Here is an edge in CTS-XHP / 63 HRC this is Carpenters steel which is designed to offer the hardness/wear of D2 blended with the corrosion resistance of 440C ( http://cartech.ides.com/datasheet.aspx?&I=101&E=343 ) these are loose promotional descriptions, not strict materials properties. In any case this is thus currently a middle of the road steel in regards to grindability considering the modern use of extreme alloys.

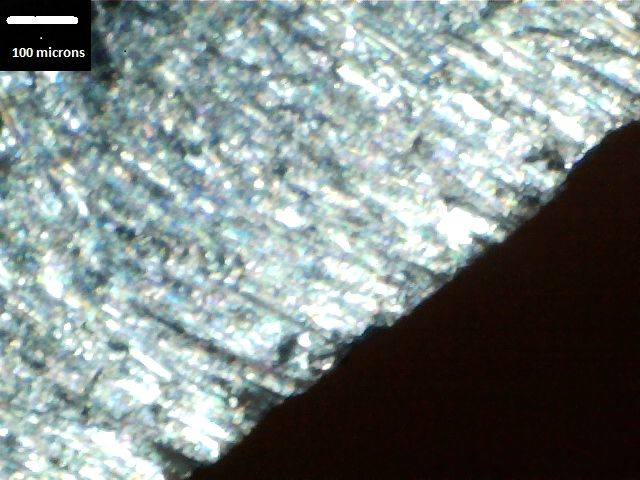

This it the as-boxed edge, multi-faceted with a decent polish.

The edge is < 15 dps on one side, < 20 dps on the other side, so will take a bit of work to clean up regardless of how it is to be sharpened. I used the 100 grit stones and set the bevel to 13 dps. In order to avoid grinding into the base that means for the first part of the edge you have to short stroke on the bottom of the hones.

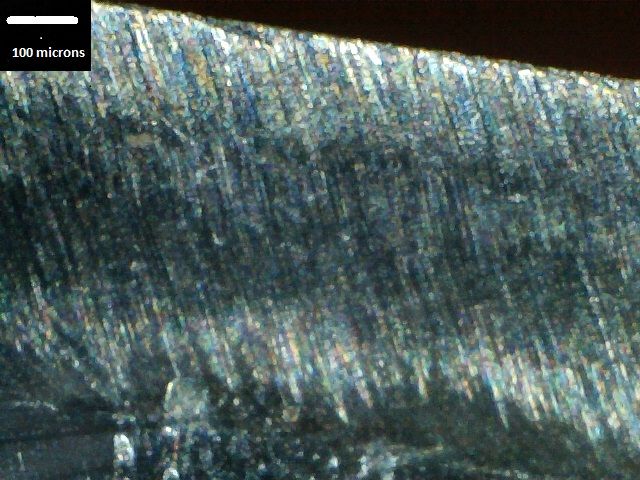

This is after 1000 passes per side on the 100 grit stones. I am using light force, I will measure it the next time, but based on what I have seen in videos I am using less force than most. You can grind with heavier force, however it does rapidly wear abrasives and in general I would always advise using a more coarse grit and less force.

At this point the remaining bevel is less than a mm wide and very difficult to even tell there is any of the original bevel left without magnification. At this point for practical purposes it is time to switch the abrasives and slightly increase the angle, there is no benefit to apexing on the shaping grit for reasons that will be apparent later. But for the sake of experiment, lets continue.

This is after another 1000 passes, at this point the bevel is so small (the original edge) that if you use a marker it looks like it is all removed in a pass. There is still some of the original bevel left under magnification but it can't be seen by the naked eye. There is really no productive point to keeping going with the shaping grit at this stage - but lets continue anyway.

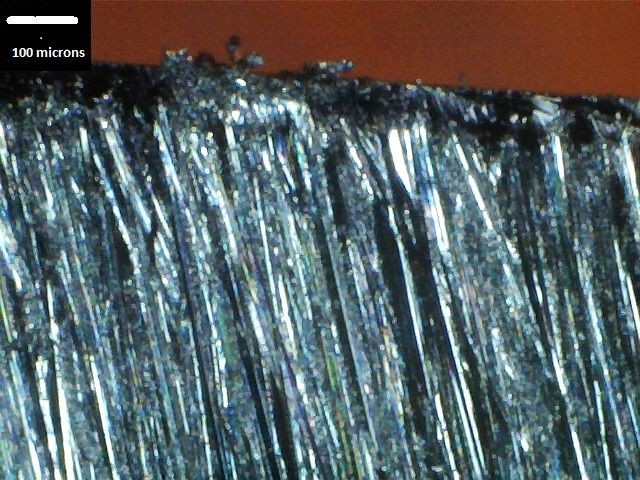

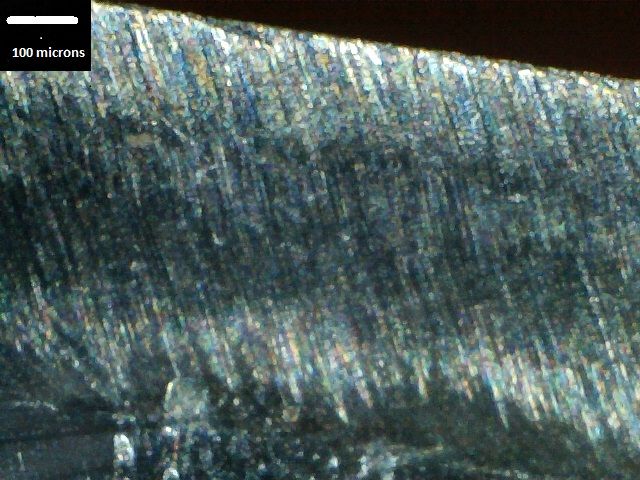

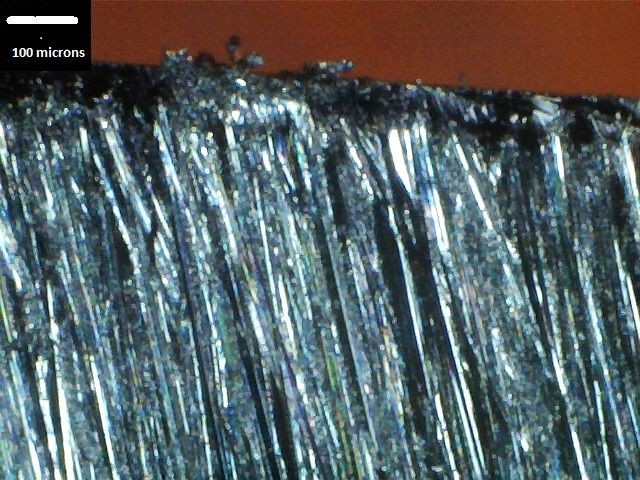

This is after another 2000 passes, so 4000 total. The edge has now been formed with the shaping bevel. However if you look closely you can see there is going to be a problem when you go to refine the polish. The edge looks straight but there are divots knocked out of it periodically. To make this really clear here is the edge after just 10 passes per side with the 1000 grit stone at a slightly elevated angle :

Note that almost immediately with just a small increase in angle (13 dps to 17 dps) the 1000 grit stone starts to eliminate the very harsh 100 grit scratch pattern but when it does it reveals what happens to the edge in those parts that the 100 grit stone has took those pieces out. In order to make the edge perfectly uniform that edge has to be ground back the depth of that divot.

In short :

-the 1000 grit stone can very quickly remove the 100 grit scratches by using an elevated bevel

-if you apex on the 100 grit stone it is going to be wasteful

-the 40 grit stones are likely of strong benefit if you reset angles on low grindability steels

However while this seems like a lot of work, this was :

-A D2 class steel at 63 HRC

-the bevel was taken down from 15-20 dps to an even 13 dps (4" blade)

-using very low force

I would in general advocate something more practical such as :

-use the 40 grit at the shaping stage

-stop when you can not see the original bevel any more

-slightly elevate and increase the grits

Repeat the last step until sharpened. With some thought to angles/finishes you can work out a way to grind efficiently in both time and steel consumed.

Of course if you don't care at all about the steel used then no big deal but given the prices of some modern knives, it might be of consideration/value.