My new 2017 F&S Pro Base Addition

Recent › Forums › Main Forum › Sharpener and Accessory Maintenance › MODS › My new 2017 F&S Pro Base Addition

- This topic has 8 replies, 7 voices, and was last updated 03/16/2018 at 10:41 am by

Expidia.

Expidia.

-

AuthorPosts

-

03/12/2018 at 4:23 pm #45486

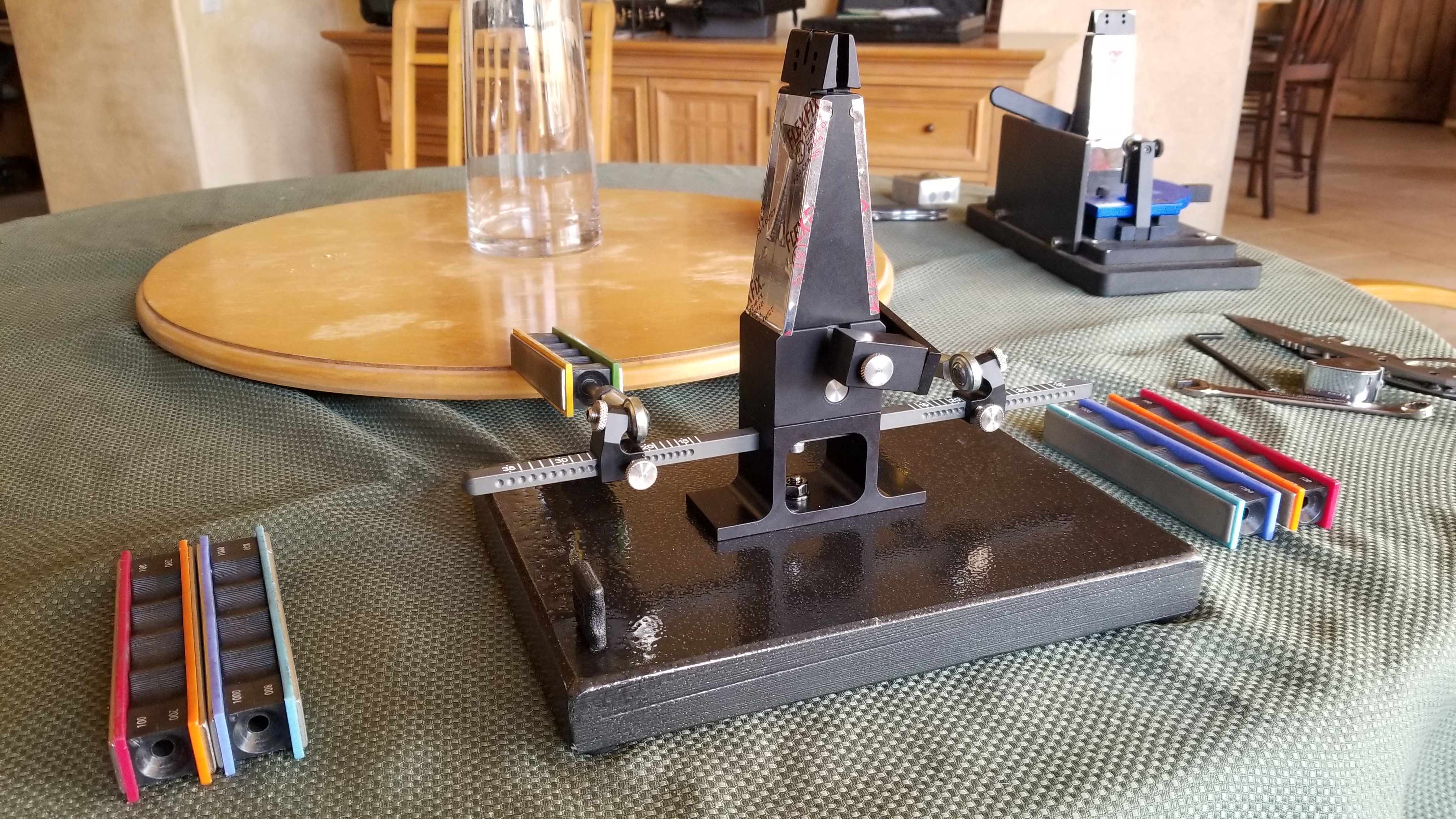

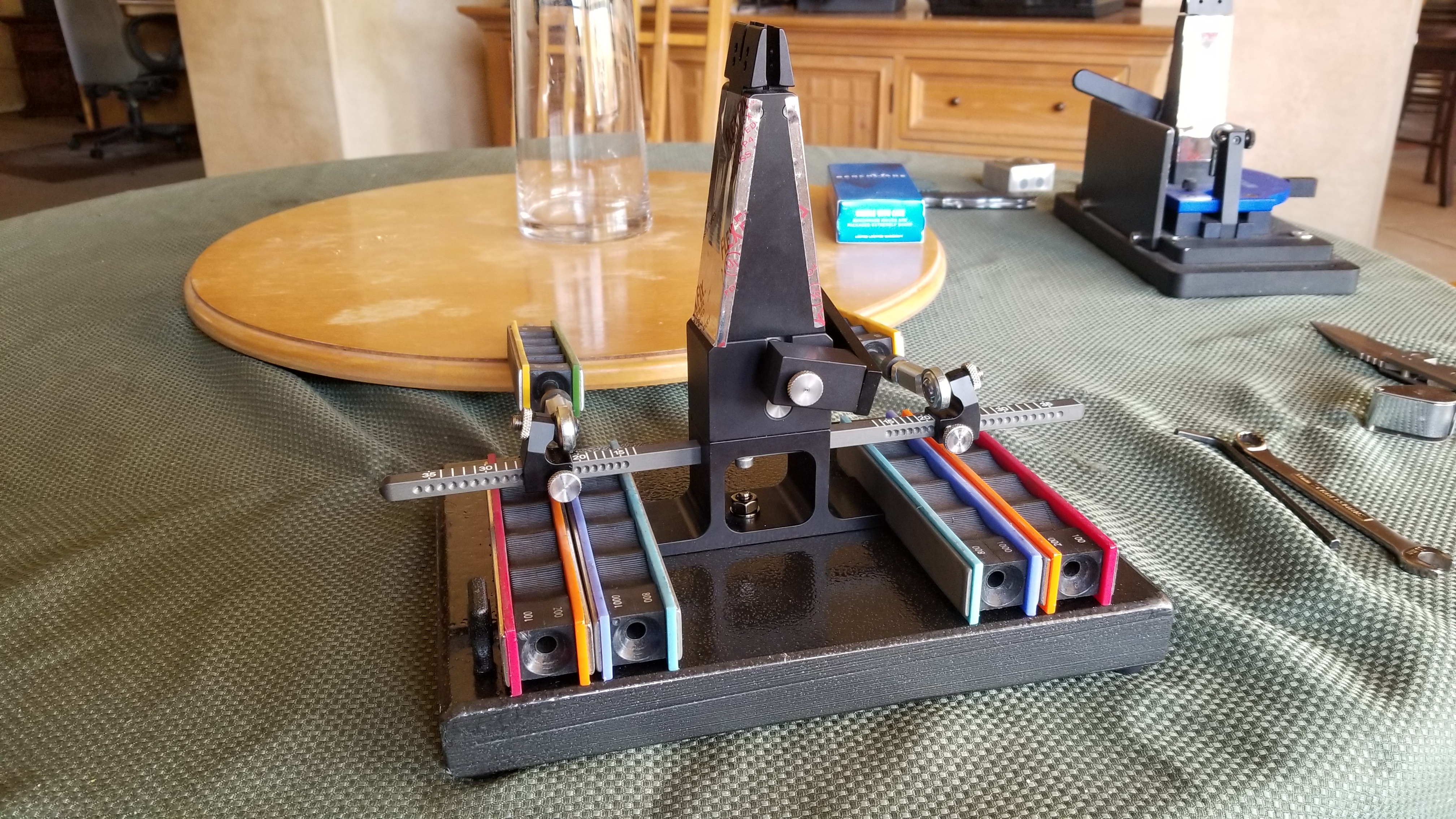

I finally finished the base I made for my 2017 WE F&S Pro. Pretty easy and cheap to make, and with the removal of just one nut, the base detaches and the sharpener is ready to “Stow & Go” in it’s carry case.

I love my 2016 WE Gen 3 Pro, but it’s not really very portable (Nor do I think it was designed to be.) However, the WE F&S Pro sharpener, when transferred into it’s slim case, is ultra portable. I think it’s the best of both worlds, at least if you travel with your sharpener now and then, like I do. No clamp when used at home, yet ready to go when you are.

Clay, see what you think, and perhaps you could offer your customers (as an accessory) a base that is pre-drilled for your WE F&S series of sharpeners. Just an idea…

Alan

-

This topic was modified 6 years, 4 months ago by

Alan.

Alan.

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

03/12/2018 at 4:38 pm #45492That’s great Alan. Definitely the best of both worlds. The only enhancement I would like to make to that is if you can add additional lower angle bar holes so the square bar could be removed and lowered as needed to allow you to achieve lower bevel angle settings while preventing the stones from contacting the vice. Of course as the angle bar is lowered you will need longer rod arms.

I have had a discussion for a similar concept allowing more versatility, with Kyle. We’re working on it. Use it well. It’s very practical. You did a first rate job making it.

Marc

(MarcH's Rack-Its)2 users thanked author for this post.

03/12/2018 at 5:49 pm #45494Really looks good Alan!

2 users thanked author for this post.

03/12/2018 at 8:15 pm #45506Alan,

Your mods are always very professional looking. Nice work!

2 users thanked author for this post.

03/13/2018 at 5:09 pm #45521I ordered (12-16) a pre 2017 F&S Pro with a paperstone base and WickedEdge drilled it to fit the F&S Pro.

2 users thanked author for this post.

03/16/2018 at 3:46 am #45532I just bought my F&S Pro a couple weeks ago and was thinking of doing the same thing. Glad to see it will work out before I start modifying mine.

1 user thanked author for this post.

03/16/2018 at 7:06 am #45535That’s great Alan. Definitely the best of both worlds. The only enhancement I would like to make to that is if you can add additional lower angle bar holes so the square bar could be removed and lowered as needed to allow you to achieve lower bevel angle settings while preventing the stones from contacting the vice. Of course as the angle bar is lowered you will need longer rod arms. I have had a discussion for a similar concept allowing more versatility, with Kyle. We’re working on it. Use it well. It’s very practical. You did a first rate job making it.

I’m trying to do the same setup for a friend who might buy my 2016 Gen III vice. This lower hole you suggest to add to acheive a lower bevel setting looks to me as we need to drill a “square” hole on each side to acheive that? Since I’m not a machinist and Kyle is at a show until next Tuesday, so I don’t know yet if the base he’s holding for us looks the same as the one above or if its different and already has extra angle bar holes already?

What tool drill a square hole?

Thx

1 user thanked author for this post.

03/16/2018 at 7:55 am #45536That was really a statement of wishfulness. The square hole needs to be exact in size, shape and positioning, a machined hole of tight tolerance. That, I believe, would need to be done prior to it’s anodizing.

Marc

(MarcH's Rack-Its)1 user thanked author for this post.

03/16/2018 at 10:41 am #45537thanks marc, i think the base that kyle is holding for us is that one that looks like an upside down U. the one shown in this thread i think comes with the F&S setup.

1 user thanked author for this post.

-

This topic was modified 6 years, 4 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.