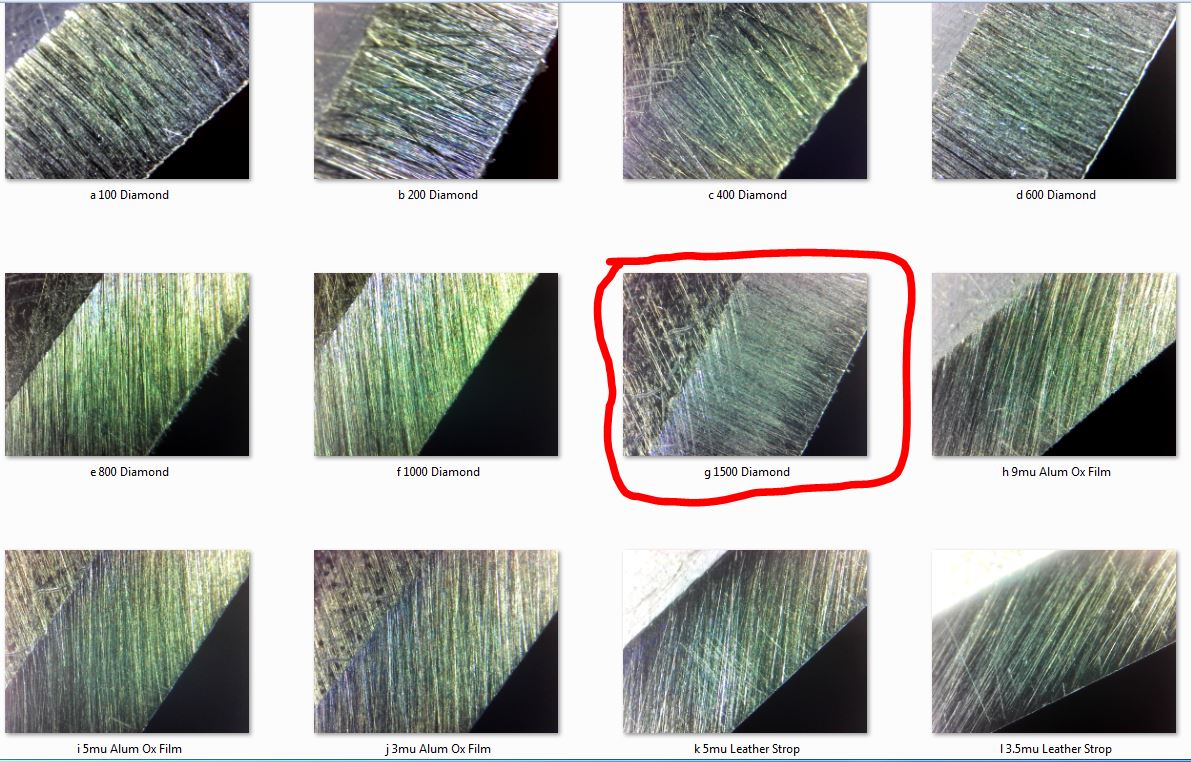

- I absolutely love the new 1500 grit diamond handles. My 1500’s are not even fully broken in as I’ve only done a few knives with them. Check out the progression below (~200x) putting a 13 DPS primary bevel (added a 16 DPS micro with the 1500 after seeing this – not in the pics) on a Shun 4.5″ chef.

Clay, keep pushing your suppliers to get diamond handles into the highest grit possible and work your distribution harder …… my local knife shop doesn’t really know how to market your stuff and I am 10 miles from NYC, I’d love to help but I have a job LOL, but I have ideas just let me know. I’m talking high end kitchen knives.

2. Steel “steel” vs Ceramic “steel”. I read a whole bunch on how the classic grooved steel steels rip up the edge and verified it with my scope. It astounds me how I never realized this before. There are ALOT of people with a dozen+ $200+ kitchen knives. I found (and bought) a Messermeister 1200 grit, 12 inch, 9/16″ ceramic steel for $40 (smoother that your 1200 under a scope) and used it on a couple of my just sharpened (slightly used) kitchen knives. As long as you go gentle with a few strokes each side, erring on a slightly more acute angle (since going more obtuse does nothing and you will never get an exact duplication of the ground WE bevel [no matter what people may claim]), then you will get a sweet alignment of the edge to keep you kitchen knife sharper longer. You would think that WE would be working on a guided “tune up” jig which would wow the kitchen crew.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.