Alchemist

Forum Replies Created

-

AuthorPosts

-

12/09/2018 at 12:51 pm #48458

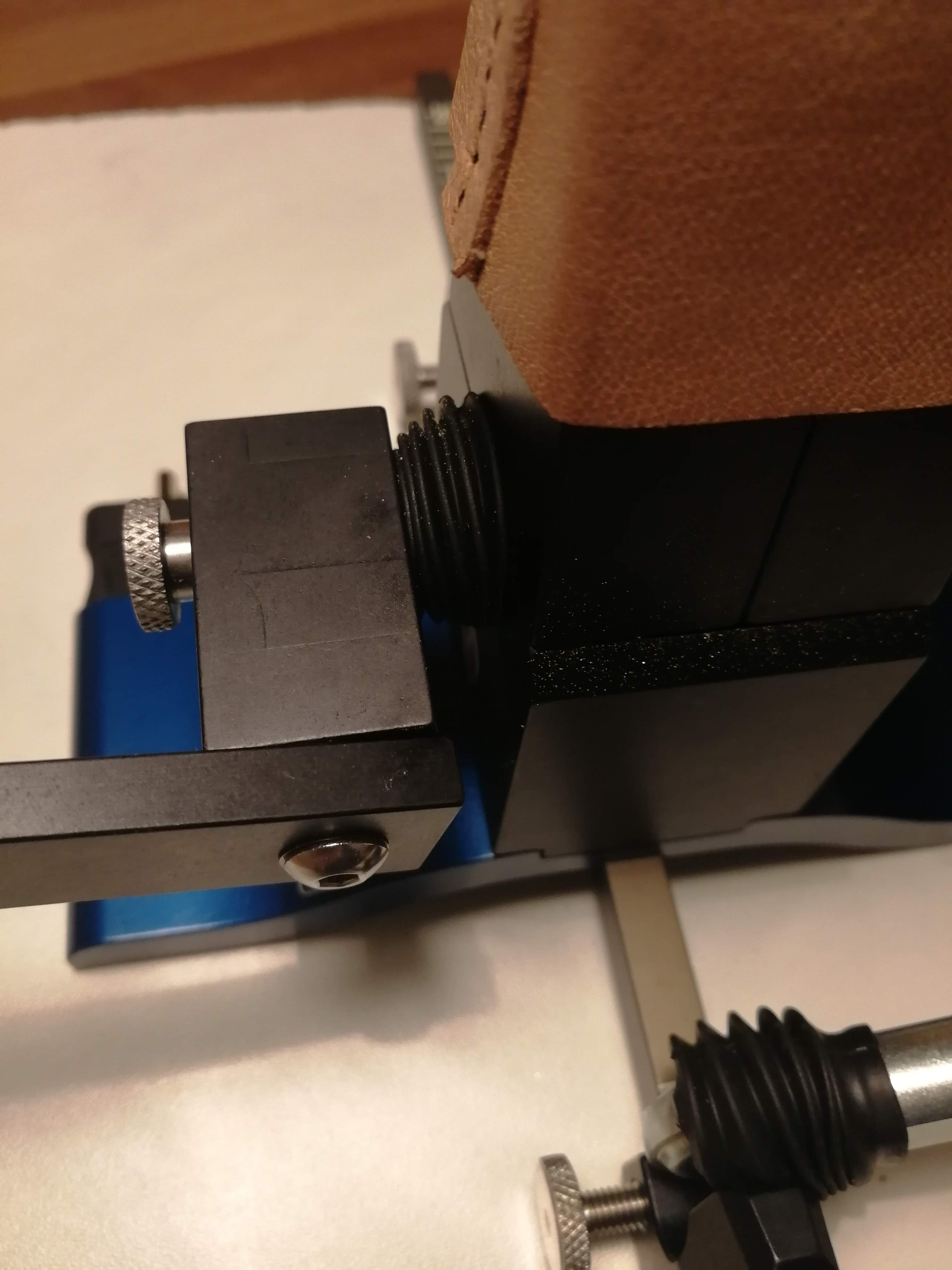

This mod is for the Generation 3 Cam-Lock Split Jaws. Here’s another couple of photos of the finished shroud. I made holes in one side to accommodate the height key – this means some dust could fall into the vice, but it will still be much less than if the vice is fully open.

I’ve attached a PDF file of the shroud (Scale 1:1) which can be printed out and traced around. It’s fairly self-explanatory how to put it together, but here are a few short steps:

- Fold face A to face B along the centreline.

- Fold in the opposite direction to step 1. along B-B and C-C.

- Glue the sections which fit over each of the jaws first (2o mm strips, up and down).

- Fold the triangular pieces on the sides around the front and back of the vice and mark where they meet. Glue.

- For extra strength, sew the pieces where they were glued.

- Locate the hole for the height key. Punch them out using a 3 mm hole punch.

-

This reply was modified 6 years, 3 months ago by

Alchemist.

Alchemist.

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

12/09/2018 at 12:19 pm #48452Hi All,

So I’m the proud owner of a new WE130 system. I’ve got two knives under my belt, they’re not scary, hair-popping sharp, but they’re a hell of a lot better than with any other system I’ve tried! With practice and using finer grits, I’m very confident I’ll master sharpening using the Wicked Edge.

Before I started sharpening, I wanted to implement a few mods I’ve seen here, as well as one or two of my own. The first are the RC car dust covers. They’re a must in my opinion. I had some trouble in the beginning with them, as they were so stiff – I’ve ended up cutting off the somewhat inflexible base, and just using the flexible top half. It covers joints adequately and doesn’t hinder their movement at all.

I also put another of the flexible covers over the pivot of the cam mechanism, to prevent dust getting inside. Judging by the amount of diamond dust and metal shavings landing on it, it seems like a good decision!

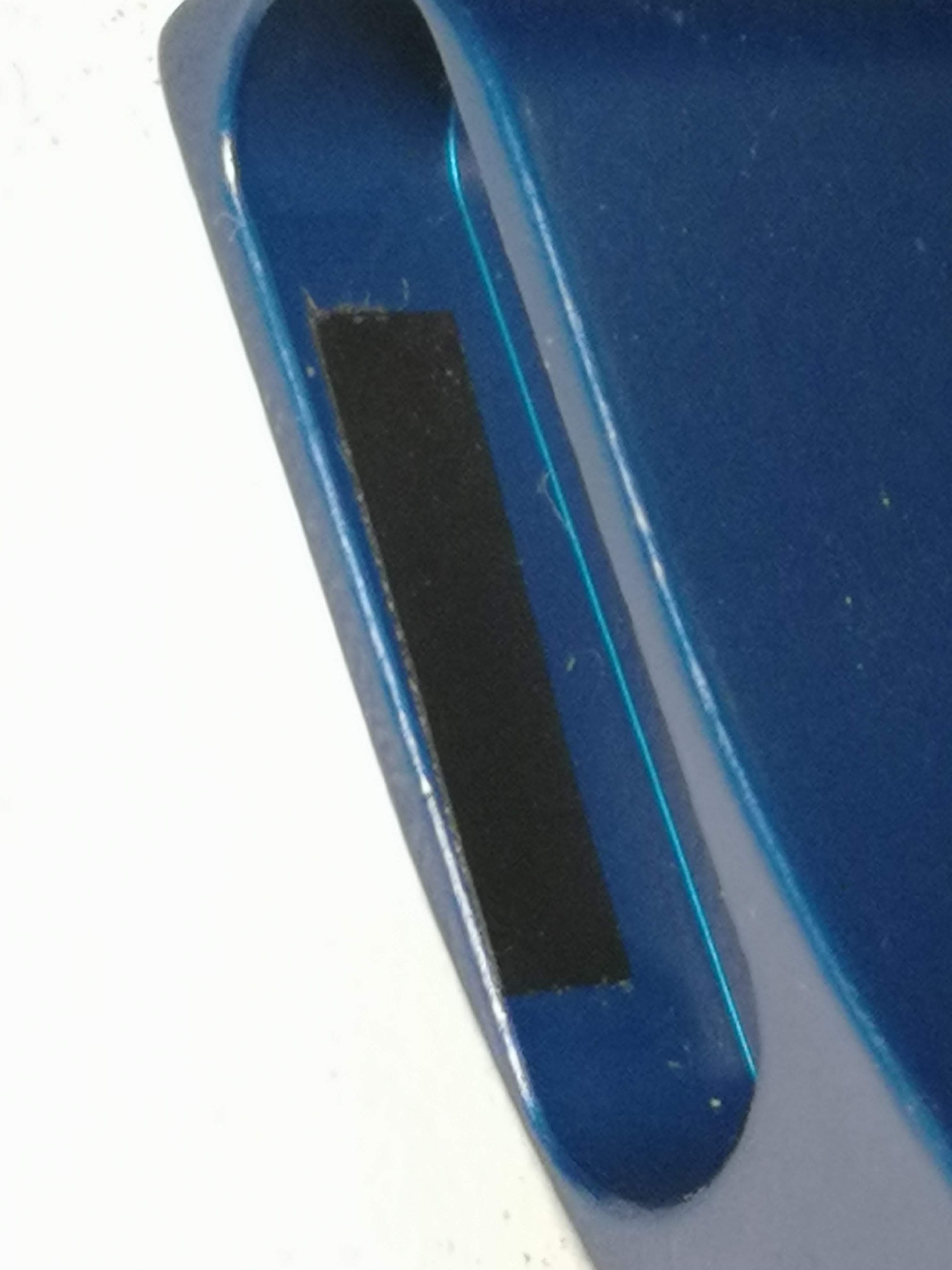

Another thing which was bothering me, was that the height key and the allen key, which fit into the base, were very loose. To remedy this I placed a small piece of tape inside where the tools sit; this is sufficient to grip the tools enough that they don’t slip out under gravity.

Lastly, I wanted to make a cover, a shroud of sorts, for the jaws and the vice, to help keep then clean and most importantly stop dust from entering the cam mechanism from the sides. I’ve seen a mod here, or somewhere online, where the user created a cover from sheet metal. I’ve made mine from leather, for three reasons:

- As a budding leatherworker I’ve got some material lying around, and thought it a good opportunity to do some leatherwork.

- It might be somewhat easier for certain users and involve less tools to create a cover from leather, than from sheet metal.

- Many people in the forums have mentioned using chamois leather to hold their knives more securely. A shroud made from leather therefore serves this purpose, in addition to keeping the dust out.

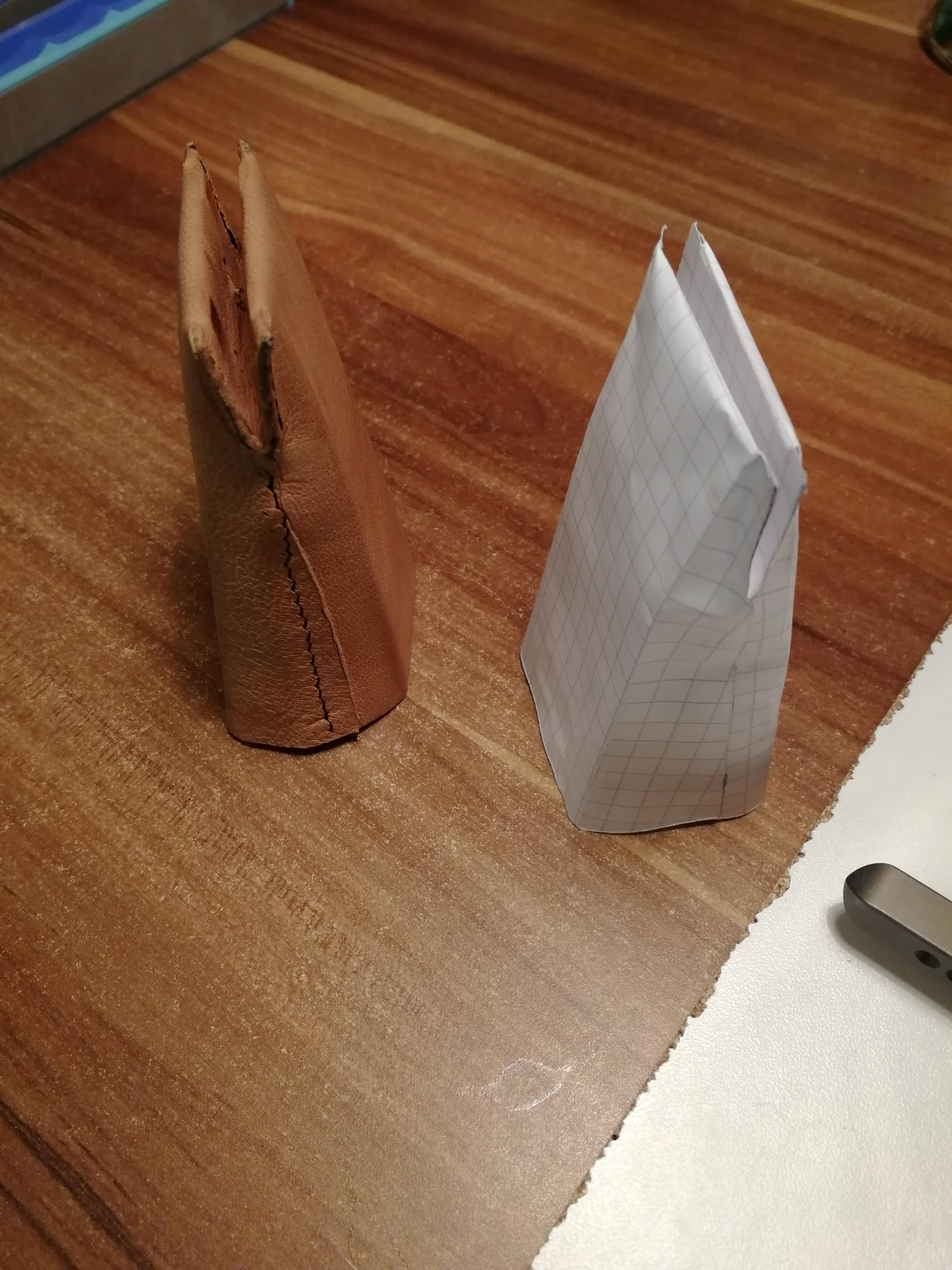

I made a mock-up from paper first, to test the measurements, before marking out and cutting up the leather.

This mod is for the Generation 3 Cam-Lock Split Jaws. I’ve got a template available as a PDF, which I’ll upload in case anyone would like to create their own.

-

This reply was modified 6 years, 3 months ago by

Alchemist.

Alchemist.

-

This reply was modified 6 years, 3 months ago by

Alchemist.

Alchemist.

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

12/09/2018 at 11:59 am #48451Hi MarcH,

Thanks very much for your reply. OK, I’ll test out the WE for a little while and see how it performs with just 4 pairs of Belleville washers. If I end up replacing the 5th pair, I’ll update here.

2 users thanked author for this post.

-

AuthorPosts