06/28/2013 at 8:41 pm #12851On the Infidel . . . I have one and have not sharpened it . . . I don’t see it being used for anything more than very light duty and show. Can’t see the mechanics of it holding up to very much strenuous use, or strictly as an offensive/defensive knife. It’s D2 steel, so it should be able to take and hold a keen edge, so 20-22 per side?

What’s the owners intended use for it? Very fun to play with. One thing I would do for sure is tape it off to keep debris out of the action.

I think you did a great job on the tip of the last kitchen knife you repaired, so just follow your own judgement. No real opinion as to angle since I’m not versed in expensive Japanese style knives. If there are lots of chips, are they from too shallow of a bevel, abuse/personal cutting style.

Personally, for the main edge, I would not bother going anywhere near a 10k stone. Maybe for the tip repair, but not the main edge.06/28/2013 at 8:42 pm #12853I think I would put quite a steep angle say 20-25Ëšon the edge first of all to both regain the tip and remove the micro chips I would keep checking it under magnification so that you do not take too much away and taking a bit more off the tip to remove the broken part then I would put the thinning bevel in as low as possible 13Ëš or less whichever is possible and work that almost to the edge it does not have to be quite to the edge since you will then sharpen that at 16Ëšl and as said I would avoid the really coarse grits if it really goes too slowly then use the 100 but ideally the 200 will do I would imagine that it should take around an hour or just over to complete. Having just discovered through these forums I would keep looking at it under magnification so as to not go too far which will help keep as much steel as possible.

I have taken a picture on my mobile of the edge on my Shun & put three green lines the first working down from the spine is the original thinning bevel then the second is mine and the third is the micro bevel .Attachments:06/28/2013 at 10:53 pm #12857This was posted in another thread on a Shun (just for a bit of additional info… Leo’s “Plan of Attack” sounds pretty good)…

Is it possible to achiever factory or better edges on Shun knives with the WE without using costly water stones? Has anyone tried using the diamond stones up to 1000 the finishing with wet paper to 3000 grit? The edges with this process have been excellent on carbon steel and a few Spidercos. Your experiences could possibly save me from a costly mistake.

Martin – I wouldn’t hesitate a moment to do what you’re talking about. I’ve had great results on a lot of Shuns doing just what you’re suggesting. My advice is to go about it gently – they only need a tiny bit of work on the micro-bevel. Use a marker to find the exact angle match and then do a few stokes, probably with the 600# stones unless there are a lot of chips you want to take out, to raise a burr. Once you’ve raised the burr from each side, then proceed gently with the 800 and 1000 grit stones using alternating strokes and light pressure. Proceed to the 3k paper with the same technique and you should have great results.

Shun Sharpening

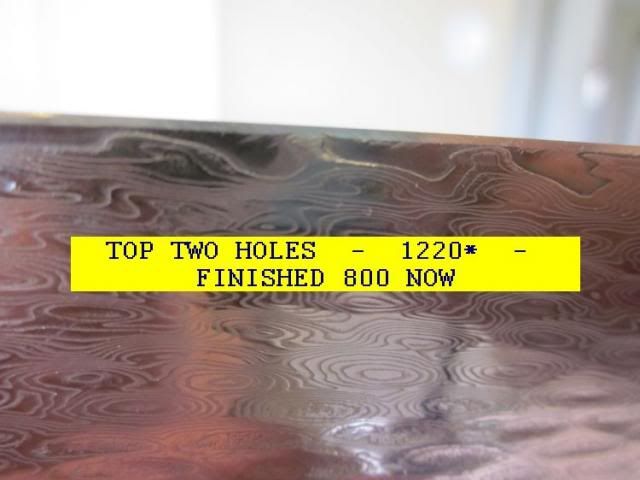

[/quote]06/29/2013 at 2:35 am #12865just finished up the 800’s

all micro chips gone – set up – top two holes at D.5 – 1220*

i might leave it right there – i looks good.

but what if i wanted micro bevel on top – where do you think it should be in degrees?? – WOULD YOU RECOMEND ONE ??

thanks

m

.

.

.

06/29/2013 at 3:52 am #12868

06/29/2013 at 3:52 am #12868Looking good although I would definitely microbevel it at 16Ëš which is the factory angle also bear in ming it has a Rockwell hardness of around 60 or more so 12-13Ëš will be prone to chipping and this will have the benefit of been nicely thinned since the knife has been sharpened quite a lot by the appearance of the edge.

Attachments:06/29/2013 at 5:26 am #12875Looking good although I would definitely microbevel it at 16Ëš which is the factory angle also bear in ming it has a Rockwell hardness of around 60 or more so 12-13Ëš will be prone to chipping and this will have the benefit of been nicely thinned since the knife has been sharpened quite a lot by the appearance of the edge.

.

.

.

I Made it higher degree – 18.50

.

.

.

.

06/29/2013 at 5:33 am #12877

06/29/2013 at 5:33 am #12877Look sweet they are so sharp I threw away the box since once taking the clip off it to get it out; the knife leapt up did a 270Ëš straight onto my finger drew blood it was the christening so I have made leather sheaths for my really sharp knives .

-

AuthorPosts

- You must be logged in to reply to this topic.