Gen 3 Modifications

Recent › Forums › Main Forum › Gen 3 Modifications

- This topic has 12 replies, 7 voices, and was last updated 01/19/2018 at 5:20 pm by

Gazillion.

Gazillion.

-

AuthorPosts

-

03/07/2016 at 4:48 pm #31816

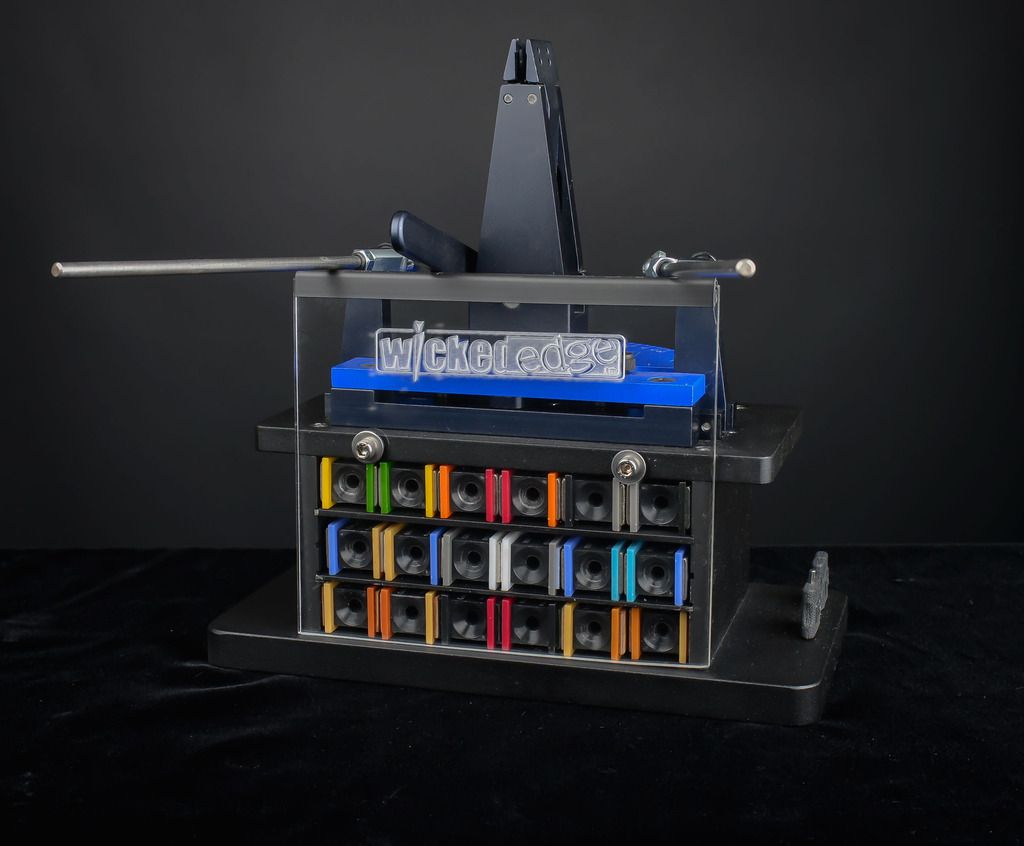

Hey guys! Got to playing around in the garage and thought of some things I thought would make the Gen 3 even better for me. I added a shelf to hold extra stones, but I didn’t increase the overall height. I just changed where the milled slot is and was able to fit 3 rows in the same space. I also milled off .035 thousandths off each side to more easily accommodate 3 sets of stones on each row. I added a hole to allow the Gen 2 Allen Wrench to my base. I also use this at gun shows to sharpen knives and to advertise my product, I laser engraved the Wicked Edge logo into the arm holder plate- for lack of a better word. People kept driving me crazy with questions about which product I was using. Just thought I would share this with you guys because this forum is so helpful to me. Thank you.

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

03/07/2016 at 5:33 pm #31819Looks like a great and practical mod… well thought out. Very nice!

1 user thanked author for this post.

03/07/2016 at 5:45 pm #31820Nice! Most excellent mods there, Todd. I think I’d like to have one of those Gen 2 hex keys. My Gen 3 didn’t come with one. Nine sets of stones… that is just a most excellent mod!

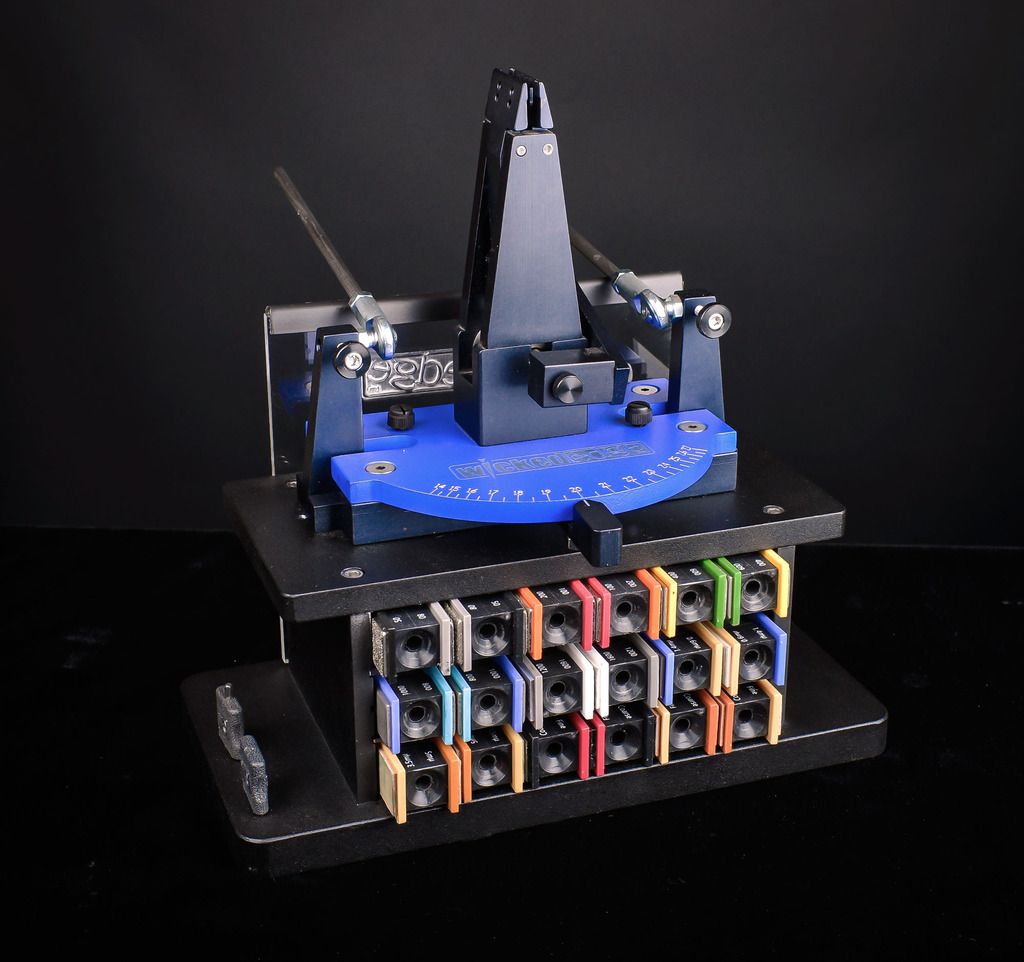

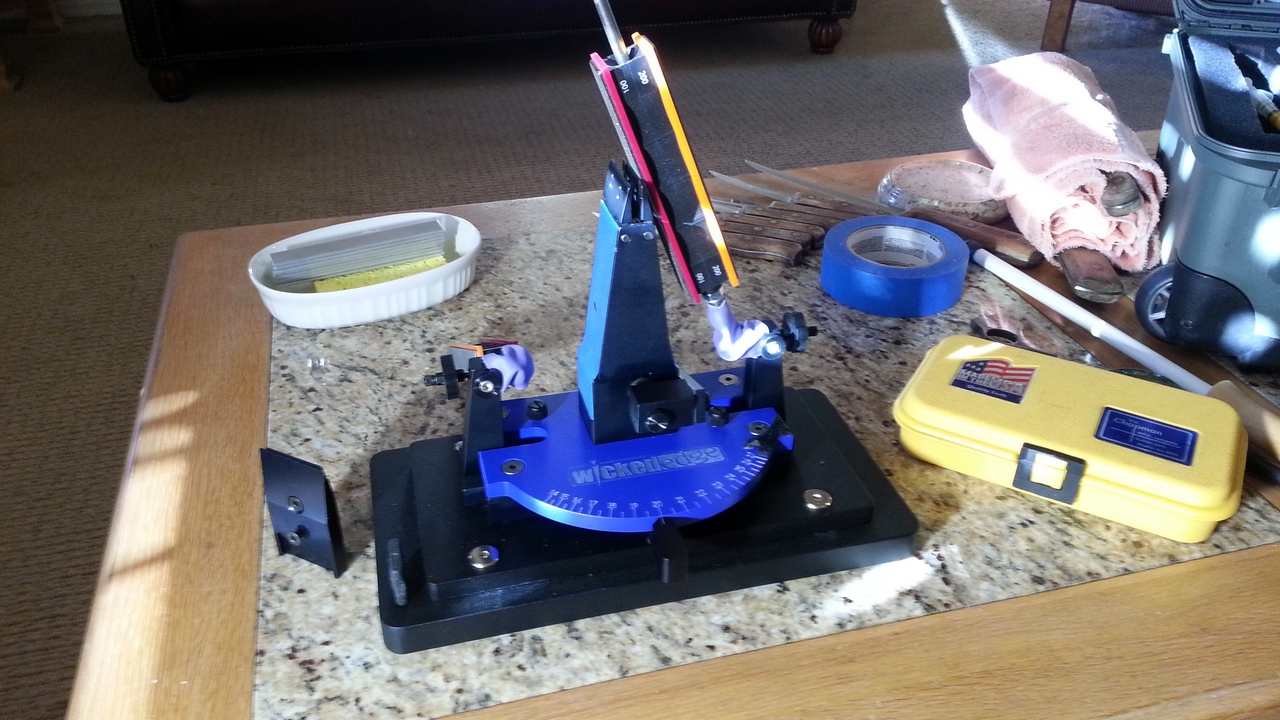

Don’t know if you ever saw my Gen 3 Pro mods, but here’s a photo. I basically did the opposite from you, and removed the shelves. I did this so that my Gen 3 Pro would sit lower, like the Gen 1 and 2 units do on their granite bases. I find it easier on my arms this way, as they are not so lifted so high. I also made an aluminum back (instead of the plastic), but it’s not pictured here.

Alan

Attachments:

You must be logged in to access attached files.

03/07/2016 at 6:50 pm #31822Yep, I did watch your video. I thought you did a great job and all good mods. That was what made me get off my butt and make these mods. Im like you, I like the lower base, but its a double edge sword. I really like having the stone storage. For me, it makes it a lot easier to be mobile. Since I have a lathe and a couple of sticks of stainless laying around I am contemplating making a new set of larger diameter guide rods, but I keep talking myself out of it. I just don’t think it will help. I don’t know how sharp you can get a knife, but they get wicked sharp now…. Hell any sharper and they would be light sabers. (Note to Clay……you can use that line 🙂

1 user thanked author for this post.

03/07/2016 at 8:31 pm #31823Since I have a lathe and a couple of sticks of stainless laying around I am contemplating making a new set of larger diameter guide rods, but I keep talking myself out of it. I just don’t think it will help.

I’ve come back a few times now to look at that mod you made. All I can say is wow! So cool and I would have never thought of an extra shelf. I’m not a metal worker, so even if I did, I wouldn’t of known even where to begin!

Super nice job there!

Super nice job there!On the thicker guide rods, Josh (of Razor Edge Knives) made some of those. I think he even has some metal bushings on his paddles. You might check out what he’s done, the thick and thin of it and his results.

Alan

1 user thanked author for this post.

03/07/2016 at 10:48 pm #31824Todd, looks practical and beautiful, too!

And Alan, that’s probably what I would do if I ever get a Gen 3. I like my WE to stand relatively low since my shoulders easily get inflamed if I’m working too high.

Molecule Polishing: my blog about sharpening with the Wicked Edge

03/08/2016 at 9:19 am #31826Looks very cool Todd!! Yeah I’ve got 3/8″ rods and they work really well although they are a little heavier. If you are doing work at shows and will be doing longer knives I would not recommend them. But I wanted something that wouldn’t bend as I’m hard on my equipment! Tom Meyer actually installed those bushings in my stock paddles so he can maybe chime in more on this.

What product do you sell at gun shows out of curiosity?

03/08/2016 at 12:30 pm #31831I do hi end custom holsters and sheaths. So to pass the time I began sharpening knives at the shows. It really brings people over to the table. Most people are more curious about the sharpener than the holsters, but it does get a conversation started. I could probably sell as many wicked edges as holsters. 🙂 Here is my website http://www.stitchdex.com I hope thats not breaking any forum rules. If so please remove.

On the rods….Are they worth doing? Like I said before, Im just not sure it would help. Boring and installing a sleeve sounds interesting. But again Im a tinkerer I guess I just look for small projects. Thats how I got into holsters, I made a few knives people wanted to buy them and they needed a sheath so that got me into leather. Things just snowballed from there.

1 user thanked author for this post.

03/08/2016 at 1:18 pm #31834I do hi end custom holsters and sheaths. So to pass the time I began sharpening knives at the shows. It really brings people over to the table. Most people are more curious about the sharpener than the holsters, but it does get a conversation started. I could probably sell as many wicked edges as holsters.

Here is my website http://www.stitchdex.com I hope thats not breaking any forum rules. If so please remove. On the rods….Are they worth doing? Like I said before, Im just not sure it would help. Boring and installing a sleeve sounds interesting. But again Im a tinkerer I guess I just look for small projects. Thats how I got into holsters, I made a few knives people wanted to buy them and they needed a sheath so that got me into leather. Things just snowballed from there.

Here is my website http://www.stitchdex.com I hope thats not breaking any forum rules. If so please remove. On the rods….Are they worth doing? Like I said before, Im just not sure it would help. Boring and installing a sleeve sounds interesting. But again Im a tinkerer I guess I just look for small projects. Thats how I got into holsters, I made a few knives people wanted to buy them and they needed a sheath so that got me into leather. Things just snowballed from there. Good talking on the phone 😉 THAT is some nice work Todd! Does your laser etcher work w/ metal too? (blades, guns?)

03/08/2016 at 1:32 pm #31835No…sadly, It will cut through just about any coating, but you need a BIG laser to cut metal and the metal cutting ones run at a different frequency also. If I do need something etched in metal I cover it with tape and laser out the design in the tape then use my metal etcher. It works well for things like a makers mark and so on. It was nice talking to you too….Oh! I am going to make the scissor jig (that was genius) I will post it up when I get it finished.

03/09/2016 at 1:28 am #31840Wow, very nice holsters, Todd!

Molecule Polishing: my blog about sharpening with the Wicked Edge

2 users thanked author for this post.

01/18/2018 at 2:51 am #44648Gosh-a-rootie, this thread is almost two years old!!

And I still can’t seem to control my impulses to modify stuff. I’ve got the new WE 12″ rods for my Gen 3 Pro and I liked them so much I decided to take it a wee step further and make a second set for my Gen 2 rig. The new WE rods measure out at 0.2554″ on my Chinese micrometer and there’s still a fair bit of play between the rods and the handle bores. I checked McMaster.com and found they had ultra-machinable letter-size F drill rod (0.257″), so I bought a couple of 3 ft lengths. I don’t have a lathe on which I could do a proper job of turning the ends down to .250″ for my 1/4″-28 dies, so I chucked up the sections in a cordless drill and spun them against my 1X30 Harbor Freight belt sander. I only had to remove about 0.004″ on the radius, so it only took a few seconds. The die did the trick and I had about four or five turns of thread on the one ends.

I was then surprised to find that these rods, at only 0.002″ bigger in diameter, wouldn’t move freely through the bores in two of my ten handles. It seemed as though something was obstructing the bores about midway through the handles. I did a bit of digging through my shooter supplies and I found a fresh bronze .243 rifle cleaning brush. I mounted it to a single section of cleaning rod and again, using a cordless drill, pushed the brush into the approximate center of the handles, gave it a few very short spins and was amazed to see how quickly bits of plastic began to show. This instantly solved the problem and all the handles now work smoothly over the 0.257″ rods.

This change added less than 0.002″ to the rod diameter, so I can’t say it was worthwhile, but there is a definite difference in the amount of play. The fact is that the 0.255″ rods are more than adequate for the job. Since switching to the new WE rods and handles, I haven’t had a need to make a correction in the middle of a sharpening session.

4 users thanked author for this post.

01/19/2018 at 5:20 pm #44693Good evening Todd,

Great mods and thank you for the pictures.

Derek

-

AuthorPosts

- You must be logged in to reply to this topic.