I think Ken sums it up on the bottom of the page you have linked . I am going to go the way of checking steerage with Ballistic Gel .

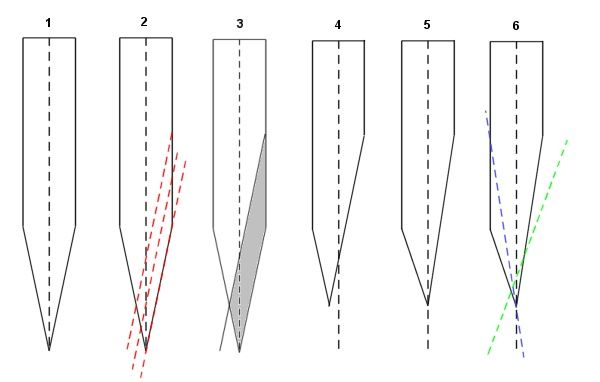

These diagrams you have included are of a blade that should be sharpened 50/50 .

An asymmetric will be so from the sine to the edge that is you could say that one side is much flatter from spine to edge whilst the other side will be thinned from spine to bevel.

Ken I would say sums it up when he says that the centre of effort must be balanced at the edge if it is not it will steer .

I think cutting to test for steerage & if necessary tuning the bevels to minimise it should help in my understanding it seems that the more we try to explain asymmetric with either drawings or maths the more mind boggling it becomes.

Haha. BALLISTIC GEL?! Man, that’s awesome!… I love the breed of sharpeners we have here on this forum.

Please keep me in the loupe (pun!) Leo. Feel free to PM me with the data.

You rock!