i now have a new issue that just developed

Recent › Forums › Main Forum › Sharpener and Accessory Maintenance › i now have a new issue that just developed

- This topic has 34 replies, 10 voices, and was last updated 06/22/2013 at 7:35 pm by

R. Jeffrey Coates.

-

AuthorPosts

-

06/09/2013 at 11:56 pm #12159

We did change the rod end a couple of runs ago due to supply issues. The manufacturer of the gold colored ones with the plastic lining wasn’t consistent enough. It turned out to be a good thing because the plastic lining was tearing on some of them and the rods were getting really sticky. I’m still hunting for the ‘just right’ model and have tried a whole bunch of them. If anyone comes across on that they’re really impressed with, I’d love to know about it. For the screws, we’re now shipping the regular, hex head thumbscrews for the degree bar and nylon tipped screws for locking in the micro-adjustments. The only downside is that I haven’t found a nylon tipped thumbscrew in stainless steel. If anyone finds a source for those, I’d love to hear about it too.

-Clay

06/09/2013 at 11:58 pm #12160after many knives my left side fine adjustment is almost frozen solid.

kinda acts like cross threaded, but i can turn it with 7/16 box end wrench.

anyone have this happen?

.

i have oiled twice and that has improved it to where i can again use the key sometimes.thanks

I’m jumping in kind of late here. Have you tried Phil’s suggestions yet and if so, what luck? I’ll keep checking here and you’re also welcome to email me directly to sort it out clay@wickededgeusa.com.

-Clay

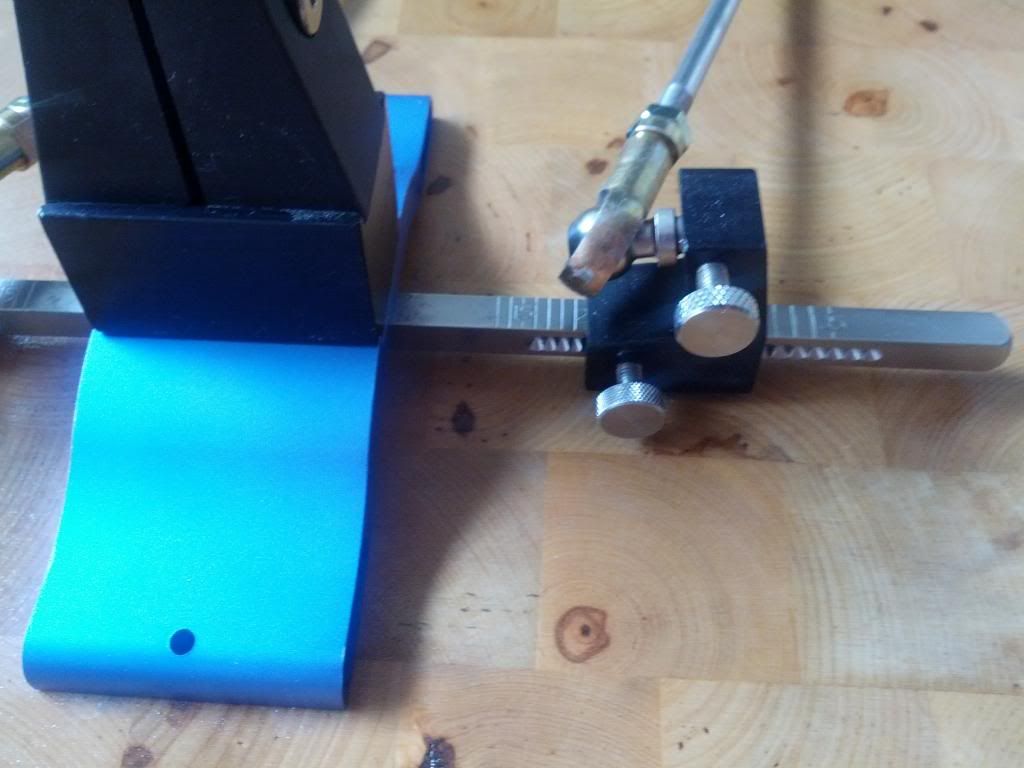

06/10/2013 at 12:02 am #12161Sorry for the bad picture quality. It’s my mobile phone. Are these the screws the current packages ship with?

Molecule Polishing: my blog about sharpening with the Wicked Edge

06/10/2013 at 12:04 am #12162For the screws, we’re now shipping the regular, hex head thumbscrews for the degree bar and nylon tipped screws for locking in the micro-adjustments. The only downside is that I haven’t found a nylon tipped thumbscrew in stainless steel.

Just missed you previous two mails, Clay.

I guess there’s been an update then? I’d love hex head screws, since it seens you can fasten them tighter.

Molecule Polishing: my blog about sharpening with the Wicked Edge

06/10/2013 at 12:07 am #12164For the screws, we’re now shipping the regular, hex head thumbscrews for the degree bar and nylon tipped screws for locking in the micro-adjustments. The only downside is that I haven’t found a nylon tipped thumbscrew in stainless steel.

Just missed you previous two mails, Clay.

I guess there’s been an update then? I’d love hex head screws, since it seens you can fasten them tighter.[/quote]

Mark – please send an email on Monday to remind me and I’ll make sure we get them out to you right away.

-Clay

06/10/2013 at 12:20 am #12165That’s wickedly kind of you, Clay!

I’ll send you the email tomorrow, but this time I want to pay for the shipping costs. Want that WE cap, too :-).

Molecule Polishing: my blog about sharpening with the Wicked Edge

06/10/2013 at 2:40 am #12170I am interested in the new style screws as well.

Maybe I will give Kyle a call Monday… If I can remember.

It is something I have been thinking about doing for awhile. Just not an absolute requirement.. I just use a small set of slip joint pliers if I need additions torque.

I do use the purple loktite on the set screws. I don’t have problems with them loosening.BTW, so far so good with the ball joints and the plastic liner. I do use a synthetic oil with Teflon on the ball joints and keep them clean..

Phil

06/10/2013 at 3:16 am #12171I too would like to get on the set screw request list? Could I email Kyle and give him my CC number?

06/10/2013 at 4:02 am #12176Eamon,

A friendly bit of advice. Don’t send your CC number anywhere with unencrypted email.Our Payment Card Industry certification will not even allow us to accept any card info by email. The risk of someone intercepting the info is too high.

06/10/2013 at 7:56 am #12183Eamon,

A friendly bit of advice. Don’t send your CC number anywhere with unencrypted email.Our Payment Card Industry certification will not even allow us to accept any card info by email. The risk of someone intercepting the info is too high.

Yeah your right Phil. I just wasn’t thinking, I was still drinking morning coffee :S

Also I guess I’m a bonehead, I just noticed after all this time the screws have a hex on them? I took out my hex wrench keys and I would think the going loose problem will be over?

I would be so lost without this forum!!:cheer:06/10/2013 at 8:05 am #12186A friendly bit of advice. Don’t send your CC number anywhere with unencrypted email.

You took the words right outta my keyboard. 🙂

06/10/2013 at 8:11 am #12187Eamon,

If you can snag some purple loctite You can find it on Amazon).. try some of that. It takes up any slop in the threads.. but is “breakable” . You will not need to tighten the set screws as much to make them stay put..

🙂06/10/2013 at 8:17 am #12188A friendly bit of advice. Don’t send your CC number anywhere with unencrypted email.

You took the words right outta my keyboard. :)[/quote]

We do agree quite often…

😉06/10/2013 at 9:56 am #12194You took the words right outta my keyboard. 🙂

We do agree quite often…

;)[/quote]‘cept of course when you’re wrong… hehehe 👿

06/10/2013 at 6:31 pm #12226I had the same problem but caught it the first time the threads were buggered up. I pulled the metal screws out and put in some nylon screws from Lowe’s that have a big head on them. then I tightened them down really good and have not moved them since. The friction of the nylon on the threads of the fine adjustment screw keep it really snug but not too tight as a lot of force is needed to turn the screw. Or if you like the screws that are on it you can place a 1/8″ long piece of a small dowel or nylon rod in the screw hole and use that material as a cushion against your threads. Then use the original screws on top of that material to push it against the threads. Hope this helps some. This is the only modification I have done to my WEPS. I am also going to put some sort of cushion on the forward edge of my base so my rods do not chip my pretty stone base. I also plan on sharpening at my local Farmers Market with the possibility of the Flea Market and my local gun range too. Keep passing on your experience at your farmers market and hopefully everyone who wishes to do this can learn from one another.

Thank you

Jed -

AuthorPosts

- You must be logged in to reply to this topic.