Strops or stones ?

Recent › Forums › Main Forum › Welcome Mat › Strops or stones ?

- This topic has 148 replies, 12 voices, and was last updated 01/05/2017 at 6:27 am by

Organic.

Organic.

-

AuthorPosts

-

03/18/2016 at 3:55 pm #32203

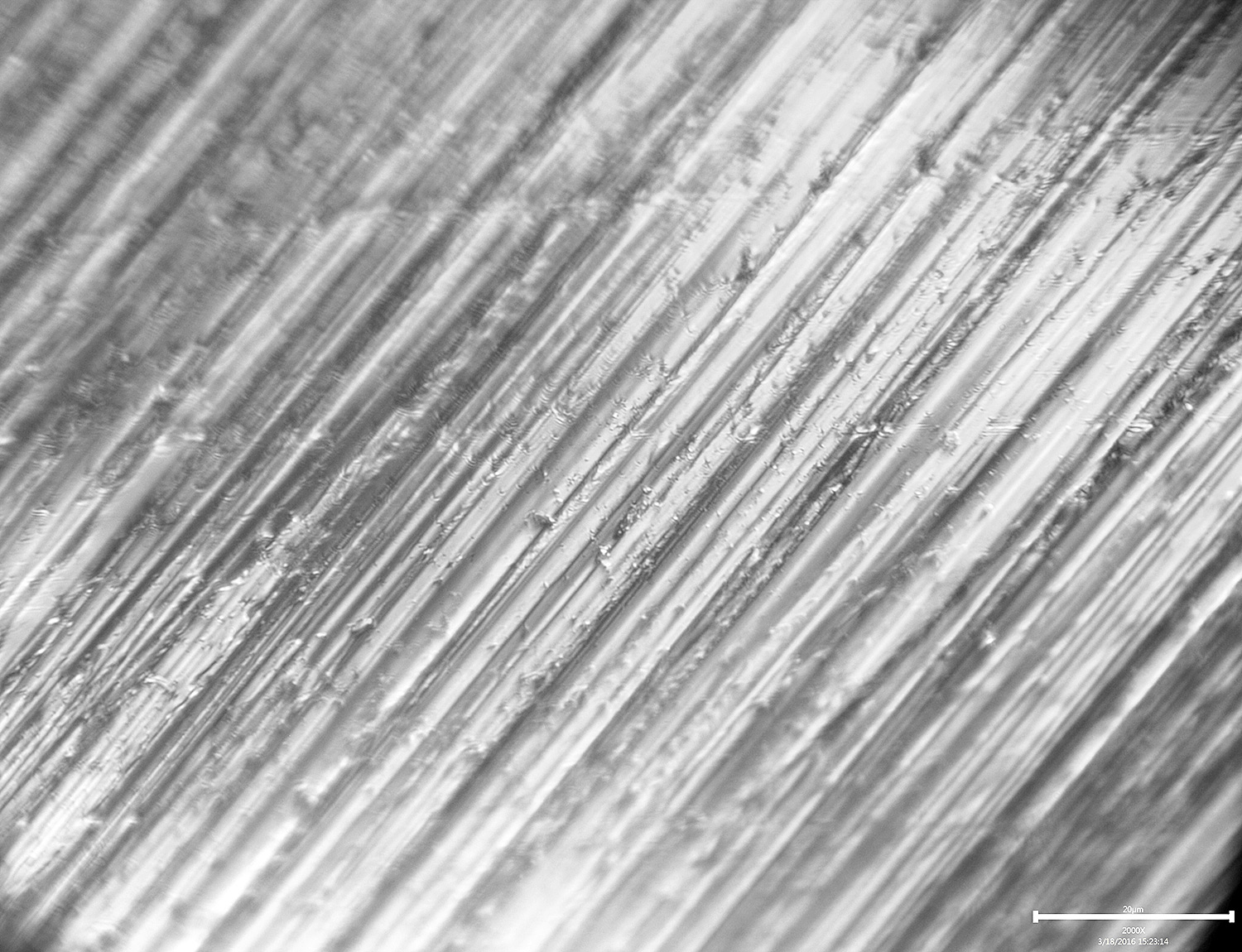

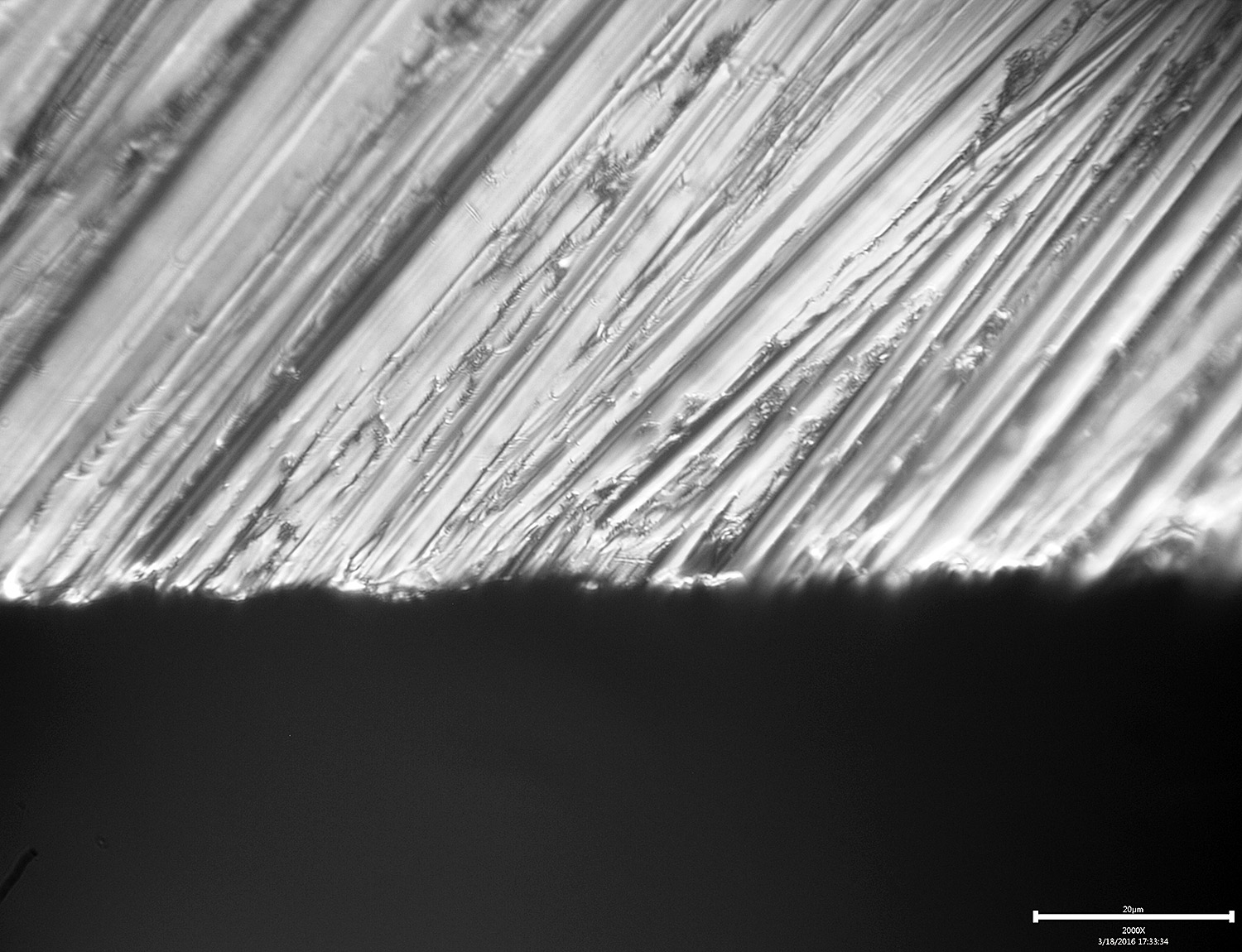

Some good points raised here. I decided to try what was suggested and check the efficiency of each of the stones at removing the scratches of the 1000# diamonds. So first I did 20 strokes with the diamonds:

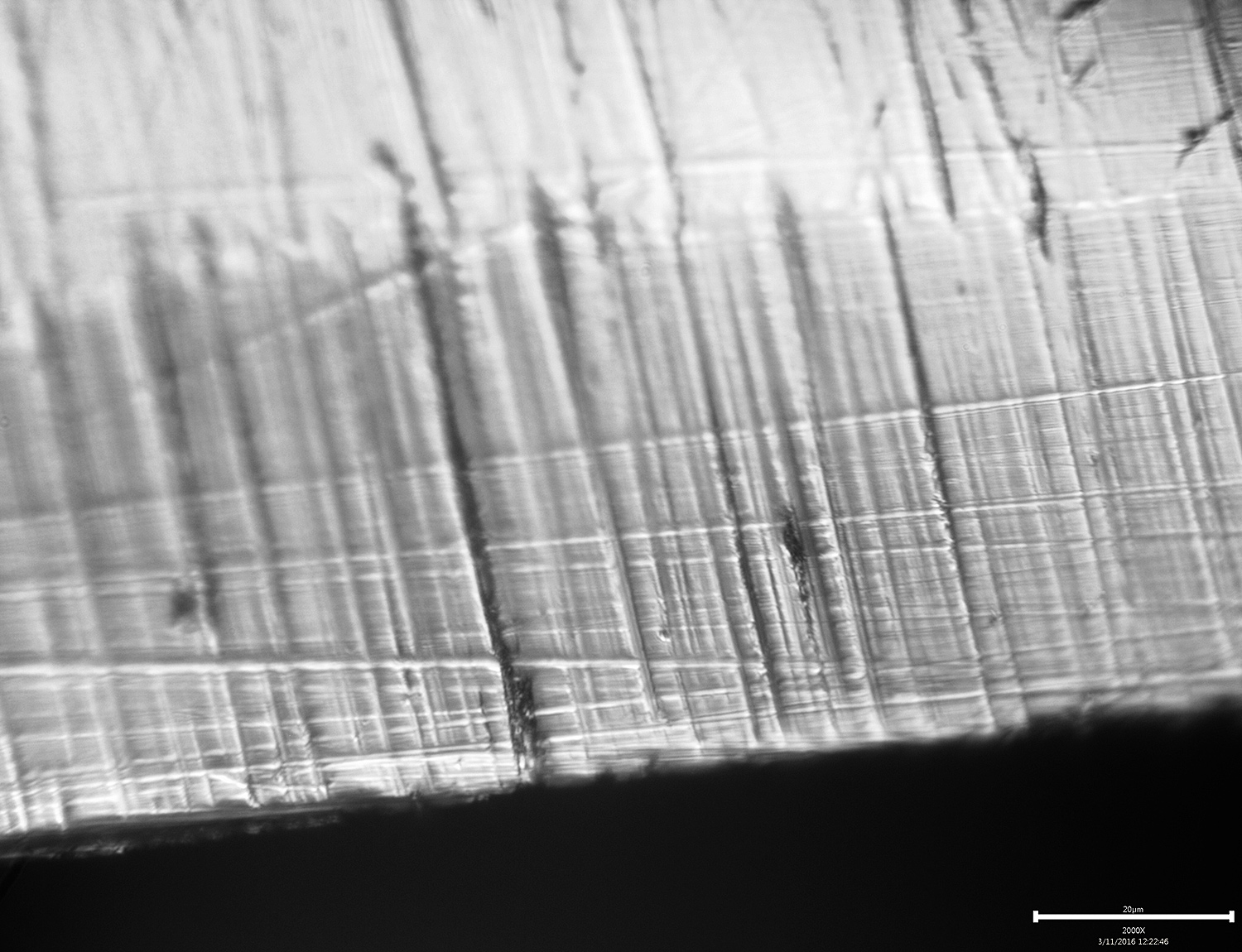

Then 50 strokes with the SFC:

Then another 20 strokes with the 1000# diamonds to erase the SFC scratches. I didn’t image that but was very confident under the loupe that the diamond stones remade the bevel.

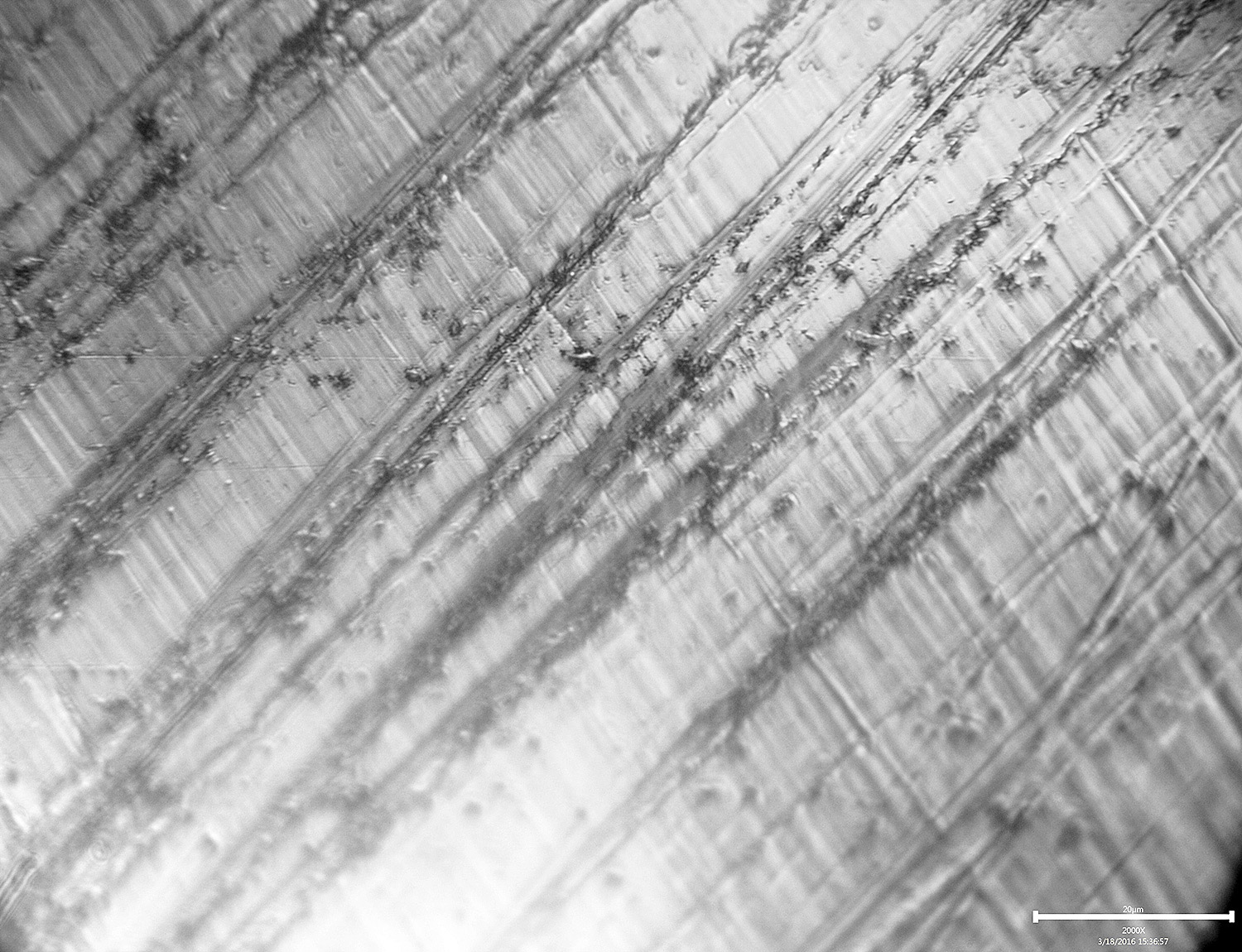

Next up were 50 strokes with the SFF:

-Clay

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

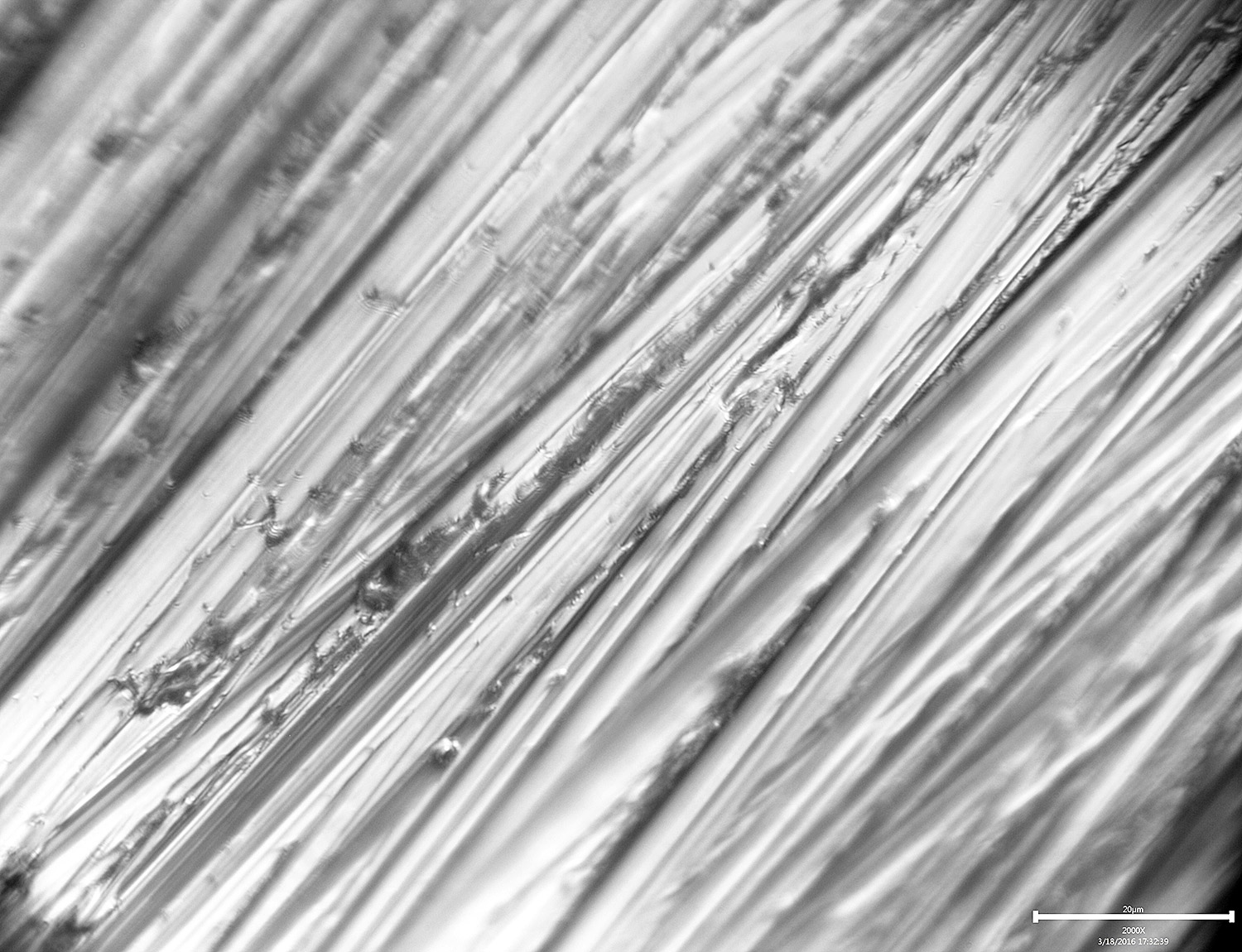

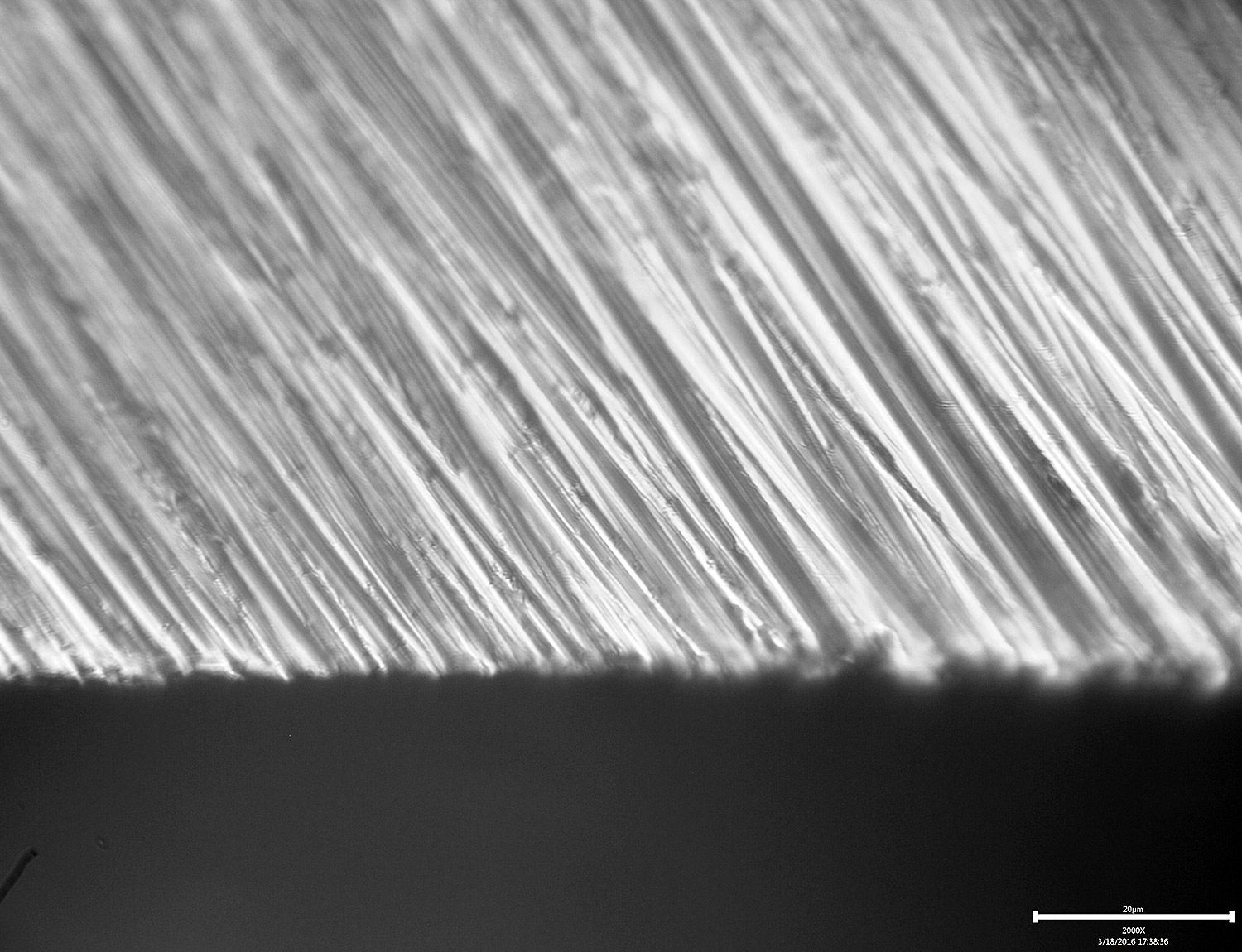

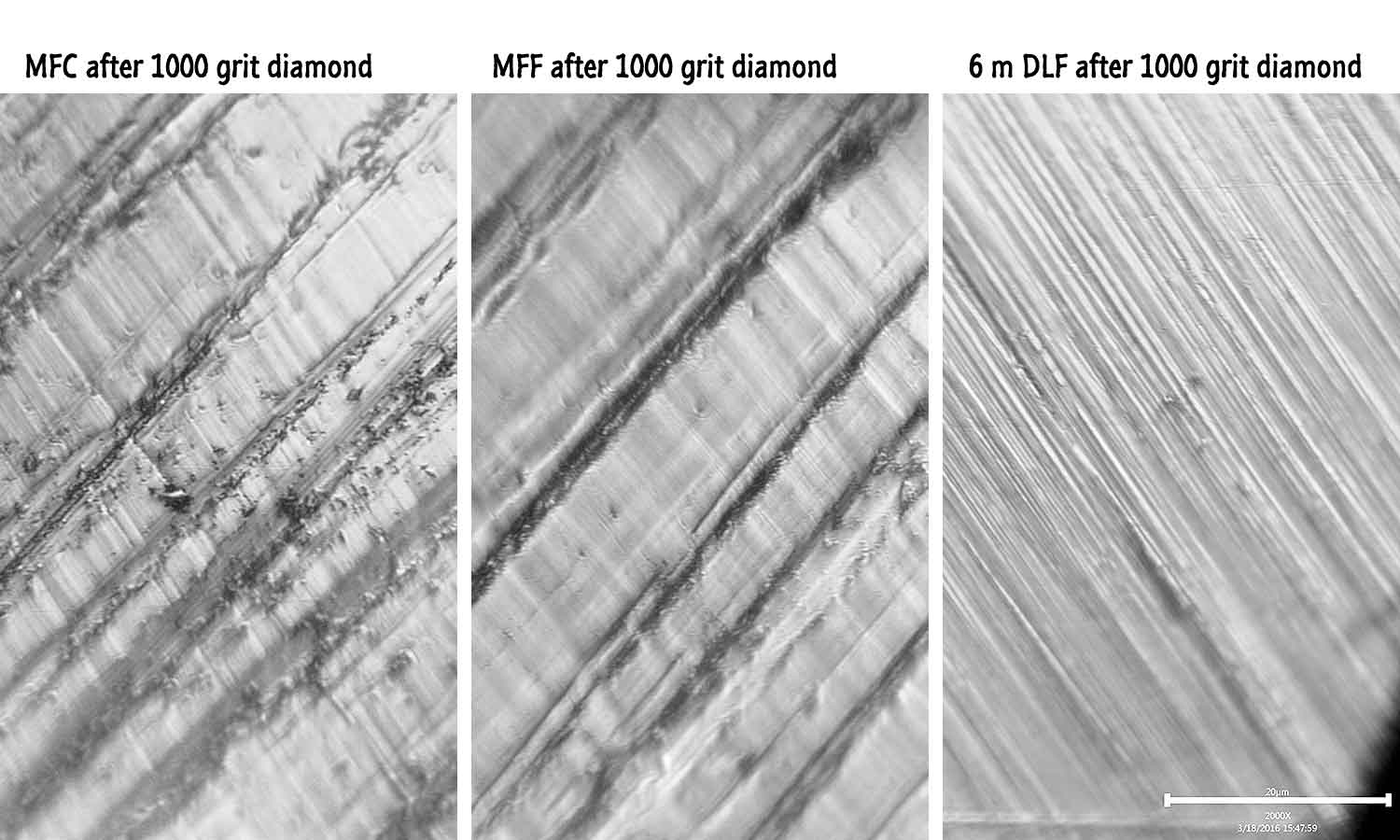

03/18/2016 at 3:57 pm #32208I remade the bevel again with another 20 strokes with the 1000# diamonds and then did 50 strokes with the MFC:

Remade the bevel again and then 50 strokes with the MFF:

And for fun, remade the bevel again and then 50 strokes with the 6µ Diamond Lapping Films:

The lapping films were already well used, definitely not new strips.

-Clay

Attachments:

You must be logged in to access attached files.

03/18/2016 at 4:13 pm #32214Probably the best, or at least the most telling tests done on this subject so far.

1 user thanked author for this post.

03/18/2016 at 4:24 pm #32216Probably the best, or at least the most telling tests done on this subject so far.

Good experiment design is everything I guess

Credit to dulledge for the suggestion, thanks!

At each iteration, the scratches going top right to bottom left (TRBL) were renewed with the 1000# stones. Any scratches going from top left to bottom right (TLBR) are from the stone listed and any remaining scratches in the TRBL orientation were 1000# scratches that the subject stone failed to remove.

-Clay

03/18/2016 at 4:37 pm #32218I kinda do what Josh suggested… although with each stone I go in both directions… I don’t go a specific direction with one stone, than switch with the next.

Curtis, I am curious why would you go both directions with each stone? Imho not only is it not needed and costs extra time, it also ‘muddles the waters’ so to speak because then you can’t tell where you are at.

Maybe you could include one of the diamond stones in the “number of strokes for scratch removal” test (e.g., using 1000 to remove 800 scratches). That way we also get an impression of the efficiency of the diamond stones vs. ceramic stones.

This would be neat across the board for sure!

However, just so the new guys don’t misunderstand and apply this though process (i.e. “x amount of strokes is guaranteed to erase the prior scratches) I think we should clarify. While in this experiment one knife is being used so these things don’t change, in real use there are a lot of unaccounted variables that play an influence in how many strokes are needed to erase the prior grit scratch pattern… such as type of steel, hardness of steel, width of the edge (from apex to shoulder) that the stone will be contacting, loading of the stone, etc.

Great idea though Mark I agree, so we can have a benchmark!

4 users thanked author for this post.

03/18/2016 at 5:20 pm #32223I kinda do what Josh suggested… although with each stone I go in both directions… I don’t go a specific direction with one stone, than switch with the next.

Curtis, I am curious why would you go both directions with each stone? Imho not only is it not needed and costs extra time, it also ‘muddles the waters’ so to speak because then you can’t tell where you are at.

I think it covers a blade better, especially if it has any recurve in it. Not sure it takes anymore time… I don’t go one direction than switch and completely wipe that grind mark out going the other way… I probably spend the same amount of time if I just went one direction at a time. Only the final stone do I set the edge the direction I want the grind marks to go. I’m not sure what you mean about not knowing “where you are at”… so I’m maybe not answering this correctly.

03/18/2016 at 5:45 pm #32225Did you also use edge-leading strokes only? (The pics are all have “leading” in their names.)

I did use leading strokes with all but the 1000# stones.

Maybe you could include one of the diamond stones in the “number of strokes for scratch removal” test (e.g., using 1000 to remove 800 scratches). That way we also get an impression of the efficiency of the diamond stones vs. ceramic stones.

I did 20 edge leading strokes with the 800# diamonds:

And then set to erasing the 800# scratches with the 1000# stones, checking every 5 strokes to see if any scratches remained. Most were gone after the first 5 strokes but it took a full 20 strokes for them to be all erased:

-Clay

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

03/18/2016 at 7:04 pm #32233Sorry, but I’m a little behind on this discussion – had a funeral to go to today. I did have a couple of comments I wanted to make.

Since Clay’s observations, I’ve been trying to stick with “edge leading” strokes. I’ve only done a few knives, but I sense that it’s producing finer edges – fewer and smaller “tooth” serrations.

Next, there was some question about the number of strokes required to remove scratches from the previous grit and it comes up frequently on this forum. I haven’t done anything specifically designed to determine the number of strokes needed to remove all traces of the previous grit, but I have paid a little attention to it. The amount of metal removed per stroke is dependent on the length of the abrasive contact for any point on the blade, the grit and the pressure applied. Certainly, the condition of the abrasive (metal loading in the grit substrate) is also a factor.

Consider a situation where you are making a full length vertical strokes over a given point. About 4 inches of the stone will abrade on that given point with each up or down stroke. If you have a very long blade and your stroke is a slowly-rising or falling pass over the same given point, the amount of abrasive passing that point is only slightly more than 3/4″. For a straight blade, the length of abrasive is the hypotenuse of the up or down slope. A shorter blade will have a much more vertical stroke than a longer blade.

Where a blade has a relatively short radius to its belly shape, the amount of abrasive passing over a given point may be even less than the 3/4″, as the stone may only make contact at something well under 3/4″.

I have a batch of seven Grizzly Z-knives, which I use here and there for all kinds of small-knife tasks around the home. Their blades are fairly short (2″) and deeply radiused, but I’ve found that five strokes of any grit will remove the scratches left by an earlier grit. The blades are certainly not straight-edged, but if they were, their short length means that the slope is about 2:1 (4″ of rise in 2″ of horizontal travel. The length of contact works out to be 2.23 times the 3/4″ width, or about 1.67″.

If you used Cliff’s pattern of strokes parallel to the edge, the length of contact over any one point would be 3/4″. If you use vertical scrubbing strokes, each up/down stroke produces 8″ of contact. Of course, the number of strokes is also then driven by the length of the blade.

My point here is that the length of the blade is a significant variable on the WEPS or any similar system. Expect to use more strokes with a longer blade.

For all the newbies who might be trying to follow all this, we only need to remove scratches from a previous grit when you are in pursuit of a mirror edge. For anything else, you should focus on the quality of the edge. That said, deep scratches produced by lower grits (<1000) can prevent the attainment of a quality edge.

5 users thanked author for this post.

03/18/2016 at 7:19 pm #32235I kinda do what Josh suggested… although with each stone I go in both directions… I don’t go a specific direction with one stone, than switch with the next.

Curtis, I am curious why would you go both directions with each stone? Imho not only is it not needed and costs extra time, it also ‘muddles the waters’ so to speak because then you can’t tell where you are at.

I think it covers a blade better, especially if it has any recurve in it. Not sure it takes anymore time… I don’t go one direction than switch and completely wipe that grind mark out going the other way… I probably spend the same amount of time if I just went one direction at a time. Only the final stone do I set the edge the direction I want the grind marks to go. I’m not sure what you mean about not knowing “where you are at”… so I’m maybe not answering this correctly.

I guess what I was meaning was how do you know for sure all the previous scratches are removed? If you are going both directions it would seem to be hard to tell.

1 user thanked author for this post.

03/18/2016 at 10:27 pm #32238I guess what I was meaning was how do you know for sure all the previous scratches are removed? If you are going both directions it would seem to be hard to tell.

It was talked about a long time ago,,, you can kinda tell when a stone is ‘done’ just by a change in how it feels (it no longer feels like it’s cuttings as aggressively), and by the sound (it quiets down a bit), and if looked at under magnification, you can still see if any scratches stand out from the current finish. (And if the last few posts are any indication, I’m probably going a bit beyond what’s needed anyway).

But I also don’t polish bevels out, especially to the level you do, so it’s not as important to me. Usually now on the W.E. I just finish with one of the diamond stones, and use leather just enough to clean up the edge a bit. If I want to refine an edge further, the polish is more of a ‘side effect’ of the sharpening, if that makes sense.

03/19/2016 at 4:55 am #32246Isn’t it if you make enough strokes, you should get the same results either way? IMHO they do look the same. The question should be – which way is faster to get there?

Agreed, which is why I agree with Curtis that Clay’s last experiment is great.

Probably the best, or at least the most telling tests done on this subject so far.

Thanks, Clay!

Josh made a good point that you should not take the number of strokes as a standard, since it depends on a lot of variables. This experiment gives an indication for how fast the various stones work relative to each other.

I think it shows that the diamond stones and films work faster than the ceramic stones. Personally it also strengthens me in my opinion that 1000->SF->MF is the preferred order.

Molecule Polishing: my blog about sharpening with the Wicked Edge

03/19/2016 at 8:17 am #32250I guess what I was meaning was how do you know for sure all the previous scratches are removed? If you are going both directions it would seem to be hard to tell.

It was talked about a long time ago,,, you can kinda tell when a stone is ‘done’ just by a change in how it feels (it no longer feels like it’s cuttings as aggressively), and by the sound (it quiets down a bit), and if looked at under magnification, you can still see if any scratches stand out from the current finish. (And if the last few posts are any indication, I’m probably going a bit beyond what’s needed anyway). But I also don’t polish bevels out, especially to the level you do, so it’s not as important to me. Usually now on the W.E. I just finish with one of the diamond stones, and use leather just enough to clean up the edge a bit. If I want to refine an edge further, the polish is more of a ‘side effect’ of the sharpening, if that makes sense.

Ahhh that makes sense! I do not cross hatch it unless I am going for a true mirror finished edge either, most of the time this isn’t the case. When I’m just sharpening one through 800-1k grit I go all the same direction =)

Isn’t it if you make enough strokes, you should get the same results either way? IMHO they do look the same. The question should be – which way is faster to get there?

Agreed, which is why I agree with Curtis that Clay’s last experiment is great.

Probably the best, or at least the most telling tests done on this subject so far.

I agree as well, it’s amazing how fast those work!

1 user thanked author for this post.

03/19/2016 at 9:35 am #3225303/19/2016 at 2:49 pm #32260Is 6 micron diamond lapping film better for removing 1000 grit diamond scratches than MFC and MFF?

Appears to be the case… from this test anyway.

1 user thanked author for this post.

03/19/2016 at 6:26 pm #32269Is 6 micron diamond lapping film better for removing 1000 grit diamond scratches than MFC and MFF?

No. Just faster

.

.Molecule Polishing: my blog about sharpening with the Wicked Edge

2 users thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.