Diamond Stone Wear

Recent › Forums › Main Forum › Welcome Mat › Diamond Stone Wear

Tagged: diamond stones, diamonds plates, knife sharpener, sharpener maintenance, sharpening, wicked edge

- This topic has 6 replies, 4 voices, and was last updated 04/27/2016 at 12:36 pm by

wickededge.

wickededge.

-

AuthorPosts

-

04/26/2016 at 11:33 am #33735

This should prove to be an interesting thread since it will ultimately cover a few topics. Some things I can imagine coming up are: the wear of the stones themselves versus the wear of the plates; results from new versus worn plates; longevity of the plates. To start, I’m trying to answer MirrorEdge’s question about whether the diamonds themselves can become worn through repeated abrasion against steel. His very good argument is that the steel should not be able to wear the diamonds because it is so much softer than the diamonds. I’ve made my own observations under the microscope of rounded looking diamonds, but that’s hardly enough information to make an informed response, so I started doing some research. The first thing that jumped out at me once I started thinking about it in the context of his question was that there is a big difference poly-crystalline and mono-crystalline diamonds. The fact that there is an industry for poly-crystalline diamonds in the first place should give us some pretty good clues. The poly-crystalline diamonds are used, among other things, in lapidary for polishing gemstones and the like. The idea behind them is that the diamonds are friable and the crystals will fracture, exposing “new, sharp points” as they’re used. This means there is a need for “new sharp points”, from which we can infer that, at some point, the performance of the diamonds would suffer if new sharp points weren’t being produced, meaning that their old points would have gotten rounded:

“As the grinding, lapping and polishing occurs, these small crystallites will cleave and expose new and sharper cutting edges. The result is that polycrystalline diamond is a self sharpening abrasives which produces improved surface finishes having higher cut rates.” *http://www.metallographic.com/pdf/Data-friable.pdf

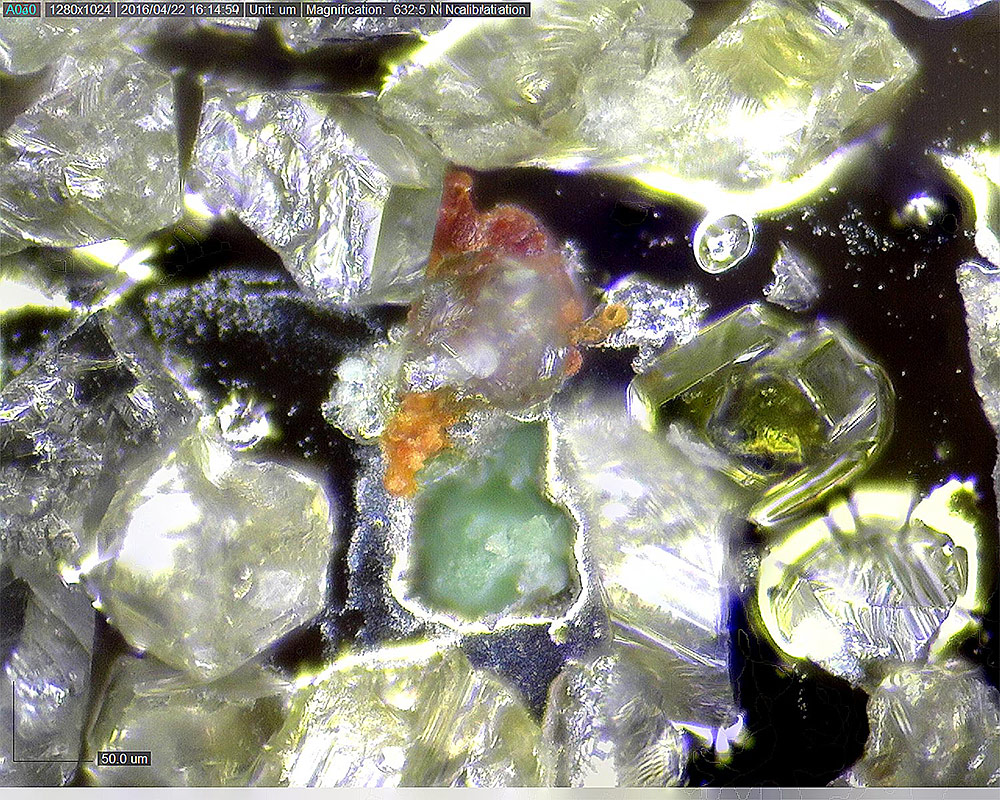

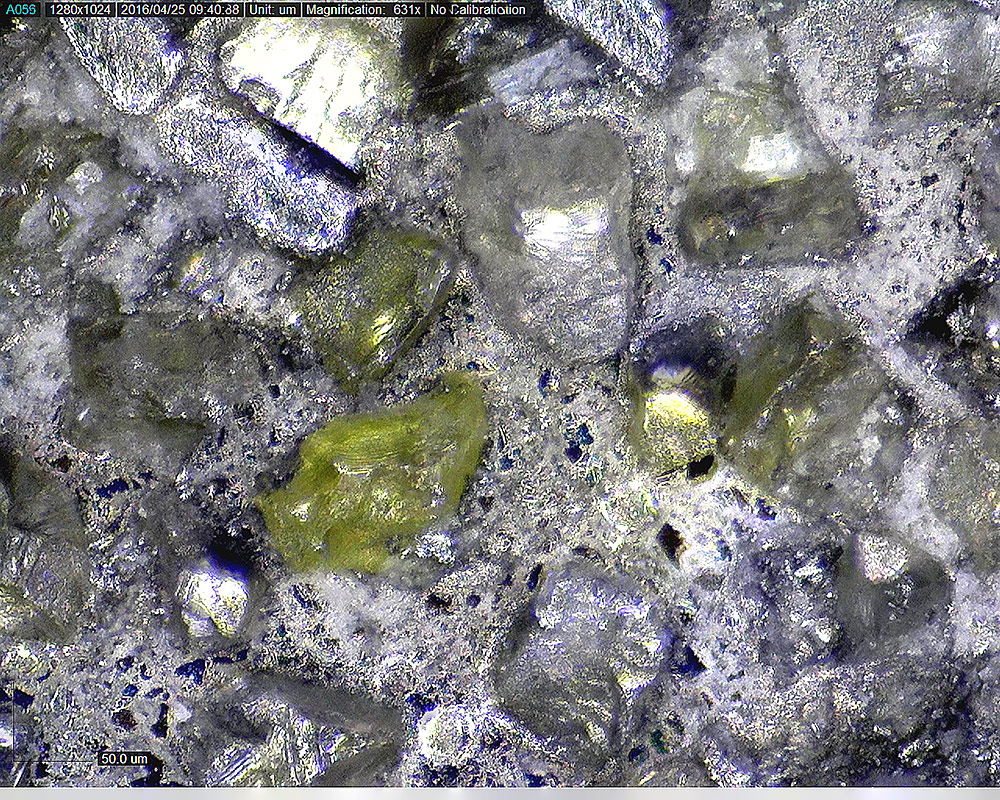

I took some photos of a new 100# plate and a worn 100# plate at 632x:

All the metal filings between the individual stones are distracting, but if you focus on the stones themselves, the worn stones do appear to have rounded corners. I don’t recall the age of the worn plate in this sample, but it’s probably a good bet that it’s sharpened around 200-300 blades. Both pictures are composite images, stacked for extended depth of field.

I decided to try another approach as well – I studied a number of images at the same magnification and counted the number of visible diamonds, both on the new and worn plates. Both plates had very similar quantities of diamonds visible. The biggest visible difference was that on the new plates, whole diamonds were sitting almost directly on top of other diamonds, which is at least one factor in why the new plates feel so much rougher. The other factor is likely that the stones in the worn plate really are rounded, as they appear to be under the scope. This is hardly the final word on whether the diamonds do wear, but it is interesting to explore and talk about and can maybe teach us a little more about this great activity of ours. I’m still working on finding a way to get all the metal filings out from between the stones so I can get some better images. I’d also like to remove some of the diamonds and try to examine them individually. I’ve learned that full strength ferric acid can do the job dissolving the nickel binder and dislodge the stones though I have to find a way to capture and isolate said diamonds once they come loose.

-Clay

Attachments:

You must be logged in to access attached files.

4 users thanked author for this post.

04/26/2016 at 11:43 am #33738I’m not arguing that the stones don’t occasionally get ripped out, but from what I see under the scope, it’s not as common as we might guess. Here’s another link that is interesting about friable diamonds: https://www.gemsociety.org/article/just-ask-jeff-what-are-friable-diamonds-polishes/. Here’s a quote from the page that stands out:

“What essentially happens to the cube or more blocky diamond crystal of the typical diamond polish is that the crystal wears on the corners and the cutting/polishing action will slow down as the diamond crystal’s corners/edges become dull. That is why recharging is needed.”

-Clay

2 users thanked author for this post.

04/27/2016 at 2:22 am #33753I wish the photo examples of the crystals was working on the site link (C’est la vie, Thats Life) (Here). I am interested in knowing if the WE nickel plates (I didn’t know they where nickel until now) are impregnated with mono crystalline or poly crystalline diamonds (Standard Diamond crystals or the Friable variety) or a mixture of both. If they are the friable variety, shouldn’t we see the diamond crystals becoming smaller on the plate over time and not rounding due to the fracturing? From the article, what I interpreted, is that the friable variety of diamond crystals break apart reveling sharper edges again (This is why they like them for polishing). It also must be identified that we are not working with polishes but plated diamonds buried in a nickle substrate.

From the Article: What does “friable” mean? -There are many types of crystals and we all know there are many types of diamond polishes. Basically a friable crystal is a long narrow crystal designed to break up as it is used.

What you are essentially getting and paying for is a particular type and shape of diamond crystal (see below) that is designed to break down during the cutting/polishing process in such a way that not only will the diamond polishing crystals become finer but they will also remain sharp through out the cutting and polishing process. These types of polishes stay sharp because as the crystals break the edges stay sharp and continue to polish -END

From the great photos provided, this may indicate that we are using standard diamond crystals but I don’t know I am just guessing. I think it is a great observation that maybe the metal shavings are actually being trapped around or embedded in the nickel sub straight around the diamonds and that is causing them to become smooth or feel less abrasive with time, great observation.

I also like the observation that the diamonds appear to be on top of each other on a new plate and not so on a worn plate. This may indicate that the diamonds are moving around in the sub straight or just falling out. If diamonds effectively cut diamonds, maybe the loose diamonds are rounding off the other diamonds with time or a little of (D. All the above). At the microscopic level, it seems like things are moving around a lot which is intriguing to me.

This is very interesting to me, I appropriate the work you are putting into this Clay. I hope others can get something out of it too.

The PDF found at this link sheds a lot of light on all these topics even though it is a advertisement . (http://www.ukam.com/smart%20cut.pdf)

Respectfully, Mirror Edge

Eddie Kinlen

M1rror Edge Sharpening Service, LLC

+1(682)777-162204/27/2016 at 8:15 am #33754Thanks for doing this research Clay, I find it very interesting!

I have had good success cleaning stones w/ windex then a good blast of compressed air… don’t know under magnification though!

04/27/2016 at 8:18 am #33755Thanks for doing this research Clay, I find it very interesting! I have had good success cleaning stones w/ windex then a good blast of compressed air… don’t know under magnification though!

Windex, or ammonia is on the list too!

-Clay

04/27/2016 at 11:41 am #33758If diamonds effectively cut diamonds, maybe the lose diamonds are rounding off the other diamonds with time or a little of (D. All the above). At the microscopic level, it seems like things are moving around a lot which is intriguing to me.

It seems obvious that the plating process results in the attachment of a “pile” of particles to the platen. This provides a maximum density of particles at the base – in contact with the platen. Particles above this level are more likely to be knocked off in the break-in process. Eventually you end up with a relatively even matrix of particles, all tightly bonded to the platen. It’s this layer that does the work.

We’ve seen SEM photos of diamond plates showing that the diamond particles are quite worn, with their sharp edges gone. (Perhaps one of our members with a better memory can point us to the page.) To explain this, I propose the following hypotheses.

The word “friable” according to dictionary.com means easily crumbled or reduced to powder. I think that with these crystals, parts which are more or less exposed (cantilevered?) from the surface are likely to be broken off, leaving more sharp working edges. I also think that once the majority of those points are broken off, the remaining parts are much more securely held by the plating attachment to the platen. From this point on, the particles are more resistant to fracture (less friable) and more likely to be “rounded off.” When the particles are so worn down that they no longer produce the needed cutting effects, it’s time to replace the stone.

3 users thanked author for this post.

04/27/2016 at 12:36 pm #33759If diamonds effectively cut diamonds, maybe the lose diamonds are rounding off the other diamonds with time or a little of (D. All the above). At the microscopic level, it seems like things are moving around a lot which is intriguing to me.

It seems obvious that the plating process results in the attachment of a “pile” of particles to the platen. This provides a maximum density of particles at the base – in contact with the platen. Particles above this level are more likely to be knocked off in the break-in process. Eventually you end up with a relatively even matrix of particles, all tightly bonded to the platen. It’s this layer that does the work. We’ve seen SEM photos of diamond plates showing that the diamond particles are quite worn, with their sharp edges gone. (Perhaps one of our members with a better memory can point us to the page.) To explain this, I propose the following hypotheses. The word “friable” according to dictionary.com means easily crumbled or reduced to powder. I think that with these crystals, parts which are more or less exposed (cantilevered?) from the surface are likely to be broken off, leaving more sharp working edges. I also think that once the majority of those points are broken off, the remaining parts are much more securely held by the plating attachment to the platen. From this point on, the particles are more resistant to fracture (less friable) and more likely to be “rounded off.” When the particles are so worn down that they no longer produce the needed cutting effects, it’s time to replace the stone.

Tom – I believe that the first part of what you’re saying regarding the plating and extra diamonds is spot on. The diamonds in our plates are non-friable, mono-crystalline, so I don’t think they’re fracturing except at their corners where they’re being rounded a little.

-Clay

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.