Is stropping just for show?

Recent › Forums › Main Forum › Stropping › Is stropping just for show?

- This topic has 27 replies, 10 voices, and was last updated 09/23/2015 at 2:57 pm by

Ravenbrook.

-

AuthorPosts

-

09/18/2015 at 12:21 am #28927

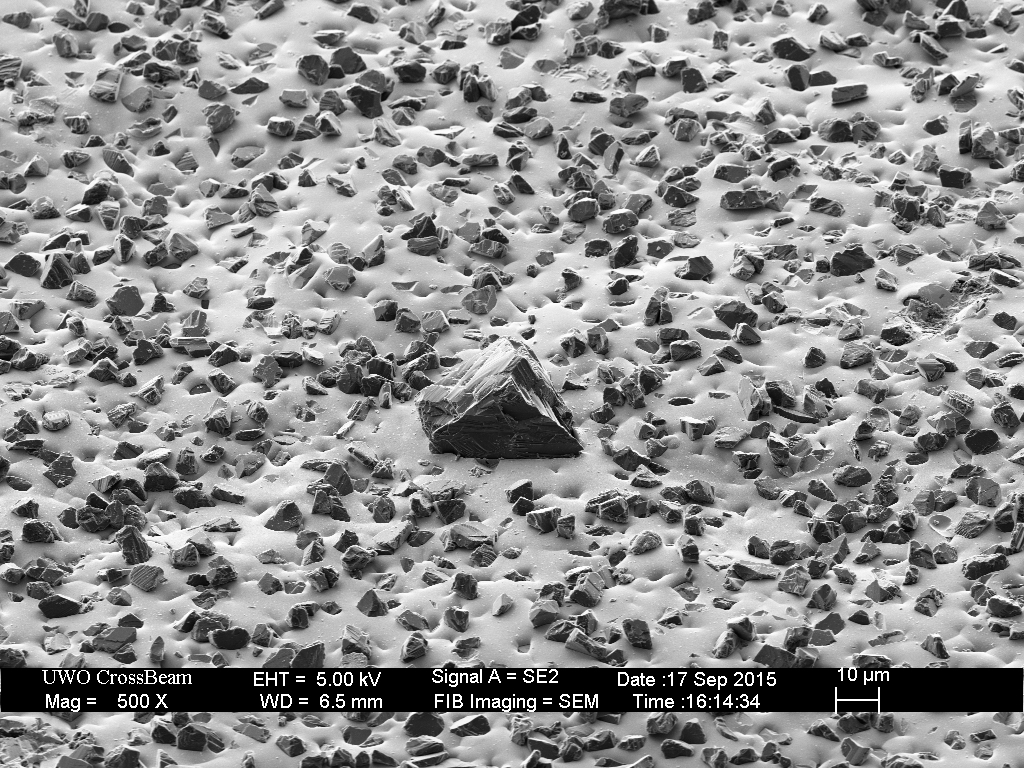

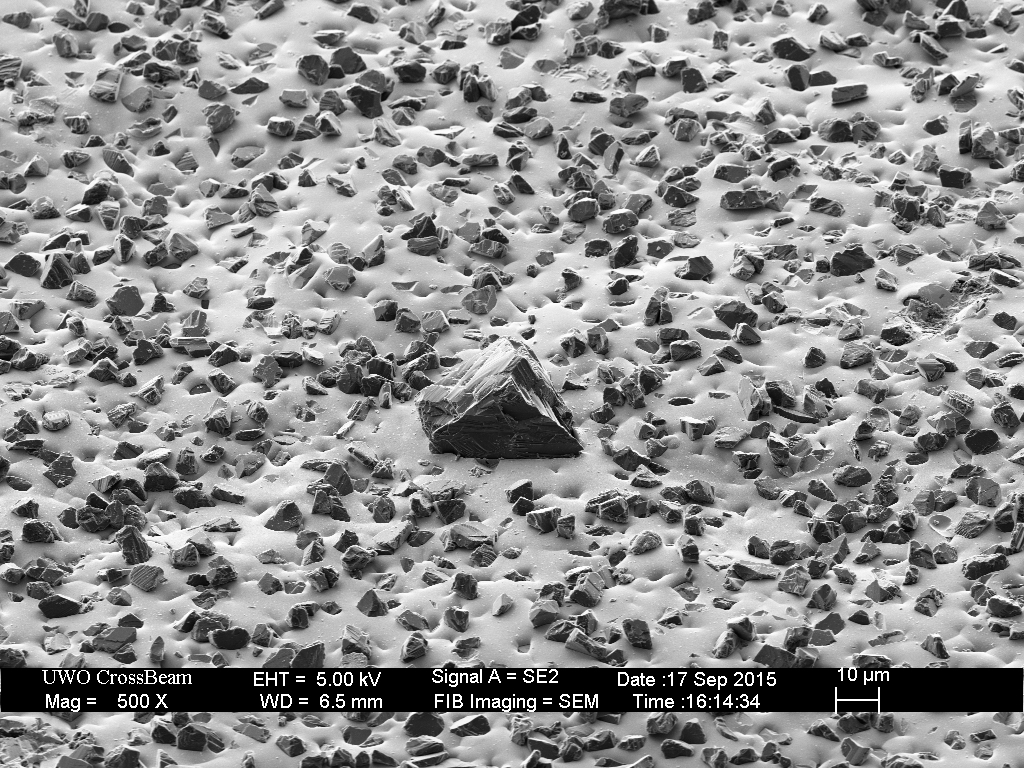

…… As a side note, when I talked to the head engineer at DMT, he told me that the 3 micron plate is exceptionally difficult to produce because of the tendency toward agglomeration which is why we don’t see diamond plates finer than 1000 grit from other manufacturers. They at DMT feel like they’ve got it fairly well dialed in though all of the plates we’ve examined do have some degree of agglomeration issues. Depositing small diamonds on an adhesive is obviously easier to do since the diamond films seem fairly common…….

09/18/2015 at 12:23 am #28928

09/18/2015 at 12:23 am #28928…… As a side note, when I talked to the head engineer at DMT, he told me that the 3 micron plate is exceptionally difficult to produce because of the tendency toward agglomeration which is why we don’t see diamond plates finer than 1000 grit from other manufacturers. They at DMT feel like they’ve got it fairly well dialed in though all of the plates we’ve examined do have some degree of agglomeration issues. Depositing small diamonds on an adhesive is obviously easier to do since the diamond films seem fairly common…….

[/quote]

[/quote]Interesting…looks like some sort of cross contamination during the plating process?

09/18/2015 at 12:40 am #28931Interesting…looks like some sort of cross contamination during the plating process?

not quite dialed in…

When I have time, I’ll check whether those large diamonds are pulled out during the break-in.

09/18/2015 at 12:42 am #28932Interesting…looks like some sort of cross contamination during the plating process?

not quite dialed in…

When I have time, I’ll check whether those large diamonds are pulled out during the break-in.[/quote]

That is very interesting… I have had one guy contact me saying that the 3um diamond stones are leaving scratches larger than his 1k grit diamond stock stones… I will see if I can get him to chime in here and give some feedback.

09/18/2015 at 1:11 am #28939Yup, although they feel smooth to the finger but seemed to feel gritty on the blade and they leave much uglier scratches than they should, at this point Ive beat them up so much trying to break them that I’m not sure if I will return them out of guilt :P. Sharpened I dunno, 30-50 times perhaps? used a ceramic hone figuring it would break it in, no luck, ground on the spine of a knife, then on some mild steel plates, no improvement. They look more and more wore each time but are no more refined, here is a picture from the last time I tried using them, the smoother portion was from last time I sharpened it, where I stopped at the 1000 grit stone, switched to sandpaper up to 2000 grit, and called it good, the scratched part was where I did edge leading heel to tip strokes through 1k grit, then switched to the 3u stones and used sweeping motions until they scratches were uniform, then reversed it again hence the crosshatch scratches near the top.

Contamination would make sense, because by some standards it feels pretty sharp, If I am really careful I once split a hair off the 3u stones, but cutting something like cloth feels like a 200 grit edge, its not uniform feeling.nevermind I can’t get it to show up, I’ll send a link and upload it instead.

https://goo.gl/photos/ZQjGiwdnj7zJys3m6

Attachments:09/18/2015 at 2:37 am #2894009/18/2015 at 2:51 am #28941Holy cow! Todd, the files with names that start with “dmt1200” (dmt1200_new_08.jpg) are the 9 micron nominal plate?

09/18/2015 at 3:21 am #28942Holy cow! Todd, the files with names that start with “dmt1200” (dmt1200_new_08.jpg) are the 9 micron nominal plate?

Yes, it’s from a (piece of) a DMT EF credit card, 1200 grit.

09/18/2015 at 10:11 am #28944I had read of some problems with the 3µ plates but you give proof that the problem affects other as well. Troubling. :dry:

09/20/2015 at 6:40 pm #28956You mentioned (OP) that your rolled an edge. Do you decrease the angle when stropping? I.e. if you sharpen with stones at 20 degrees per side, do you stop at 19 or 18 dps. Since the leather is pliable it is usually reccomended to reduce the strop angle. This also depends on how much pressure you use when stropping. The more pressure the more you need to compensate the angle to avoid rolling the edge.

09/21/2015 at 2:59 pm #28963With that knife I did use the 3.5 and 5 micron strops and VERY GENTLY stropped the blade for about 50 strokes at the original angle. Then I used my 1 and 0.5 micron Balsa strops and went a bit harder. I guess I should adjust the angle for the leather and put it back for the balsa?

09/23/2015 at 2:52 pm #28975I would set the leather aside for now and see what you can do with the balsa.

If you have produced a clean apex with the ceramic, the balsa strops should have a dramatic effect.

If it doesn’t happen at the sharpening angle, try increasing the balsa angle slightly.09/23/2015 at 2:57 pm #28976Thanks for the tip. I’m going to sharpen my ZT 0562CF again soon. Started out at 20 degrees just to see how she liked it but now I think I’ll go to 18 degrees this weekend.

-

AuthorPosts

- You must be logged in to reply to this topic.