Re: Ceramic or 1000 grit stone for convex bevels???

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Thoughts/Theories/Science Related to Sharpening › Re: Ceramic or 1000 grit stone for convex bevels???

- This topic has 39 replies, 10 voices, and was last updated 02/17/2013 at 9:42 am by

Ken Buzbee.

-

AuthorPosts

-

01/23/2013 at 2:51 pm #9044

I am either the bozo that knows not what he’s taking about, or a fly in the ointment on the ax/maul convex edge idea. I have 2 mauls, one whose edge is narrow for a “considerable length” and another that “blunts” quite quickly.

These are the factory edges with the exception that the narrow ones edge has been touched up from time to time over the last 35 years with a file.

I will tell you, that the blunt one will jar you to your very soul and not split the wood, while the narrow one gets in deep enough before acting as a wedge and splits the wood. I am able to swing my maul (circular fashion, not just raised back and hit the wood) and am able to hit the wood with considerable force and accuracy. The blunt one, no, I do not recall it becoming stuck. The narrow one becomes stuck at times, but is by far the better splitter, the blunt one, bounces and jars.

Just say’n

01/24/2013 at 6:41 am #9054I will tell you, that the blunt one will jar you to your very soul and not split the wood, while the narrow one gets in deep enough before acting as a wedge and splits the wood. I am able to swing my maul (circular fashion, not just raised back and hit the wood) and am able to hit the wood with considerable force and accuracy. The blunt one, no, I do not recall it becoming stuck. The narrow one becomes stuck at times, but is by far the better splitter, the blunt one, bounces and jars.

This is entirely consistent with what I wrote (and others – it was a summary). A sharp edge will – as long as it doesn’t get damaged – obviously get deeper into the wood than a blunter edge. However, assuming that the blunt edge has wider shoulders, the sharp edge will have a larger surface area in contact with the wood. So it will get stuck earlier.

I don’t know if you wrote the above in response to Clay’s remark on why a convex edge splits wood more easily. What I think Clay meant (but please speak for yourself, Clay) is that once a convex edge has made a substantial crack in the wood (the initial split), the shoulders of the convex edge aid in splitting the wood further apart.

But this does require that the edge of your edge is sharp enough to make the initial crack. Otherwise it doesn’t only get the first few blows right on its head, but the remaining ones as well. And the wood doesn’t get split.

Molecule Polishing: my blog about sharpening with the Wicked Edge

01/24/2013 at 7:31 am #9056I don’t know if you wrote the above in response to Clay’s remark on why a convex edge splits wood more easily. What I think Clay meant (but please speak for yourself, Clay) is that once a convex edge has made a substantial crack in the wood (the initial split), the shoulders of the convex edge aid in splitting the wood further apart.

But this does require that the edge of your edge is sharp enough to make the initial crack. Otherwise it doesn’t only get the first few blows right on its head, but the remaining ones as well. And the wood doesn’t get split.

Exactly. The sharp edge initiates the crack, the shoulders force their way in and begin splitting the material.

-Clay

01/25/2013 at 10:16 pm #9081Hey guys,

I turned my above post into a blog entry. You can read it here[/url].

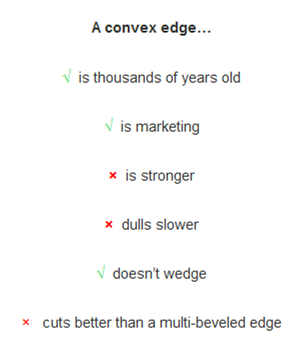

I corrected one error (about why a convex edge doesn’t dull slower – you have to keep sharp

). But for the rest I just tried to formulate things a bit sharper. And the verdict is:

Molecule Polishing: my blog about sharpening with the Wicked Edge

01/27/2013 at 1:00 pm #9112Exactly. The sharp edge initiates the crack, the shoulders force their way in and begin splitting the material.

I think this same sort of think is going on with the wedging that Mark talks about with food prep.

This is caused more because of the blade design above the bevel than the edge of the edge. A thick tall knife will wedge regardless of having a few thosandths of the leading edge use a V or a convex. After the edge breaks the surface and penetrates the surface for a small distance, the shoulders of the blade are pushing out enough that the edge may not even be in contact with the material… hence, wedging occurs.

A thinner blade with a hollow grind will cause less wedging than a convex grind blade, regardless of the profile of the edge of the edge.Phil

02/15/2013 at 9:36 pm #9534I made an update to my blog post. I added some pictures to illustrate why claims like “a convex edge is stronger” are rather meaningless when one omits the angles.

Like:

Molecule Polishing: my blog about sharpening with the Wicked Edge

02/16/2013 at 11:42 am #9545Mark,

Thanks for drawing this. This simple diagram says quite a lot in a few words.

02/17/2013 at 12:22 am #9556Thanks for drawing this. This simple diagram says quite a lot in a few words.

It does. It also points out that I need to find a (testable) definition of “sharp”. I mean, I kinda know it when I feel it but there are illusive things I can’t explain, define or defend. Like why my M4 Bradley “feels” sharper than any other knife I own.

Ken

02/17/2013 at 8:27 am #9561It also points out that I need to find a (testable) definition of “sharp”. I mean, I kinda know it when I feel it but there are illusive things I can’t explain, define or defend. Like why my M4 Bradley “feels” sharper than any other knife I own.

This makes me think of how the ISO defines quality: fitness for purpose. Very true, but rather difficult to make operational.

For a practical approach, try Dan’s site: http://www.howsharpisit.com/

Molecule Polishing: my blog about sharpening with the Wicked Edge

02/17/2013 at 9:42 am #9571Agreed!

I love Dan’s site. Haven’t visited in a while, I need to head back over there.

Ken

-

AuthorPosts

- You must be logged in to reply to this topic.