Sharpening Stainless Steel and Japanese High Speed Tool Steel

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Advanced Techniques and Sharpening Strategies › Sharpening Stainless Steel and Japanese High Speed Tool Steel

- This topic has 67 replies, 8 voices, and was last updated 10/14/2017 at 9:05 am by

Marc H (Wicked Edge Expert Corner).

Marc H (Wicked Edge Expert Corner).

-

AuthorPosts

-

12/01/2016 at 10:03 pm #36124

After using and collecting enough kitchen knives to decide what shape and style knives I enjoy using I have set out to use and learn more about some of the harder, so called “more exotic” Japanese Stainless Steels.

When I first bought the Wicked Edge System my only real kitchen knife and fish fileting knife experience was with milder German Steels and High Carbon French Steel Sabatier’s. Then I learned of VG-10 Stainless. A relatively hard and durable Stainless Steel able to hold a fairly narrow angled bevel edge and generally inexpensive knives to buy. Then as I read more and learned more I wanted to try some harder Rockwell rated steels. I picked up a Aus-8 knife and then an AEB-L knife. These also pretty inexpensive.

I wanted to try some truly hard steels. After researching the forums and the web my first experience was when I tried to buy a Miyabi 7000MC, ZDP-189 knife, but learned they were not available. I settled for Miyabi Birchwood Series, my most expensive investment to that point. It was touted to be “the world’s sharpest knife”. It was named MicroCarbide Powder Steel with Rockwell Hardness of 63 hence “MC63”. Some sites call the steel “SG2”. I don’t know yet if they are synonymous, (MC63 and SG2), i.e. actually the same steel.

This first experience was less than stellar. Out of the box the knives were very sharp. I found the Miyabi Birchwood MC63 bevel to crumble as I sharpened it. One second I was making great progress on the edge and in the next instance the edge fell away leaving a ragged hole. It didn’t seem like I was chipping the steel. It just sort of fell off. I tried repeatedly on both my Miyabi Birchwood Gyotu and Santuko with similar results. I even invested in a set of Shapton Stones thinking the WE diamond paddles were chipping the steel. After many repeated tries with different techniques I contacted the manufacturer. Zwilling exchanged them for me with Kramer’s FC61 knives, VG-10, that are a beefy geometry that stay very sharp and have a nice secure feeling handle shape.

Then I bought several different Yaxel Gou knives, these made of SG2, also called MC63 with Rockwell 63. These get and stay very sharp but seem to also crumble when sharpening but to a much lesser extent than the Miyabis or maybe my technique may be improving with this steel.

Next I bought a Fu-Rin-Ka-Zan ZDP-189 Clad Wa Gyuto 210mm to try another Japanese High Speed Tool Steel. I got it last week. It came very sharp, out-of-the-box and I am yet to sharpen it.

Last, I ordered a Fu-Rin-Ka-Zan R-2 Damascus Wa Series Gyuto 210mm. It should arrive Saturday. Then I’ll have three or four different exotic High Speed Tool Stainless Steels knives to compare.

It’s been about two years with the WE and I feel my experience and technique are pretty good. In the next couple weeks I’ll have gained experience using and sharpening seven or eight different Stainless steels: VG-10, AUS-8, AEB-L, ZDP-189, MC63, SG2, (these last two may be the same steel?), and R-2, along with some milder German Steel Wusthofs, and Forschners, and also a couple High Carbon Non-Stainless Steel Japanese and French Knives.

I invite you to join in and share your experience sharpening different steels.

Thanks,

Marc

Marc

(MarcH's Rack-Its)4 users thanked author for this post.

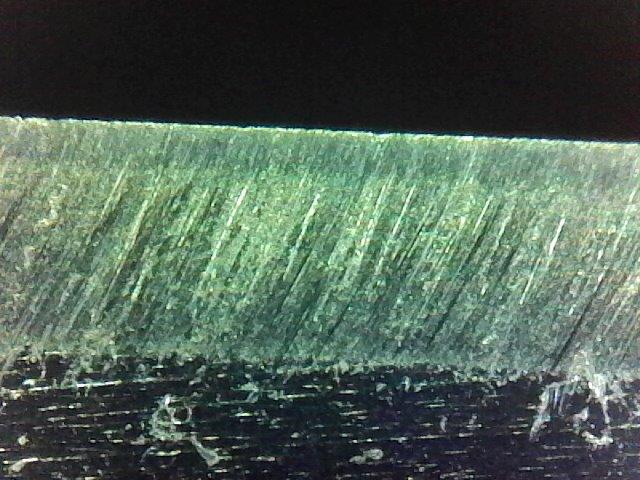

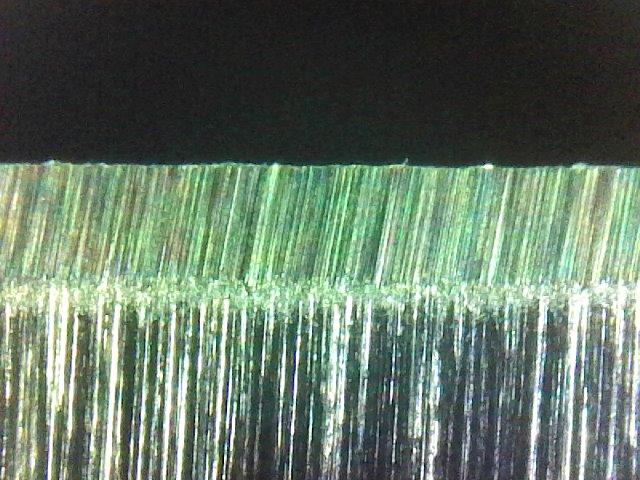

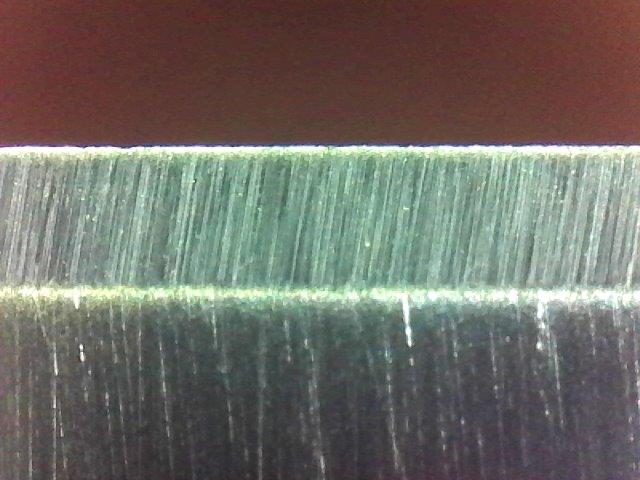

04/29/2017 at 9:34 am #38761Here’s a photo from USB Microscope (supposedly @ 250X) of the bevel edge of a Yaxel Gou Kitchen Knife made with SG2 Stainless Steel which is a microcarbide powder stainless steel hardened to Hrc 63

You can see the bright horizontal bevel with all its little microchips, pits or bumps. The side of the bevel appears almost dark because it is very smooth and polished but it does have quite a few tiny wispy scratches across it. I have used this knife some since it’s last sharpening.

You can see the bright horizontal bevel with all its little microchips, pits or bumps. The side of the bevel appears almost dark because it is very smooth and polished but it does have quite a few tiny wispy scratches across it. I have used this knife some since it’s last sharpening.Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

04/30/2017 at 5:51 am #38772Great thread, Marc! As we discussed in my Maxamet thread, yes, I’ve seen similar results on hard, high carbide steels. Switching to a different media (in that case, the micro ceramics) made a huge difference. It may well be that if I could examine the edge under even higher magnification I would still see this but from a practical perspective the edge left by the micro ceramics is very clean, lacking the chipping/pitting evidenced by the Atoma plates

I’d be interested in hearing anyone else’s experience and how you tried resolving it.

Ken

3 users thanked author for this post.

05/01/2017 at 10:11 am #38814Can’t help much with those types of steel but have also experienced the blade powdering on several hunting knives. Two were bucks and both manufactured in china. I had to file the edge down and remove basically the whole bevel on one. I found it was a bad spot in the metal as it was happening in a spot about a 1/32 to 1/16 of an inch on both knives. My conclusion was that either the heat treating wasn’t great or that the steel had course or maybe hard pockets in them, both of which I believe relate to the heat treating. On a couple of others the whole edge was powdering and I had to kick the angle out to be able to sharpen them and I’m still waiting to see if they held up, not really an option on the knives you were doing though. Spent a lot more time on them than I would have liked but chalked it up my learning process. I have’t had it happen on the kitchen knives yet, with the exception of a couple of cheap paring knives witch seem to be holding up ok, but have not attempted the steel you have encountered.

Thanks for the info on those knives Marc

2 users thanked author for this post.

08/06/2017 at 5:22 pm #40493In the last year or so in my Wicked Edge sharpening experience I have become a more “cerebral” sharpener. When I first got my Wicked Edge, I sharpened everything and anything I could get my hands on. It didn’t matter if I had ever used the knife or even had seen it before. If it was a knife I would clamp it and sharpen it. Now I put a lot more thought into what I’m doing.

Since I started this thread some months back, I have taken a new route with my knives. I continue to be intrigued by knives made of what I like to call the “Super Steels”. These are often Japanese Chef’s Knives made with exotic super hard steels and stainless steels. These are the knives that I want to use. I’ve slowed down on my buying knives and now spend more time using them. I’m not as quick to just sharpen them right away. Now I like to photo document my knife edges, right out-of-the-box, with the USB Microscope, 250X, to see what the edge looks like as made by knife makers. It gives me photo-documentation of what the maker had intended to make, for future reference. Often times, by the shear nature of these steels, these knives are made by Master Forgers and true Artisans.

I’ve learned that the edges I can produce with the Wicked Edge, a little bit of experience and some good technique often exceeds the visual quality of the original new factory edge. My pretty edge is sometimes not as good, though. When I first started sharpening everything, before I even used it, I never allowed myself to feel the edge as the maker intended. I was feeling Marc’s, sharpened edges. Now I allow myself this experience, to feel the edge as it was made and I feel this makes for a better sharpened knife, when I do sharpen it.

Through visually inspecting the last six or eight knives, I bought, I observed something they have in common.

- The edges aren’t very special the way they’re sharpened.

- The edges are far from perfect in the grind patterns of the sharpening.

- The edges are very basic looking in how they’re sharpened.

- The edges are sharpened with a relatively vertical grind pattern.

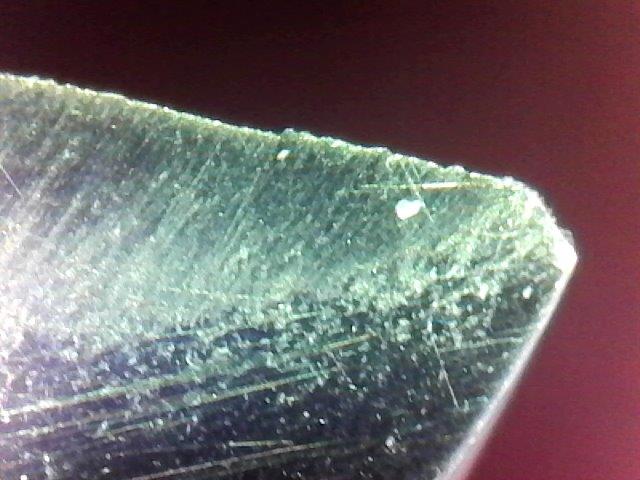

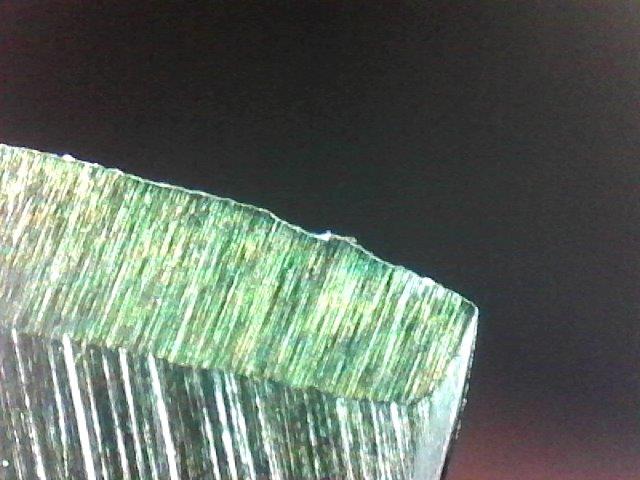

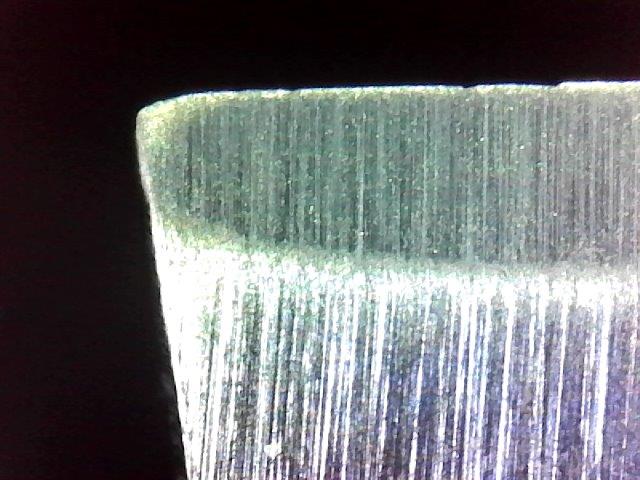

Here’s a couple of photos of several of the last knives I bought exemplifying what I’m saying:

As you can see the edges and the tip are nothing special to look at.This discussion continues with the next post.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

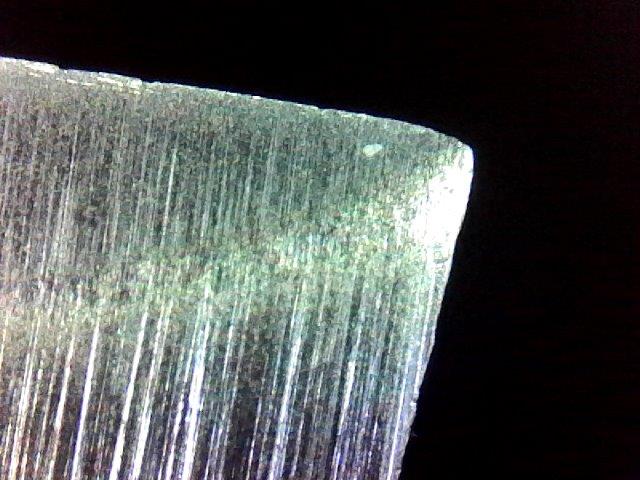

08/06/2017 at 5:45 pm #40498Continued from previous post. Here’s a couple more knife tip photos. You can see they’re not even sharpened or ground all the way to the tip:

All three of these knives were extremely sharp out-of-the-box and excellent cutting knives. That was counterintuitive for the snob sharpener I’d become. I have tried to emulate these grind techniques when I sharpen these super hard steels and my results have improved remarkably. I stick with a more vertical edge leading scratch pattern. I like to use whetstones, Shaptons, because I find they give an even predictably spaced and depth scratch pattern and lack stray deep random scratches. Also I feel the water cools and lubricates as I sharpen while keeping the knife steel dust down.I try to sharpen these hard thin steel chef’s knives at 14dps. I usually start with 500 grit, unless I need to debur the edge for bad chips then I may use a 220 or 320 stone, perpendicularly, to start. I follow the progression 500, 1000, 2000, then 4000 grit. I use scrubbing strokes first then follow with alternating, bilateral edge leading strokes, with each grit stone. I keep the grind pattern mostly vertical like the photos show. I work the long knives in sections and move along it’s length to blend it all together. I use plastic safety shields to protect my finger tips with the more risky edge leading direction pattern. Then I use WE cow leather strops and call it done. ( 4µ, 2µ, 1.0µ, then 0.5µ)

I used to try to put a more polished edge, 16K & 30K, with a more horizontal edge trailing stroke on these steels and often as the apex thinned I lost the bevel. It just disintegrated or fell off or wiped off with my cleaning towel. Now with this edge leading, mostly vertical, method I find I have a really sharp durable edge. This discussion is continued with the next post.

Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

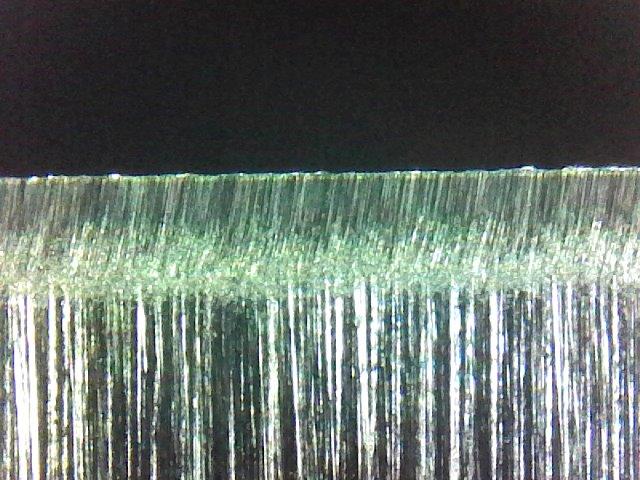

08/06/2017 at 5:57 pm #40501This is a continued discussion from the above two posts. The last thing I want to say, this knife , my latest acquisition, is the hardest HRC 68-69 rated knife I’ve seen, except maybe the Spyderco Maxamet. Like all the rest of my recent purchases, I photo documented it with the USB Microscope and I’ll use it till it really needs to be sharpened. I’ll strop it when it dulls a little to see if that helps first. That way I use a knife like the maker made it to feel and not just feel my sharpening job. So these days, I look forward to experiencing sharp knives made by the makers of sharp knives….not, maybe a sharp knife, sharpened by Marc.

Here’s pictures of the new knife edge showing the same thing I discussed in the posts above:

As you see nothing special and very vertical. Also not polished at all. The knife was very sharp out-of-the-box. It easily sliced and push cut newspaper.Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

08/07/2017 at 10:30 am #40510Marc,

Thanks for sharing your findings with us. Have you tried using your perpendicular edge leading strokes with the 16k or 30k finish? If so, could you comment on how the performance of these edges differed from your 4,000# edges?

I’ve been reading the sharpening section on the Chef Knives to Go forum and it is interesting to note that the vast majority of members there seem to finish their knives between 3,000# and 8,000# and then they strop the blade on leather or colored newsprint. No one seems to be after the mirrored finish that the pocket knife enthusiasts covet.

3 users thanked author for this post.

08/07/2017 at 11:27 am #40513Marc,

This is a really great post. Thanks!

-Clay

08/07/2017 at 2:50 pm #40523Marc, Thanks for sharing your findings with us. Have you tried using your perpendicular edge leading strokes with the 16k or 30k finish? If so, could you comment on how the performance of these edges differed from your 4,000# edges? I’ve been reading the sharpening section on the Chef Knives to Go forum and it is interesting to note that the vast majority of members there seem to finish their knives between 3,000# and 8,000# and then they strop the blade on leather or colored newsprint. No one seems to be after the mirrored finish that the pocket knife enthusiasts covet.

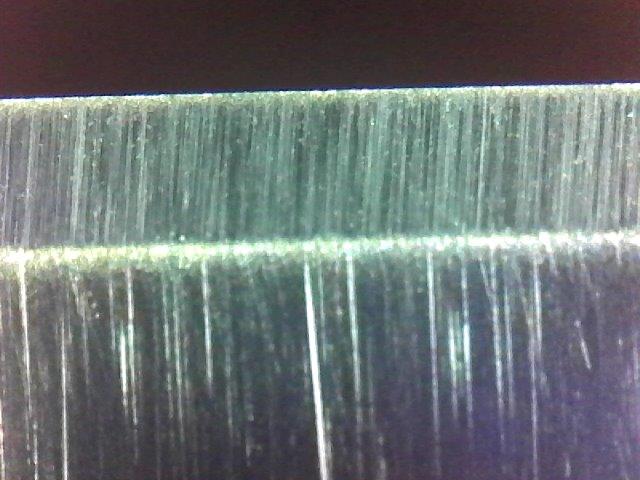

Organic, I did sharpen a ZDP-189 Clad Stainless Steel Knife HRc 65 with 16K and 30 K. I found beyond 4000 I saw no improvement in the edge to these hard steel knives. As the edge gets thinner and narrower with the finer grits it chips more.

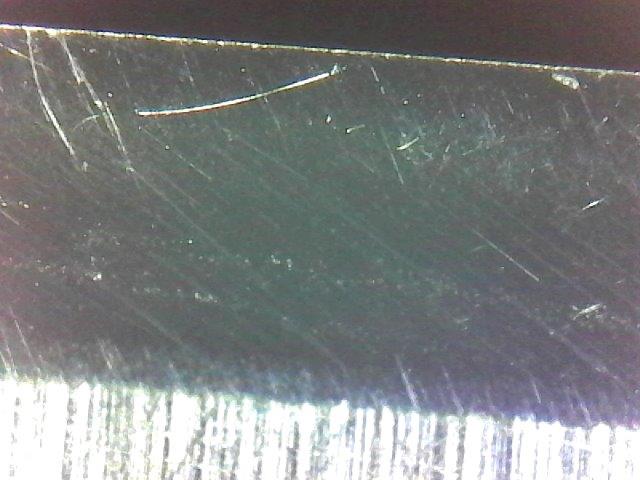

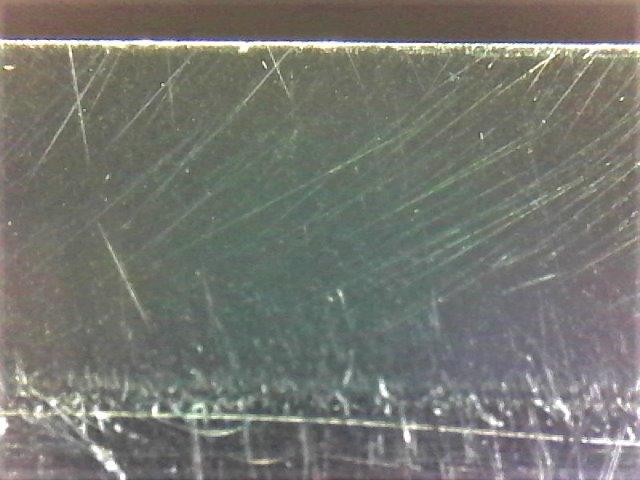

This 16K:

This is 30K:

As you see the edge has deteriorated. I saw no improvement over 4000 grit when I continued with 6000 and 8000, either. I’m using Shapton’s Glass Stones. I don’t know how these compare or differ from the stones the free-hand sharpeners are using.Marc

(MarcH's Rack-Its)Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

08/07/2017 at 2:56 pm #40526That’s a very interesting observation, Marc! I never looked at it from that point of view.

Molecule Polishing: my blog about sharpening with the Wicked Edge

08/07/2017 at 3:08 pm #40528Interesting. It certainly looks like the edge develops micro chips and becomes more jagged at the higher grit finishes. Does this observation also carry over to high carbon non-stainless steels, or do you find that they behave differently? I have seen many people say that they believe white #1 to be the steel most amenable to a super refined edge.

The most popular stones that the sharpeners on Chef Knives to Go site are using seem to be the Shapton glass, Naniwa Chosera, and the Kohetsu stones, but there are many others that get mentioned regularly including natural stones from Japan.

08/07/2017 at 3:16 pm #40529Marc,

Are you able to measure the width and depth of those chips? How do they correspond to the size of the teeth left by lower grits?

-Clay

1 user thanked author for this post.

08/07/2017 at 3:21 pm #40530Interesting. It certainly looks like the edge develops micro chips and becomes more jagged at the higher grit finishes. Does this observation also carry over to high carbon non-stainless steels, or do you find that they behave differently? I have seen many people say that they believe white #1 to be the steel most amenable to a super refined edge. The most popular stones that the sharpeners on Chef Knives to Go site are using seem to be the Shapton glass, Naniwa Chosera, and the Kohetsu stones, but there are many others that get mentioned regularly including natural stones from Japan.

David I find the high carbon or higher carbon steels take the finest edges I can sharpen. The Aogami Super or Super Blue steel knife , which has the balance of hardness, durability and ease of sharpening, takes the sharpest edge I’ve ever put on a knife.

Marc

(MarcH's Rack-Its)08/07/2017 at 3:26 pm #40533Marc, Are you able to measure the width and depth of those chips? How do they correspond to the size of the teeth left by lower grits?

No simply qualitative observations. I don’t have the ability to quantify the depth of the scratches. All I can say is they are very very tiny because if I were to guess the width of the field of the photograph is between 1/4 and 1/2 inch.

Marc

(MarcH's Rack-Its) -

AuthorPosts

- You must be logged in to reply to this topic.