Super blue steel

Recent › Forums › Main Forum › Super blue steel

- This topic has 54 replies, 8 voices, and was last updated 03/01/2016 at 3:01 pm by

Darragh O’Flaherty.

-

AuthorPosts

-

02/23/2016 at 10:00 am #31499

Hey,

I am having trouble sharpening my super blue steel masakage koishi on the wicked edge, I am using the diamond stones 100 all the way to 1000 grit but it does not seem to be sharpening correctly.

half way down the blade the edge seems to get rough, looks like micro serrations,

Do I need ceramic stones to sharpen this steel??

Thanks

02/23/2016 at 10:23 am #31502It sounds to me that the coarse 100g stone may have chipped out the edge, which can happen on harder steels. It’s best to try not to go all the way to the edge with a coarse stone to prevent this.

Others may chime in who have specific experience, but my suggestion would be to just try and clean up the edge with the finest stone you have a bit more, and see if it smooths it out. Might take a little time, but you should see improvement as you progress.

I hesitate to recommend ceramics since I don’t have experience with that particular knife, but in general they will perform better at a finer finish, so it would probably result in a better edge overall.

1 user thanked author for this post.

02/23/2016 at 10:52 am #31503Anonymous

Inactive- Topics: 14

- Replies: 427

I know you sent me a private message and an email… Without knowing the problem, I cant offer a solution. I don’t want to guess. I’m hardly an expert.

There is not one answer for all of the issues that can go into sharpening a knife. the actual set up is important..

- how do you know you have the knife set in the jaws in the correct position? Did you use the sharpie method?

- ?. There is only one correct position for each knife..

- what angle are use using and how did you determine that angle.. ? Did you use an angle cube ? and what angle did you use.

- Is this an old knife or a new knife. ? Do you know the correct previous angle? If not , did you re profile the knife ?

- did you scrub one side in an up and down motion to establish a burr ?

- Did you check to see that the bur extended all the way from heel to tip?

- Did you then make a bur on the opposite side?

- how many stones do you have?

- Is there any blade deflection from using too much applied pressure ?

There is an extensive learning curve to understand all of the above values, and there impact on each other. The technique is established through experience.. Its very hard to say a knife is not sharp all the way through the edge.. My first thought would be the center of the blade is supported for deflection by the jaws. but the tip and the heel can easily see a much more obtuse angle than the center if you apply too much pressure.I am not the right person to give you a definitive answer. I can help with detective work on your problem but without enough clues, its hard to say.there are lots of experienced member here on this forum. I am not one of them….Good luckBill aka ET02/23/2016 at 10:55 am #31504Anonymous

Inactive- Topics: 14

- Replies: 427

To answer your question about ceramics, I can make a blade so sharp that is scary sharp using # 600 grit stones as my final media. it will be toothy and without a mirrored bevel, but it will cut through fleshy stuff found in the kitchen like a hot knife through butter.

So something isn’t right with your set up or technique.

02/23/2016 at 4:01 pm #31532Thanks for the replys! Yes maybe i chipped it with the 100 grit as I did make sure to make a Burr either side all the way along heel to tip with the 100 grit.

To answer a few questions to help figure out whats going on, Im using a angle cube set to 17 degrees either side. Im using the Pro pack one so its more like, 16.95 left and 16.85 on the other because i can’t fine fine the angle. The tip and the heel of the knife will easily slice paper but the middle section will not.

The knife is new ( 3 weeks old) reason I put it on the wicked edge is because I got a chip on the top and wanted rid of it which i did no problem.

I did scrub up and down a bit to help get a burr, I used the sharpie tip to see if the angle was around what I was doing it, i think its about right not too sure but i did reprofile as to get rid of the tip. unsure of how to use it to find where the position of the knife should be.

Has anyone any experience with this steel or any carbon steel? as im wondering are the stones suited for sharpening this kind of steel, i’ve only ever used it with stainless steel type knives and i’ve got some good results.

thanks guys

02/23/2016 at 4:23 pm #31533How old is your system? The reason I ask is because it makes a difference as to how broken in your diamond plates are.

-Clay

02/23/2016 at 4:37 pm #31534Its just over a year old, Sharpened about 20/30 knives with it.

02/23/2016 at 4:43 pm #31535Its just over a year old, Sharpened about 20/30 knives with it.

Okay, then it probably isn’t that your stones are too new.

-Clay

02/23/2016 at 8:17 pm #31541Congratulations on your knife choice! It’s a great kitchen knife. I happen to have it, too

:

:

I think accidentally chipping the knife is the most likely diagnosis for your problem. Blue super steel can take a lot (also reasonably good toughness), but here it is very hard (HRC 64, according to Masakage). If it happens more often, you could start at 200 grit or 400 grit. But I’ve never had this problem even with hard carbon steels.

The diamond stones are suitable for any type of steel. I personally like the edges on my kitchen knives slightly more refined than 1000 grit, so I usually use the ceramics after the diamond stones. And you may want to try an even more acute angle on this knife. The steel can take it.

Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

02/24/2016 at 1:17 am #31548The fact that you sense the roughness of the edge is the clue that you are indeed producing serrations in the edge with the coarse grits that you are not removing with the normal progression.

I only use my 100/200 stones on a reprofile, and then as cbwz34 says, try to never touch the apex with them. As a grit particle approaches the edge, it reaches a point where the strength of the steel to resist cutting suddenly drops off. At this point, a chunk substantially larger than the depth of the scratch may break off, leaving a deep notch in the edge.

I find that when I go on to the 400s, it takes a lot of work to clean up the edge. After that, each grit goes pretty fast. On 90% of the knives I do, I start with my 400s, so I wear out my 400/600s faster than any other grits. It may take 50 strokes on the 400s to form a good bevel and to smooth out the edge, but only 10 strokes on each grit thereafter.

02/24/2016 at 9:10 am #31550Really appricate all the replies guys. Mark76 yes it’s a fantastic knife, very happy with out of the box edge and feel of the knife. What’s angle do you have yours set to?? Do you know the masakage factory angle?

I am going to try wit the same angle but just start at 400 and work up to 1000 grit. Will let ye know how it goes and maybe get some pics up.

Also going to buy and 1200 /1600 grit soon, what grit are the next ceramic stones as I only see coarse and fine printed on them? Are they much more refined than the 1200/1600?

Anyone any experience with Japanese waterstones for the WE, overkill for kitchen knives?

02/24/2016 at 1:08 pm #31556I usually do a 15 degree angle on a J-knife, but I think with this steel you could go lower. Just give it a try.

And I wrote a number of blog posts on stones, including ceramic stones and waterstones: link

Molecule Polishing: my blog about sharpening with the Wicked Edge

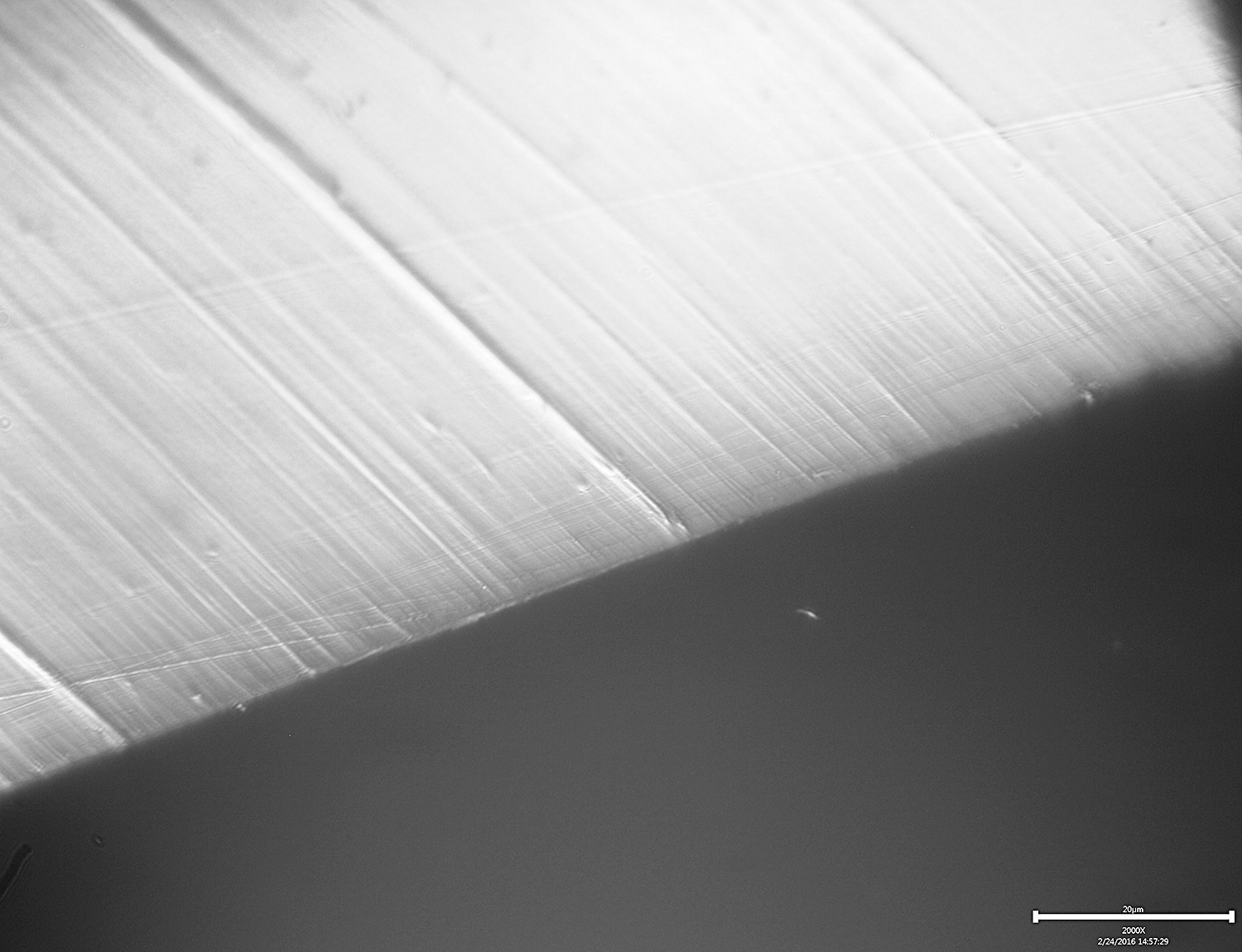

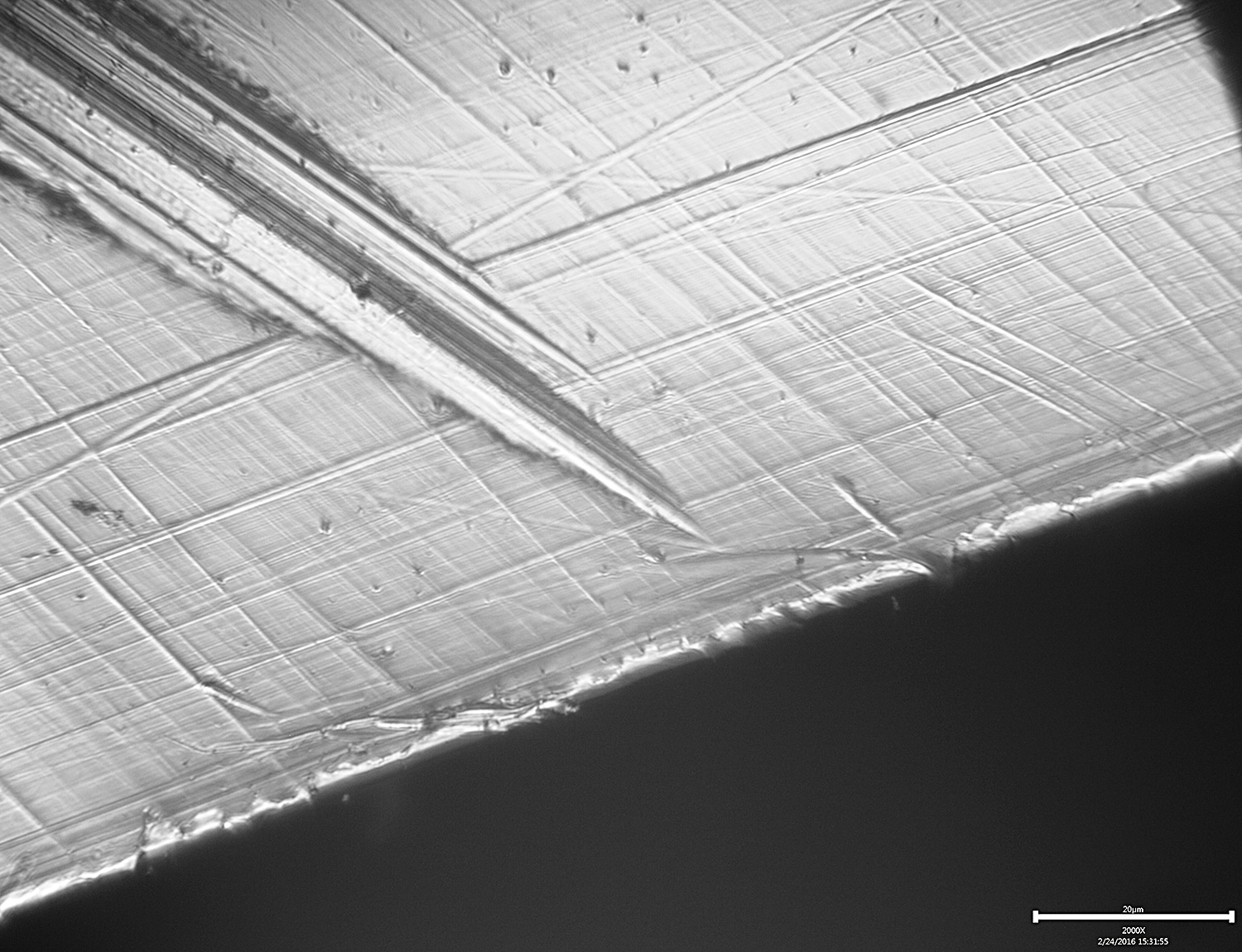

02/24/2016 at 4:51 pm #31564I wanted to take some time and provide a visual reference for what Tom was talking about regarding taking the coarse stones all the way to the edge when you’re reprofiling. Here is an image of a blade I prepared at 16° per side and then added a 20° micro-bevel, then stropped it at 16° down to .5µ:

This is at 2000# and shows the slight curvature at the edge where the 16° primary bevel blends into the 20° micro-bevel.

-Clay

Attachments:

You must be logged in to access attached files.

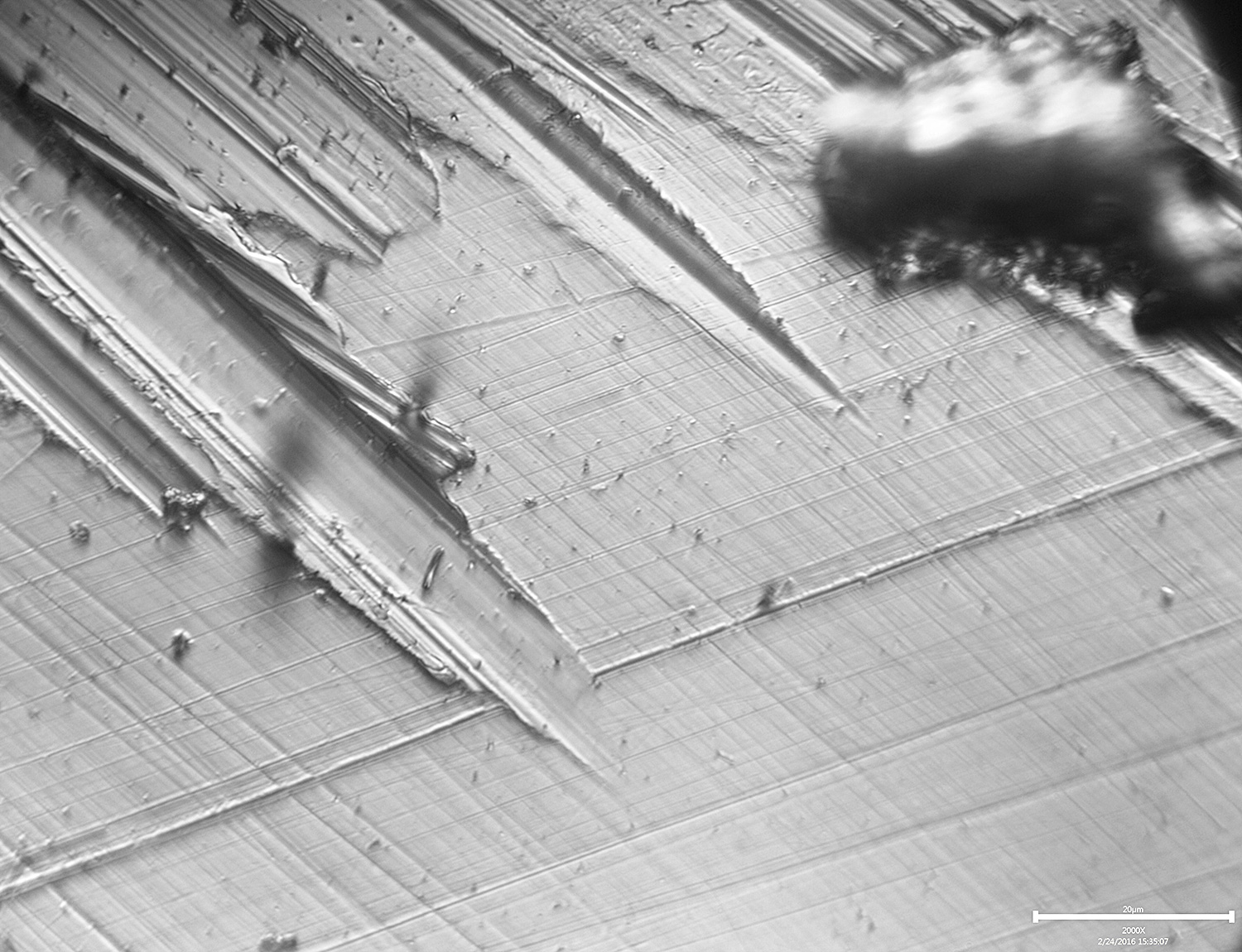

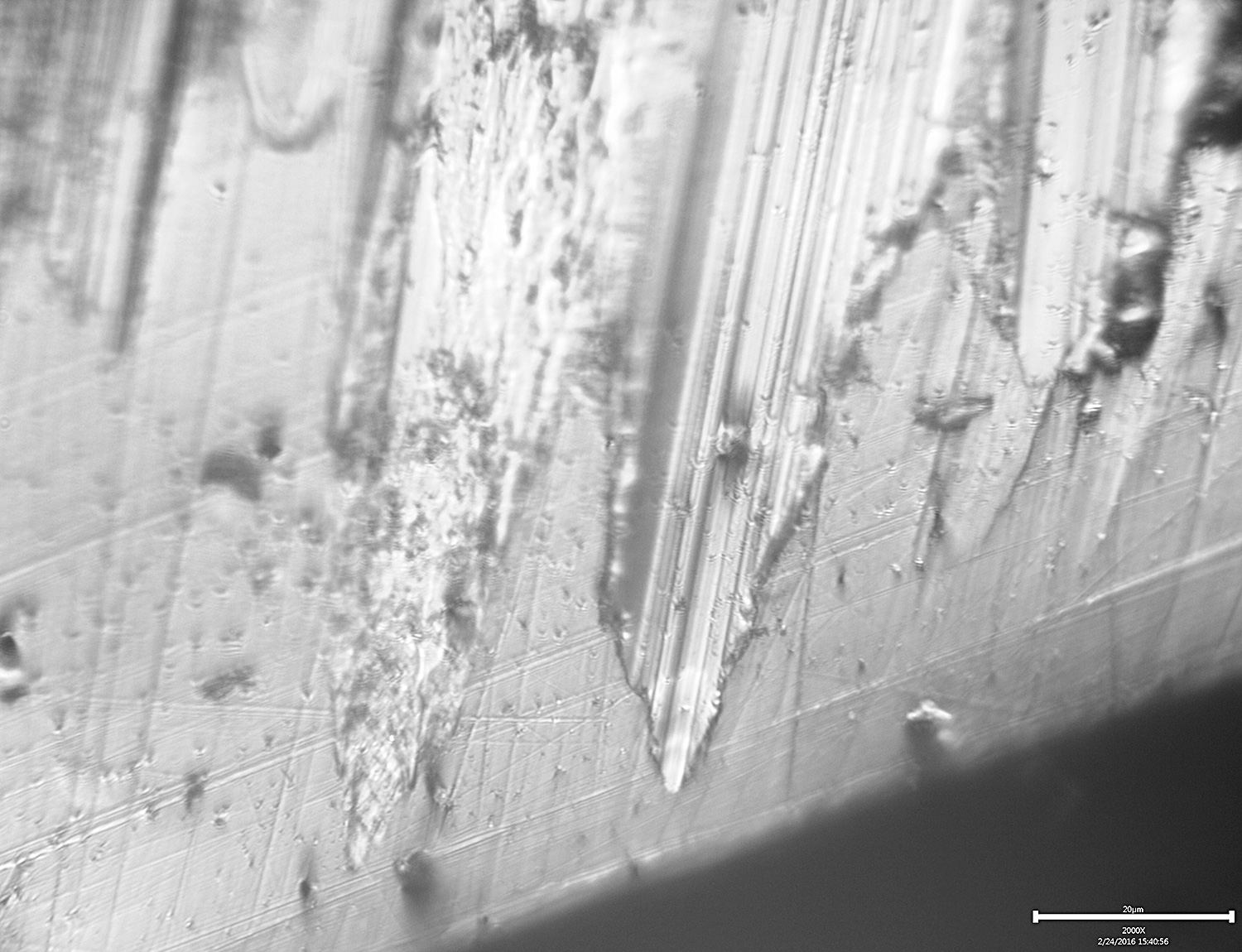

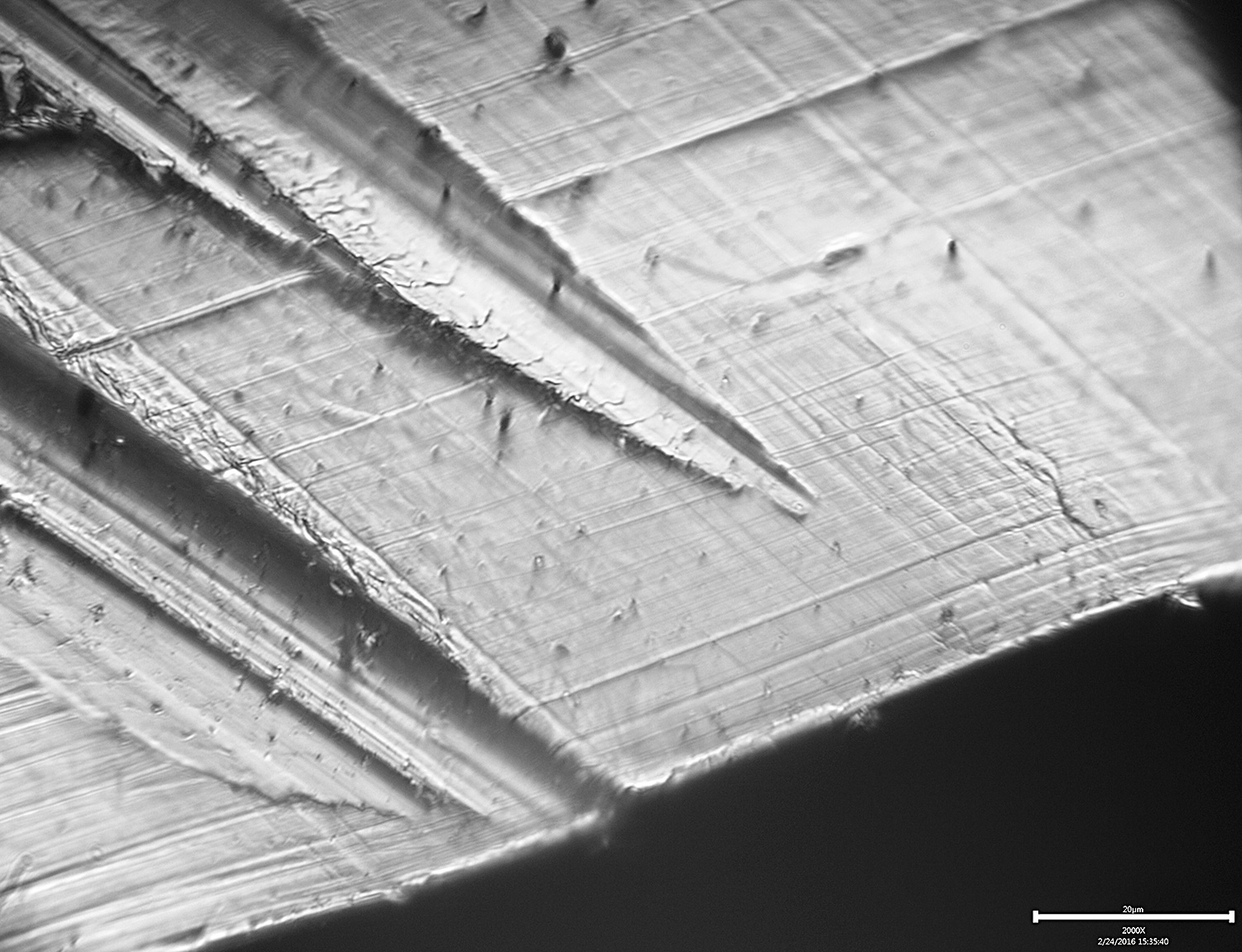

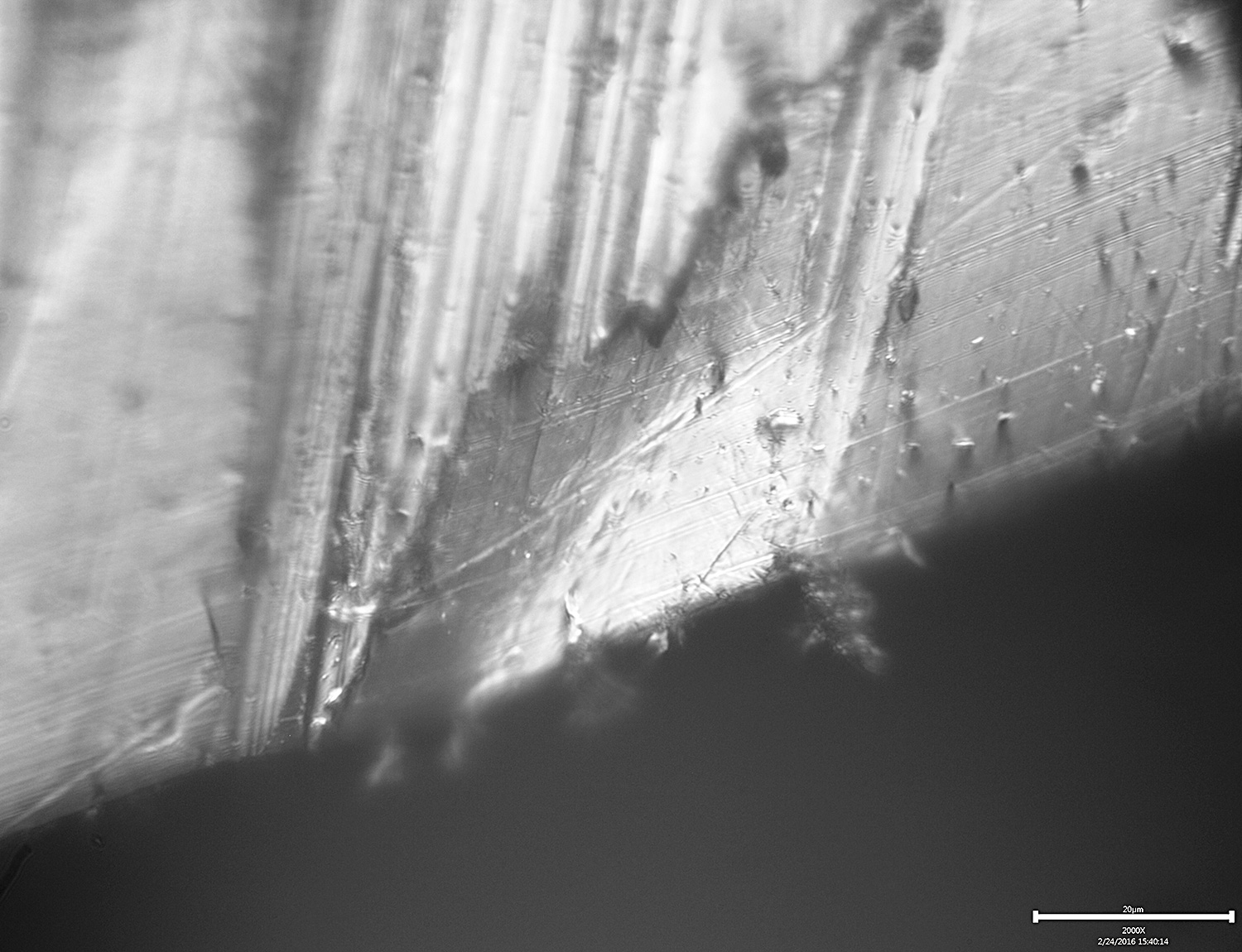

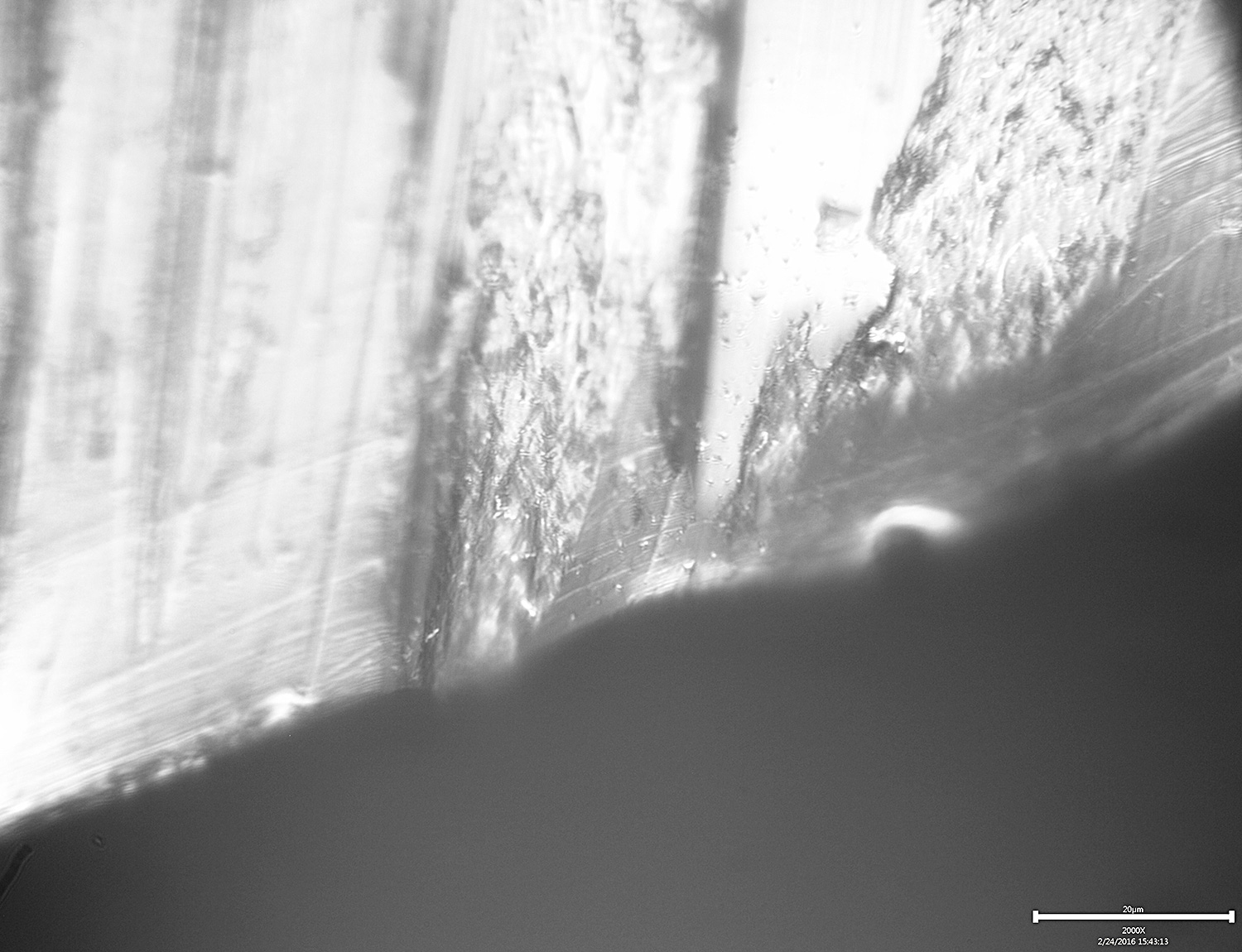

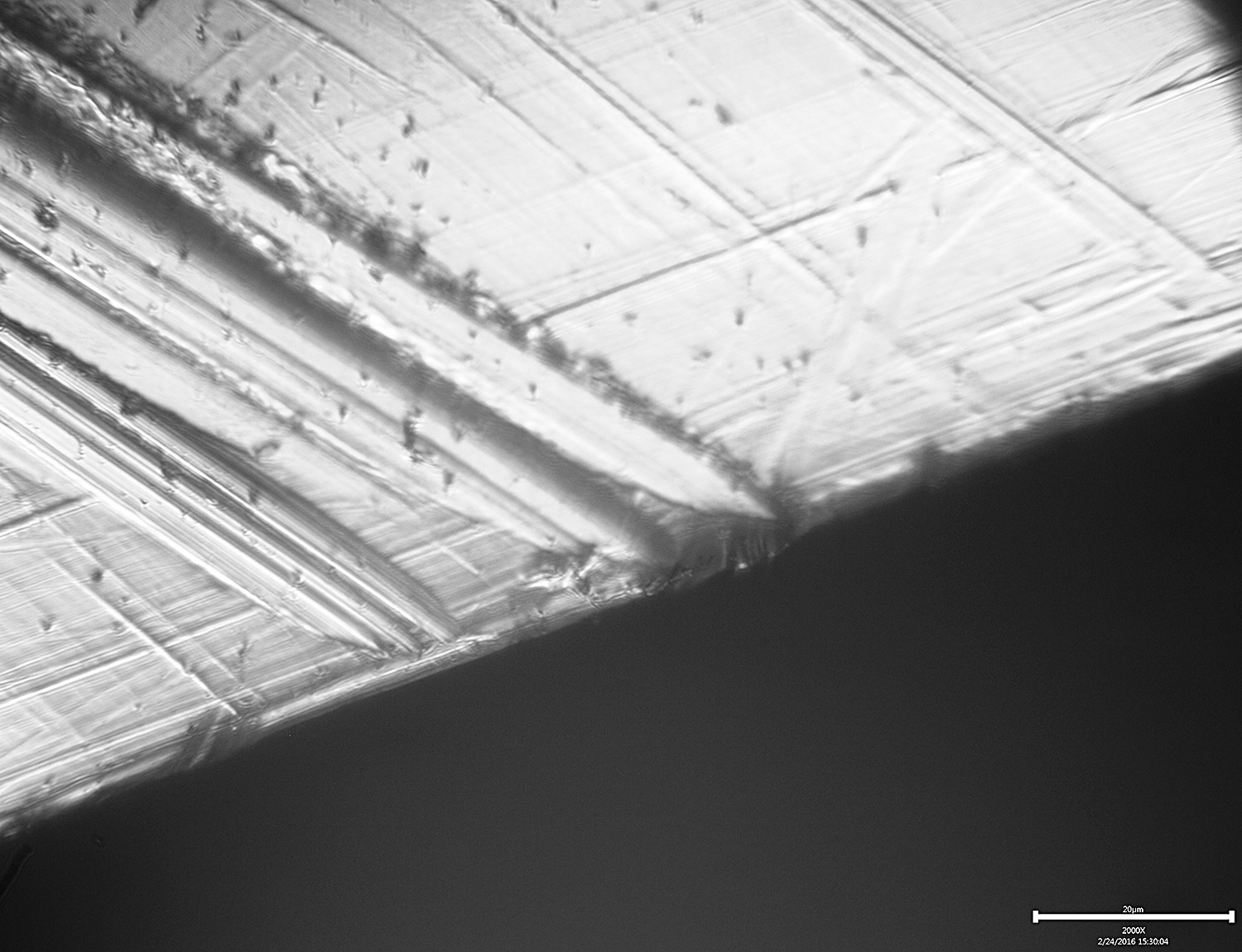

02/24/2016 at 4:56 pm #31567In the above image, the edge is very clean and straight. Next I started sharpening with a used set of 100# diamonds and slowly approached the edge. Because I’d put in a micro-bevel, I could sharpen at 16° and know that I would not be hitting the edge right away. Here are some shots of the process at 2000#:

It’s interesting to see the scratch lines approaching the edge and the edge starting to deform even before the scratches make it all the way. I checked the other side of the blade to be sure that the scratches there weren’t making it to the edge early and causing the deformation. Nope, they were about the same as the first side.

-Clay

Attachments:

You must be logged in to access attached files.

02/24/2016 at 5:00 pm #31571 -

AuthorPosts

- You must be logged in to reply to this topic.