Competition Chopper

Recent › Forums › Main Forum › Welcome Mat › Competition Chopper

- This topic has 12 replies, 4 voices, and was last updated 09/30/2016 at 9:13 am by

wickededge.

wickededge.

-

AuthorPosts

-

09/27/2016 at 12:16 pm #35160

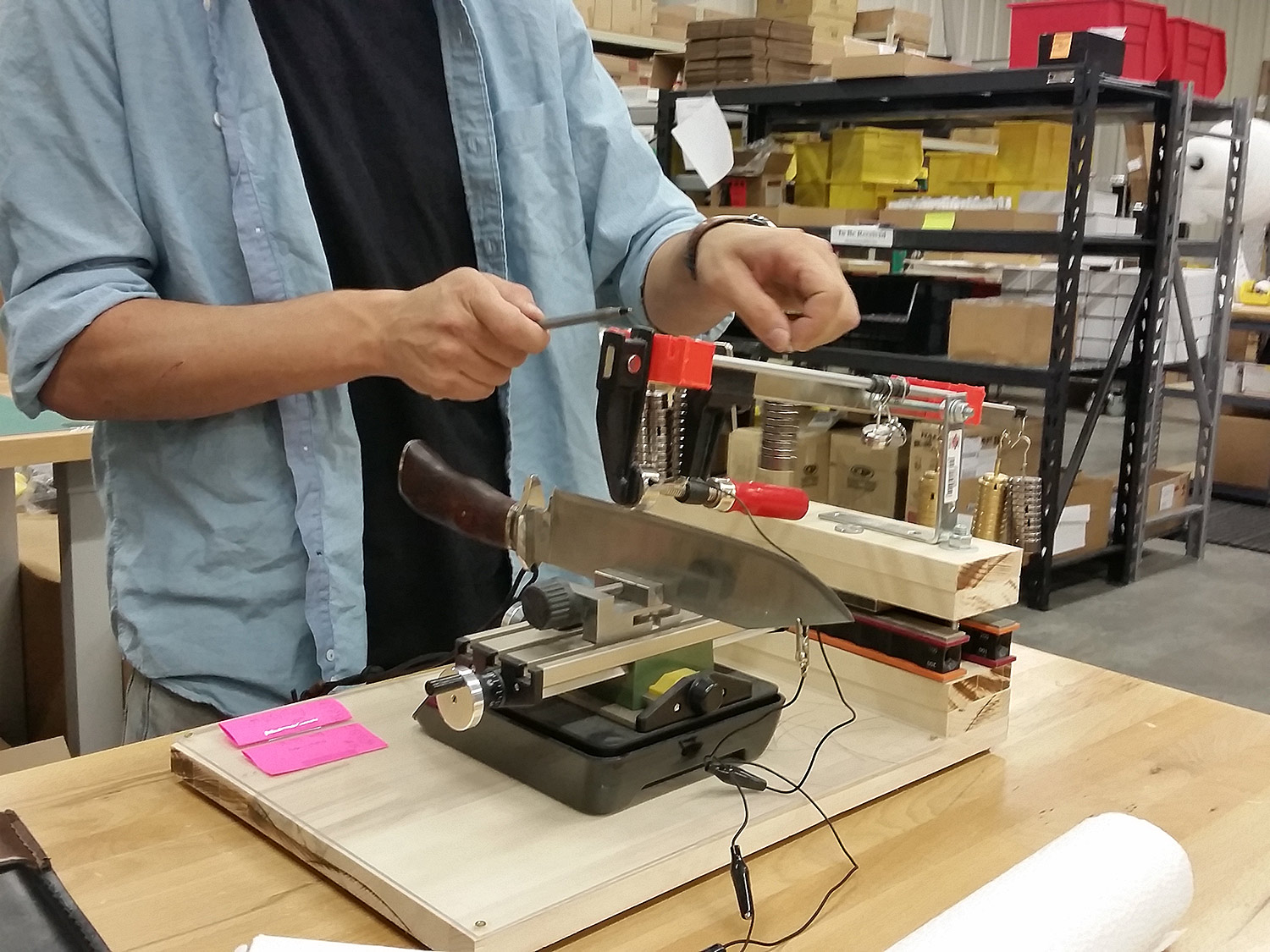

Here’s a quick video of a knife we worked on last week. It was brought in to our shop to get it ready for an upcoming chopping competition:

Here’s the whole write up of our process for evaluating the knife and tuning it to be its best for the tasks it would need to do:

On Friday, one of our long time customers, Bruce Ripper, arrived at our door with a custom chopping knife made by Dan Petersen.

Bruce uses this knife in cutting competitions and is competing in Arkansas in early October. Bruce has a Wicked Edge Sharpener of his own, but he happened to be in Santa Fe and wanted to see if we could take his knife to the next level. We were happy to accept the challenge. He is preparing for a cutting competition and told us about some of the cutting tasks that he would need to complete during the competition. They sounded like a lot of fun so we decided to create our own testing to replicate some of the tasks. These are the ones we decided to do:

- Water Bottles: Line up as many water bottles on the edge of a table as you think you can cut through with a single swing. You get a point for every water bottle you cut through, but you get no points if the knife fails to cut through even a single one.

- Wooden Dowel: Place a 1” wooden dowel on a table and chop it in half. No points are awarded if you don’t chop completely through it.

- Hanging Rope: Hang a 2” piece of rope from the ceiling and tie a knot in the bottom to help stabilize it. Swing your knife and cut completely through it. (we couldn’t find a 2” rope locally on such short notice so we cheated and used 1”)

Each of the events presents a different material and possibly a different requirement for the edge geometry and finish. Dan Petersen is a world renowned knife maker that specializes in building these kinds of choppers, so we decided to match the existing geometry and focus on the finish. For us, the challenge was to find the finish that was the most effective through all the materials that Bruce would be cutting. A toothy edge lends itself to cutting through fibrous materials like rope, and performs especially well with the long slicing motion that is performed during this part of the competition. The dowel, on the other hand, practically begs for a highly polished edge and bevel; the chopping motion used to cut the dowel is essentially a powerful push-cut like you see when you’re pushing a chisel through wood. In order to determine the best edge, we set up a series of tests to help us rate the performance of the various edge finishes we applied to the knife.

In addition to the competition tasks, we also tested the edge to see if it would cut paper and shave.

These were our findings for the knife before we did any sharpening:

Dan Petersen 10” Custom Chopping Knife – Sharpened using the Wicked Edge Pro-Pack II Sharpener

- Angle: 27 degrees on degree bar, 23.75 degrees on angle cube

- Depth: Second setting

- Alignment: K2 on Advanced Alignment Guide

- Initial sharpness: 425g (our sharpness testing machine tests how many grams of force it takes an edge to cut through a given medium)

- Shaving? Nominally

- Cut paper? Nominally

- Water bottle test: 2 bottles

- Rope test: Fail

- Wooden dowel: Fail

We refinished the edge using a 1000 grit diamond stone and a few light strops with 14 micron diamond paste on leather. We used a down-and-forward series of strokes in order to minimize the formation of a burr, and set the ‘rake angle’ of the micro teeth to orient them in the most aggressive way possible. Here’s how it performed:

- Initial sharpness: 285g

- Shaving? Yes

- Cut paper? Yes

- Water bottle test: 6 bottles

- Rope test: Pass

- Wooden dowel: Pass

Though the 1000 grit finish did pass all of the tests, there was more resistance on the rope than we had hoped for, and we were also shooting to cut though more than 6 bottles. (We set up 8 on the table and two were left standing.)

After the testing the knife showed a 72% loss of sharpness, requiring 491g to cut through the media.

We decided to create a toothier finish to determine if there was any performance improvement with the rope test, so we used a 600 grit diamond stone and several light strops with the 14 micron paste on leather. These were our findings:

- Initial sharpness: 333g

- Shaving? Yes, but not very well

- Cut paper? Yes

- Water bottle test: 6 bottles

- Rope test: Pass, extremely easily

- Wooden dowel: Fail

Our hypothesis was correct in that the toothier 600 grit finish significantly outperformed the 1000 grit on the rope, matched it with the water bottle test, but it failed the dowel test.

The next finish we tested was a 1000 grit diamond stone, followed by 6 and 3 micron Diamond Lapping Film on glass, and some very light stropping with 14 micron diamonds on leather. Results:

- Initial sharpness: 255g

- Shaving? Yes, very easily

- Cut paper? Yes

- Water bottle test: 7 bottles

- Rope test: Pass

- Wooden dowel: Not quite, the knife went about 15/16 of the way through

The edge completed two of the three tasks with ease but failed the dowel. When we examined the knife after completing the tests we noticed a fair amount of week residue stuck in the groves of the grind lines on the shoulder of the blade. We hypothesized that the rough finish on the shoulder of the bevel was creating additional friction, slowing the blade through the chop and causing it to fall just short of cutting all the way through the dowel. To reduce the friction, we then polished the entire bevel to remove the grind lines.

The primary bevel was convex ground, so we applied 9 Micron Diamond Lapping Films onto leather strops, which allowed the lapping film to conform to the curvature of the bevel. We began polishing at 8 degrees and then increased the angle in 1 degree increments until we had reached the 23 degree edge. We then repeated this process with both the 6 and 3 micron Diamond Lapping Films. The benefit of the pliable leather underneath the film was that it allowed us to polish the convex shoulder without changing the geometry created by the knife maker. When we were done with this process, there was a ½ inch mirrored shoulder in place of the rough texture left by the initial grinding of the blade.

We touched up the edge again with the 1000 grit diamond stone, 6 and 3 micron films, and the 14 micron leather strop, and tested it again:

- Initial sharpness: 266g

- Shaving? Yes, very easily

- Cut paper? Yes

- Water bottle test: 7 bottles

- Rope test: Pass

- Wooden dowel: Pass

We then had a result that we were satisfied with. We tested the sharpness one more time to check the edge retention and found the sharpness to be 334g, only a 26% reduction. Eliminating the friction by smoothing the shoulder worked as planned.

Bruce and his buddies came back for the knife in the afternoon on Monday and performed the water bottle test. They were quite happy with the results. Thank you, Bruce, for allowing us this opportunity. Good luck at the competition!

-Clay

Attachments:

You must be logged in to access attached files.

3 users thanked author for this post.

09/27/2016 at 9:08 pm #35168That’s a great story! Occasionally we have this type of competetion here too. But I don’t know of anyone who optimizes their edges in such a structured way. (Nobody has access to a WE I think anyway

.)

Very nice results!

And here’s a vid of a local Bladesports (as it is called here) competetion here:

Molecule Polishing: my blog about sharpening with the Wicked Edge

2 users thanked author for this post.

09/28/2016 at 9:37 am #35173Very interesting exercise, Clay…

If I understand correctly, you’d want a toothy edge with polished bevels. You didn’t say so, but since your last test passed on cutting the rope, I assume that you retained some tooth on the edge. If so, and given my findings on avoiding the apex by reducing the angle (by maybe 0.1 or 0.15degrees) with film on a hard platen, it seems to me that one might be able to produce polished bevels while accurately avoiding the toothy edge.

You didn’t show what the width of the bevels was, but if they were substantial, it might be a good idea to go to a polished double-bevel (not a micro-bevel). You’d retain most of the strength of the edge, get the improvement in cutting (seen with thinner edges), the toothiness needed to bite into tough, fibrous materials and the low friction needed to promote penetration. Kind of sounds like a convex edge, doesn’t it? Is that what the edge looked like when you were done?

09/28/2016 at 9:57 am #35174If I understand correctly, you’d want a toothy edge with polished bevels.

Good point and applicable to mainy more appplications, I think.

Molecule Polishing: my blog about sharpening with the Wicked Edge

09/28/2016 at 10:17 am #35175Very interesting exercise, Clay… If I understand correctly, you’d want a toothy edge with polished bevels. You didn’t say so, but since your last test passed on cutting the rope, I assume that you retained some tooth on the edge. If so, and given my findings on avoiding the apex by reducing the angle (by maybe 0.1 or 0.15degrees) with film on a hard platen, it seems to me that one might be able to produce polished bevels while accurately avoiding the toothy edge. You didn’t show what the width of the bevels was, but if they were substantial, it might be a good idea to go to a polished double-bevel (not a micro-bevel). You’d retain most of the strength of the edge, get the improvement in cutting (seen with thinner edges), the toothiness needed to bite into tough, fibrous materials and the low friction needed to promote penetration. Kind of sounds like a convex edge, doesn’t it? Is that what the edge looked like when you were done?

Great questions. The the final product was a convex ground blade that sloped steadily toward the edge and ended in a small bevel. It wasn’t a true micro-bevel, it was a little bit larger than what you’d get if you created the primary bevel all the way to the edge and then increased the angle and made a few strokes. What we did instead was to color in the whole width of the bevels from where the shoulders started to slope toward the edge from the flats of the blade. We then worked with the lapping films and strops in 1 degree increments from the should toward the edge but stopping just shy of the actual edge, which we could visualize with the thin layer of marker that was remaining. Then we adjusted the angle so we were sure we were hitting the edge and we lightly reestablished the tooth pattern we wanted with the films and then did about three light strokes with the strops to clean it up. I stayed away from a true double bevel because I was worried that the vertex between the two bevels would cause the knife to lose momentum as it penetrated. Our technique essentially ground away that vertex so that the transition was smooth.

-Clay

2 users thanked author for this post.

09/28/2016 at 10:18 am #35176Of course now I have the bug and want to get a chopper to keep in house and do more testing. It’s pretty fun stuff to do and a good break from routine to get the crew into it.

-Clay

09/28/2016 at 3:33 pm #35181We should organize an online competition

.

.Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

09/28/2016 at 3:39 pm #35182By the way, what were about the specs of the chopping knife? Lenght, thickness at spine, any special features?

Molecule Polishing: my blog about sharpening with the Wicked Edge

09/28/2016 at 4:35 pm #35184By the way, what were about the specs of the chopping knife? Lenght, thickness at spine, any special features?

Good questions, but we didn’t actually take those measurements

. I’ll get Kyle to email the guy to see if we can find out.

. I’ll get Kyle to email the guy to see if we can find out.-Clay

09/28/2016 at 4:38 pm #35185Here is the knife makers website: http://www.petersenknives.com/

-Clay

09/28/2016 at 4:59 pm #35186Thanks!

Molecule Polishing: my blog about sharpening with the Wicked Edge

09/30/2016 at 7:46 am #35201Nice write up Clay! So the angles were dps and not inclusive, correct? That seems quite obtuse for a competition chopper! Looks like it performed great though

09/30/2016 at 9:13 am #35204

09/30/2016 at 9:13 am #35204Nice write up Clay! So the angles were dps and not inclusive, correct? That seems quite obtuse for a competition chopper! Looks like it performed great though

The angles are dps. I haven’t messed around with competition choppers before so we just went off the way the knife was ground by the maker. The wood chops seem pretty brutal, so it made sense to us but maybe we’re missing something. I did order a couple production choppers to play around with so I could learn more, plus it was super fun to do. What angle would you suggest we try?

-Clay

-

AuthorPosts

- You must be logged in to reply to this topic.