The perfect combination of toothy and polished

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Thoughts/Theories/Science Related to Sharpening › The perfect combination of toothy and polished

- This topic has 20 replies, 11 voices, and was last updated 11/30/2014 at 2:47 am by

Cliff Stamp.

-

AuthorPosts

-

05/16/2014 at 5:36 am #18758

I also really like the fact that discussion of any sharpening method is allowed, even if it is a rival product. I love, I mean love, my WE and will never be without one. But I have a lot of convex edge knives and Japanese knives that I prefer to sharpen by hand. I have learned a lot in my few months on this forum and, for better or for worse, have been sharpening knives for over 40 years (started young 😉

Sent from my iPad using Tapatalk

11/28/2014 at 11:13 pm #21623… I went to cut some paracord to see how it would perform and though it will easily push through it, the cord would slick along the length of the edge. This was extremely sharp but not aggressive enough though you could feel the ‘grab’ when you felt the edge with your finger.

As an honest question, why would you call the edge sharp if it just slid along the paracord? Put it another way, if you left an edge really coarse, and after use it had dulled it would likely do the same. Both edges can’t cut the paracord, why is one dull and the other one sharp when they both physically behave the same way if you try to slice the rope?

Here is a simple experiment :

-take a piece of rope (or something similar)

-sharpen a knife with a very coarse grit, say 36

-make a slice for a specific length and record the amount of force usedNow increase the grit and repeat until very high grits (8k+) or you become bored. The force should keep decreasing until it hits some point at which a draw isn’t needed as it will just sink through the rope once that force is applied.

If at any time it slips then the knife didn’t get sharper, for some reason it was dulled by the higher grit, often through apex rounding. Now a lower grit finish in some cases may (will) produce higher edge retention, but it can’t produce higher initial sharpness.

The main reason it is often argued that it does is because there is an over reliance of strops/buffers to produce polishes which tend to rounding apexes. Often was is being compared then is a coarse edge with a V-formed apex vs a polished edge with a rounded one.

As a point of interest/reference, with 1/2″ hemp you should be able to do a cut with a 2″ draw with a load of 4-5 lbs with a very sharp edge (with a thin cross section). With a very coarse edge the force will by higher, ~10 lbs with a 36 grit edge.

11/29/2014 at 12:56 pm #21638Here is a simple experiment :

-take a piece of rope (or something similar)

-sharpen a knife with a very coarse grit, say 36

-make a slice for a specific length and record the amount of force usedNow increase the grit and repeat until very high grits (8k+) or you become bored. The force should keep decreasing until it hits some point at which a draw isn’t needed as it will just sink through the rope once that force is applied.

If at any time it slips then the knife didn’t get sharper, for some reason it was dulled by the higher grit, often through apex rounding. Now a lower grit finish in some cases may (will) produce higher edge retention, but it can’t produce higher initial sharpness.

The main reason it is often argued that it does is because there is an over reliance of strops/buffers to produce polishes which tend to rounding apexes. Often was is being compared then is a coarse edge with a V-formed apex vs a polished edge with a rounded one.

Thanks for your clear explanation, Cliff! I think many of us understand how a (leather) strop can dull an edge. Or how misuse of a (higher grit) stone can dull an edge. But if you use a stone properly, is there any way in which a higher grit stone can dull an edge sharpened at a less high grit?

Molecule Polishing: my blog about sharpening with the Wicked Edge

11/29/2014 at 3:09 pm #21640Here I am again months later with another update. Thank you Cliff for stopping in. You are definitely correct and reading my post where my little experiment obviously took place in the past I have learned much more. I am almost certain that back in the day I would have been using strops, probably incorrectly where it would have a rounding effect, and my stone skills are not what they are today :).

Nowadays most of my EDC edges are just straight 140 grit from my Atoma Diamond plate. Reason being I don’t have a lot of time to progress higher and to be honest if you just take the time to really refine your edge with very light alternating strokes, it leaves an edge that shaves, push cuts newspaper, and slices like an animal. When I do treat myself to progressing higher in grits, I tend to favor edges no higher than 1,000 grit. In fact, I normally stop at 220 or 500 Shapton Glass. With proper technique, of course, for me, those grits are more than enough to handle every day tasks and then some.

Lately I have been experimenting with 140 grits edges, and just giving maybe 5 strokes per side progressively up to my Shapton 8k, just to refine the 140 grit, since I no longer use strops for high grits. The results are interesting. I love the teeth from the 140 but I get the polished sensation when I feel the edge.

More information is surely to come.

Thanks guys.

11/30/2014 at 2:42 am #21646[…]

But if you use a stone properly, is there any way in which a higher grit stone can dull an edge sharpened at a less high grit?If you use a stone properly then almost by definition it can’t happen, but “proper” use of some stones is not trivial at all.

If a stone is very muddy for example then that slurry tends to make it very difficult to prevent an apex from rounding. If you want to see this happen fairly easily then take a King 1000 and try to get an edge which push cuts newsprint. The stone will put a very high finish on the sides of the edge but it can be really difficult to actually refine the apex as the stone is so soft and muddy. I like a King 1000 to preset an apex before a micro-bevel, but would never pick it to actually apply one unless I wanted some kind of challenge or amusement.

11/30/2014 at 2:47 am #21647…. The results are interesting. I love the teeth from the 140 but I get the polished sensation when I feel the edge.

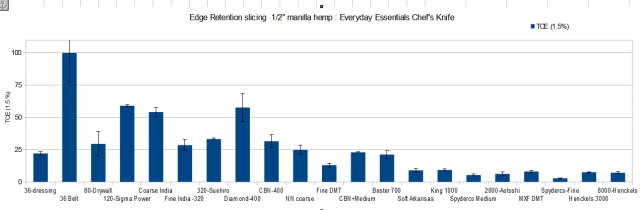

I think that is an interesting way to approach getting a medium coarseness edge. I recently did a little work with it while looking at the edge retention of various grit finishes with a 3Cr13 knife :

If I took the CBN finish for example (Sharpmaker rod) and then started working it with the medium grit rods then the initial sharpness and edge retention would move from the CBN directly towards the medium rod finish. It is a way to basically get an “effective” grit from a a narrow range. However I am not sure that if you had the grits it would not be simpler just to micro-bevel at the intermediate grit. But the two would not be expected to be identical.

-

AuthorPosts

- You must be logged in to reply to this topic.