Strops or stones ?

Recent › Forums › Main Forum › Welcome Mat › Strops or stones ?

- This topic has 148 replies, 12 voices, and was last updated 01/05/2017 at 6:27 am by

Organic.

Organic.

-

AuthorPosts

-

03/25/2016 at 2:31 pm #3261903/25/2016 at 2:59 pm #32627

Clay these tests are most informative. Looks to me like one could almost use the new #600 grit stone for a little re-profile work while breaking it in. Maybe the same for the lower grit #100/#200/#400 stones as well?

Alan

1 user thanked author for this post.

03/25/2016 at 3:35 pm #32632Clay these tests are most informative. Looks to me like one could almost use the new #600 grit stone for a little re-profile work while breaking it in. Maybe the same for the lower grit #100/#200/#400 stones as well?

I think that’s true – one mistake I think people make when they’re first starting out is to do all the work with their 100# stones and they wear them out pretty quickly while they don’t adequately break in their higher grit stones. Personally I prefer to start with the highest grit possible, especially when I’m matching an existing bevel, just improving it etc… and then I’ll work backward, to lower grits as needed. Lowering the angle by 1 degree should be pretty easy to do with the 400#/600# stones.

-Clay

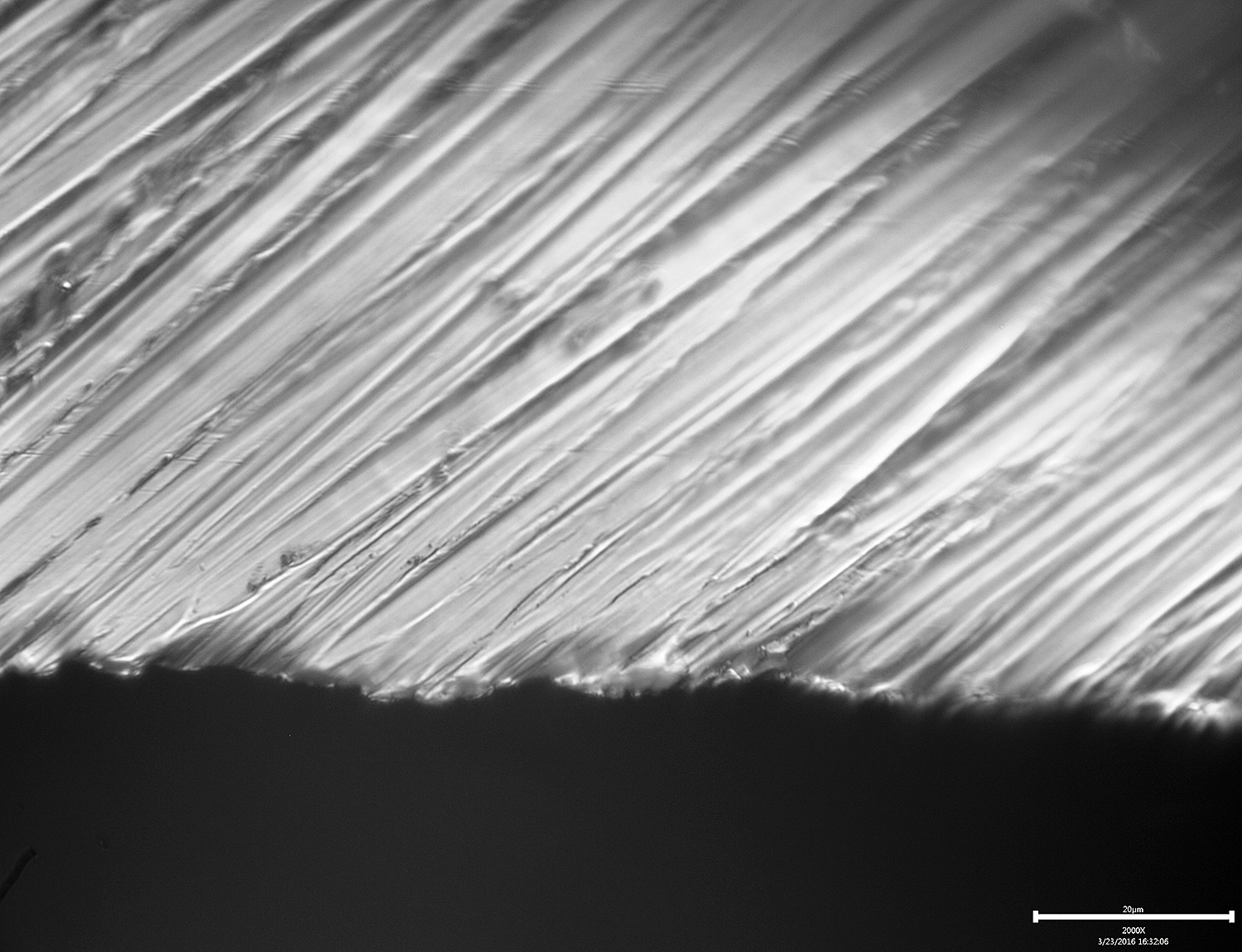

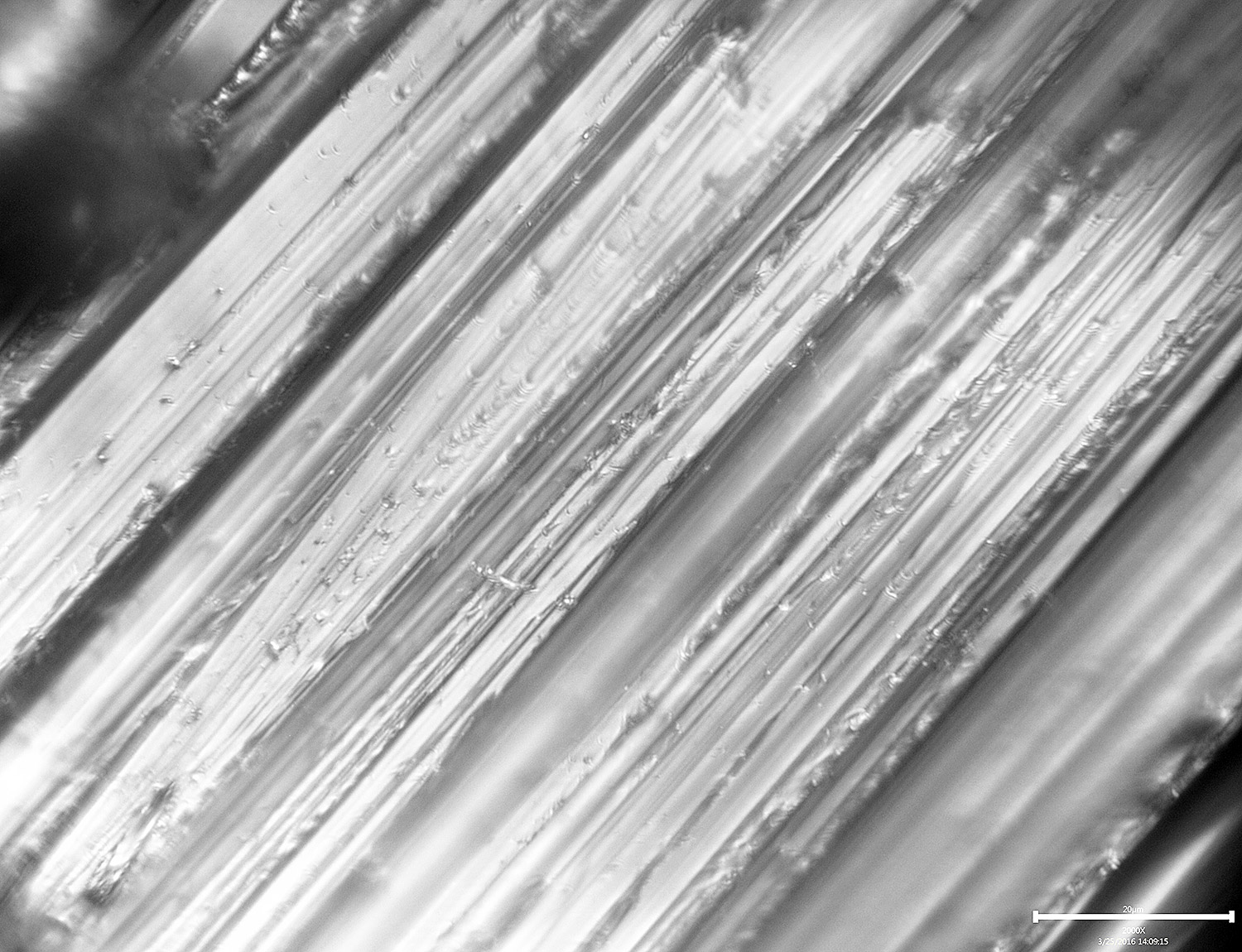

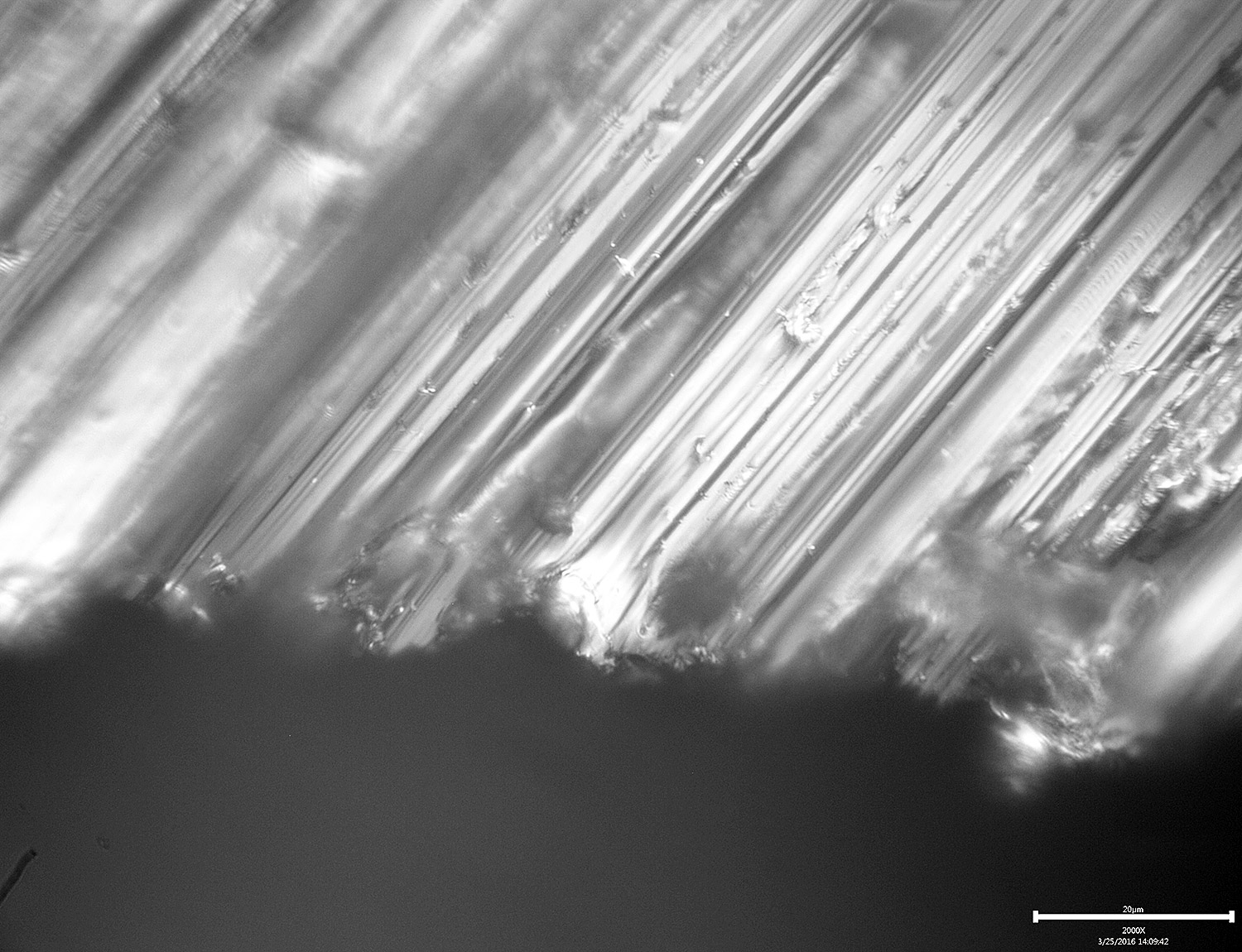

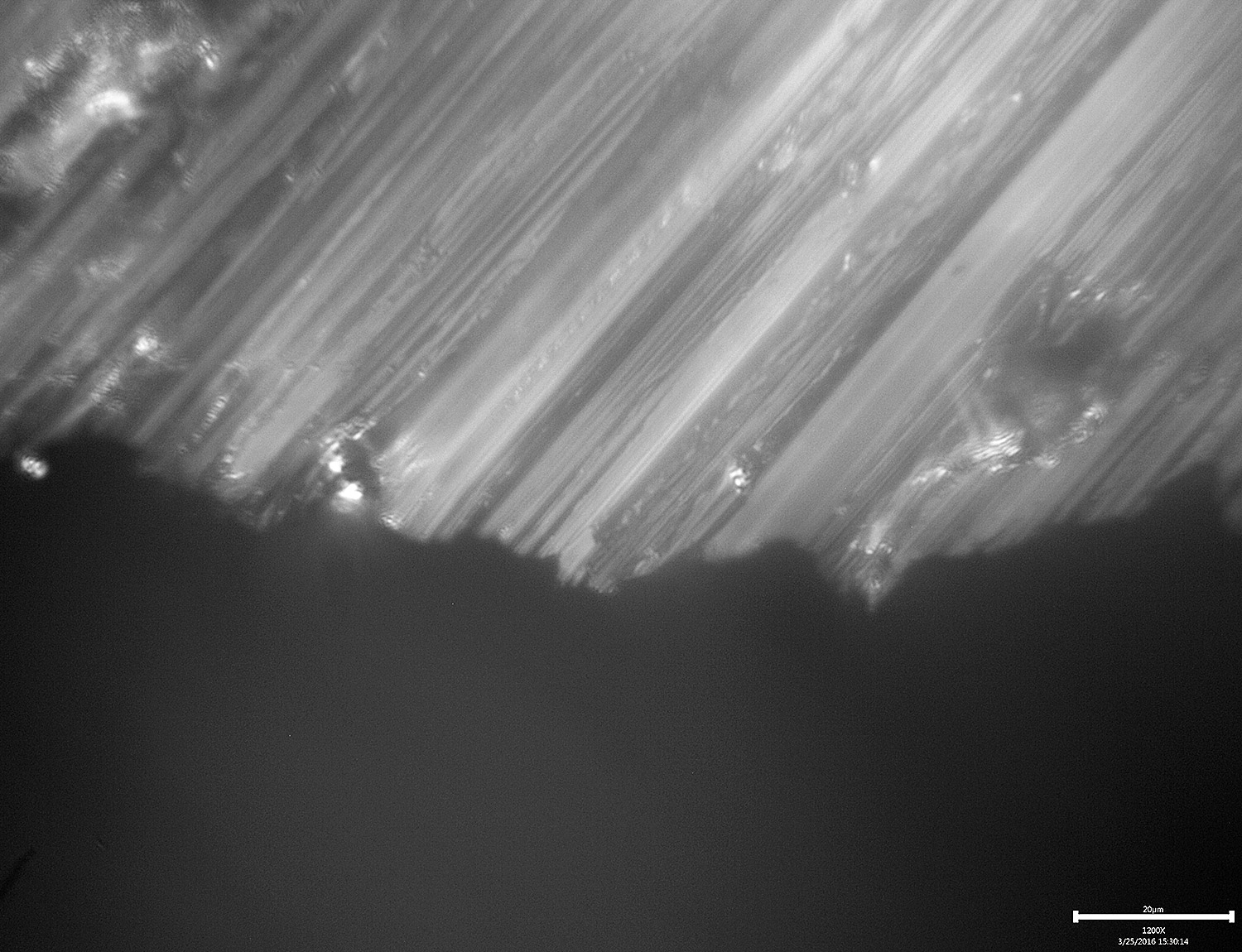

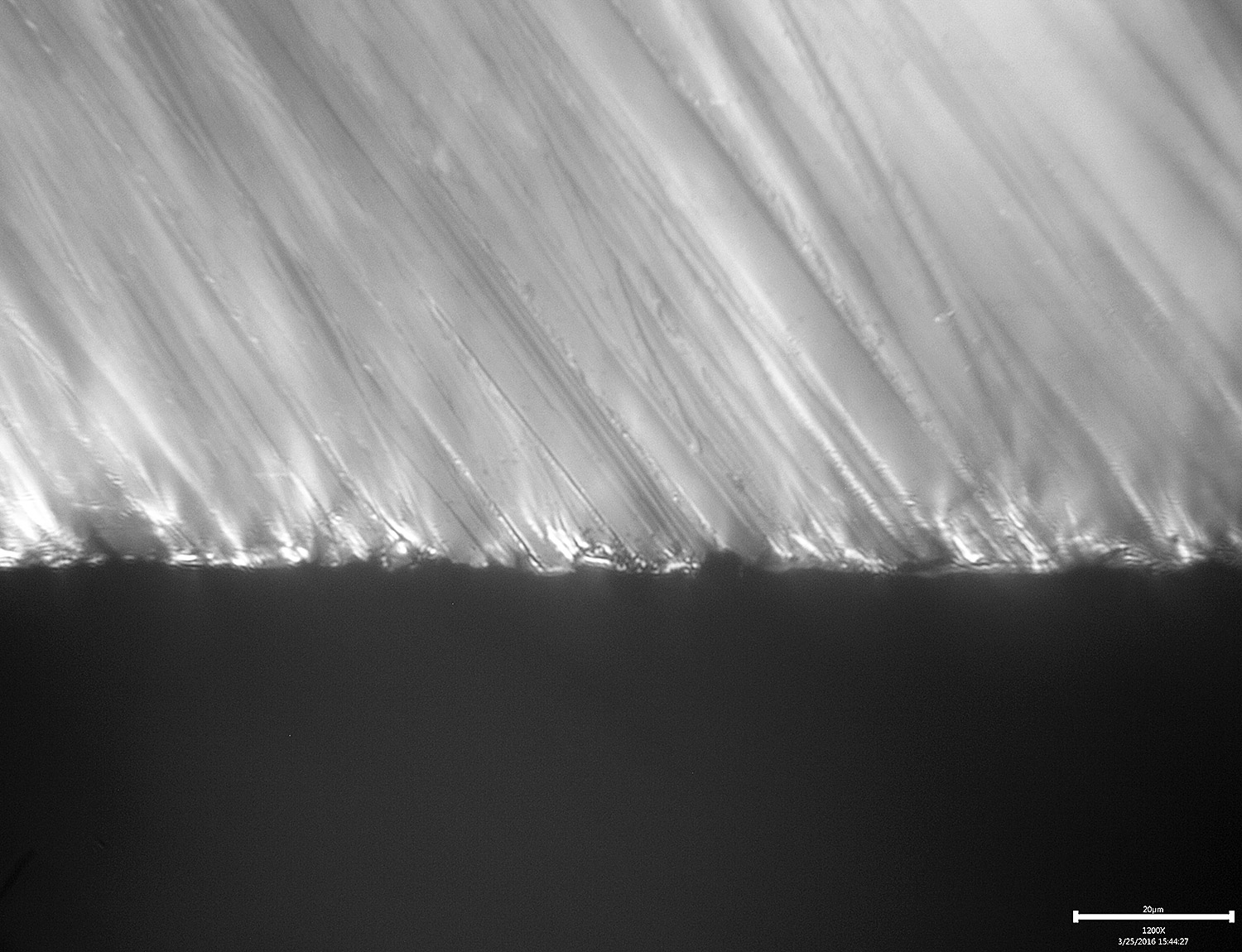

03/25/2016 at 3:55 pm #3263703/25/2016 at 3:56 pm #32641Broken in 600# Stone:

New 600# Stone:

Thank you Clay! On new stone variance in ridges is so high that many are out of focus. Broken stone definitely has more uniform scratches.

03/25/2016 at 4:08 pm #32644Looks to me like one could almost use the new #600 grit stone for a little re-profile work while breaking it in.

No. I think it will be wrong. Unbroken stone has diamonds sticking out. I’ll try to make a sketch below with “o” representing good diamonds, “A” representing sticking out diamonds.

Unbroken 600# ooooAoooooAooooooAoAoooAooooooAoAoooooA

Broken 400# OOOOOOOOOOOOOOOOOOOOOOOOOOOOO

Sticking out diamonds are not as uniform as in lower grit stones. You will have just bigger rare scratches. It is just my guess for 2 cents.

03/25/2016 at 4:18 pm #32646Broken in 600# Stone: New 600# Stone:

Thank you Clay! On new stone variance in ridges is so high that many are out of focus. Broken stone definitely has more uniform scratches.

Nice observation about the height of the ridges/depth of the scratches. That’s the reason I switched to the 1200x lens; to get a better depth of field. Here’s the same edge taken at 2000x:

All the blurriness comes from surfaces of unequal height.

-Clay

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

03/25/2016 at 7:10 pm #32650Alan: In fact, I am currently doing exactly that -using the new 400/600 stones to remove material more rapidly, then the broken in stones to do the finish work. I can feel the new stones “dig in”. The amount of force required to move the new stones is clearly greater than the force needed to move the old stones. It sure seems to me to be effective, but I’m comparing them with my old stones which are closer to being broken out.

2 users thanked author for this post.

01/02/2017 at 9:10 pm #36451Just bought a set of SO Lapping films, 9,5 and 3 microns. Decided to do my first knife with them last night. Pulled out a ZT0566CF in M390. Reprofiled the edge to 17 degrees starting with the 100/200 stones and on up to the 800/1000 stones. Then on to the 1200/1600 ceramics and finally on to the new 1500 diamond stones I just received. After doing the 800/1000 stones I tested the edge to see where I was at. Felt pretty good. Moved on to the ceramics and still felt good after doing both. Then on to the 1500 and then tested again and the blade felt worse off. I used a piece of phonebook paper and manually pushed it into the blade and after the 1600 ceramics it cut nicely, after the 1500 diamonds it was far worse. Is this because the 1500’s need time to break in? Or should I use them after the 1200’s and before the 1600’s? Or just skip the ceramics and use the 1500’s and then the lapping films? This grit thing has me confused as to what progression to use.

I ended up going from the 100/200’s on up to the 1200/1600 and then using the films and while I didn’t get a really shiny edge, it was ok, and it was pretty sharp. Anybody live on the west coast of Florida and want to help me out with this stuff? I can get ok results, but not edges like I’ve seen posted on this site.

01/03/2017 at 10:46 am #36460@Ravenbrook – Your 1500# diamonds need time to break in, just like the rest of the diamond plates. You’ll see a big improvement once they do.

-Clay

01/03/2017 at 10:59 am #36461My 1500# diamond stones are relatively new (have only been used for 7 knives at this point) but I can already tell that they are breaking in substantially. Coming off of the 1000# directly to the 1500# I have seen the beginnings of mirroring on the last two knives whereas the 1500# finish looked more like a fine satin on the first few knives.

01/03/2017 at 2:39 pm #36467Just bought a set of SO Lapping films, 9,5 and 3 microns.

You can skip ceramics 1600/1200. Post below has a few quotes regarding films and ceramics.

01/04/2017 at 8:08 pm #36486Thanks for the advice guys. I’m planning on doing a knife or two this weekend and plan on skipping the ceramics and go from the 1000 grit to the 1500 grit and then to the SO films. Should I just use the 3 micron as someone suggested or also use the 9 and 5’s?

Again, thanks! And what a great forum that isn’t full of all the drama that I’ve found on so many others! Great work Clay!

01/05/2017 at 6:27 am #36492You would be well served to include the 9 micron and 5 micron films in your progression. Clay did try going from a well broken-in 1500# directly to the 3 micron diamond film (previous thread), but after 10 strokes on each side he could still see the 1500# scratches so it would likely take significantly more strokes with the 3 micron aluminum oxide films to eliminate the 1500# scratches.

-

AuthorPosts

- You must be logged in to reply to this topic.