Edge on vs edge off

Recent › Forums › Main Forum › Welcome Mat › Edge on vs edge off

- This topic has 9 replies, 6 voices, and was last updated 04/28/2016 at 12:02 pm by

tcmeyer.

tcmeyer.

-

AuthorPosts

-

04/25/2016 at 8:08 pm #33718

I was wondering if running the diamond stones from down to up (edge off) to from up to down (edge on) was better or worse?

It seems edge on would be harmful to the diamond stones. Picking diamonds off the substrate.

I haven’t received my wicked edge yet so this may all be a non-starter.

Also, what are the effects on the edge between these two directions?

04/26/2016 at 1:34 am #33721We refer to the up or down strokes as “Edge Trailing” and “Edge Leading” respectively. This is more clearly understood if you think of the edge moving on the face of a stationary stone.

I once wrecked a diamond stone by pressing way too hard and jumped to the same conclusion (edge-leading is bad juju), but normal use on the Wicked Edge won’t create those kinds of very high pressure points. As you go through the “break-in” process, your intent will actually be to break off those diamond particles standing proud and less securely attached to the platen. Work on some cheap knives as you develop your skills and work your way through the break-in process as well. When your stones cut smoothly and leave uniform scratch patterns, you’ll know it’s time to move on to more sophisticated blades.

Evidence suggests that “Edge Trailing” strokes are more likely to break off particles along the edge than “Edge Leading” strokes, thereby leaving a “toothier” edge. This is most exaggerated at the lower grits, but likely happens with higher grits stones as well.

When I’m trying to remove a lot of metal, I confess to using “scrubbing” strokes – repeated up and down strokes in a specific area. When the focus is on achieving a highly refined edge, I’ll try to stick with “edge leading” strokes. I don’t know that this is the general consensus in this forum, so I’ll look forward to other comments.

5 users thanked author for this post.

04/26/2016 at 9:33 am #33733The Wicked Edge diamond stones are some of the most durable diamond stones out there imho… I’ve used em every which way, edge leading, edge trailing, scrubbing, hard pressure, light pressure. Under moderate pressure using any scrubbing motion you want I have been seeing about 400 knives or so before they need to be replaced.

I’ve tried Atoma and DMT stones and the diamonds always rip out (DMT was the worst, Atomas lasted about 40-50 knives).

6 users thanked author for this post.

04/27/2016 at 3:56 pm #33765I thought DMT made the stones for the Wicked Edge? I always use edge leading strokes. One of my preferences coming from the Edge Pro.

1 user thanked author for this post.

04/27/2016 at 4:05 pm #33766I thought DMT made the stones for the Wicked Edge? I always use edge leading strokes. One of my preferences coming from the Edge Pro.

DMT only makes our 3µ stones.

-Clay

4 users thanked author for this post.

04/27/2016 at 8:10 pm #33768Thank you for the clarification, Clay!

04/28/2016 at 5:00 am #33780Evidence suggests that “Edge Trailing” strokes are more likely to break off particles along the edge than “Edge Leading” strokes, thereby leaving a “toothier” edge. This is most exaggerated at the lower grits, but likely happens with higher grits stones as well.

I am very interested in this topic. Would you minding linking to the evidence referenced?

I might be completely wrong, but I thought that edge trailing strokes (only) lead to forming of a burr and with edge leading strokes (Only) the burr will never form because the burr is breaking off with each pass of the stone or plate. With this understanding; Wouldn’t the edge leading strokes result in a toothier edge than the edge trailing strokes whcih result in a large foil burr at the tip of the apex? Regardless of the stone, plate, or strop being used?

Respectfully, MirrorEdge

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/28/2016 at 8:41 am #33793The reference I made to “edge trailing” strokes breaking off particles along the edge was a observation made by clay in one of his posts about a month ago.

Edge-trailing strokes do seem to form a burr – edge leading not so much. The chipping at the edge is not a uniform thing. It seems to be a function of the stone and maybe weak spots along the edge; probably also the quality of the steel. This edge-chipping contributes to a toothier edge, but I don’t think it’s the single source of it. Going to only “edge leading” strokes would tend to reduce the “toothiness” but not eliminate it entirely. If you eliminate the edge-chipping, the toothy edge should be more uniform.

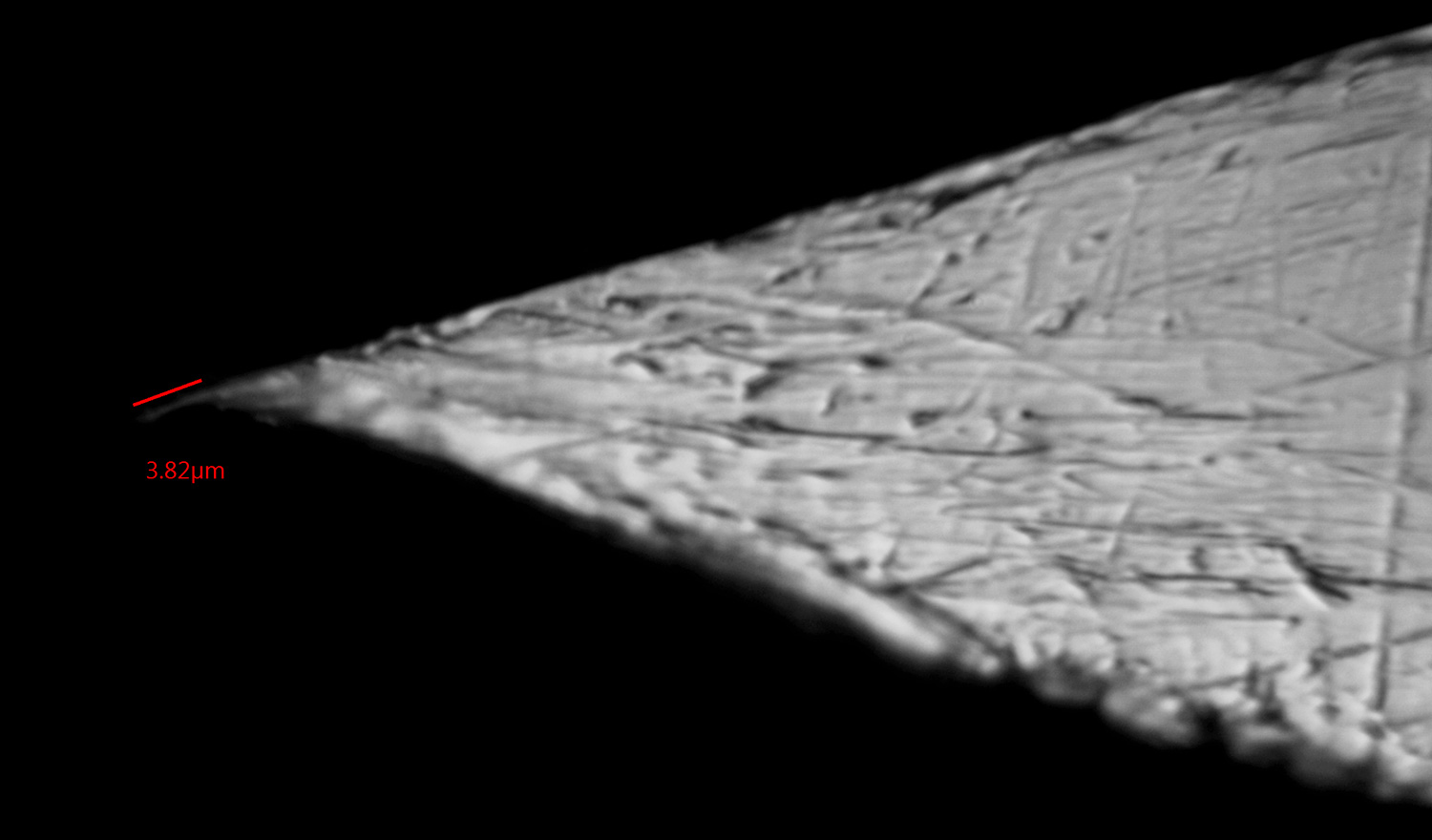

04/28/2016 at 11:12 am #33797Edge trailing definitely can pull up a wire edge, even when you’re alternating every stroke. I wanted to try and reproduce some of Todd’s SEM work with my scope if I could and I also wanted to dig in a little further into the issue that I documented when the edge collapsed under light pressure from the microscope, so I cut one of my sample blades to reveal a cross section and then sharpened and stropped it. After about 40 strokes with the strops, I had a very definite wire edge drawn up:

You can see a definite wire edge extending from the apex. It’s pretty small, only 3.82µ in length and 0.62µ thick. The photo was taken at 2000x.

-Clay

Attachments:

You must be logged in to access attached files.

2 users thanked author for this post.

04/28/2016 at 12:02 pm #33800Can edge-leading strokes do the same? Of course it would have to be tested at lower grits or with film.

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.