Strops or stones ?

Recent › Forums › Main Forum › Welcome Mat › Strops or stones ?

- This topic has 148 replies, 12 voices, and was last updated 01/05/2017 at 6:27 am by

Organic.

Organic.

-

AuthorPosts

-

03/12/2016 at 4:09 pm #31917

Some more comments after re-reading this thread…

I don’t remember when we changed the formulation with the 1200/1600, but it’s been a few years now. Your comment makes a good question. I’ll have to dig up an old pair from before the change and test them against the new ones.

I still have the old email in which I ordered the 1200/1600 grit stones. I did it on December 1 2012. (Wow, I have the WEPS only three years now… It feels much longer

.)

IIRC WE changed to the new manufacturer a couple of months (half a year?) later. This could be consistent with Frans’ observations of his 1200/1600 stones.

I tend to bounce around a bit and try a little of everything and often wind up saying “this is my new favorite!” and go with whatever that is for a while. […] Currently, my “new favorite!” are the lapping films. [..] I really love the diamonds with PSA backing. The diamonds are wonderfully efficient and last a surprisingly long time. They are expensive though…

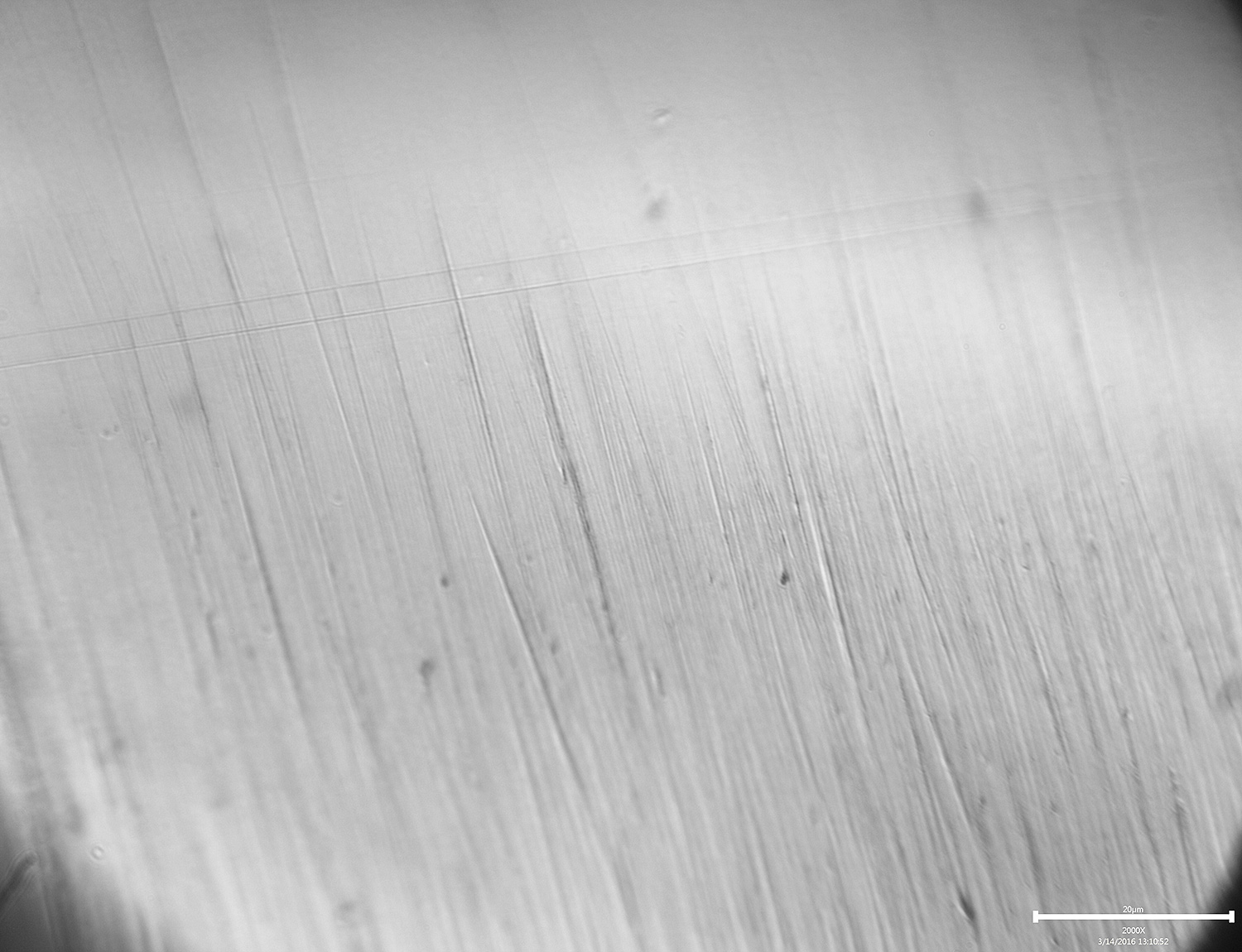

These are my new favourites as well. But I think it’s more than just a temporary thing. They work fast and they are reliable. I was particularly impressed when I saw the scratch pattern the 6 micron diamond film produced (after the 1000 grit stones), of which you posted pictures in one of threads. I have never been more impressed by such a uniform scratch pattern.

I am waiting for Knives & Tools to get the diamond film and will then experiment whether the transition from 1000 grit diamonds to 6 micron diamond films works fine or whether you’d be better off with the 9 in between. Tom even uses the 15 micron in between and Josh even starts with the 30 after the 1000 grit diamonds.

(My current solution is to use all 4 ceramic stones after the diamond stones and then go to the 3 micron film.)

Molecule Polishing: my blog about sharpening with the Wicked Edge

6 users thanked author for this post.

03/12/2016 at 7:07 pm #31922I don’t remember when we changed the formulation with the 1200/1600, but it’s been a few years now. Your comment makes a good question. I’ll have to dig up an old pair from before the change and test them against the new ones.

I bought my 1200/1600 in March 2013 but I was not happy with them. The stones felt chalky, easily chipped at the edges and one came loose from the plastic handle. Would the currently available stones be better? Is there any way that I can check/see from which production run/period my stones are?

It’s hard to say. I’ll try to investigate it by going back through archived emails to see if I can pin down the date.

-Clay

1 user thanked author for this post.

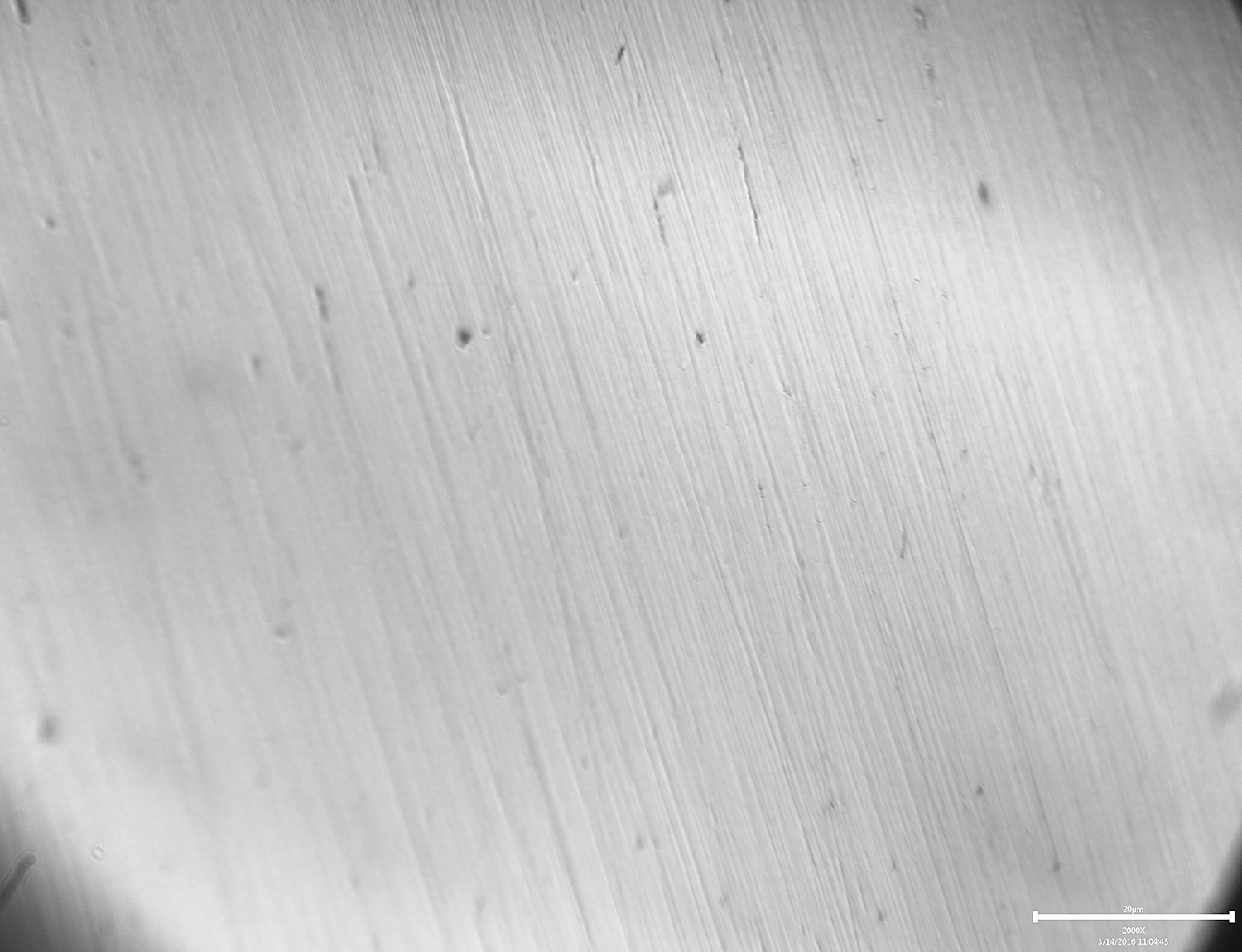

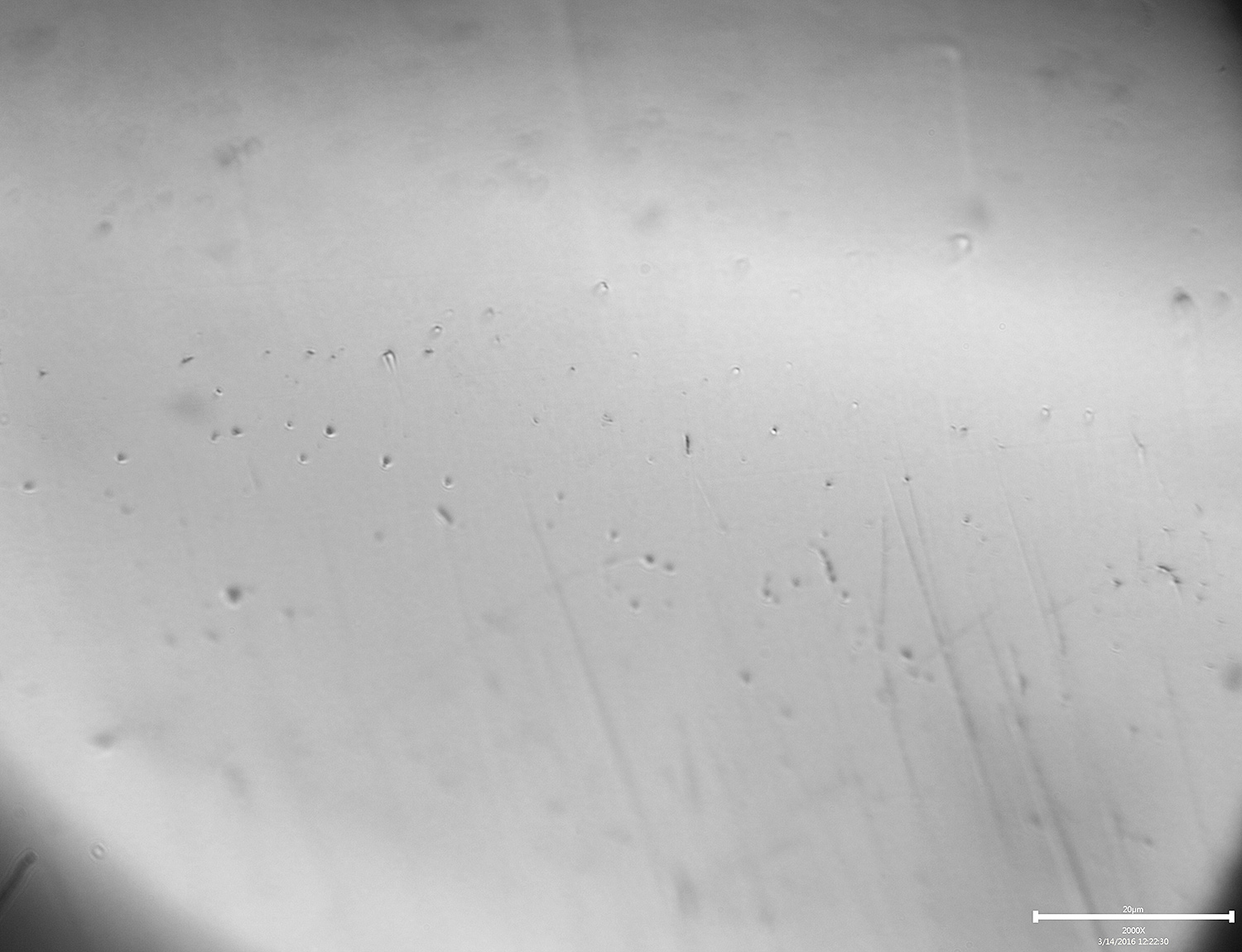

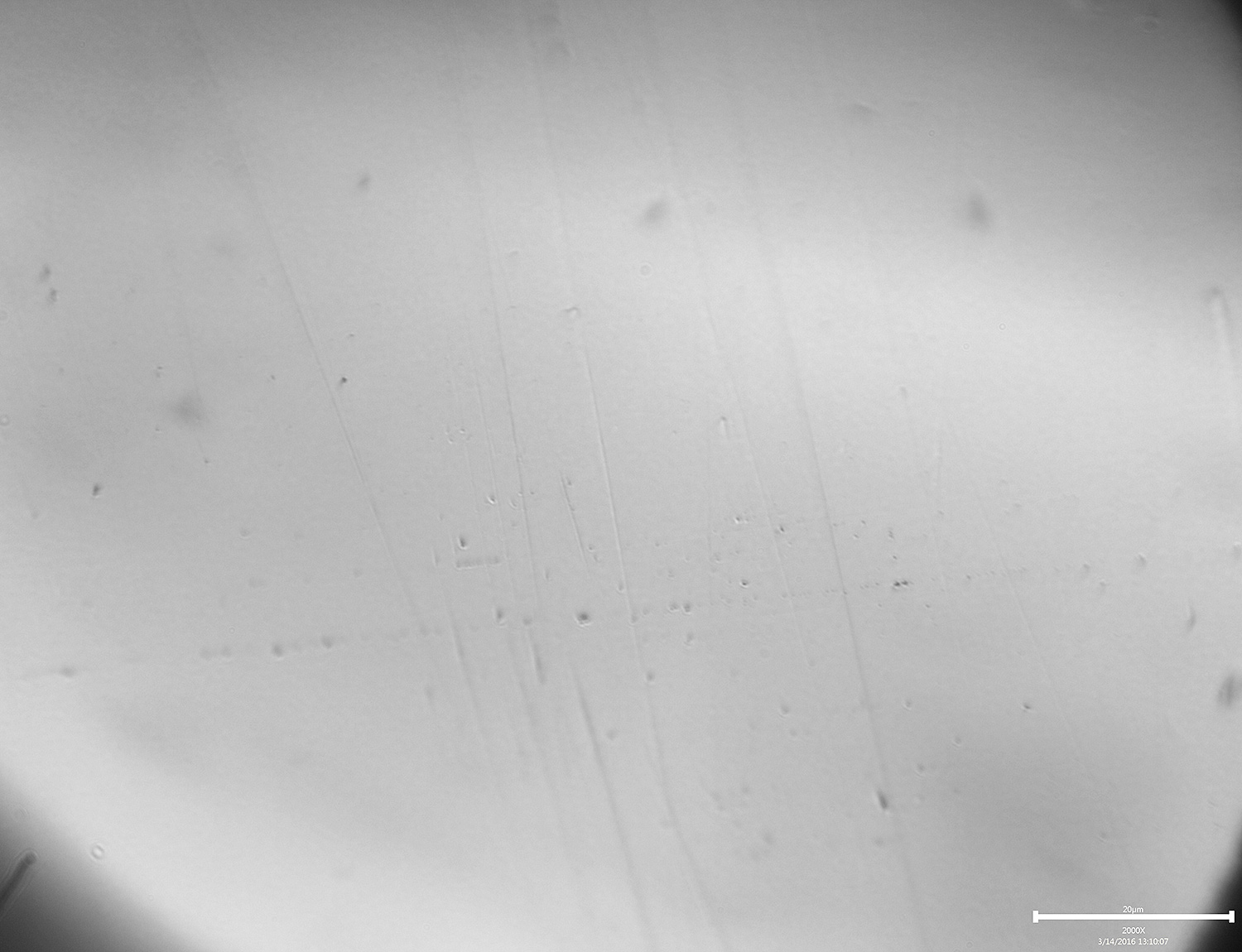

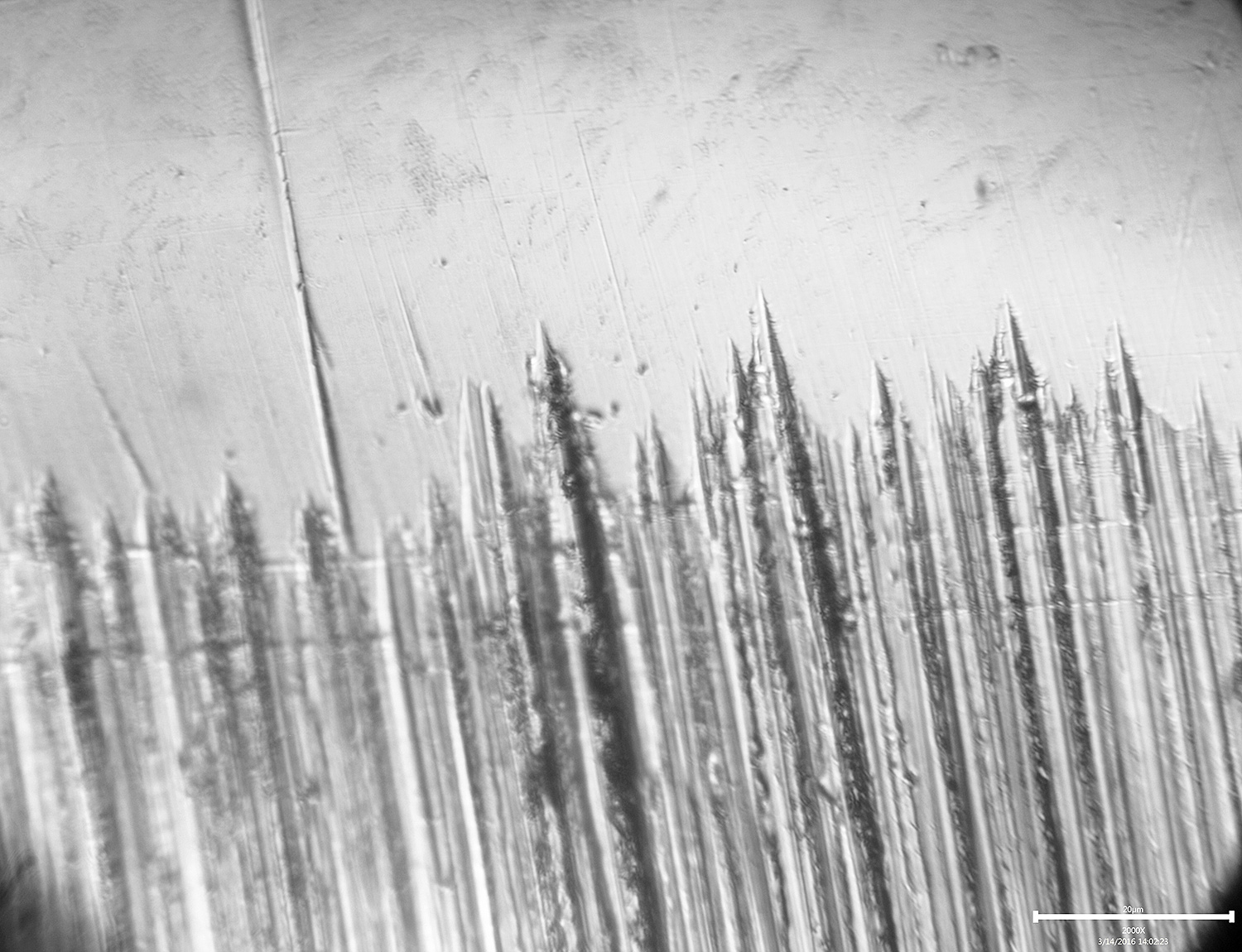

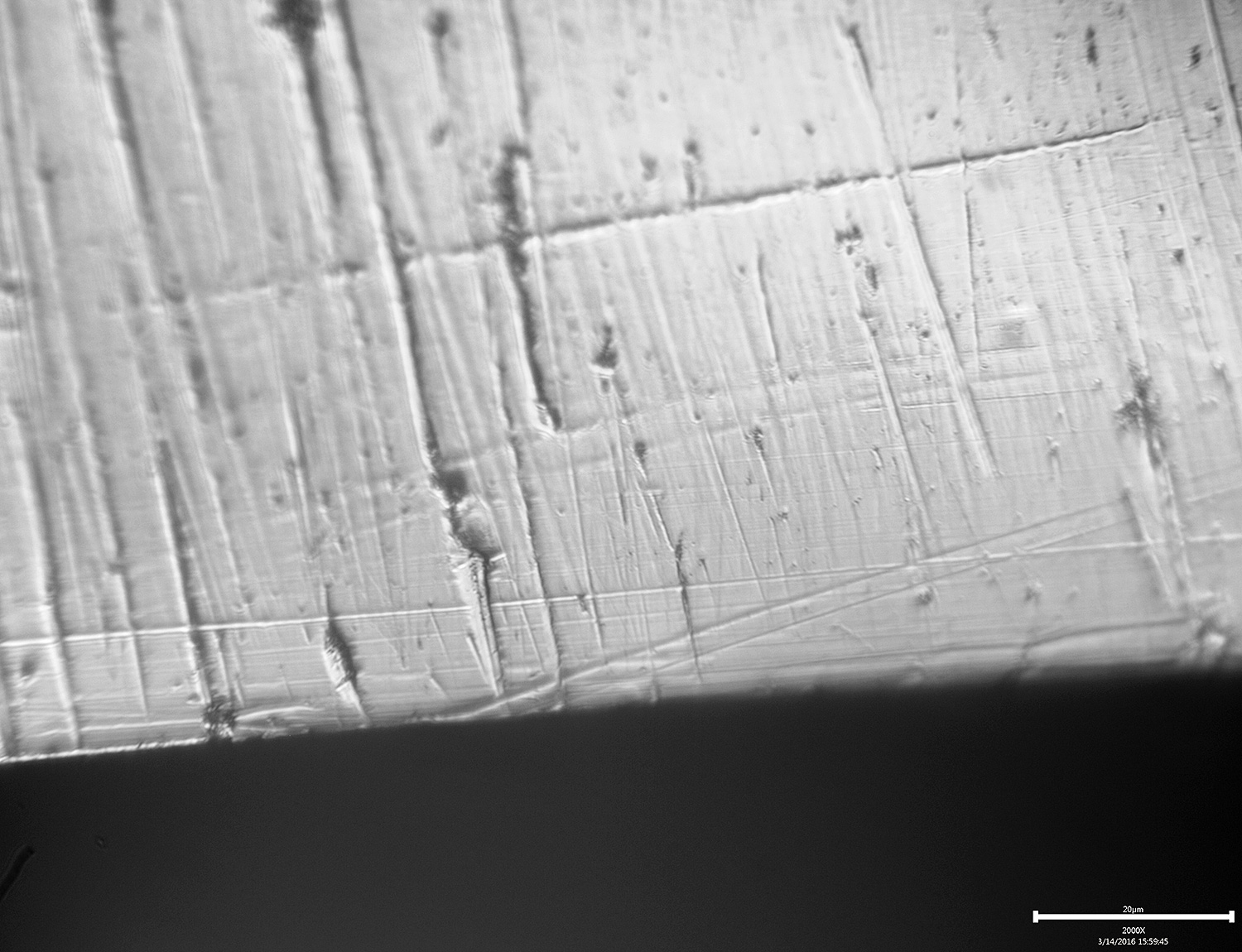

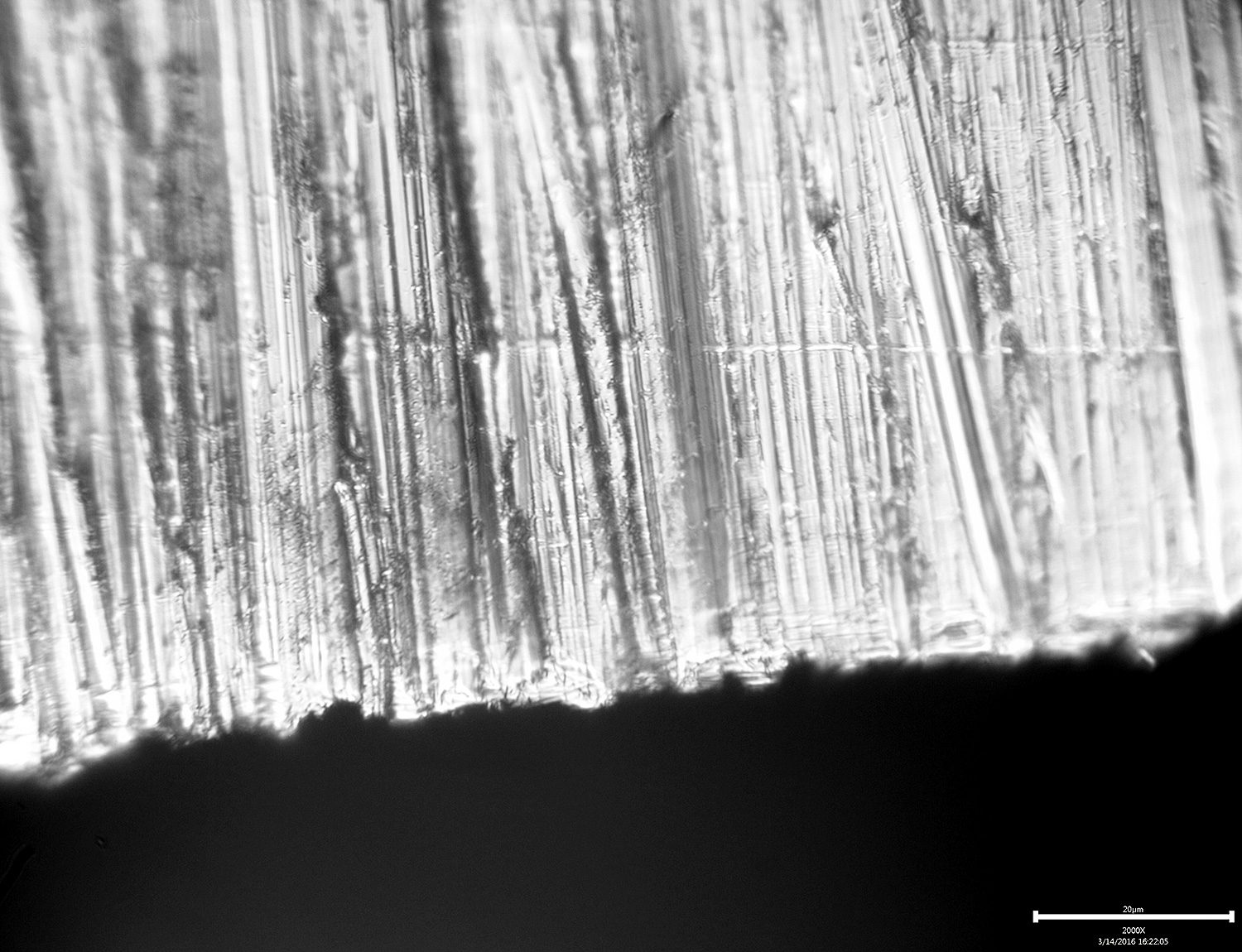

03/14/2016 at 11:52 am #31942A few more pics this morning. I decided to clean up the primary bevel of the sample with a new set of diamond lapping films and the kangaroo strops. Here’s what we’ve got so far:

.25µ Diamond on Kangaroo Strops

-Clay

Attachments:

You must be logged in to access attached files.

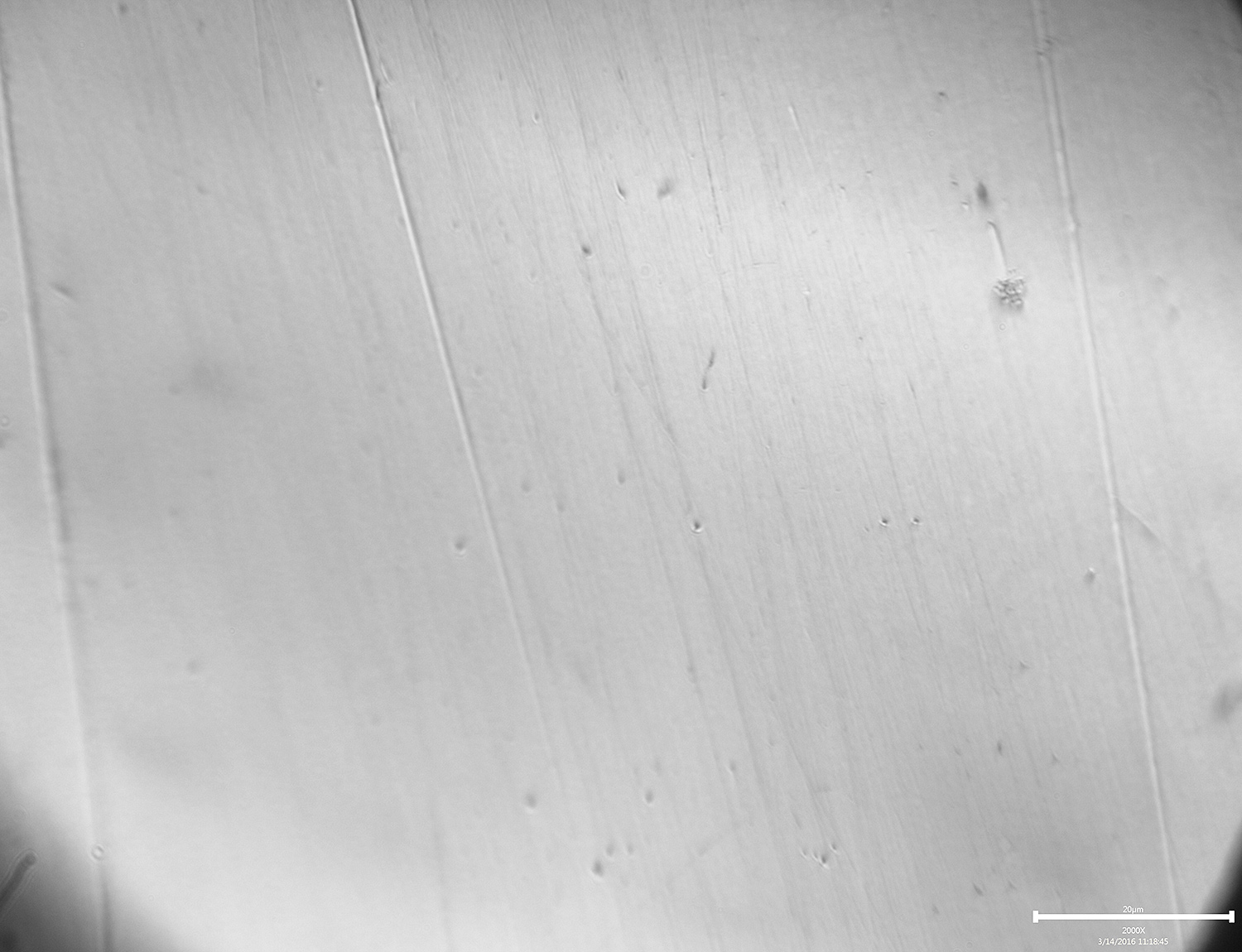

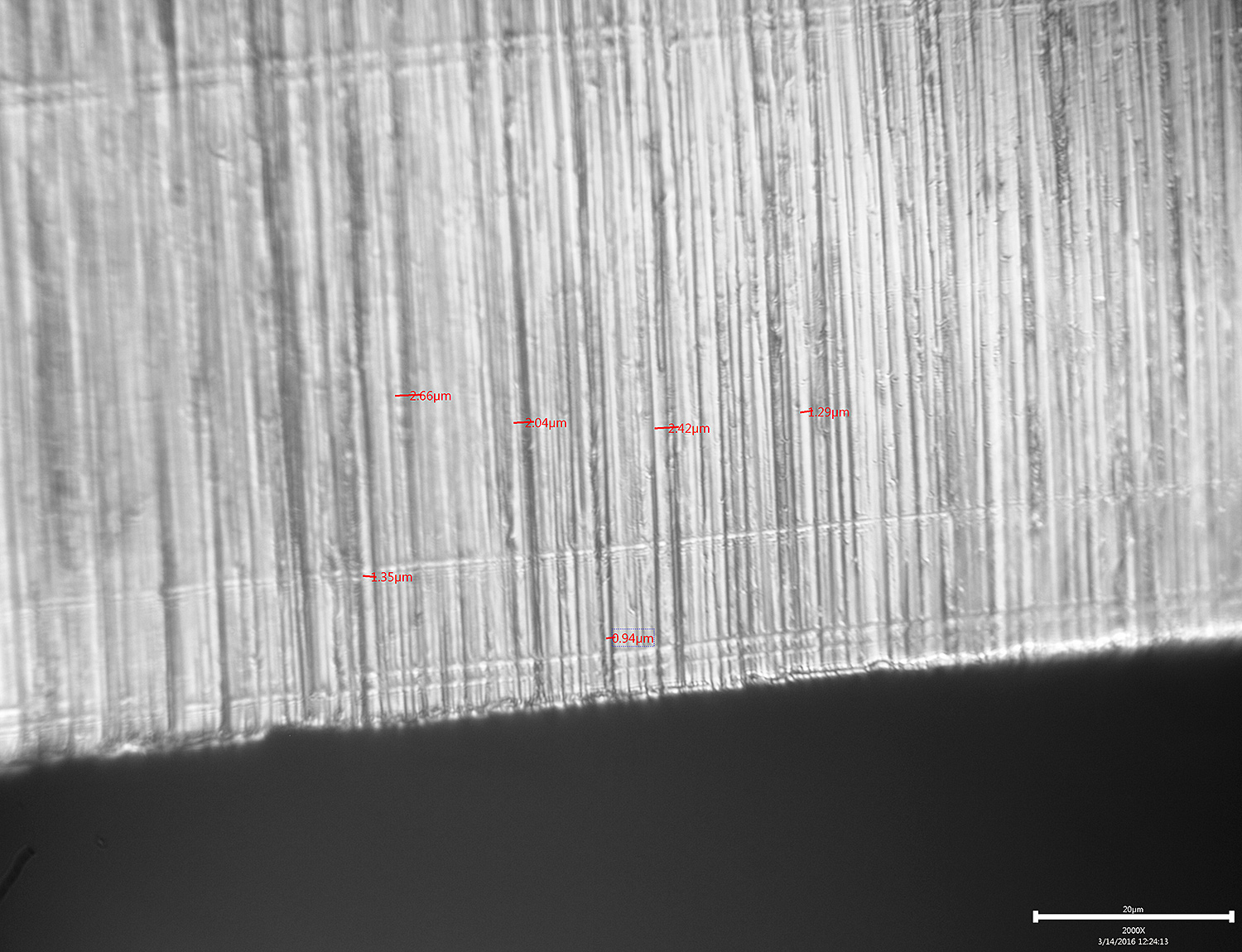

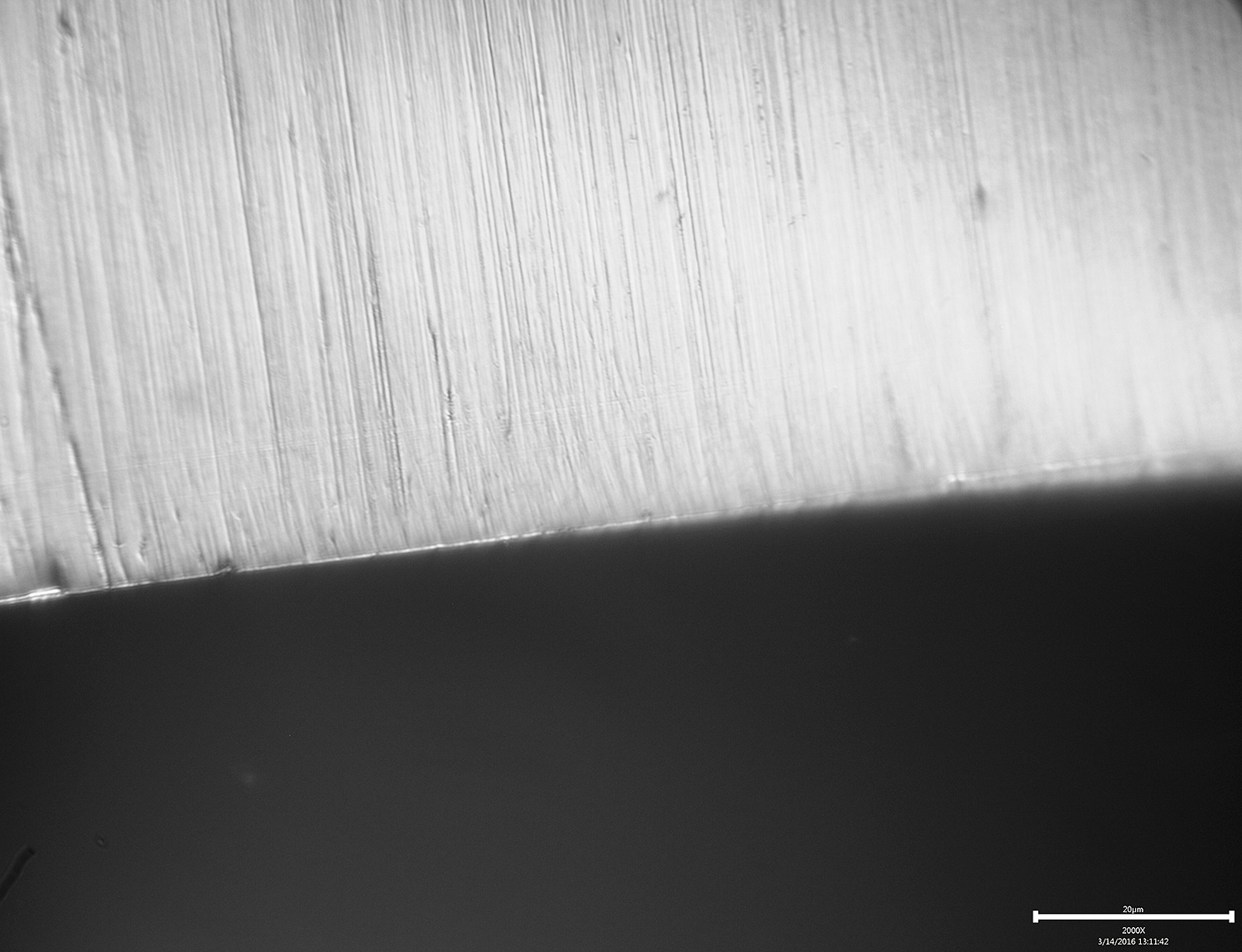

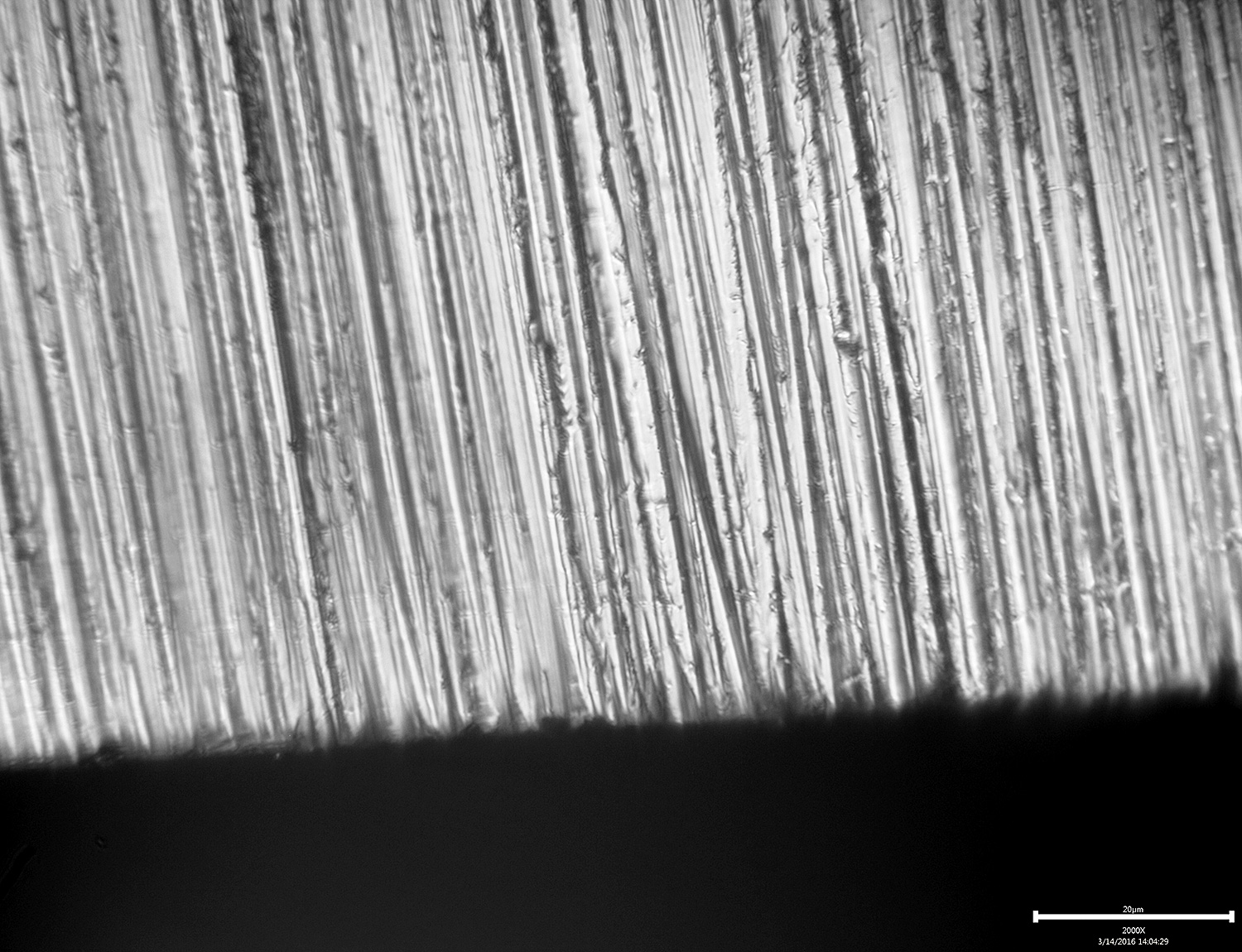

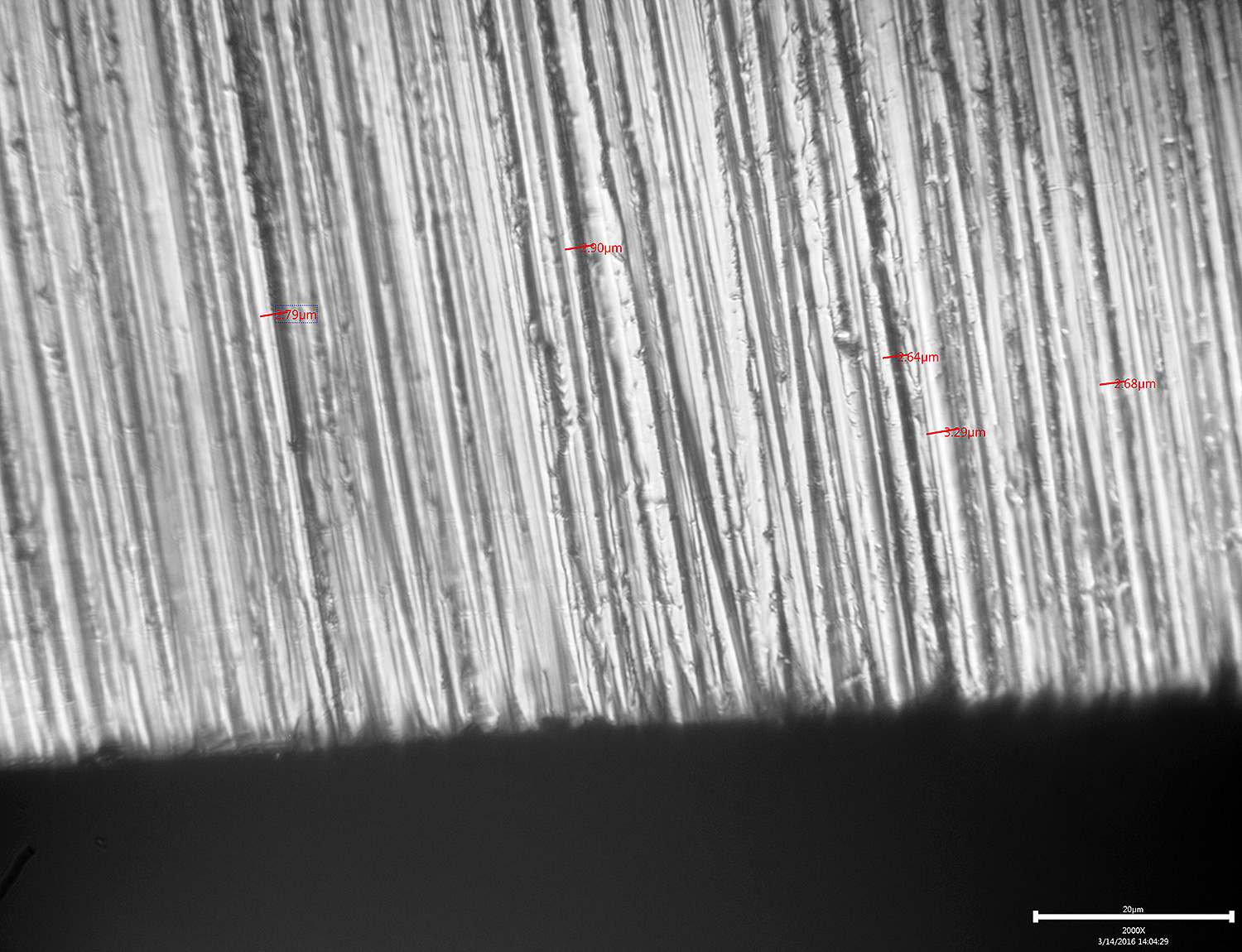

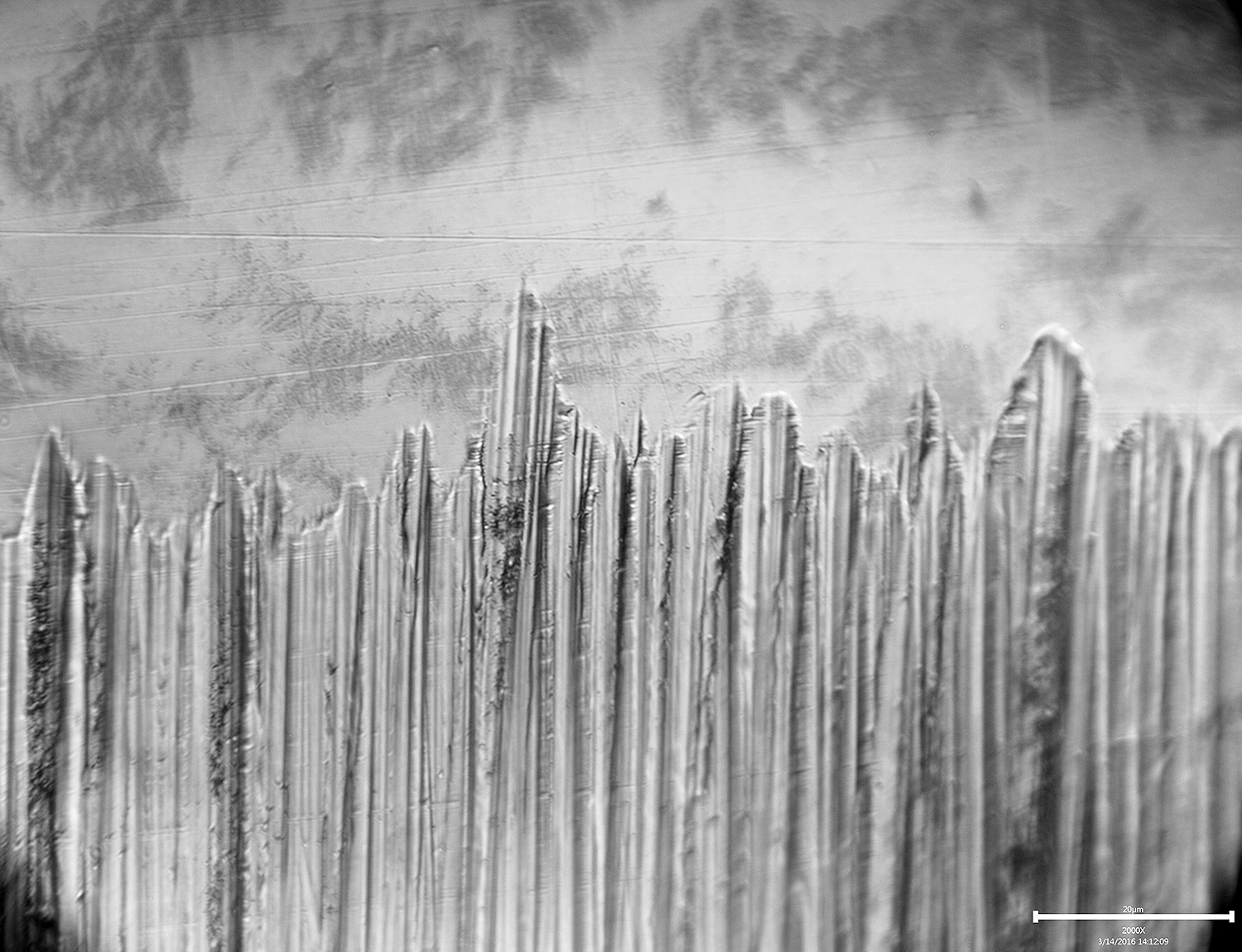

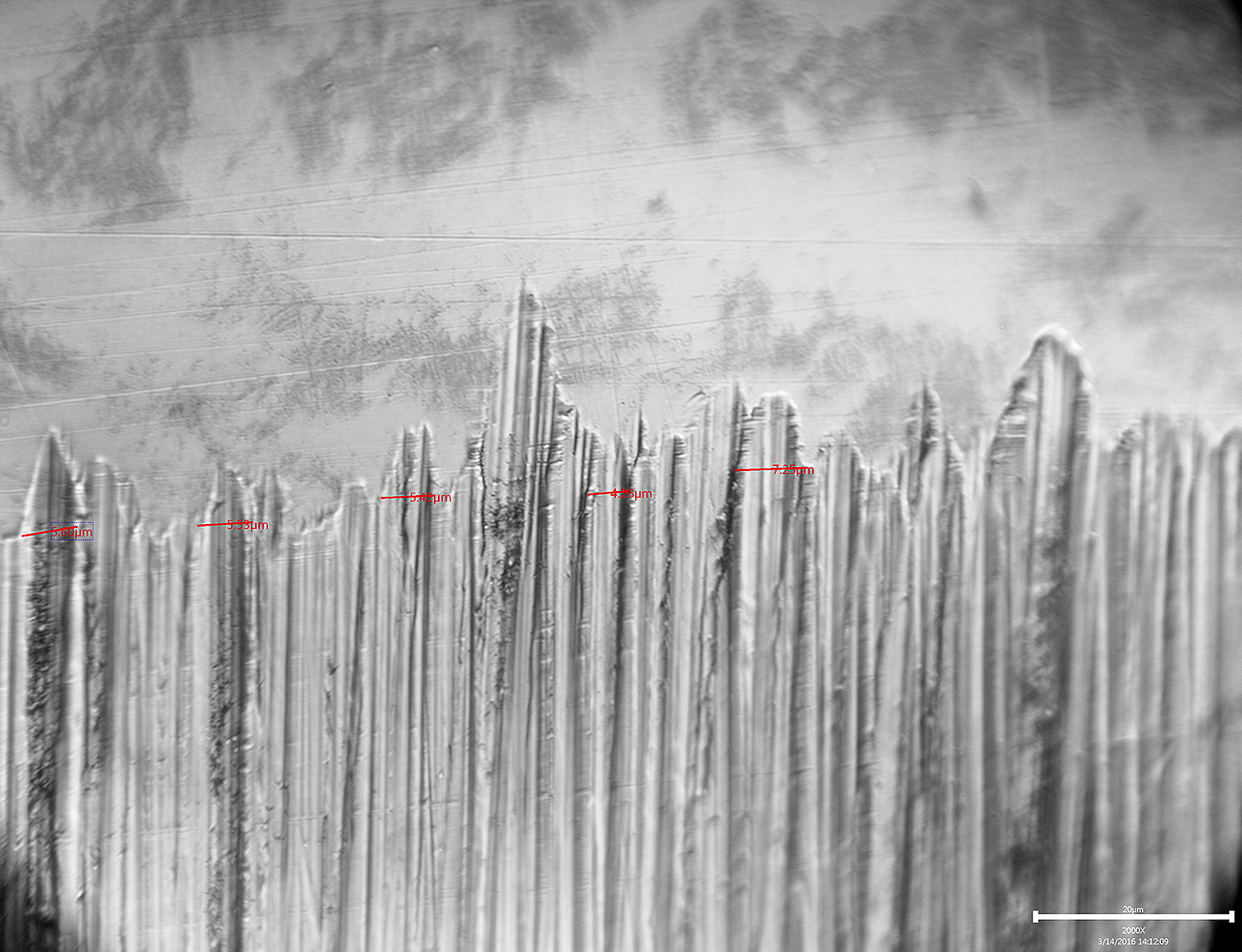

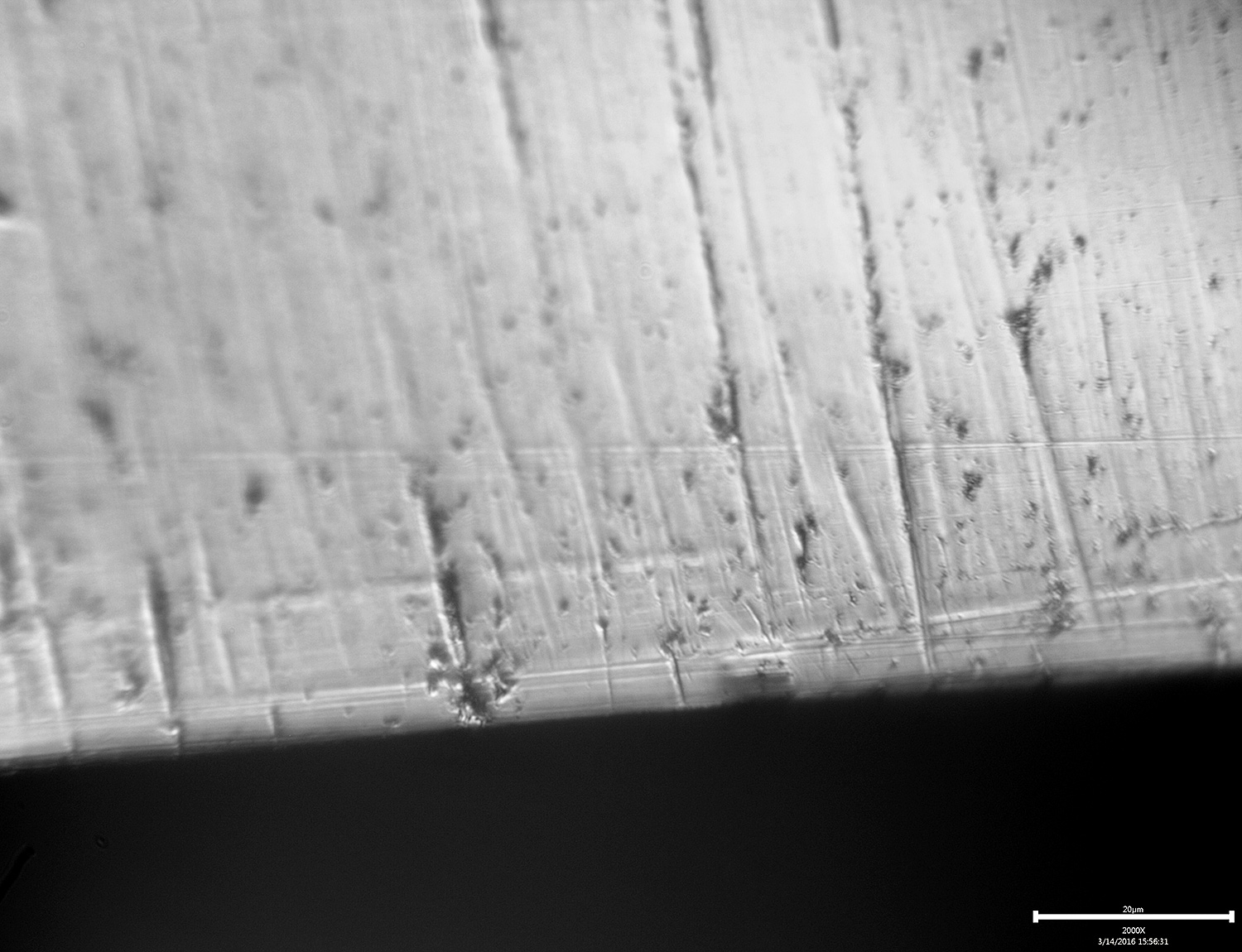

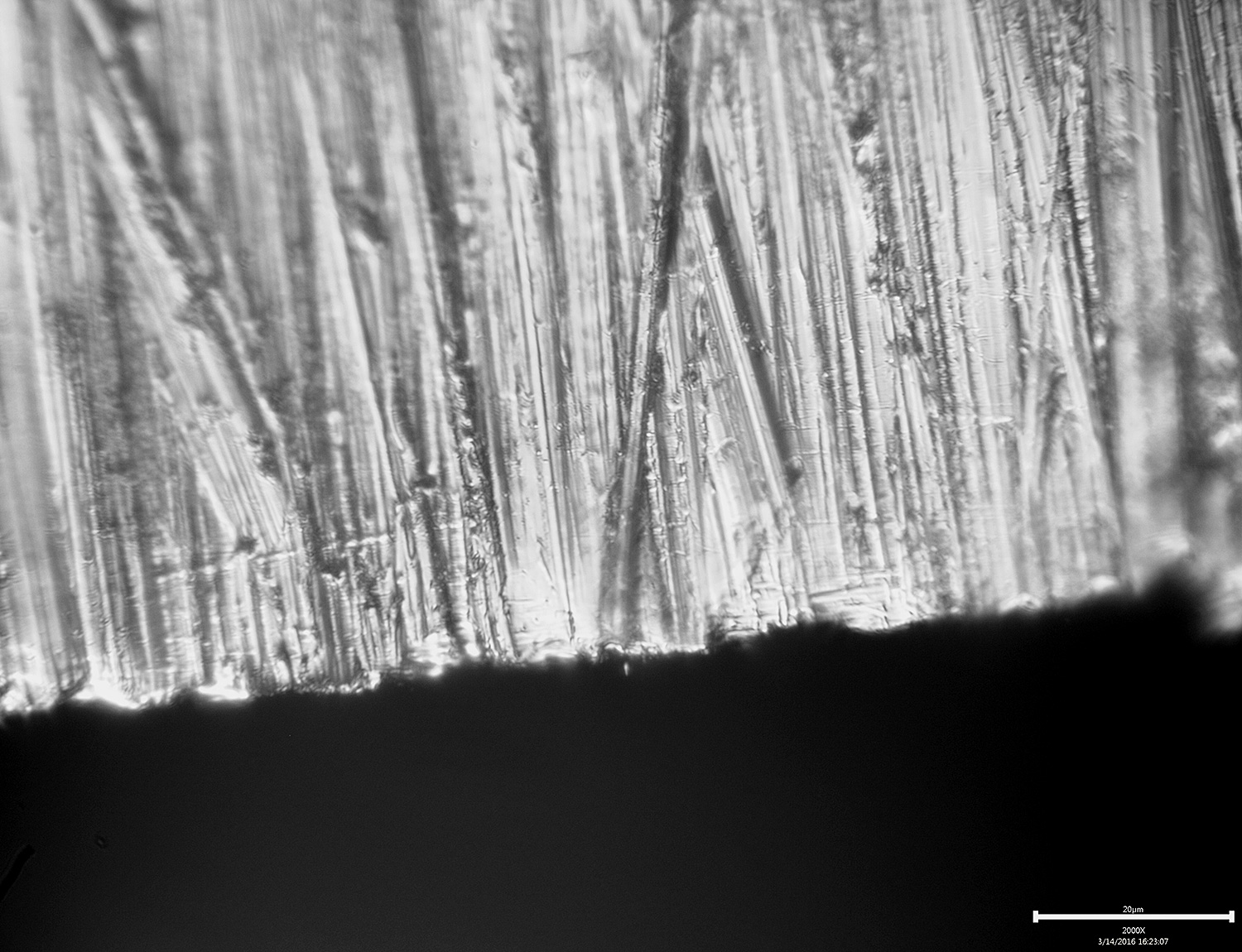

03/14/2016 at 11:53 am #31947Next I’ll look at the 1200# and 1600# ceramics on the micro-bevel.I decided to clean up the micro-bevel first, so I started with the 6µ films:Here’s the primary bevel, polished to .25µ diamond on kangaroo:

And here is another look at the 6µ edge with measurements of some of the scratches:

-Clay

Attachments:

You must be logged in to access attached files.

1 user thanked author for this post.

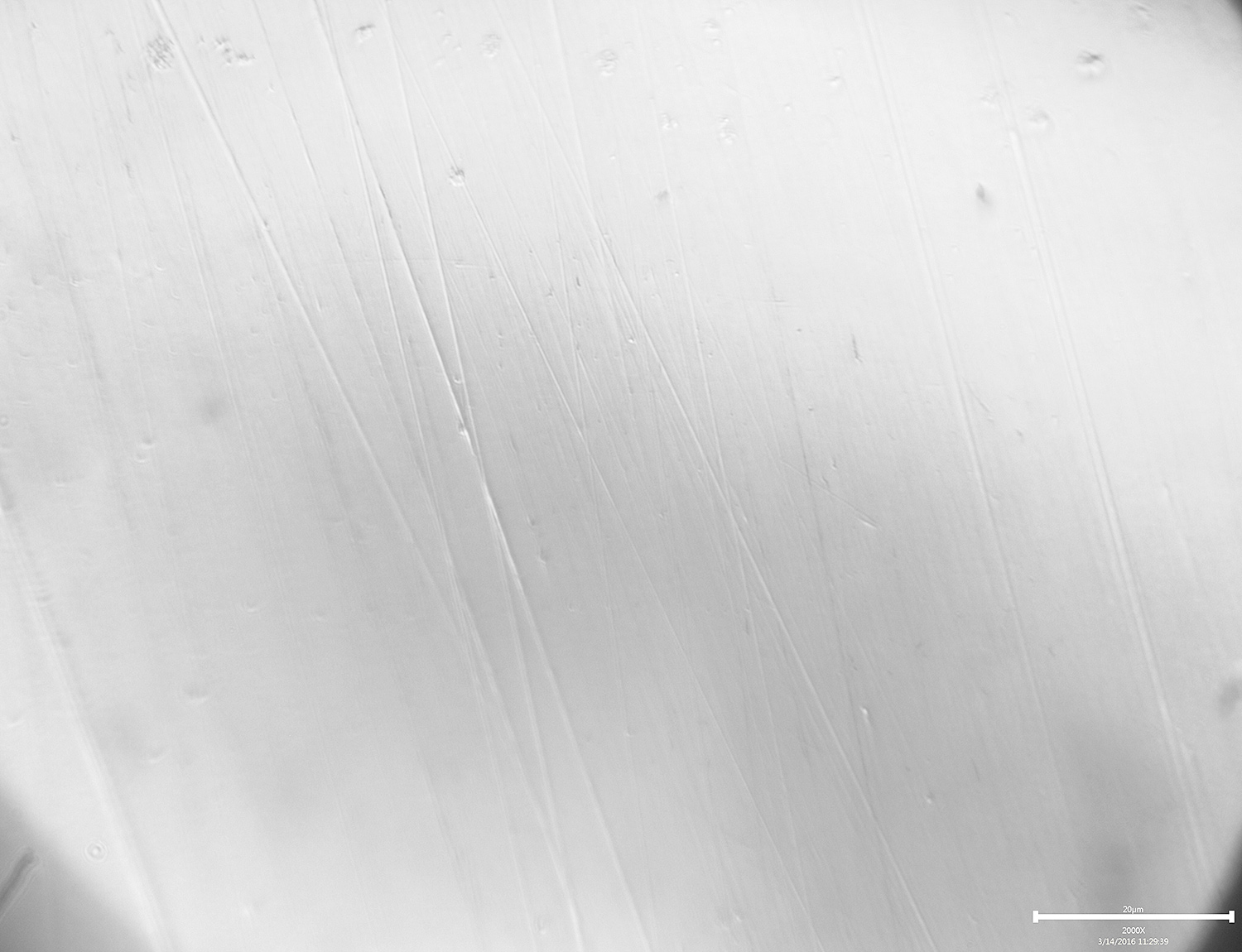

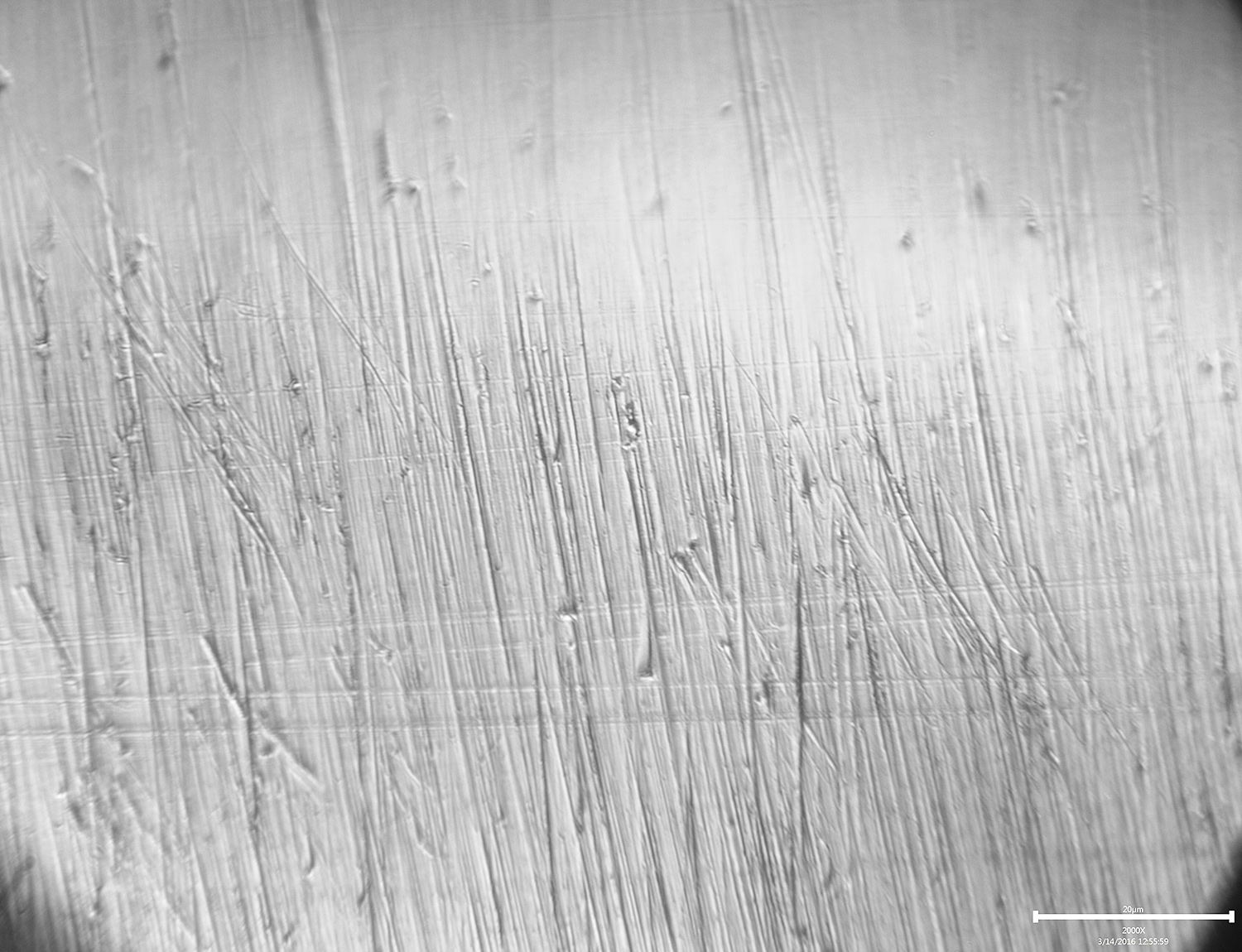

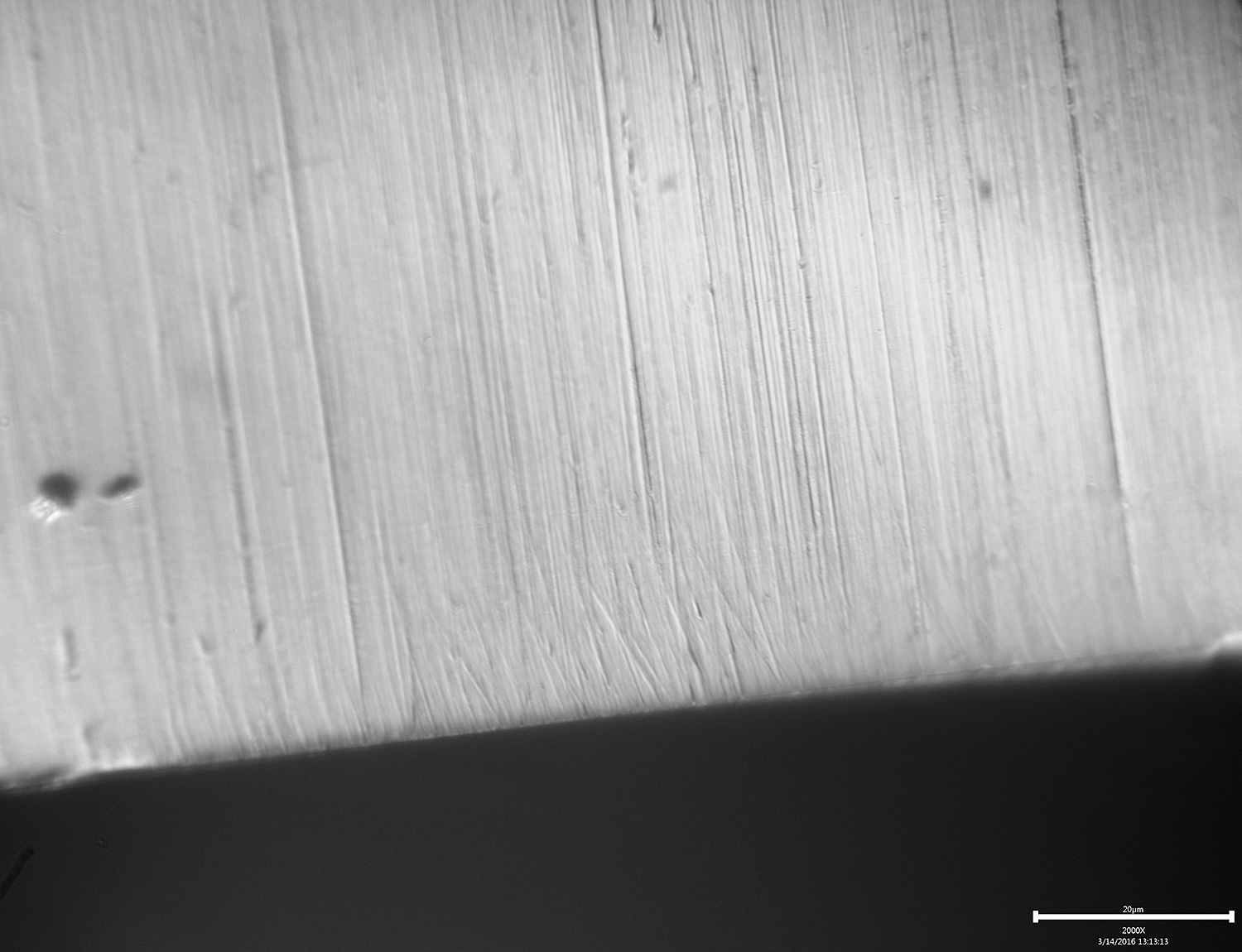

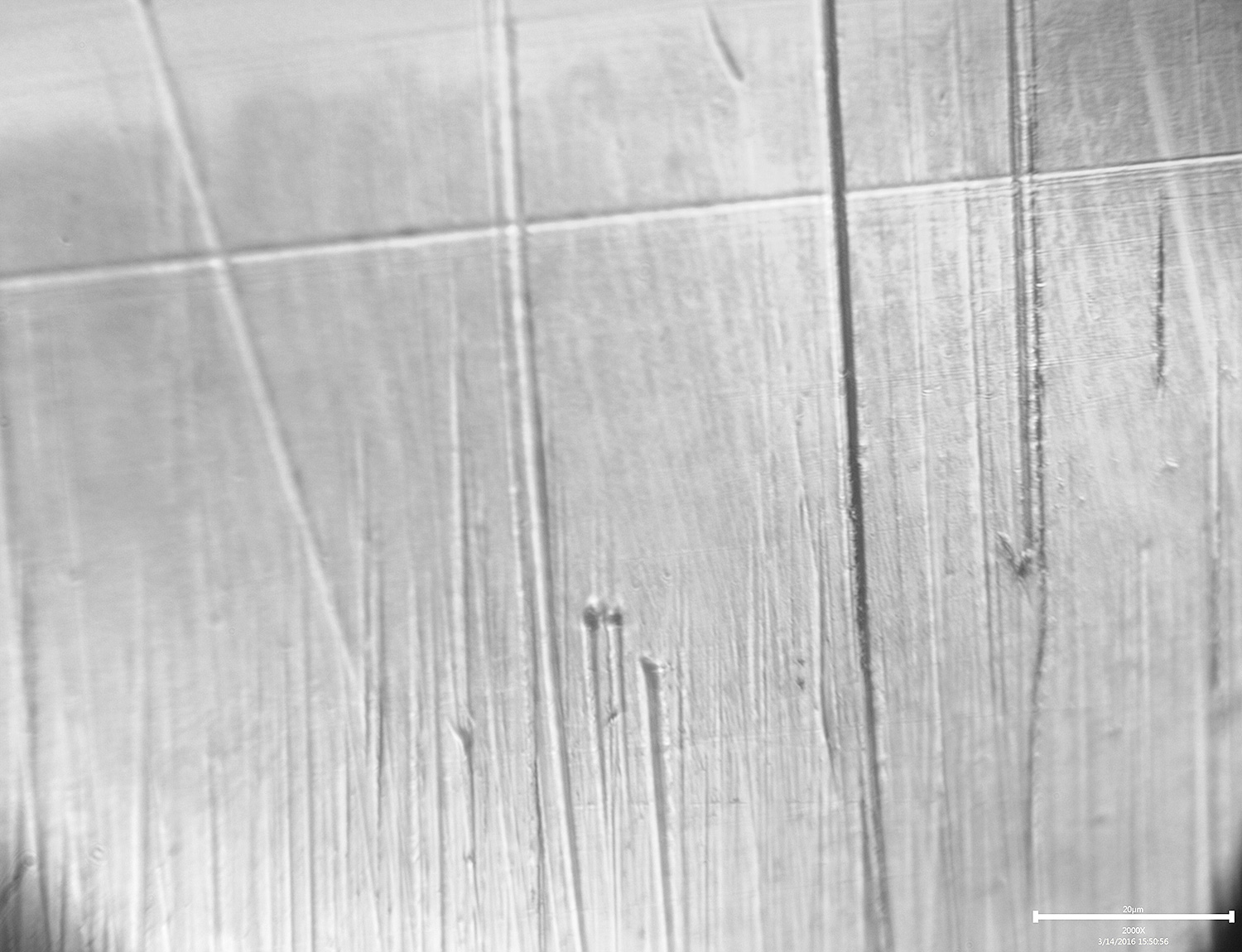

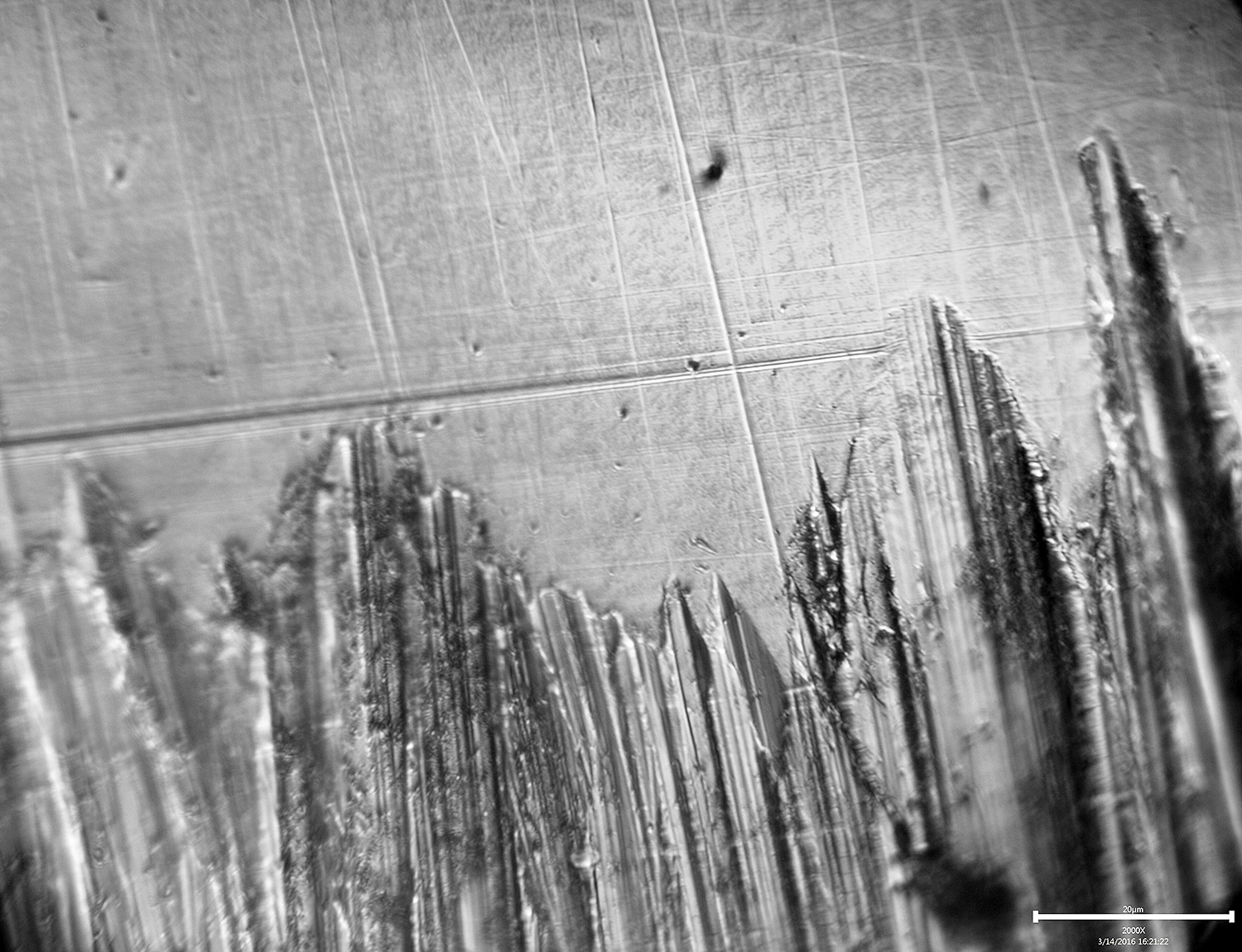

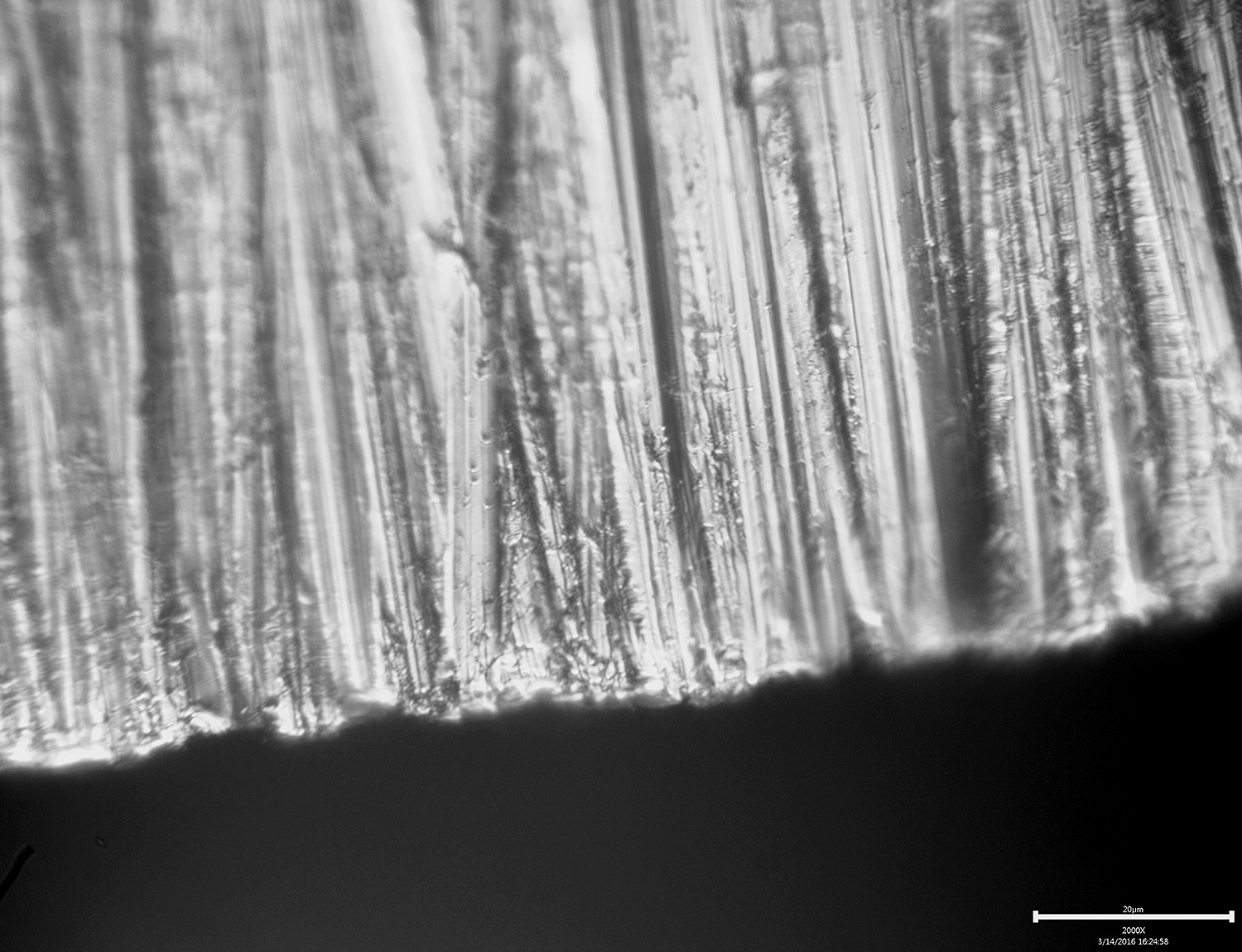

03/14/2016 at 1:20 pm #3195203/14/2016 at 1:24 pm #3195503/14/2016 at 2:27 pm #3196003/14/2016 at 2:33 pm #31964And now the Superfine Coarse stones:

These scratches are also about the right width though they seem more shallow for some reason. I’m not sure what that would be but a guess might be that they’re softer than the fine stones or that the pores are more loaded with filings since they’re more coarse.

-Clay

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

03/14/2016 at 3:49 pm #31971Great experiment! Good to see that the superfine stones work about as expected. I’m also curious how the microfine ceramics would come out in an experiment like this.

I already knew the diamond lapping films rule (although there are some unexpected scratches with the .1 micron film?). But the fine diamond/CBN sprays on kangaroo leather also rule.

Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

03/14/2016 at 4:27 pm #3197303/14/2016 at 4:30 pm #3197703/14/2016 at 4:38 pm #31982Wow, particularly the microfine coarse stones are a huge surprise to me! In my experience they were a lot more coarse. I have to repeat my experiments. I’m also interested what other people’s experiences are. (Unfortunately we don’t have such nice USB-microscopes as you, Clay.)

Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

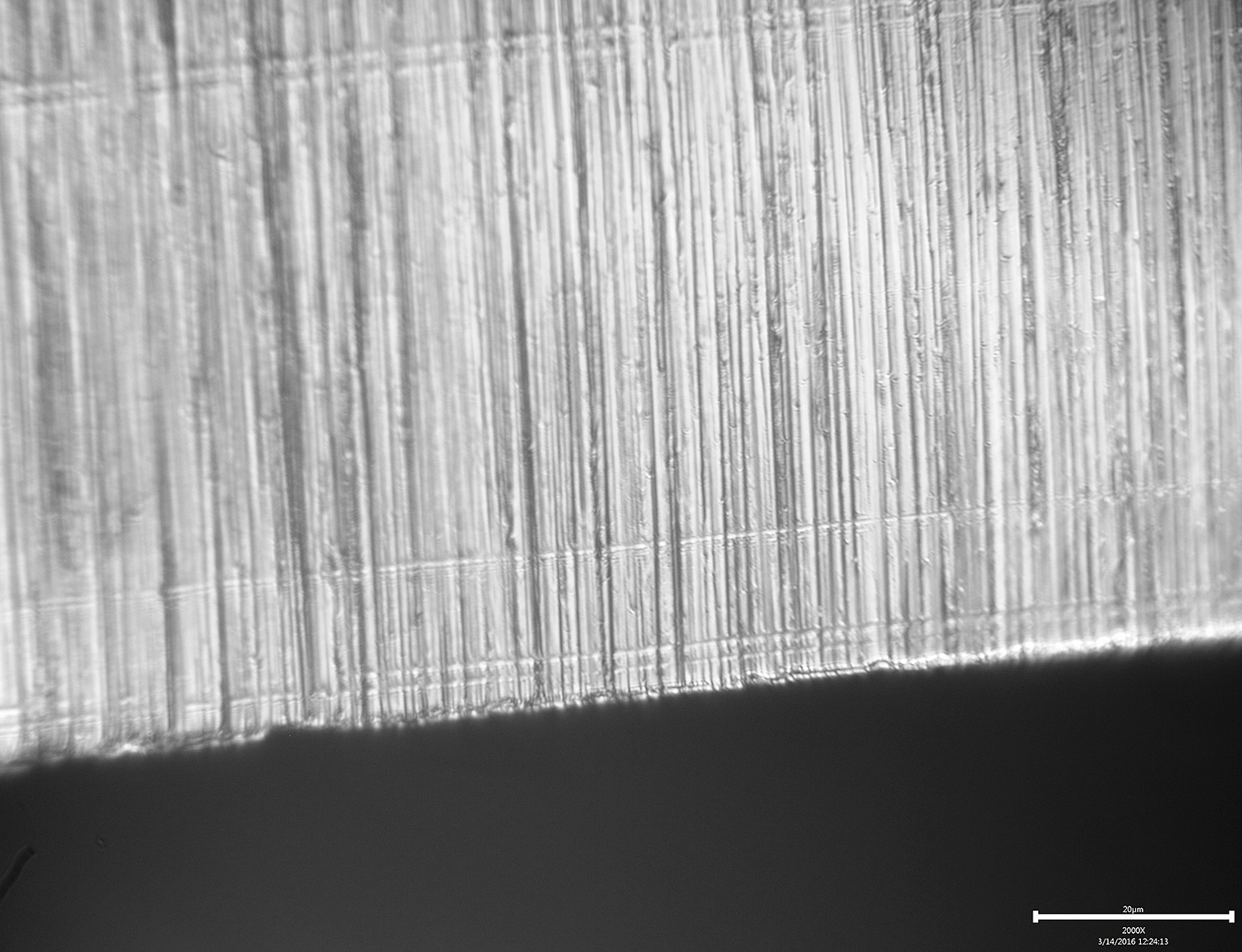

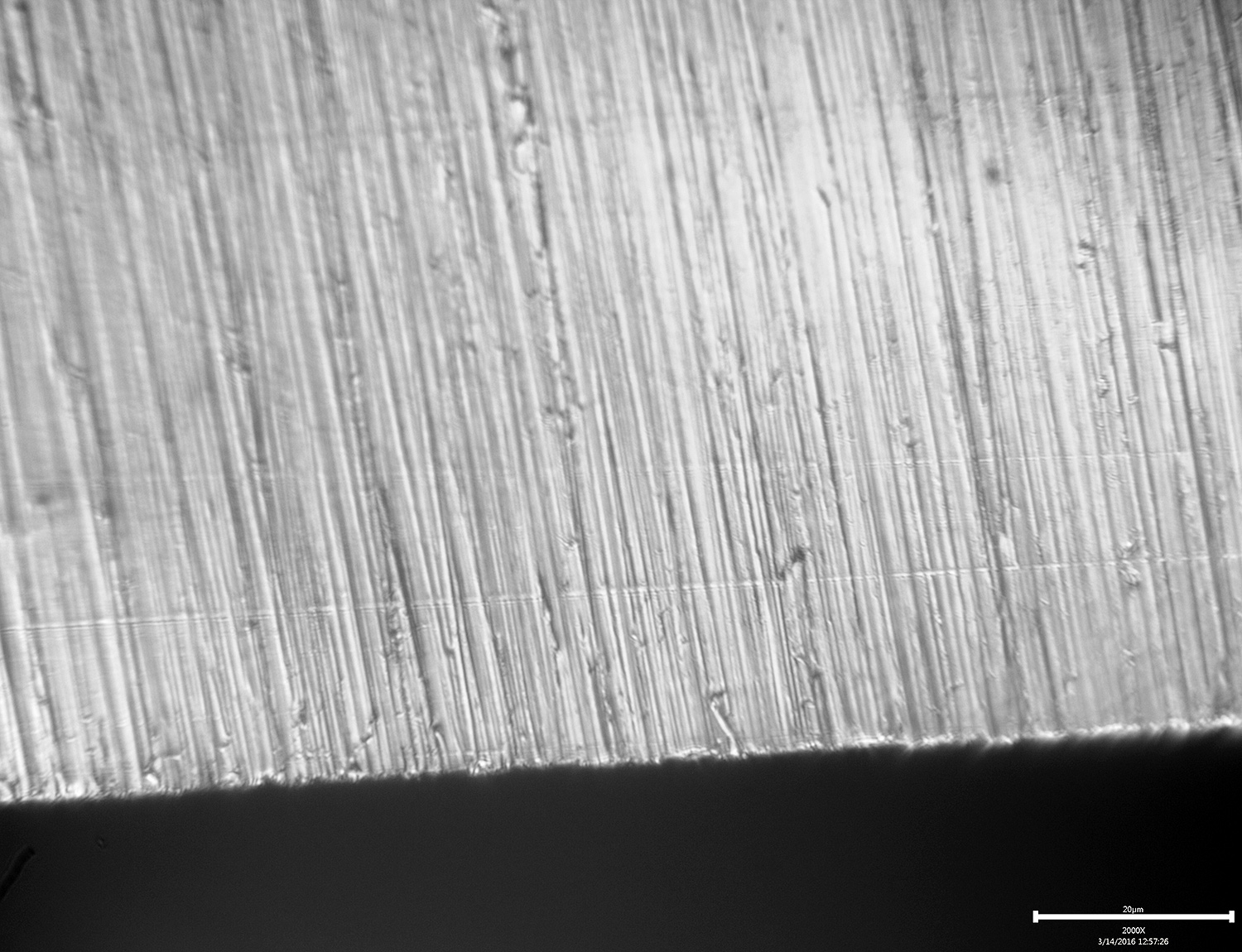

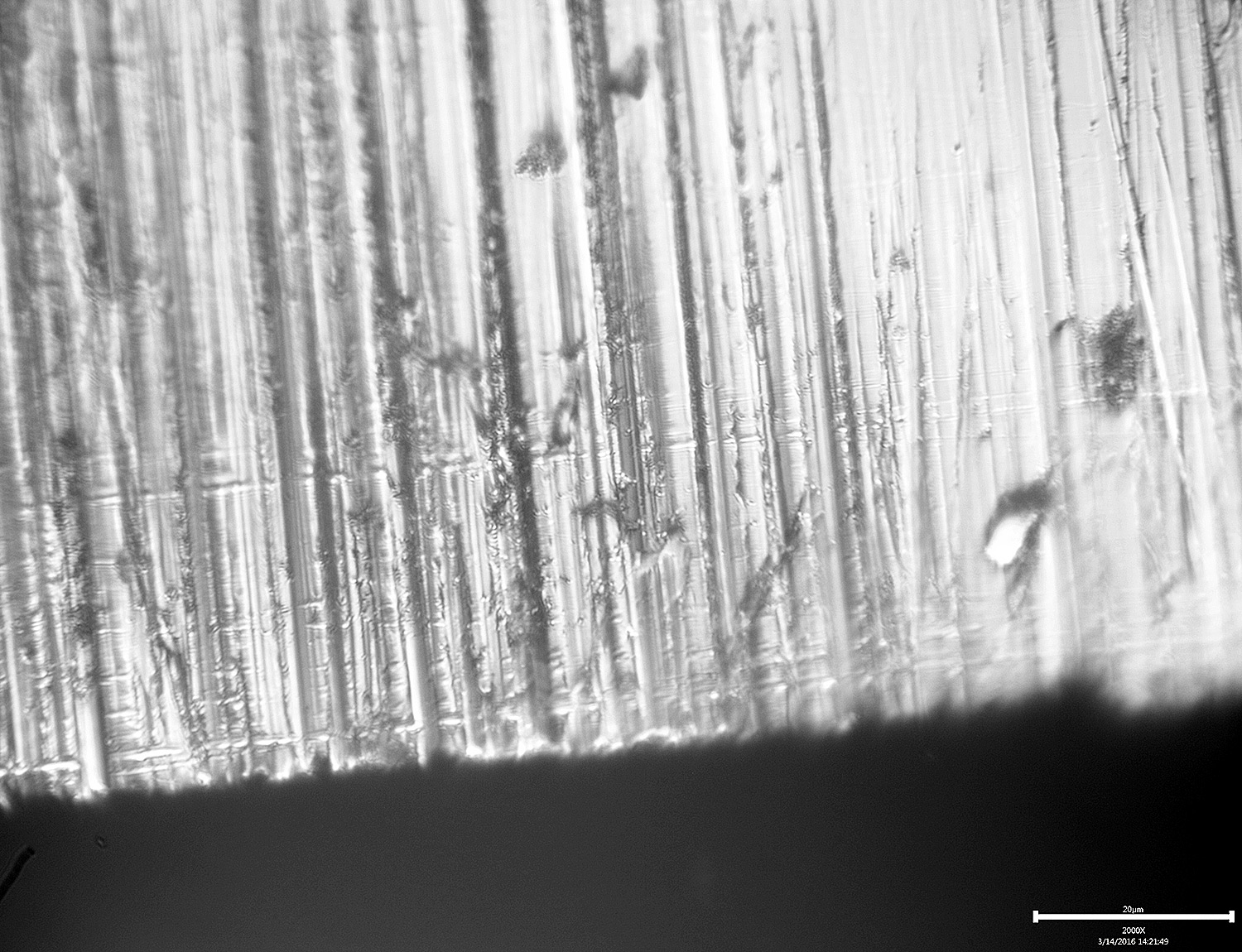

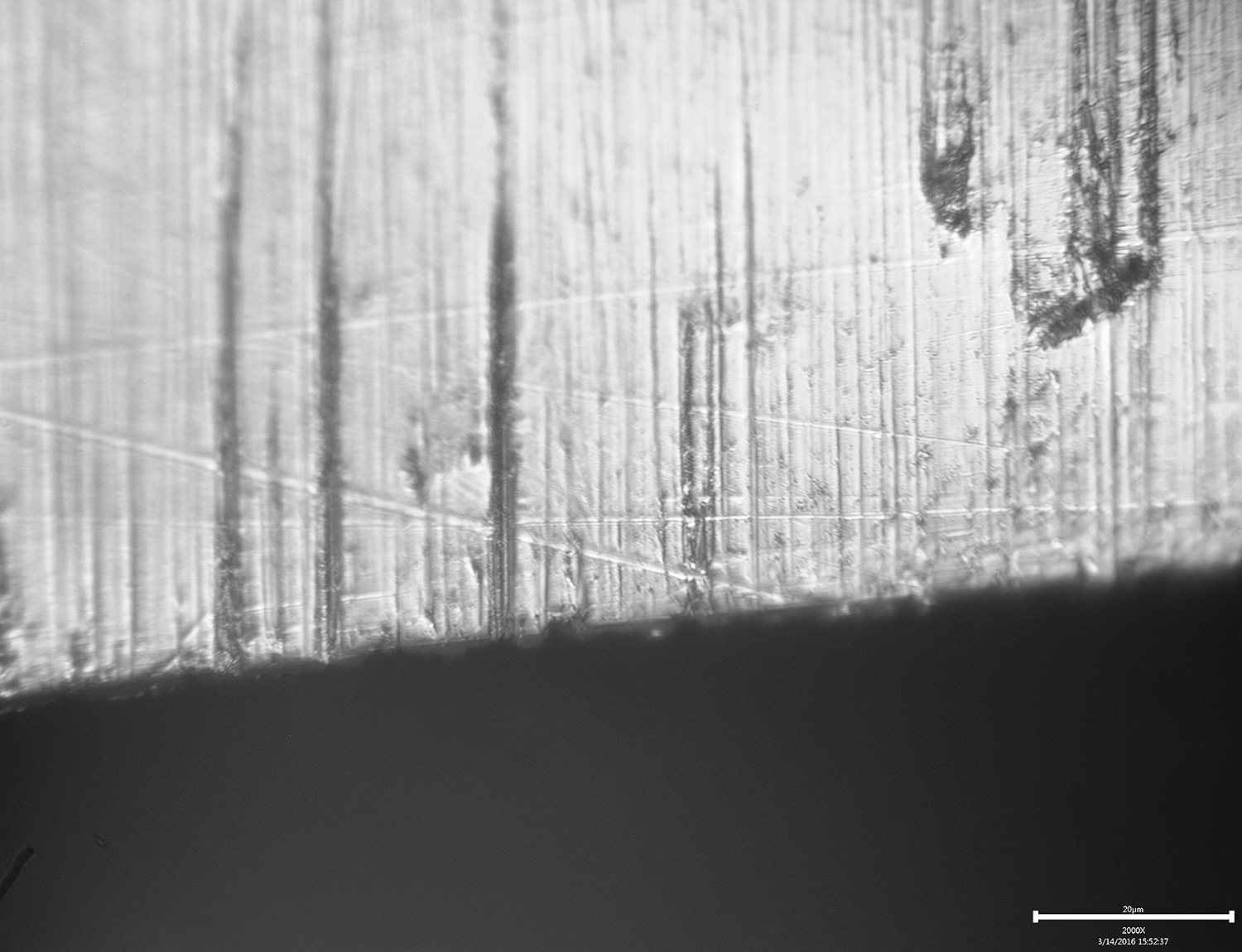

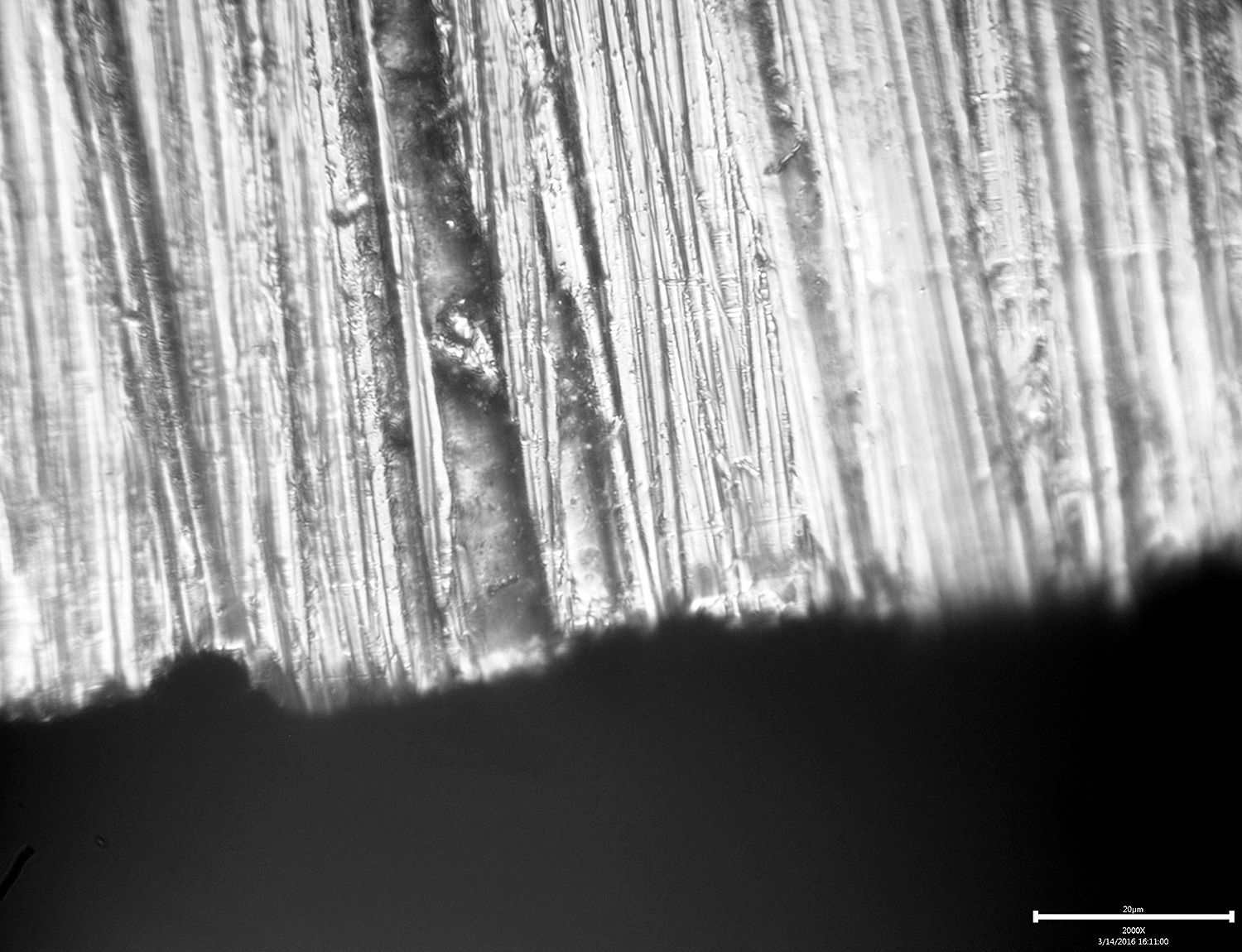

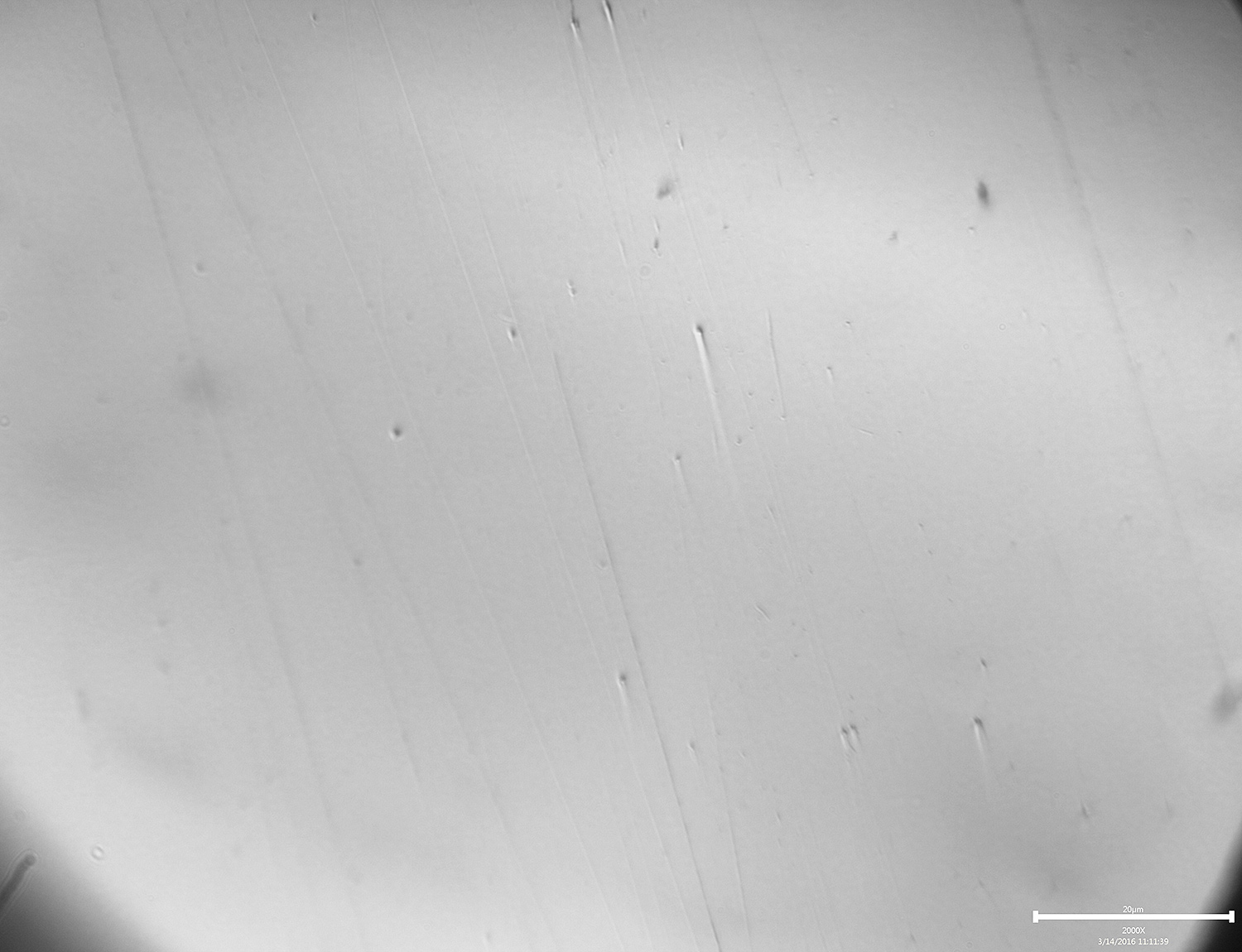

03/14/2016 at 4:39 pm #3198403/14/2016 at 4:41 pm #31989So I lapped the 3µ on my Micro-Fine Fine stones and redid the micro-bevel:

That seemed to make a pretty good improvement. I could feel and hear the difference right away when using the stones.

-Clay

Attachments:

You must be logged in to access attached files.

03/14/2016 at 4:43 pm #31993Great experiment! Good to see that the superfine stones work about as expected. I’m also curious how the microfine ceramics would come out in an experiment like this. I already knew the diamond lapping films rule (although there are some unexpected scratches with the .1 micron film?). But the fine diamond/CBN sprays on kangaroo leather also rule.

I think the scratches at the .1 micron film are from two things; 1) a few remaining scratches that I hadn’t removed 2) some contamination on my films. I haven’t been operating in a pristine environment, so some grit is probably getting onto the stones and films.

-Clay

-

AuthorPosts

- You must be logged in to reply to this topic.