Adjustable Height Vise Prototype

Recent › Forums › Main Forum › Sharpener and Accessory Maintenance › MODS › Adjustable Height Vise Prototype

- This topic has 17 replies, 5 voices, and was last updated 02/18/2016 at 10:43 am by

Victor.

-

AuthorPosts

-

02/15/2016 at 6:32 pm #31295

The sweet spot discussion from a few days ago rattled this loose that I had early on attempted to make and had left partially complete.

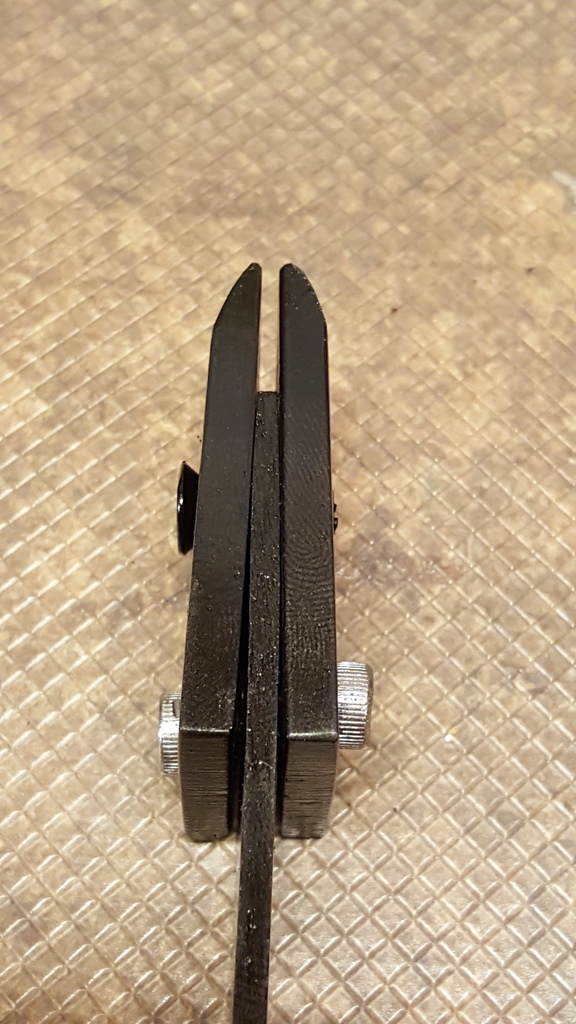

Now with the help of a belt sander and more experience it doesnt quite look like a failed 8th grade shop project anymore(kinda):

Its adjustable up and down and has independent clamping vise jaws for FFG and kitchen knives.

Here it is finding the sweet spot. I raised it up until the sweep ran along the entire curve of the blade.

And then set the angle to 15 degrees. It could go steeper if I clamped shallower in the vise but 15 should be good for most kitchen applications.

The rods are aftermarket 11″ long and the lock collars under the paddles become VERY important. Without them the stones will slide down the face of the knife and wreck your day!

I can see something like this having very mainstream applications. I know that for my system this setup will see use especially on many larger kitchen knives.

Aloha, Cliff

Attachments:

You must be logged in to access attached files.

02/15/2016 at 7:07 pm #31301Dude that looks great!! I have wondered if Clay can, for the 4th gen vise, create one that will have a center knob that will allow you to spread the jaws or move them in with a simple twist of a knob! I love what you did here, you have a very creative mind my friend!

And I have GOT to get some of those stop collars! Where do you get them from? I would need the .375″ size though…

02/15/2016 at 7:11 pm #31302This looks quite interesting!!

1 user thanked author for this post.

02/15/2016 at 9:43 pm #31303And I have GOT to get some of those stop collars! Where do you get them from? I would need the .375″ size though…

Josh you know me, Im the bargain basement Baron. I took a 50 cent nylon sleeve from the hardware and tapped the threads for a nylon screw to be inserted. Works!

The 2 things I like about this vise concept is first it can be raised to change to increase the arc of the sweet spot….and the independantly adjustable vise jaws allow for different tapered blade profiles to be locked in.

A side bonus is you can adjust the vertical plumb of the blade while its clamped by loosening one side and tightening the other.

The only design flaw Id change if doing again would be to stack the adjustment screws vertically down the middle instead of staggering them side to side(on their respective sides), it tends to twist the vise jaws a bit wonky.

1 user thanked author for this post.

02/16/2016 at 1:08 am #31306My brother made a mock-up of the WEPS using some hardware he bought at a local Habitat Restore. His vise sat at about chest level and the pivot point was down on the floor. About a 54″ radius. Worked really nice, but wouldn’t follow a short radius belly.

02/16/2016 at 7:59 am #31307Ok, I thought Clay brought his up in another thread, (can’t find it right now), but doesn’t the fact that the stone pivots or rotates around the rod allow it to “follow the curve”? I know you still have to set it for the angle… but didn’t think it was necessary for the curve???

02/16/2016 at 10:08 am #31310

02/16/2016 at 10:08 am #31310Ok, I thought Clay brought his up in another thread, (can’t find it right now), but doesn’t the fact that the stone pivots or rotates around the rod allow it to “follow the curve”? I know you still have to set it for the angle… but didn’t think it was necessary for the curve???

The paddles will follow the curve and can rotate to adjust to blade contours if Im understanding your question right….the vertical adjustment is just to allow for different blade profiles(curves) better.

The closer the blades curve is to the exact curve of the sweeping arc of the paddle as it travels will mean that the bevel angle your sharpening at will remain constant throughout the length of the bevel.02/16/2016 at 10:49 am #31314Hmmmmm. Here’s the post I was thinking of, from p.8 of the Alignment Guide thread…

Redheads, Are you accounting for the rotation of the stone around the guide rod as the blade curves? People generally describe the motion of the guide rod as conical, which I think is correct, but within the path of the of the rod, the stone also rotates, changing the plane of contact with the blade. I notice this out toward the tip. If we were using square rods with square holes in the stone blocks, there wouldn’t be any rotation and the conical model would work.

Maybe tcmeyer could somehow post a picture or two of how the giant WE travels around the knife mentioned.

I can appreciate your setup being more precise… guess I’m just trying to figure out how much difference it’s making (or if there really is one?)

02/16/2016 at 4:44 pm #31336guess I’m just trying to figure out how much difference it’s making (or if there really is one?)

The only really point or advantage I am aware of to having the vise higher up is widening the sweet spot for shallow curves like on the apex bevel of longer kitchen knives. At least that was its only intended purpose.

With a giant rig at Tom described I can easily visualize how it would sharpen a samurai sword(not that you would) by following the sweep closely along the same arc of the giant blade.

02/16/2016 at 5:53 pm #31337I’m more interested in seeing how it “wouldn’t follow a short radius belly”… and what the path actually looked like.

02/16/2016 at 6:04 pm #31338I’m more interested in seeing how it “wouldn’t follow a short radius belly”… and what the path actually looked like.

We’ll for a short radius belly I would remove this vise…and I mould remove the double riser blocks I have installed for the shortest radius possible.

The idea was to have a range of versatility to meet different situations.

02/16/2016 at 6:19 pm #31339Got it… I was actually talking about tcmeyer’s post.

sorry for the confusion.

02/16/2016 at 7:03 pm #31340Got it… I was actually talking about tcmeyer’s post. sorry for the confusion.

My bad…carry on. lol

02/17/2016 at 12:13 am #31347Sorry I can’t post a diagram, but for a stone to follow a specific angle as the edge sweeps down towards the pivot point, it needs to stay more or less perpendicular to the edge. Where the rod end pivot point is way off to the south – “no can do.” If the tip sweeps to a vertical orientatation, the stone can rotate about the rod and therefor about the tip, Thereby losing any reference to the plane of the knife’s edge.

02/17/2016 at 8:48 am #31348Cool. Didn’t want a diagram… more interested in actually what happened with your brother’s setup.

I can understand that the stone can’t follow a curve if the radius doesn’t match, IF the stone didn’t also rotate. But since it does, I’m back to the original question, how necessary is adjusting the height?

Here’s the best I could do this a.m. …

Took a flat aluminum bar 3ft. long, and tried to duplicate the pivot location and 20° angle of a standard setup. Then tried to take a picture of the “stone” at the tip. Because the stone rotates, it appears that it could still cover the tip (since I can’t actually sharpen, maybe not).

My guess is that at some point it would matter, for example when the blade curve reaches 90° perpendicular. (Which also leads me to wonder that when we pivot the blade, are we really approximating the arc, or just keeping the curve in a position where the change doesn’t significantly matter?)

Mostly I wonder simply because a lot of knives of various shapes have been sharpened without the use of any vertical change, not just on the WE, but many guided devices of various sizes. Not saying it doesn’t make setup any easier, my guess is it does, just… does it ultimately affect the outcome?

-

AuthorPosts

- You must be logged in to reply to this topic.