Steel will cut jack

Recent › Forums › Main Forum › Steel will cut jack

- This topic has 10 replies, 2 voices, and was last updated 12/21/2020 at 2:43 pm by

Marc H (Wicked Edge Expert Corner).

Marc H (Wicked Edge Expert Corner).

-

AuthorPosts

-

09/22/2018 at 5:42 pm #47707

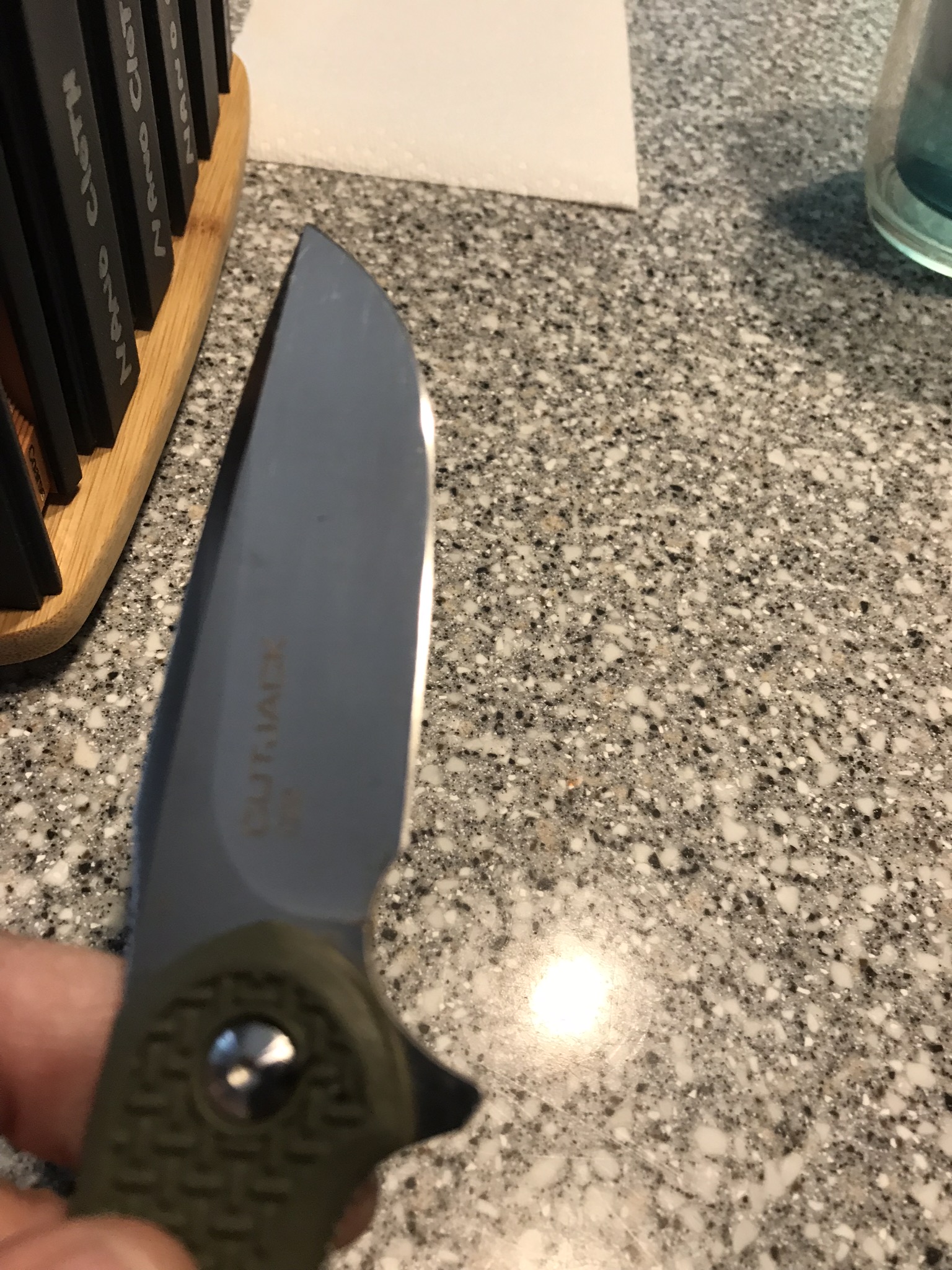

First time sharpening D2 on the wicked edge system. Markered the blade found the sweet spot matched the angle on both sides and went through the stones finished with ceramic and I am very happy with the edge.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

09/22/2018 at 6:57 pm #47710That’s all that really matters is that your happy with the results. What angle did it match at? D2 steel has a wide range of hardness, from 55 to 62, on the Rockwell C scale, depending on how it was hardened and tempered. So the steel could be from what would be considered soft to pretty hard on the other end of the scale.

I’ll be curious to see how it stands the test of time and use.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

09/23/2018 at 12:58 am #47711The angle was pretty close to 20 degrees per side 20.35 on one side and 20.45 on the other chose to go with 20 degrees. I EDC this knife in rotation for work everyday and have found I like the 20 degree angle for cutting of shrink wrap and cordage that I cut everyday. The steel will is not expensive but being knew to the WE system I wanted to try sharpening D2 on an inexpensive blade. As my confidence gets better I will move up to the lapping and polishing as you much more experienced gentlemen do. I would also like to thank all the members that are willing to give me the benefit of their experience. I am glad I found this site. You are willing to share your knowledge without hesitation no matter how simple the question.

4 users thanked author for this post.

09/24/2018 at 1:18 pm #4772409/24/2018 at 2:47 pm #47727That’s a great looking bevel Travis! You did a good job clamping the blade in the sweet spot as evidenced by the even bevel width across the length of the blade.

1 user thanked author for this post.

09/24/2018 at 3:41 pm #47728Travis what degree angle did you use on your cut jack ? That is one great looking bevel

1 user thanked author for this post.

10/02/2018 at 11:25 am #47800I think I did that one at 17 dps

1 user thanked author for this post.

11/29/2018 at 6:55 am #48352Just did a Mini Cutjack, FDE color. Super sharp

Attachments:

You must be logged in to access attached files.

12/02/2018 at 11:24 am #48385Great looking edge I really like sharpening the cut jack

12/20/2020 at 6:27 pm #55467Would you by chance have the setting you used to clamp the knife I seem to be really struggling to find the sweet spot

12/21/2020 at 2:43 pm #55473Adam, welcome to the Wicked Edge forum.

I have not personally sharpened this knife. From looking at the photos of that knife posted earlier in this thread, it appears you’re pretty limited to how you can clamp that blade. I’d attempt to clamp it on the narrowing tapered curving parallel flat plane surfaces on both sides of the knife just below the spine bevel. I’d try to position the knife in the vise jaws so it’s clamped as far forward, towards the tip, on the knife as possible. If there’s not enough height on the flat spot to find a secure purchase for the jaws then I’d slide the knife so the jaws are just as far back as is required, to find the flat spot height needed to get it clamed securely. As you clamp the knife further back on the blade closer to the ricasso you’ll gain more height in the curved flat spot. This may allow you some clamping adjustability to rotate the knife so it’s positioned just slightly more “tip up” as clamped. This may help with finding the “Sweet Spot”.

Realize that every knife we clamp in the W.E. for the first sharpening will undergo some small amount of blade edge profiling, seen generally at the extreme ends of the blade, tip and heel, as the blade coordinates with the fixed angle sharpening method used with the W.E. Each subsequent sharpening will not require further edge reprofiling as long as the first clamping position is used again.

I wanted to add, it’s not necessary for the knife to be resting down on the depth key pins whenever positioning and clamping a knife. The only requirement is that the knife be clamped stationary and securely. If it requires the knife be positioned so it’s just held by the very jaws tips to find a good clamping position then “so be it”. Still use the alignment guide positioned with the depth key to record the knife’s clamping position and for future touchups.

Marc

(MarcH's Rack-Its)-

This reply was modified 4 years, 3 months ago by

Marc H (Wicked Edge Expert Corner).

Marc H (Wicked Edge Expert Corner).

-

This reply was modified 4 years, 3 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.