Stropping plate design for Rockstead knife

Recent › Forums › Main Forum › Techniques and Sharpening Strategies › Tips for Specific Knife Grinds and Styles › Stropping plate design for Rockstead knife

- This topic has 15 replies, 4 voices, and was last updated 04/12/2016 at 12:17 pm by

Miles Spathelf.

-

AuthorPosts

-

04/11/2016 at 12:25 pm #33244

Hello,

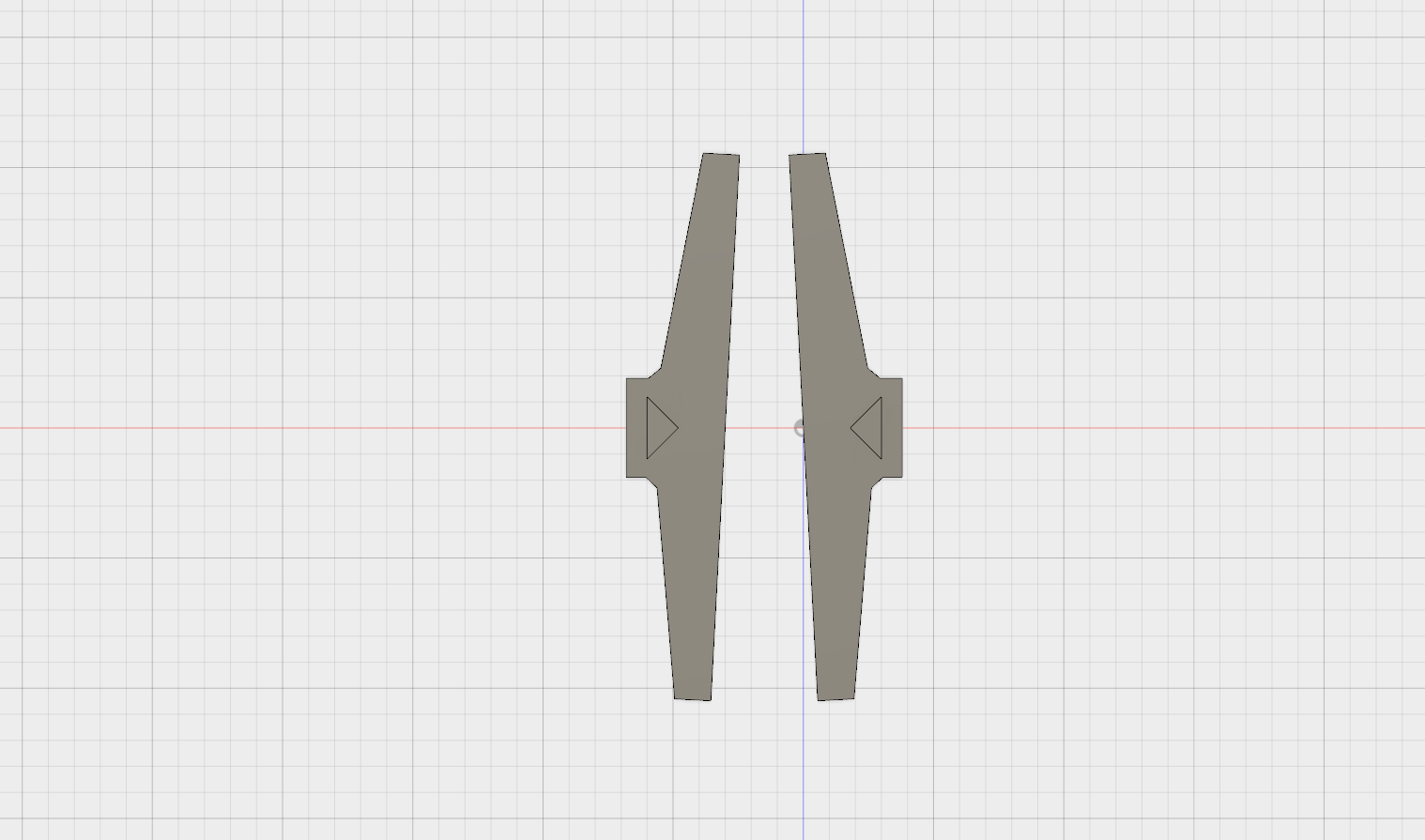

I’m designing a 3d printed stopping plate for a rockstead knife that has a 30 degree inclusive angle at the haft and 24 degree inclusive at the tip. I’m mocking up designs so I could set my wicked edge in the middle (13.5 degrees on one side for the middle) and strop the entire blade. I’ve gone from this design

to this

and back. The idea is to have a change of 1.5 degrees from the back to the middle and another 1.5 degrees from the middle to the tip. My original design would “move” the strop surface closer to the tip of the knife and away from the heft which I thought would allow for a continuous angle change.

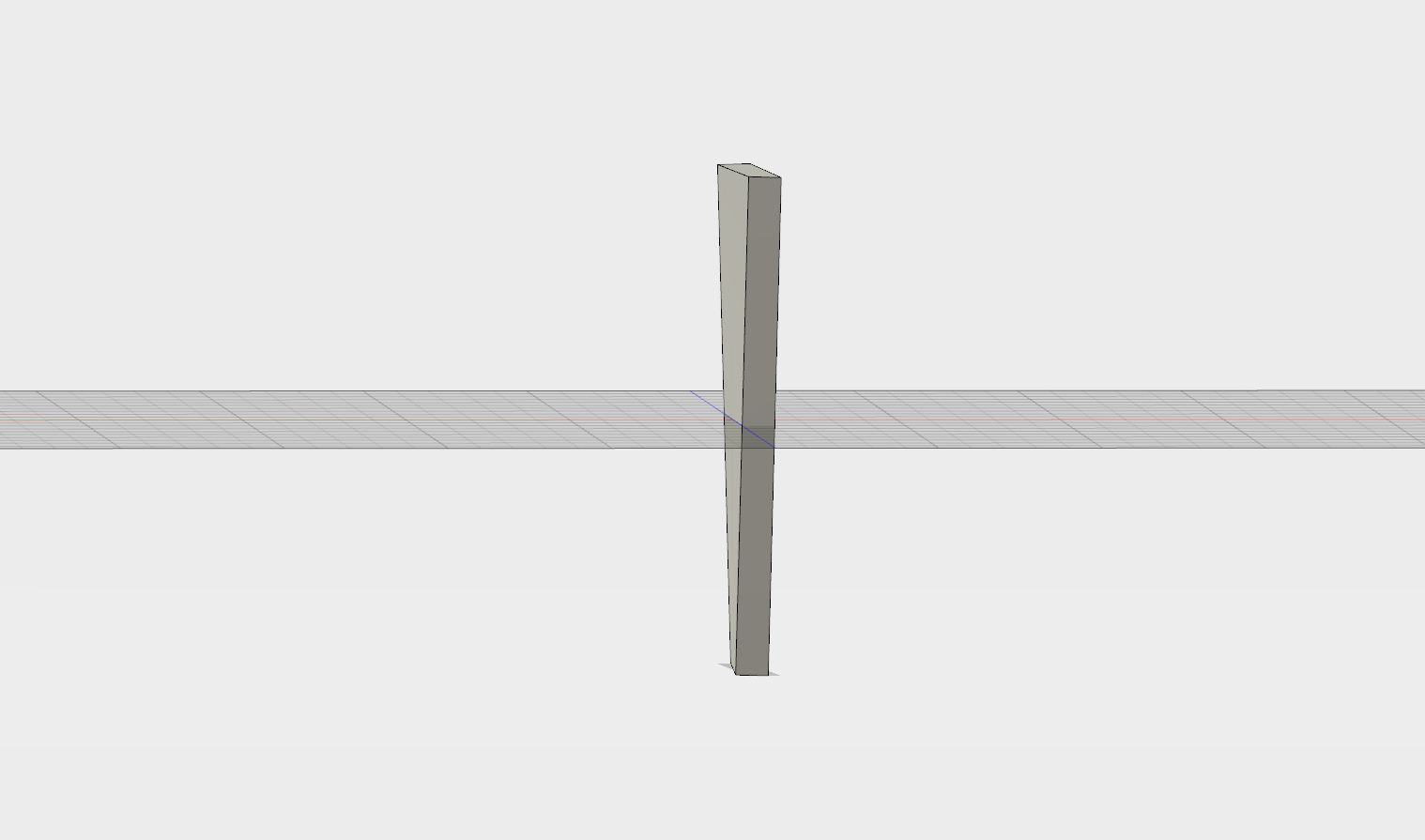

But then I thought about “twisting” the plate so the tip would be angles 1.5 degrees away and the heft 1.5 degrees towards the blade. The attached image is looking from the tip side.

In my head both work…and don’t work… so I think I’ll just have to do foam mock up with sandpaper and a piece of cheap wood in my wicked edge to see what’s going on when the plate move against something.

Any insight would be appreciated.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

04/11/2016 at 3:25 pm #33252I kinda get it… do you have a picture of the actual knife? Might make more sense to me.

And, have you seen this diagram, where you can change the angle as you approach the tip… just by adjusting how far from the clamp you are? (Not sure if it applies, since I don’t know what your knife looks like)…

From this page… https://www.wickededgeusa.com/does-the-angle-change-along-the-length-of-longer-blades-on-the-wicked-edge/

2 users thanked author for this post.

04/11/2016 at 4:52 pm #33256Thanks for the post. The knife in question is a rockstead shun. It has a ~4.125″ blade with a wharncliffe-ish shape so there isn’t much of a “belly” . I’m fairly certain it’s not long enough to meet the necessary length to have a 3 degree change of the stropping angle 🙁

Also…another way to think of the “Twist” version is if I molded something to the side of the blade and then elongated it to a square.

Cheers

04/11/2016 at 5:57 pm #33261Having never even seen one… I’ve been looking for info on the Internet… nothing I’ve found indicates that it’s sharpened at a decreasing angle… so hasn’t been much help. Their website seems to show just regular stropping to maintain it… maybe they just assume you’ll match the angle.

I think I understand that you want to angle the knife horizontal (or side to side) so that the tip is closer? I think that would work, but you’d only be able to strop one side at a time, then switch the angle to the other side. If that’s the case, couldn’t you just stick something at the rear of the clamp on one side, and the front on the opposite side, that would angle the knife?

Or maybe something on the base of the clamp so you could rotate it back and forth a certain angle, so you could leave the knife clamped.

Or maybe I’m missing something (wouldn’t be the first time).

1 user thanked author for this post.

04/11/2016 at 6:26 pm #33263The knife in question is a rockstead shun. It has a ~4.125″ blade with a wharncliffe-ish shape so there isn’t much of a “belly” . I’m fairly certain it’s not long enough to meet the necessary length to have a 3 degree change of the stropping angle

What if you rotate tip up? I have a reverse case, when angle increases dramatically towards the tip of the blade. I was able to address it by rotating tip down. Required angle difference was greater than 8 dps. Search forums for microtech closer thread.

1 user thanked author for this post.

04/11/2016 at 7:24 pm #33266Ah a Shim!!! That sounds much easier than making a huge honing plate…not to mention all of the diamond spray it would use.

I was just going by how they made the knife…I really haven’t seen too much on maintenance as they offer a sharpening service. I just think I can do better 🙂

1 user thanked author for this post.

04/11/2016 at 7:25 pm #33268The knife in question is a rockstead shun. It has a ~4.125″ blade with a wharncliffe-ish shape so there isn’t much of a “belly” . I’m fairly certain it’s not long enough to meet the necessary length to have a 3 degree change of the stropping angle

What if you rotate tip up? I have a reverse case, when angle increases dramatically towards the tip of the blade. I was able to address it by rotating tip down. Required angle difference was greater than 8 dps. Search forums for microtech closer thread.

I tried that with a ruler but didn’t get the angle I wanted….though I didn’t actually sharpen anything and tried to get measurements from the angle cube. I’ll give it a go with a sharpie! Thanks!

04/11/2016 at 7:45 pm #33270Good luck! I think tormek adapter might help as well, as far as rotating the blade goes. Not just for small blades only ? Please let us know of an outcome!

1 user thanked author for this post.

04/11/2016 at 10:48 pm #33273Good luck! I think tormek adapter might help as well, as far as rotating the blade goes. Not just for small blades only

Please let us know of an outcome!

Please let us know of an outcome! This little guy?

http://www.tormek.com/en/jigs/svm00/index.php

It certainly would make using shims pretty easy…far easier than adjusting the blade each time 🙂

04/12/2016 at 7:28 am #33286Ah a Shim!!! That sounds much easier than making a huge honing plate…not to mention all of the diamond spray it would use. http://rockstead.jp/making/ I was just going by how they made the knife…I really haven’t seen too much on maintenance as they offer a sharpening service. I just think I can do better

Ah… didn’t see the ‘making’ page. Interesting that it’s not only ground different heel to tip, but also convex… yet their only suggested maintenance is stropping on a hard strop. Just seems a bit of a disconnect between how it’s made. But I can see why they recommend sending it back for sharpening. Would like to see the machine they use…

i understand your first post now… I was thinking along a different track. It does seem to me angling the knife would be simpler… hard to tell without a bit of experimenting.

p.s. The link you posted on the Tormek is the correct one.

1 user thanked author for this post.

04/12/2016 at 8:21 am #33292According to the Rockstead “making” page, they have a continuously varying angle, starting at 30 deg at the heel and ending with 24 deg at the tip. With the WEPS, the angle as it would be used on the Shun pretty much stays the same. How would you duplicate the factory edge except by hand?

Are these degrees per side or inclusive? Never mind, I see in your first post that it’s inclusive. I just didn’t (don’t) really understand your widget.

04/12/2016 at 8:30 am #33295According to the Rockstead “making” page, they have a continuously varying angle, starting at 30 deg at the heel and ending with 24 deg at the tip. With the WEPS, the angle as it would be used on the Shun pretty much stays the same. How would you duplicate the factory edge except by hand? Are these degrees per side or inclusive? Never mind, I see in your first post that it’s inclusive. I just didn’t (don’t) really understand your widget.

The ‘varying angle’ heel to tip is what he’s trying to address. The original widget, if I understand it now… was to make a wide angled strop. My idea was to angle the blade horizontally (or left to right) somehow to address it (assuming tipping the blade doesn’t work.)

1 user thanked author for this post.

04/12/2016 at 9:28 am #33306Ah a Shim!!! That sounds much easier than making a huge honing plate…not to mention all of the diamond spray it would use. http://rockstead.jp/making/ I was just going by how they made the knife…I really haven’t seen too much on maintenance as they offer a sharpening service. I just think I can do better

Ah… didn’t see the ‘making’ page. Interesting that it’s not only ground different heel to tip, but also convex… yet their only suggested maintenance is stropping on a hard strop. Just seems a bit of a disconnect between how it’s made. But I can see why they recommend sending it back for sharpening. Would like to see the machine they use… i understand your first post now… I was thinking along a different track. It does seem to me angling the knife would be simpler… hard to tell without a bit of experimenting. p.s. The link you posted on the Tormek is the correct one.

Thanks! Yeah I like the idea of angling the knife and/or raising the tip to get my desired effect. I’m pretty much just refining the edge with diamond spray. I’m not sure what they use 🙂 but originally the cnc-ed the blade and then did some hand work. I’m curious about all the jigs they must have. Cheers

04/12/2016 at 9:32 am #33308If I kept the knife straight and level it would be at pretty much the same angle throughout the blade on the WEPS. However adjusting the the blade side to side angle and up and down angle (Thanks for the suggestions!) I should be able to create a smooth transition from 30 inc to 24 inc degrees. Granted if I adjust the side to side angle of the knife I could only work on one side at a time…but it’ll be worth it to me. Cheers

According to the Rockstead “making” page, they have a continuously varying angle, starting at 30 deg at the heel and ending with 24 deg at the tip. With the WEPS, the angle as it would be used on the Shun pretty much stays the same. How would you duplicate the factory edge except by hand? Are these degrees per side or inclusive? Never mind, I see in your first post that it’s inclusive. I just didn’t (don’t) really understand your widget.

04/12/2016 at 12:13 pm #33316So maybe if you had a trapezoidal stone or hone so the angle would change as you raised and lowered the block relative to the edge… Then if you carefully used continuous motion, raising the block as you traversed along the edge, you might come pretty close to matching the angle at the edge. Or not.

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.