Super blue steel

Recent › Forums › Main Forum › Super blue steel

- This topic has 54 replies, 8 voices, and was last updated 03/01/2016 at 3:01 pm by

Darragh O’Flaherty.

-

AuthorPosts

-

02/26/2016 at 11:19 am #31650

That’s interesting… doesn’t look to take many strokes to erase the 200 grit damage, or is that my mis-conception?

No, I think you’re right. I wish I’d done fewer strokes to begin with just to see how many licks it takes to get to the center of the blow pop

-Clay

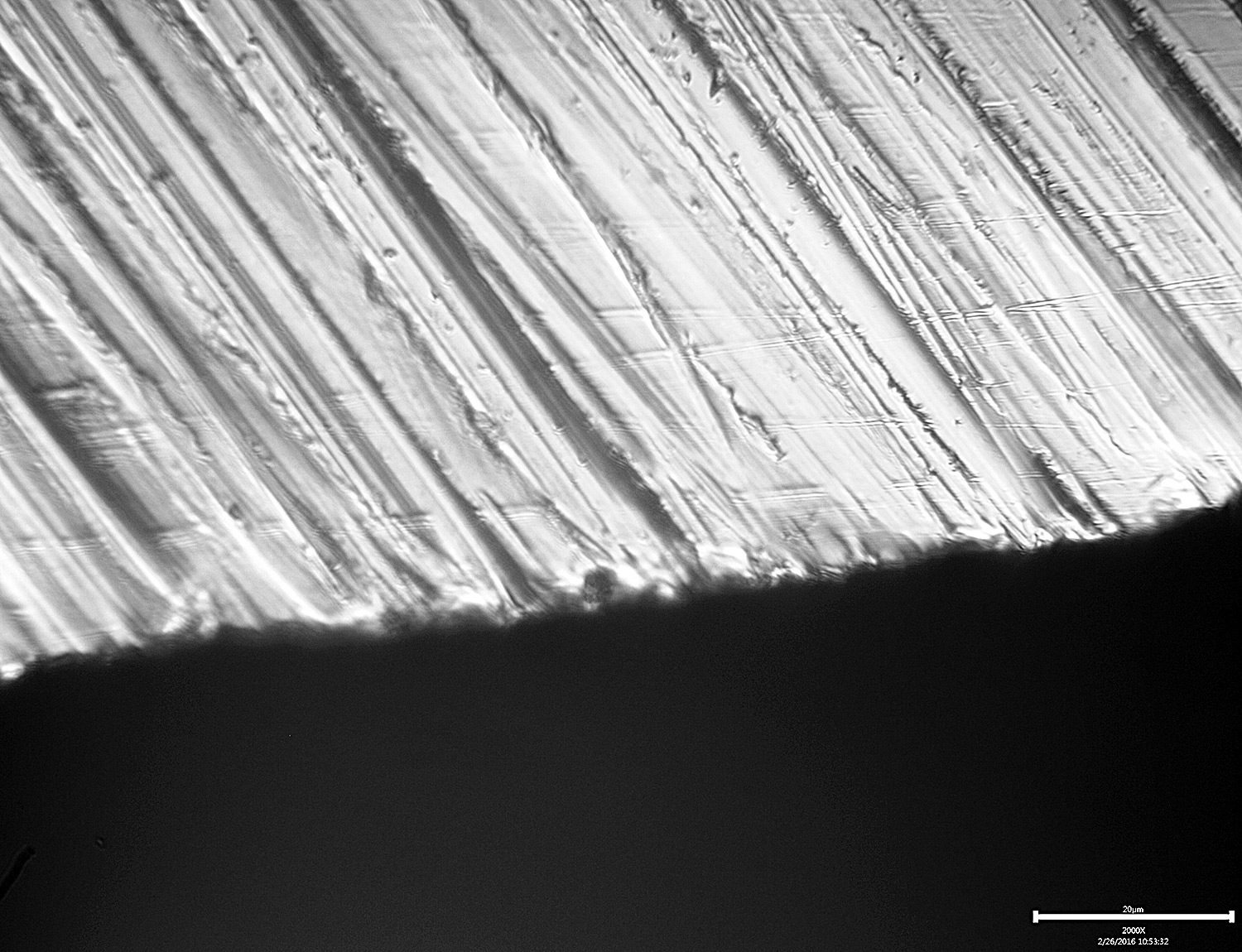

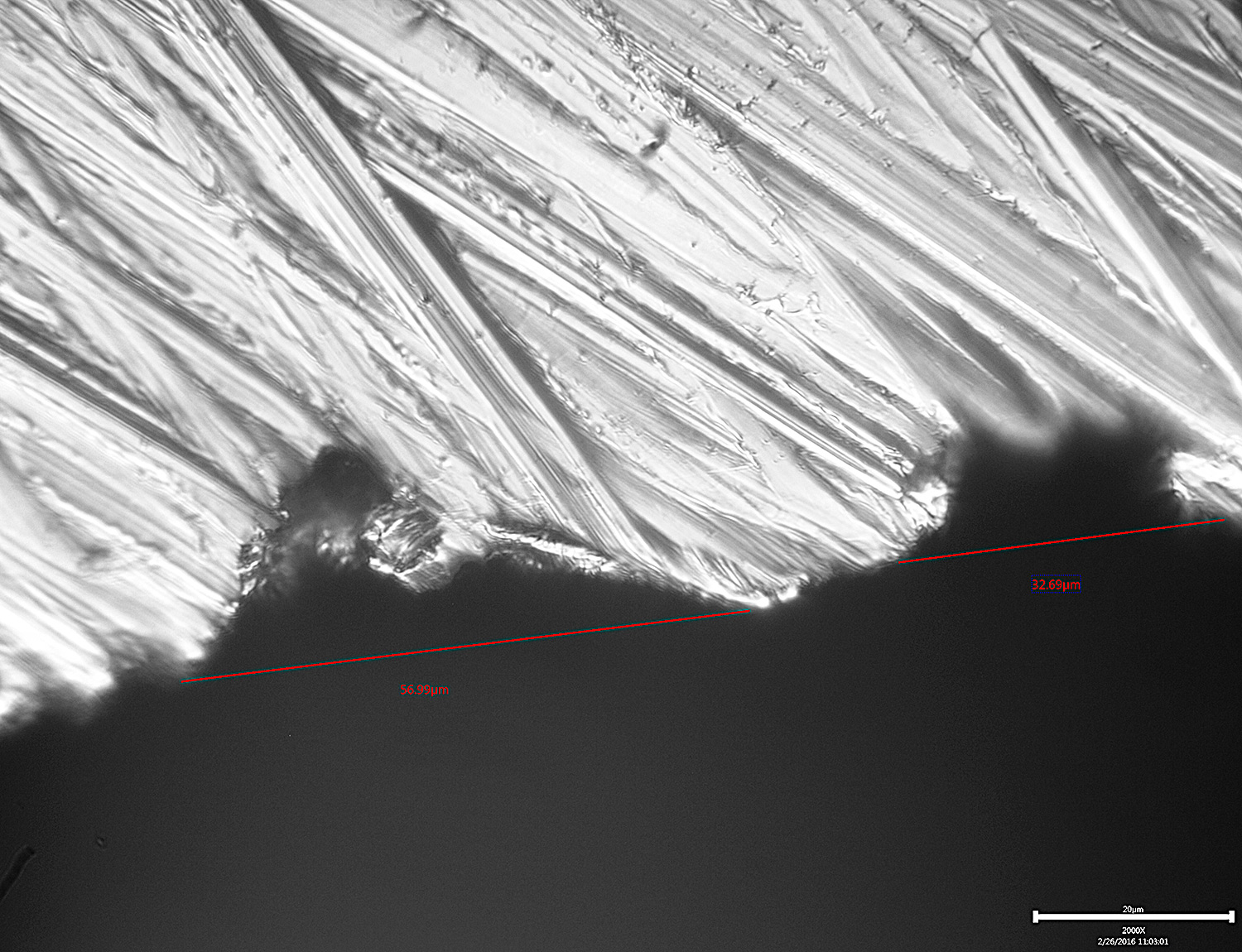

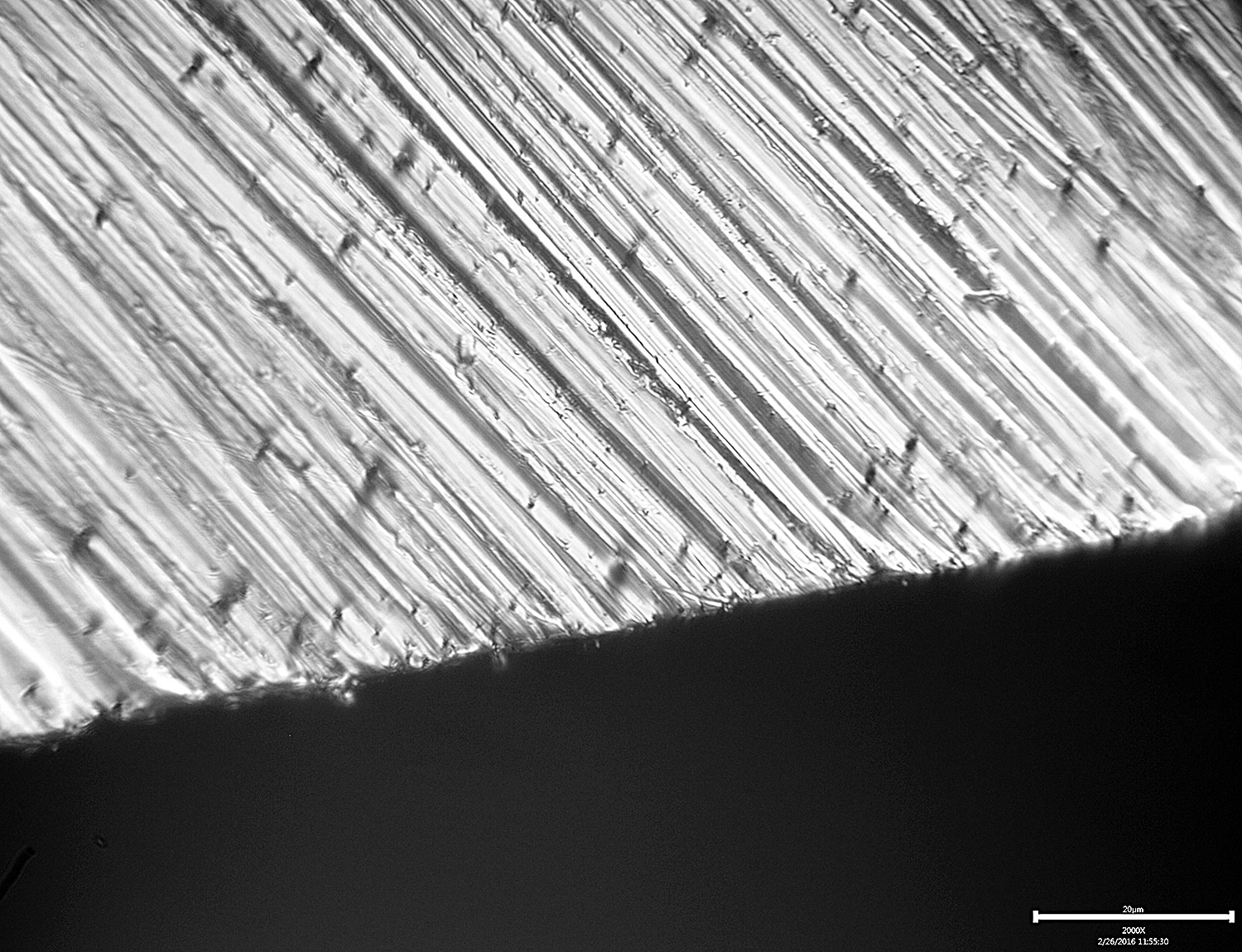

02/26/2016 at 11:20 am #3165102/26/2016 at 11:22 am #31654Then 20 very light, controlled edge trailing strokes:

I was kind of surprised by this series. The first image looked good, then I moved down the blade a little and saw some serious damage, moved a little more, saw more damage, then a little more and it looked pretty good again.

-Clay

Attachments:

You must be logged in to access attached files.

02/26/2016 at 11:24 am #31659when you say trailing or leading ? is leading mean from the choil or heal of the blade to the tip, or the other way around . thanks for the info and the learning opportunity .

02/26/2016 at 11:25 am #31660when you say trailing or leading ? is leading mean from the choil or heal of the blade to the tip, or the other way around . thanks for the info and the learning opportunity .

By leading, I mean that I’m pulling the stone toward the edge of the blade continuing on toward the spine. By trailing I mean the opposite; pulling the stone upward in the direction of spine to edge.

-Clay

1 user thanked author for this post.

02/26/2016 at 11:30 am #3166502/26/2016 at 11:39 am #31670wow Clay! Those are some serious chunks missing for a 600 grit stone!

I’m curious… are the edge trailing passes causing this? I have noticed my edges receive more of this type of damage when I am doing edge trailing but it may just be the way I’m using my stones (I may rock more when I trail as I am more stable on leading). Can you clean up the chunks and then see if the damage reappears w/ trailing?

02/26/2016 at 11:50 am #31671wow Clay! Those are some serious chunks missing for a 600 grit stone! I’m curious… are the edge trailing passes causing this? I have noticed my edges receive more of this type of damage when I am doing edge trailing but it may just be the way I’m using my stones (I may rock more when I trail as I am more stable on leading). Can you clean up the chunks and then see if the damage reappears w/ trailing?

Yeah, this is a little confusing because we don’t know for sure if this is damage left over from previous stones or is being done by the current stones/technique. I just completed the 800# edge leading stage and noticed some pretty sizable tear out there as well. So I went on to the 1000# and did another 20 edge leading strokes. Still had tear out that I could see with my handheld (supposedly) 60x loupe. I could easily see the little chips missing with that, so I continued on to 40 strokes, 80 strokes and up to 100 strokes, looking at each interval with the loupe. The chips gradually disappeared for the most part. So it’s possible that I just didn’t image the big chunks earlier, it’s easy to miss them if you don’t hunt the entire edge… They are big chunks if they’re indeed produced by the 600# stones. In theory, they should only be around 16 microns. Now I’ll check out the 1000# edge with 100 leading strokes.

-Clay

1 user thanked author for this post.

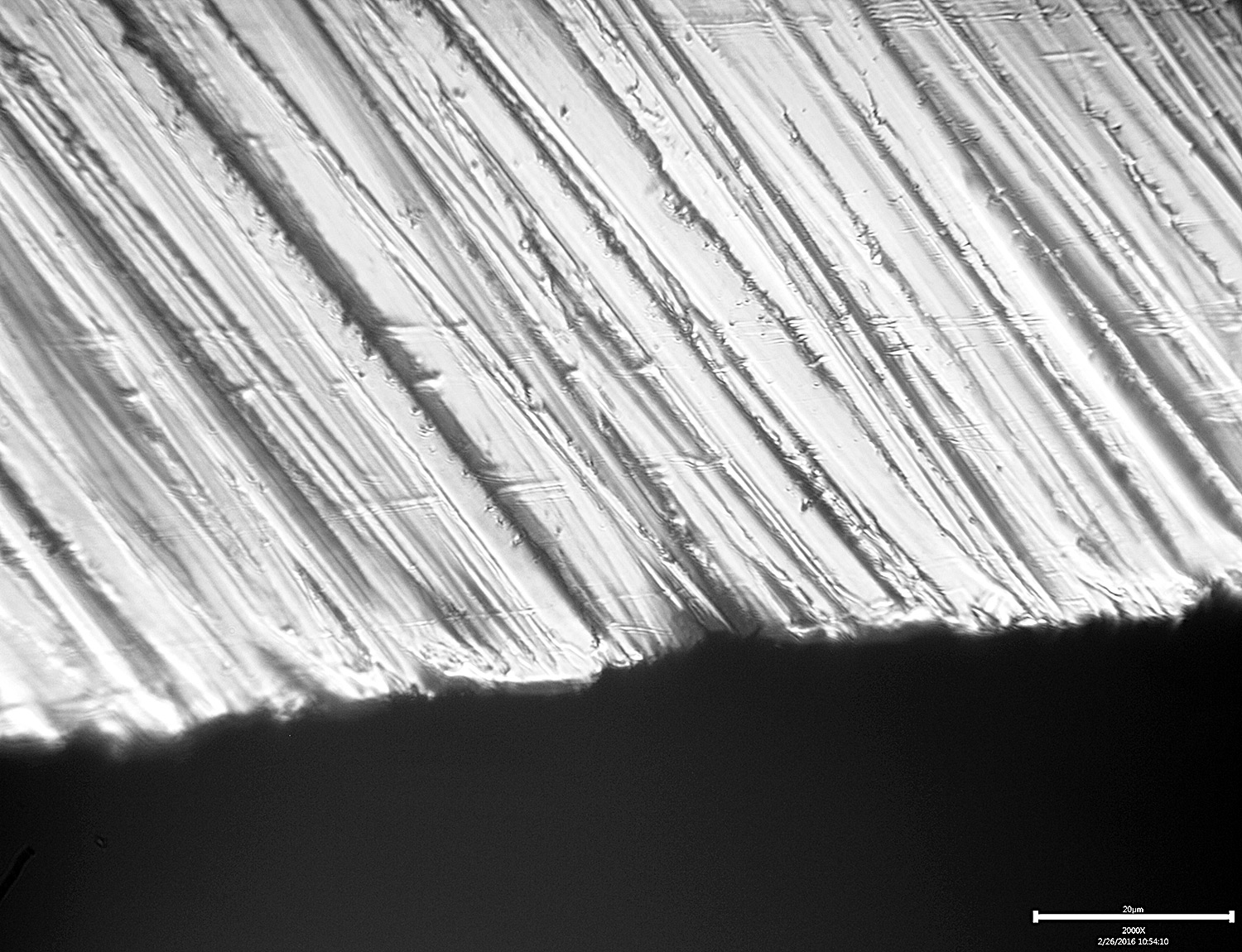

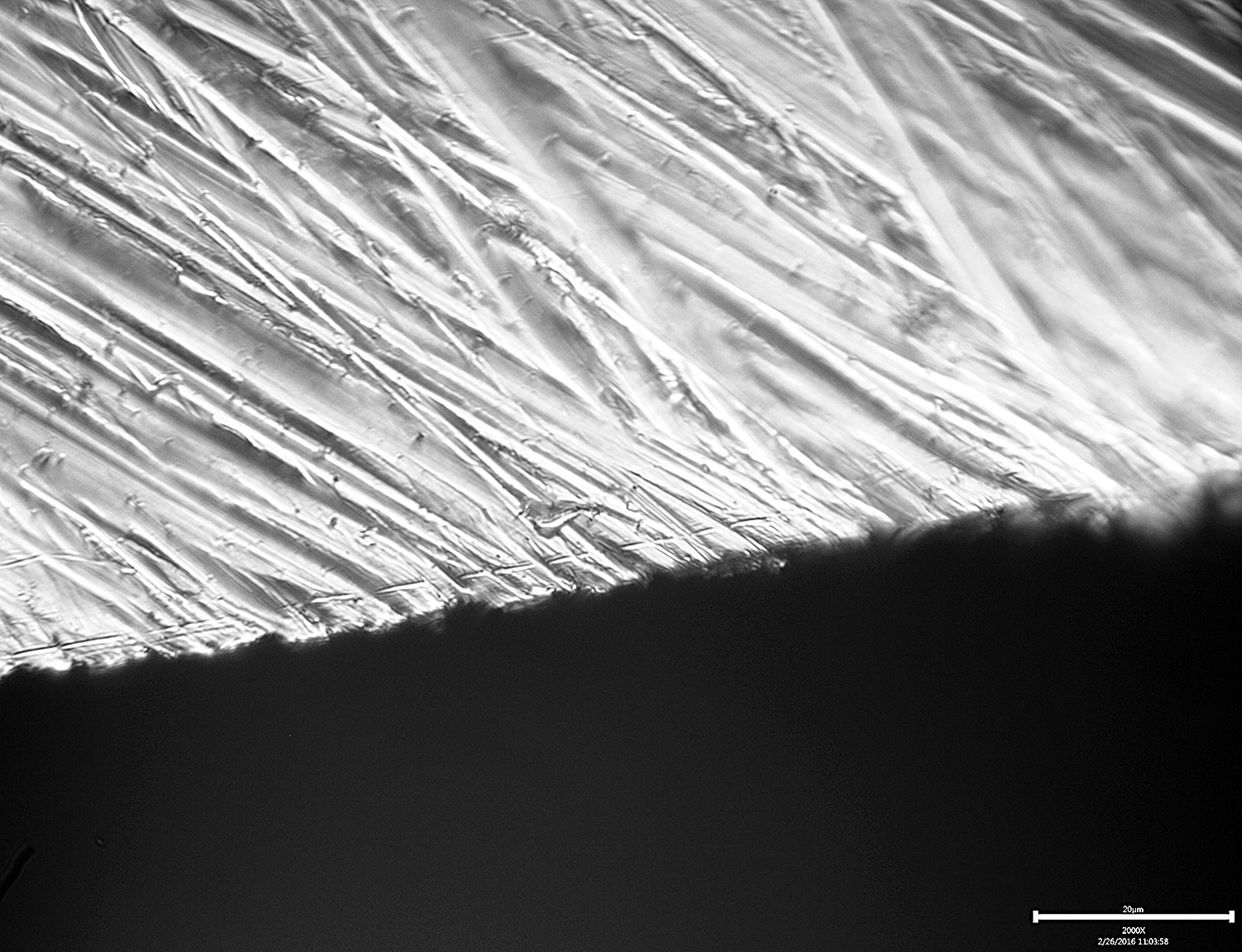

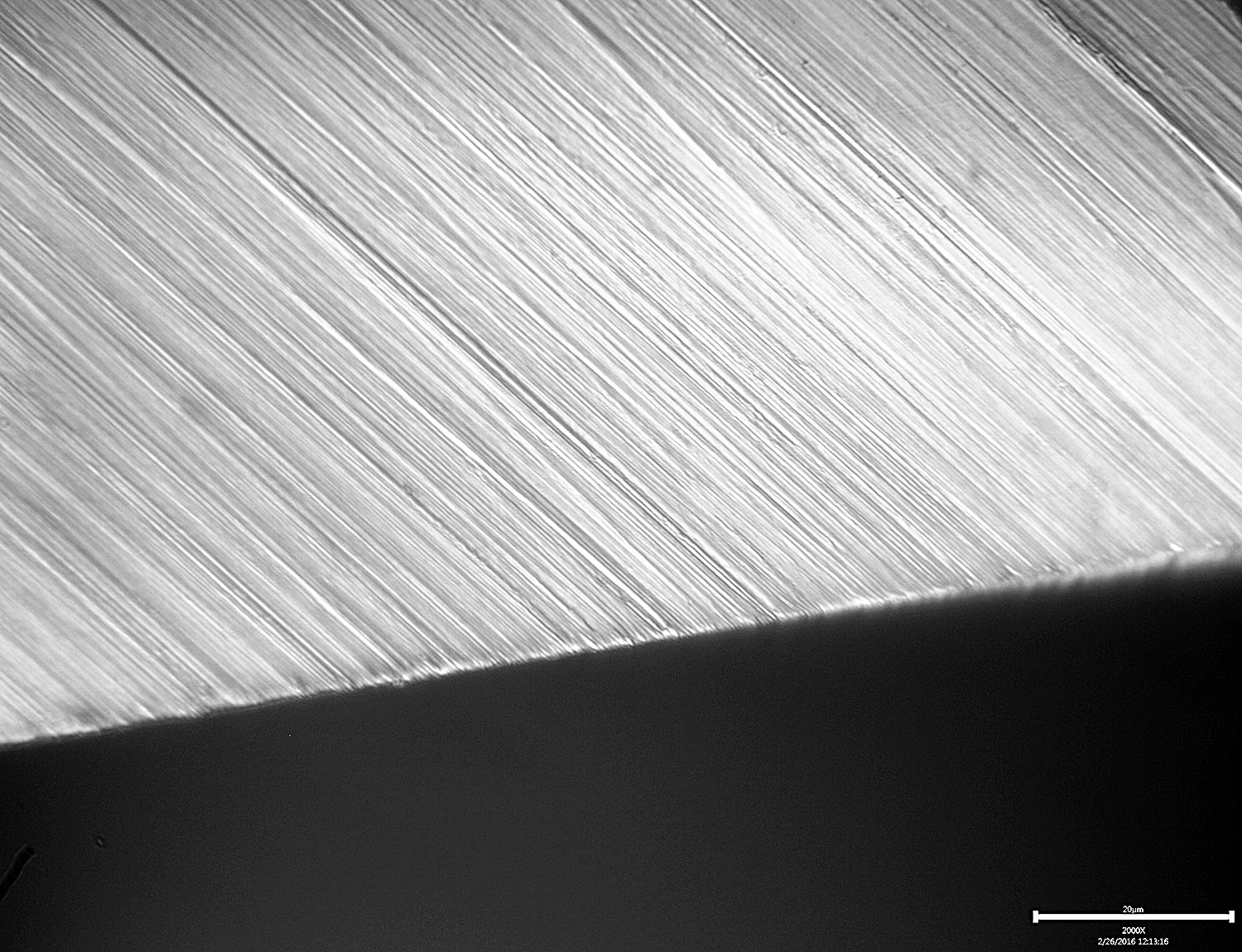

02/26/2016 at 12:00 pm #3167202/26/2016 at 12:01 pm #31674And 1000# with 100 very light, edge leading strokes:

You can clearly see a big chunk from the edge in the first image. This was the only one I found on the whole length of the blade. The rest of the blade looks like the second image.

-Clay

Attachments:

You must be logged in to access attached files.

02/26/2016 at 12:13 pm #31677Anonymous

Inactive- Topics: 14

- Replies: 427

Some very serious analytical photographs. Thanks

Bill

1 user thanked author for this post.

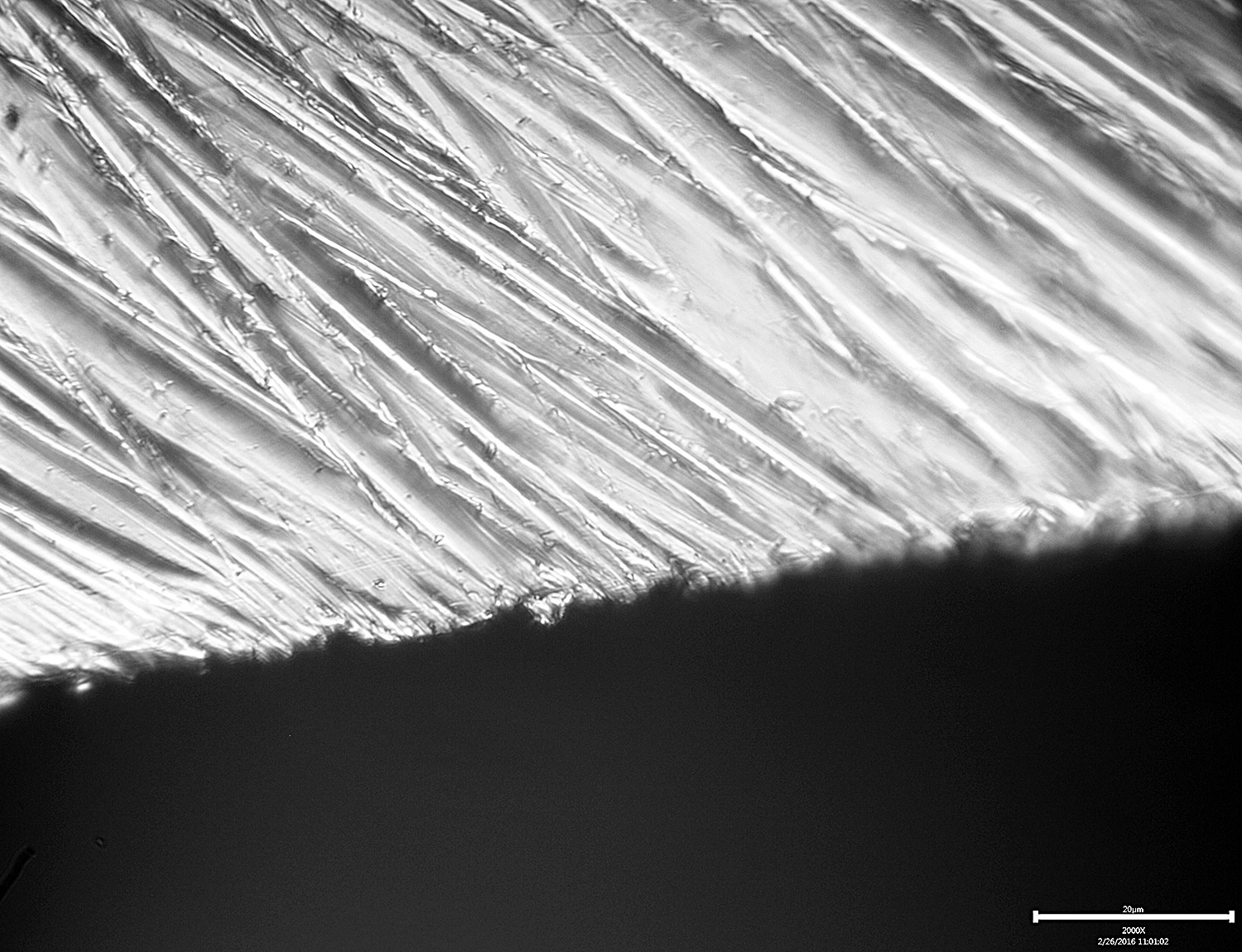

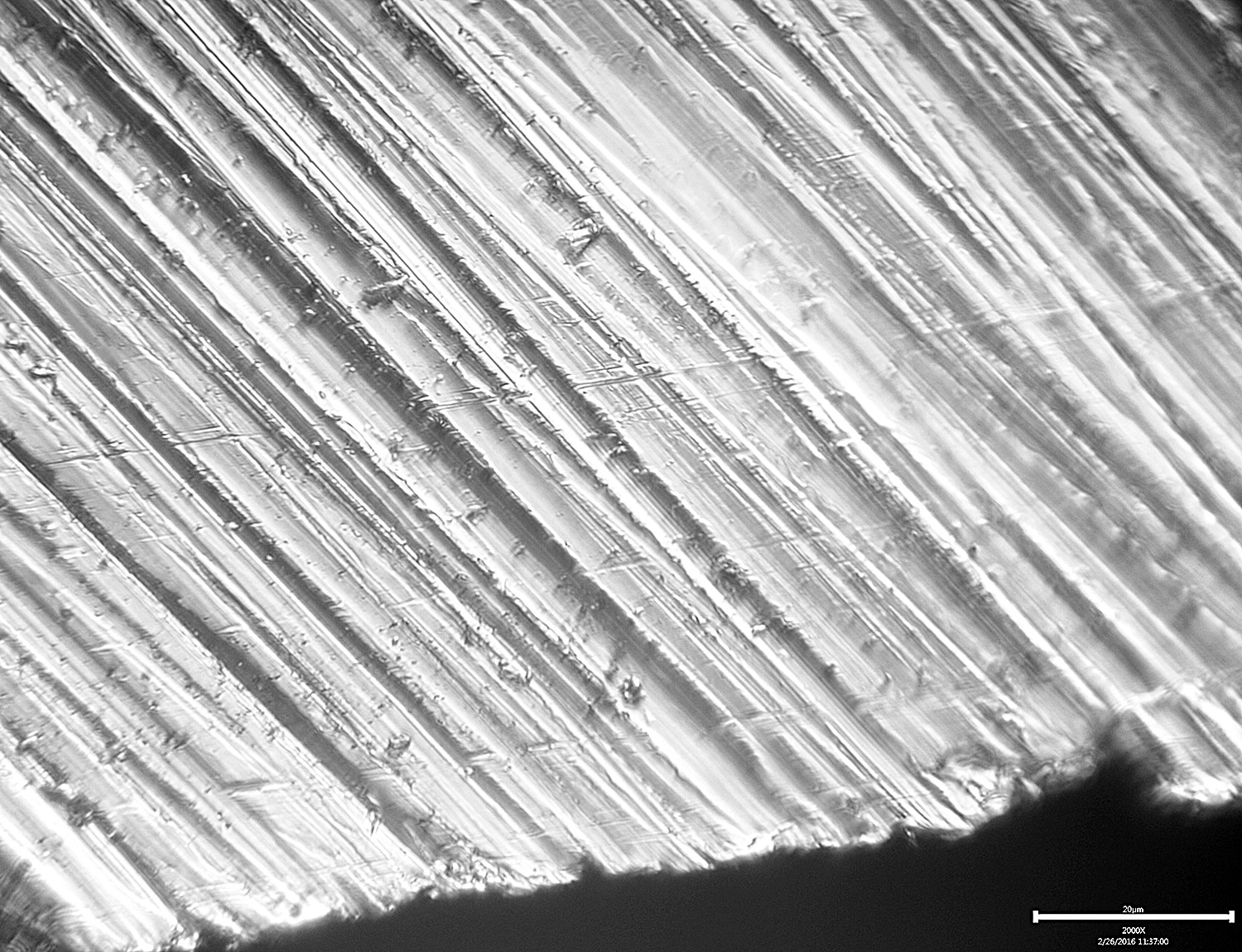

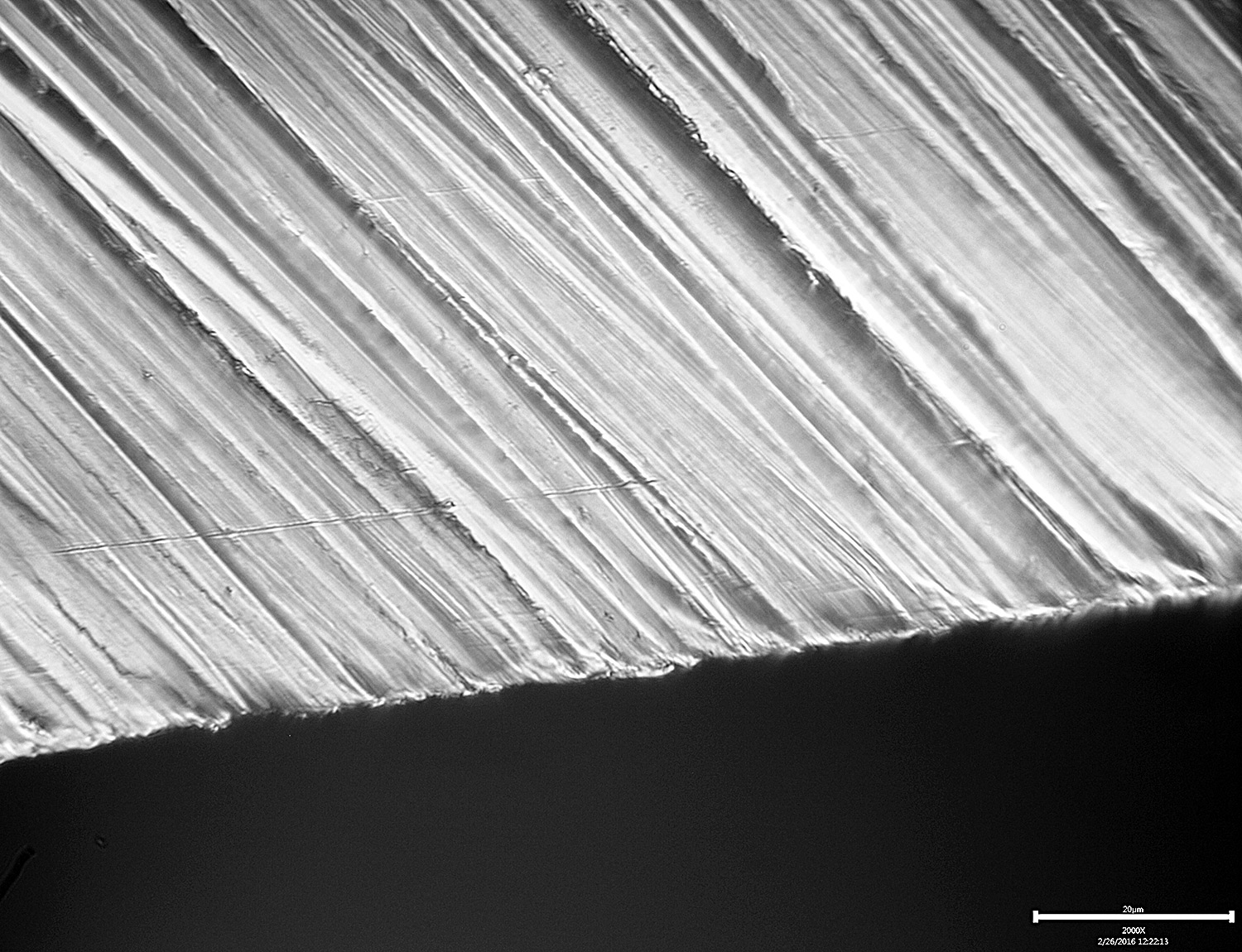

02/26/2016 at 12:16 pm #31678I went ahead with the 6µ diamond films. Man do I love these things:

They cleaned up the edge very nicely, very quickly. These are the same films I’ve been using for 2 weeks, so they’ve had a lot of use and are still going strong. I followed Tom’s (TC) lead and cleaned them off with rubbing alcohol to remove the metal loading and they continue to perform well.

-Clay

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

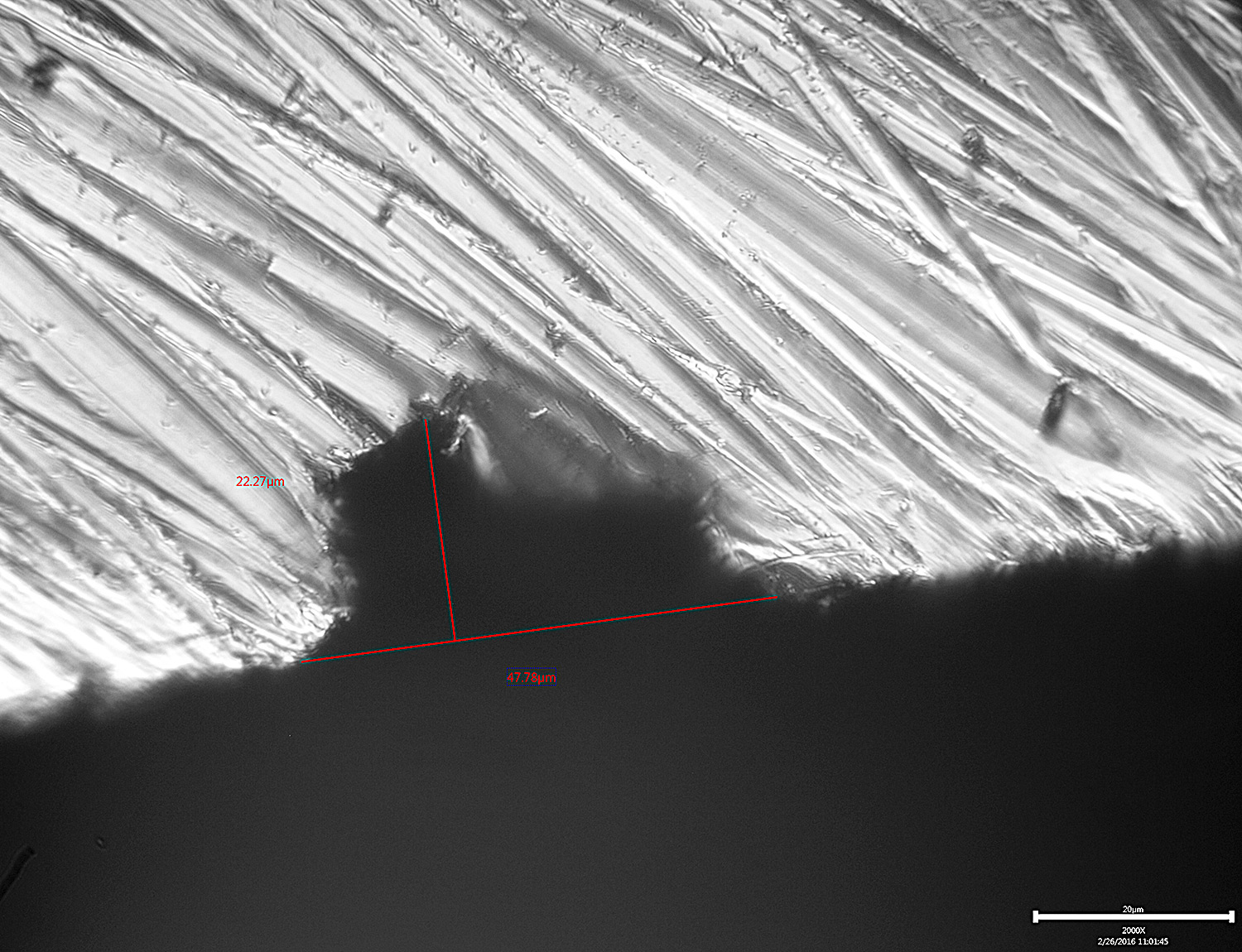

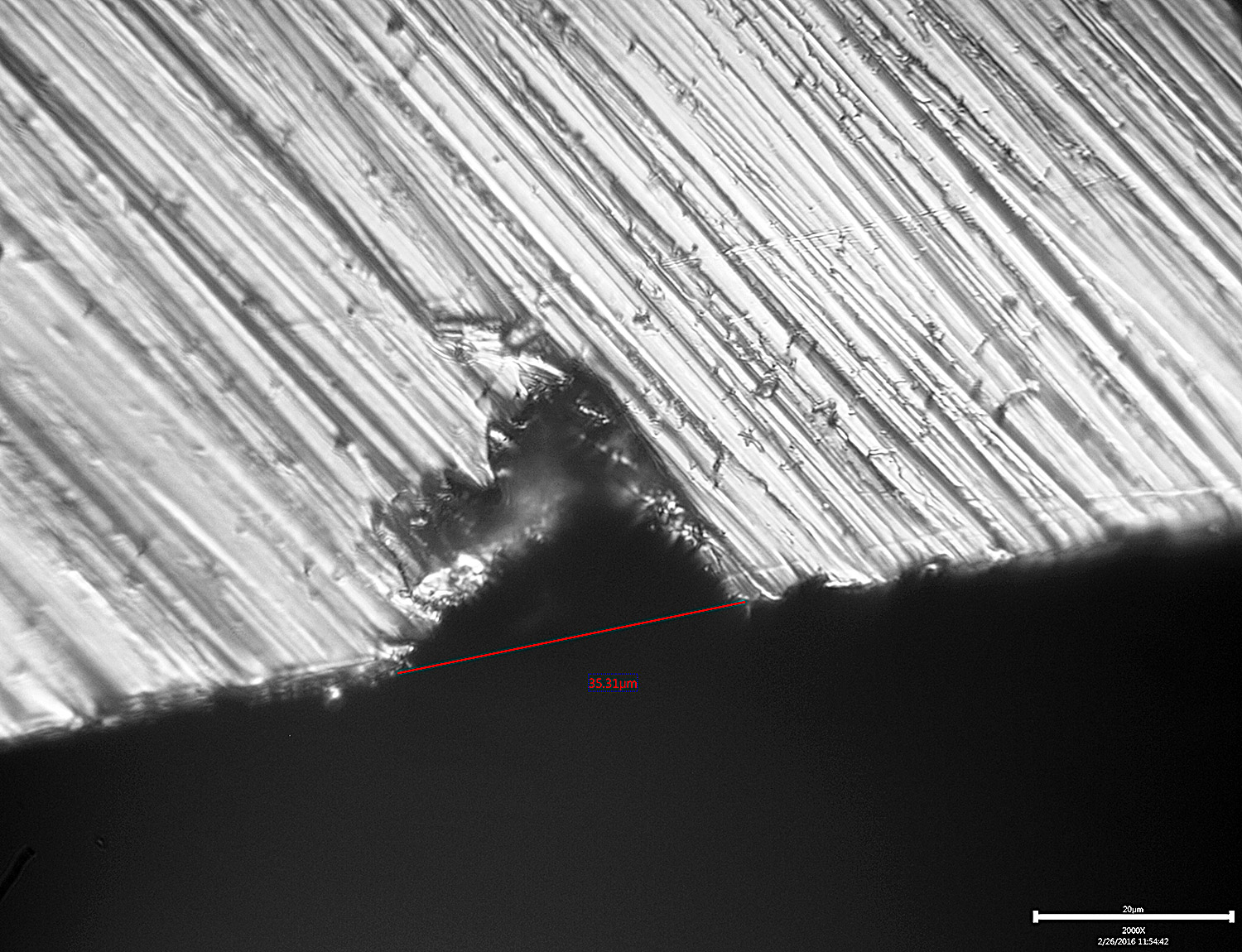

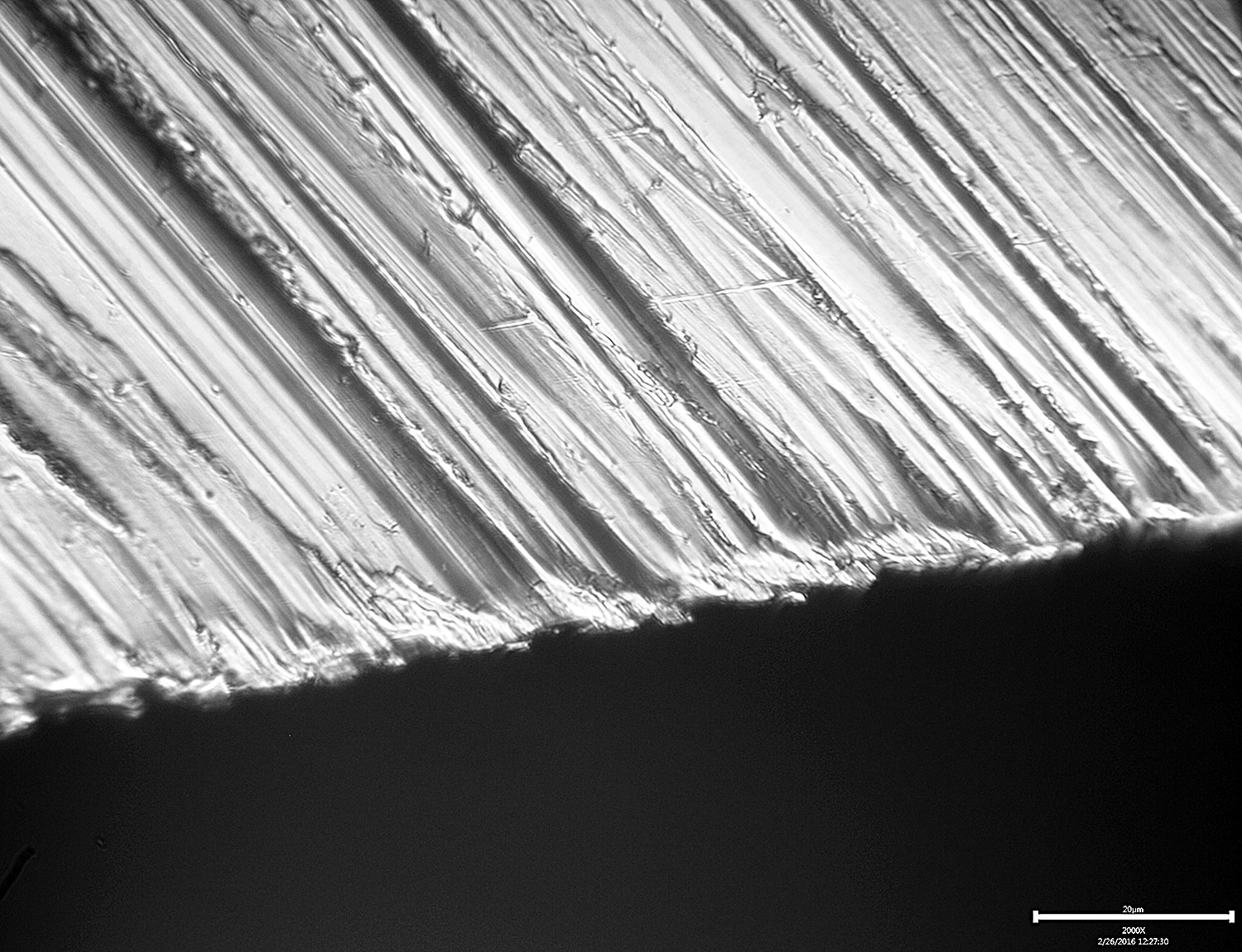

02/26/2016 at 12:30 pm #31680Once the edge was nice and clean from the 6µ films, I went back to the 600# stones and performed 10, very light, controlled edge trailing strokes:

Then I did another 20 strokes for good measure. Again, edge trailing, very light and controlled:

This makes more sense!

-Clay

Attachments:

You must be logged in to access attached files.

02/26/2016 at 12:34 pm #31683I’d hazard the following guess – the large chunks we saw in the first 600# edge trailing images were leftover from the 200# stones because the size of the chunks fits fairly well. It is possible for a smaller stone to tear out a bigger chunk, especially if the steel is fatigued, so it’s by no means established that the 400# or 600# stones are not responsible, but there is a greater likelihood that the edge wasn’t adequately cleaned up prior to moving on to the higher grits. It does seem clear that edge trailing strokes are good for removing material and that a few edge leading strokes to finish the edge can be helpful.

-Clay

1 user thanked author for this post.

02/26/2016 at 2:13 pm #31685I think you’re right. What happened here is that you’ve been checking your progress at 2000X, which would take forever to examine the entire length of the blade, thus missing damage still there from previous grits.

I think your exercise here validates what I’ve been preaching to newcomers about being sure that you’ve removed all the damage before moving on to the next grit. I inspect the entire length of the blade, but at only 50X. At this low magnification, it’s hard to see the type and size of edge damage you’re seeing at 2000X, so I scan the entire length of the blade from directly above and stop to check any suspicious spots. Swinging the ‘scope from side to side, you can usually see slight dips in the edge, but probably not much below 25 microns. Maybe you could inspect full-length with a 200X handheld before dismounting the knife for the 2000X inspection.

The improvement in the edge seen with the 6 micron film is amazing. Did you do any grits between the 1000’s and the 6 micron?

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.