WEPS Chosera Stone Progression

Recent › Forums › Main Forum › Knife Photos › WEPS Chosera Stone Progression

- This topic has 33 replies, 7 voices, and was last updated 08/26/2011 at 7:53 am by

Dave Schur.

-

AuthorPosts

-

08/25/2011 at 6:08 am #152

It’s worth mentioning that I haven’t taken the bevel all the way to the very edge of the blade yet. I’m leaving the edge alone since I’m working at a more shallow angle and there is no reason to take additional metal just to reach the edge at this stage. Once all the grits have been applied, I’ll go back and start creating the multi-facets at slightly wider angles before blending them with the strops. The current bevels are set at 16.5 degrees. The final angle at the edge will be 21 degrees and I’ll reach it in just a couple of strokes once I move the collars out.

-Clay

08/25/2011 at 7:08 am #153Now the 1500# Shapton Stones:

When you’re sharpening with these stones, you see within a few strokes how much the bevel is brightening and the edge is getting refined. A quick test of the knife’s edge with a fingernail shows how sharp it is; the edge immediately bites into the nail.

Approximately 90 strokes per side. Elapsed time: 00:01:30

-Clay

08/25/2011 at 7:29 am #154Shapton 2000#:

While the jump from 1500# to 2000# seems small, the bevel of the knife is much more polished and the scratches are noticeably smaller. The stones feel harder and appear to burnish the metal as well as polishing it.

Approximately 90 strokes per side. Elapsed time: 00:01:30

-Clay

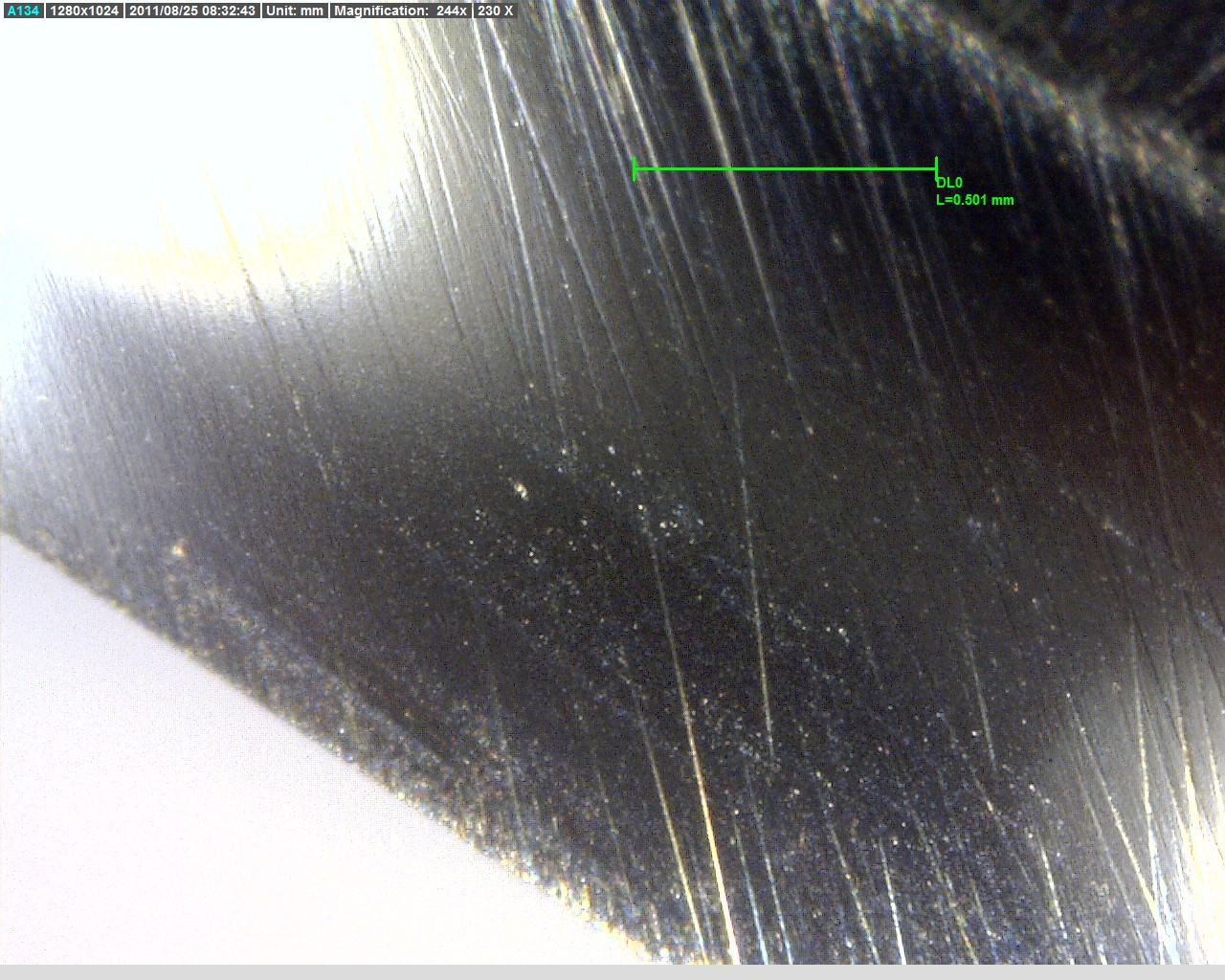

08/25/2011 at 7:46 am #155After the 5000# Shaptons, the edge is coming along beautifully:

5000# Shapton Stones – 230x

I went a little longer with the 5000# stones since the jump up from the 2000# stones was larger. The edge looks like a mirror to the naked eye at this point and it’s both polished and burnished. Due to the high polish, the microscope’s camera is starting to have a hard time focusing. I see this a lot with highly polished edges.Approximately 180 strokes per side. Elapsed time: 00:03:00

-Clay

08/25/2011 at 8:18 am #156Next step was the 8000# Shapton Stones. Some contamination, probably from my mounting plate, seems to have gotten onto the stones, digging some deeper grooves. All in all, the bevels look great and you can see the increasing polish from the finer stones:

I spent a little extra time on this stone trying to get the deeper scratches out. I’ll probably have to drop down a few grits to fully remove them.

Approximately 240 strokes per side. Elapsed time: 00:04:00-Clay

08/25/2011 at 11:55 am #157How is it possible for scratches that were there earlier to suddenly appear now as Tom suggested. If they were there in the first place, wouldn’t they have been visible earlier. Again I can’t understand…no doubt brain plaque setting in. 😆 To me I think there may have been some contamination as Clay suggested…but no big deal anyway.

Leo the dense

08/25/2011 at 9:16 pm #158Hmmm! As I drink my morning coffee the fog from last night clears. When I think of it, that knife has been through a lot of use and experimentation with various edges. It is quite possible that I inflicted some deep scratches on that blade early on, even before I got the WEPS. I suspect now that I am the culprit here, not contamination. It definitely was not done by the maker. I examined that blade when it arrived and it was pristine.

Good thinking Tom! Bad Leo! :silly:Leo

08/26/2011 at 12:20 am #162Good morning Leo 🙂

I took about 10 minutes to go back through the grits, starting at 1500# to remove the scratches. It was definitely some kind of contamination on the stone because I could clearly see the big scratches with the naked eye. Here is the knife at 8000# again after reworking it:

-Clay

08/26/2011 at 12:55 am #164And finally, the 15000# Shaptons stones:

-Clay

08/26/2011 at 12:57 am #165And finally, the 15000# Shaptons:

I spent a little more time with the 15k stones to try and ensure that we were only seeing the scratches from that grit.

Approximately 240 strokes per side. Elapsed time: 00:04:00Here is a shot (for Tom) with the blade slightly tilted so I could get a better focus on the edge:

-Clay

08/26/2011 at 3:44 am #16808/26/2011 at 5:44 am #172Yowsa. That’s an egde.

Will the recommendation be to buy all of the grits of the Shaptons (from 220# on up), or will they be able to be integrated as higher grits to the existing diamond and ceramic stones after 1600#. As an example, I might like to be able to add the 2000, 5000, 8000, 15000 shaptons (maybe in stages based on budget) and preserve my existing investment (from 50#-1000# on diamond and 1200# 1600# ceramic), but the switchover on angle due to the thicker Shaptons sounds tricky.

08/26/2011 at 5:54 am #173Yowsa. That’s an egde.

Will the recommendation be to buy all of the grits of the Shaptons (from 220# on up), or will they be able to be integrated as higher grits to the existing diamond and ceramic stones after 1600#. As an example, I might like to be able to add the 2000, 5000, 8000, 15000 shaptons (maybe in stages based on budget) and preserve my existing investment (from 50#-1000# on diamond and 1200# 1600# ceramic), but the switchover on angle due to the thicker Shaptons sounds tricky.

Your thinking on the progression is right – I’d probably stick with the existing diamonds and ceramics and then jump to the Shaptons at 2000#. The switch over shouldn’t be too tough, it’s an almost perfect 3 degree difference. I’ll try to do a knife soon with that progression and document the progress.

-Clay

08/26/2011 at 5:58 am #174Excellent results once again Clay. You do such meticulous work and at the same time are informative and clear. I wish I had had you on my teaching staff back when I was in the education business.

Will you continue with the PXL folder and the Choseras tomorrow?

Thanks very much Clay!Warm regards

Leo08/26/2011 at 6:01 am #175That sounds awesome, I can’t wait to see the stones. I really like the idea of stones up that fine, and a lot less strops.

Any idea if I was gonna refresh the wickededgeusa.com website looking for them what might be a good week to mark on my calendar? :whistle: 😉

My new Richmond Remedy is sitting at home right now with a factory edge. I can’t wait to see it and put it on the wicked edge. It might be number 2 in line though as I also got an S30V Spyderco Military delivered today also. It was a good day for my mailbox.

-

AuthorPosts

- You must be logged in to reply to this topic.