Strops or stones ?

Recent › Forums › Main Forum › Welcome Mat › Strops or stones ?

- This topic has 148 replies, 12 voices, and was last updated 01/05/2017 at 6:27 am by

Organic.

Organic.

-

AuthorPosts

-

03/18/2016 at 10:17 am #32146

If we are discussing how long it takes to remove the scratches from the prior grit, could you simply set up the edge in a cross hatch pattern? In other words, set up all your grind lines going one direction ////////// then go the opposite direction\\\\\\\\\\ w/ each subsequent stone while scrubbing and see how many strokes it takes?

I started doing just that yesterday. It was surprising how long it took to completely remove the scratches from the previous stones, especially the 1000# diamonds. I checked every 10 strokes and found that I had to go to 120 strokes with the SFC stones to remove the scratches from the diamonds. I was equally surprised at how long it took to remove the MFC scratches with the MFF stones, also over 100 strokes.

I kinda do what Josh suggested… although with each stone I go in both directions… I don’t go a specific direction with one stone, than switch with the next. Hadn’t really thought about ‘scrubbing’ first with the ceramics… don’t know why… good idea.

While I spend a bit more time on each level in testing than I might normally do in sharpening, I do try and balance time in some of this testing to try and show what is reasonable… I suppose that given enough time all the scratches might eventually come out, I try to get an idea of when I think the stone is no longer being particularly effective… in testing I might go a bit beyond that, before documenting what I think the results are.

03/18/2016 at 10:22 am #32148Clay… Just outta curiosity, what type of blade steel is that in your pics?

Unspecified “high carbon” steel, a.k.a. utility blade, Fat Max brand.

I was curious because in the pictures of the blades in the Bladeforums post I referenced… eKretz (the guy taking the pictures) shows little holes where he says the Vanadium? is being pulled out of the metal. I noticed something similar in your pictures, where it looks like something is being pulled out, and then scratches down the blade. Wondered what it could be.

03/18/2016 at 10:48 am #32150Clay… Just outta curiosity, what type of blade steel is that in your pics?

Unspecified “high carbon” steel, a.k.a. utility blade, Fat Max brand.

I was curious because in the pictures of the blades in the Bladeforums post I referenced… eKretz (the guy taking the pictures) shows little holes where he says the Vanadium? is being pulled out of the metal. I noticed something similar in your pictures, where it looks like something is being pulled out, and then scratches down the blade. Wondered what it could be.

I think Phil Pasteur and Anthony Yan also made the same comment on my photos a while back. It looks like some kind of particle or grain is ripped out and then dragged across the surface. I notice it most with the strops, especially once I’ve gotten the surface very smooth and I’m using the kangaroo strops with a fine spray.

-Clay

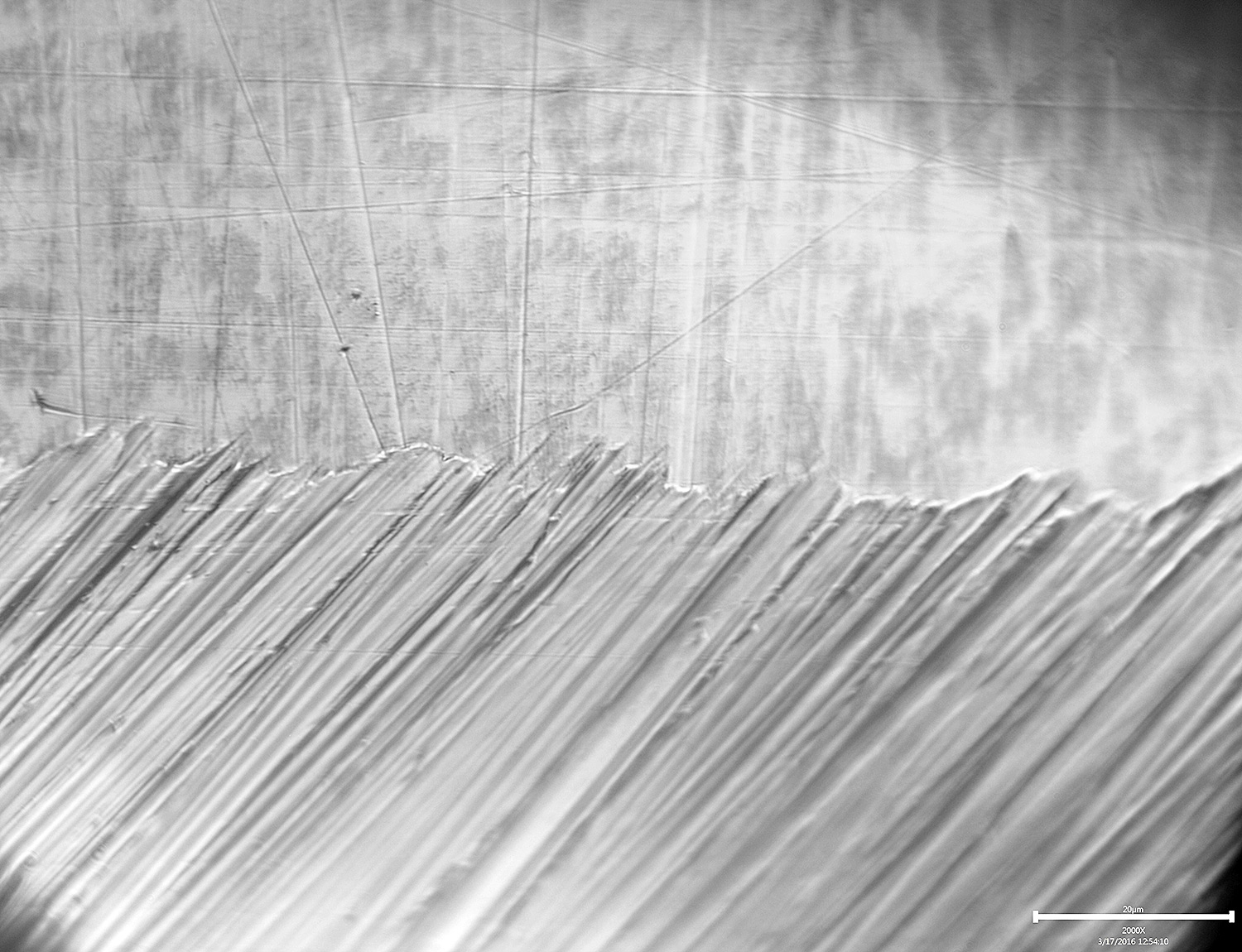

03/18/2016 at 11:23 am #32152Here is the new set with the following progression: 1000#> SFC> SFF> MFC> MFF utilizing a crosshatch pattern to ensure that the previous scratches were completely removed.

-Clay

Attachments:

You must be logged in to access attached files.

03/18/2016 at 11:24 am #3215703/18/2016 at 11:26 am #3216203/18/2016 at 11:27 am #3216703/18/2016 at 11:28 am #3217203/18/2016 at 11:36 am #32177Some of the things about technique that this study reinforced:

- Pressure really matters! Push a little harder and you get deeper scratches which can extend to the very edge and rip out chunks of the edge. This is true for all grits.

- How clean vs. loaded the ceramic stones are really matters. It was taking forever to remove all the scratches from the previous grits until I cleaned my stones with Barkkeeper’s Friend. Before I used that, I did a little cleaning with rubbing alcohol which definitely helped and sped up the scratch removal process.

- I want to compare the number of strokes that are needed to remove the 1000# scratches with the SF, MF and Diamond Lapping Films. I’m guessing that the lapping films are much faster.

- The crosshatch method is very effective for ensuring that you’ve removed the scratches from the previous stones but you really need a good, lighted loupe to take advantage of the technique.

-Clay

03/18/2016 at 12:24 pm #32180Looks good… of course now you have to go back and do the other scenario the same way hahaha…. I still want my way to “win”. (Kidding of course).

It’s interesting seeing whatever the particles are getting ripped out… that Bladeforums thread for some reason made me think about it more than in the past.

Thanks!

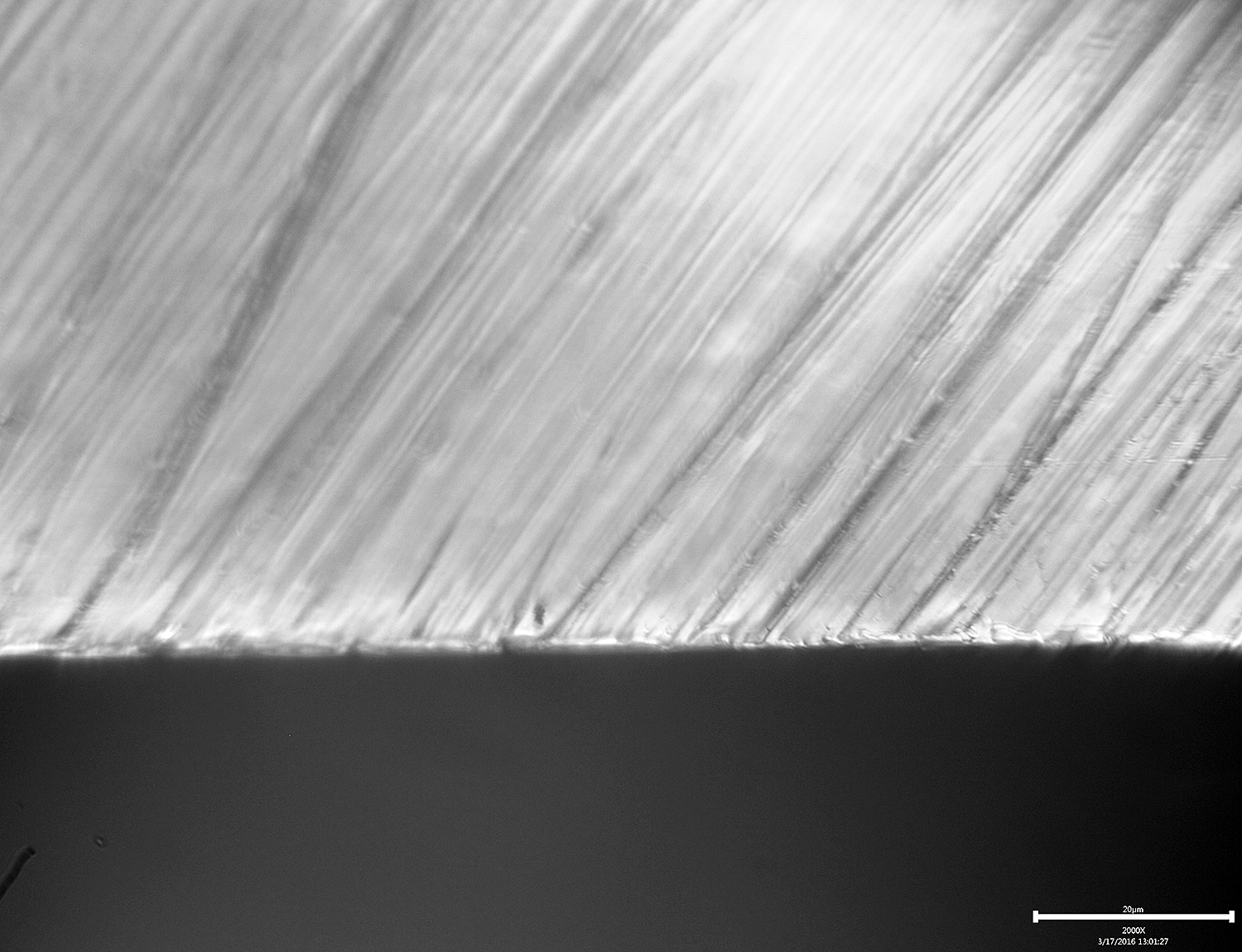

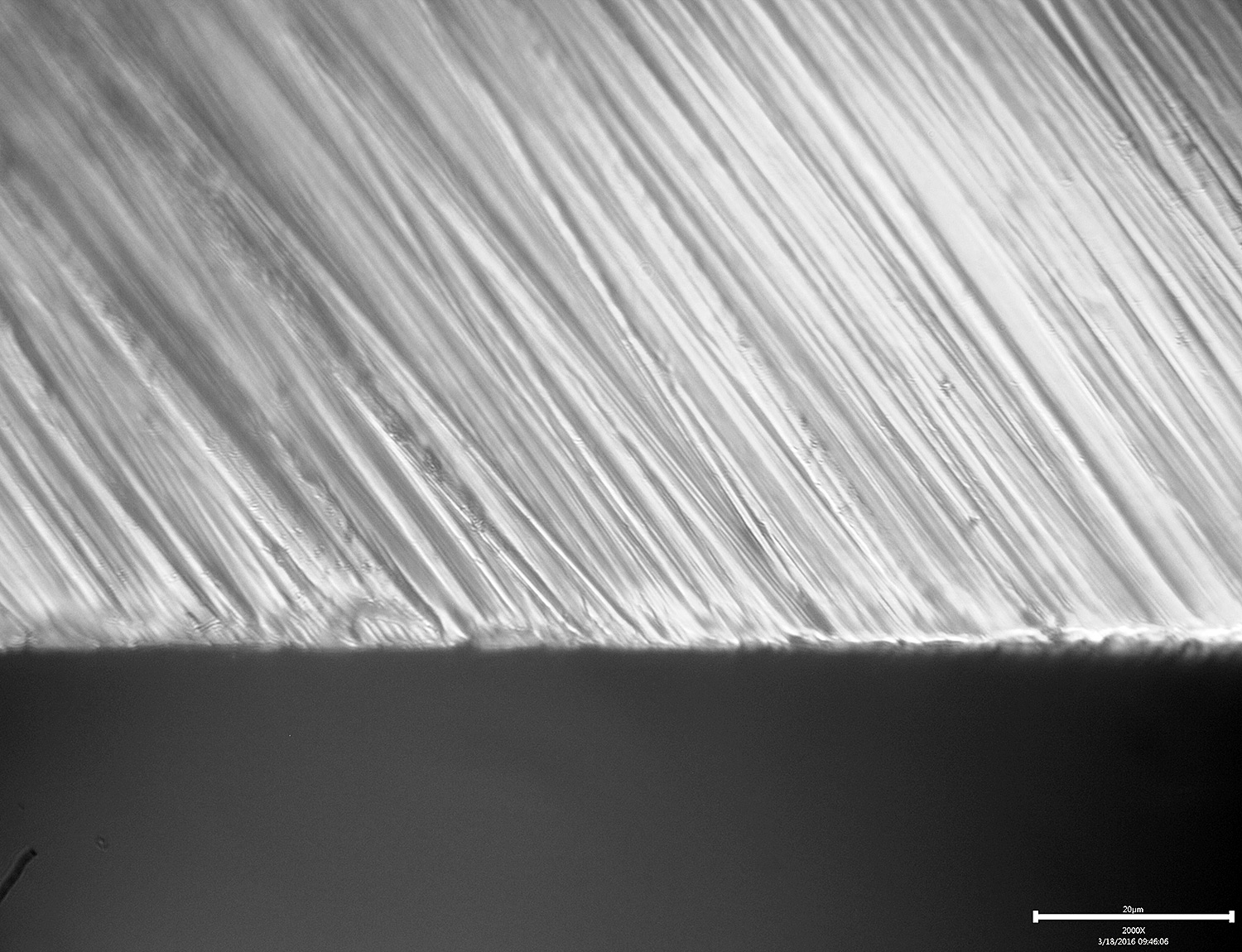

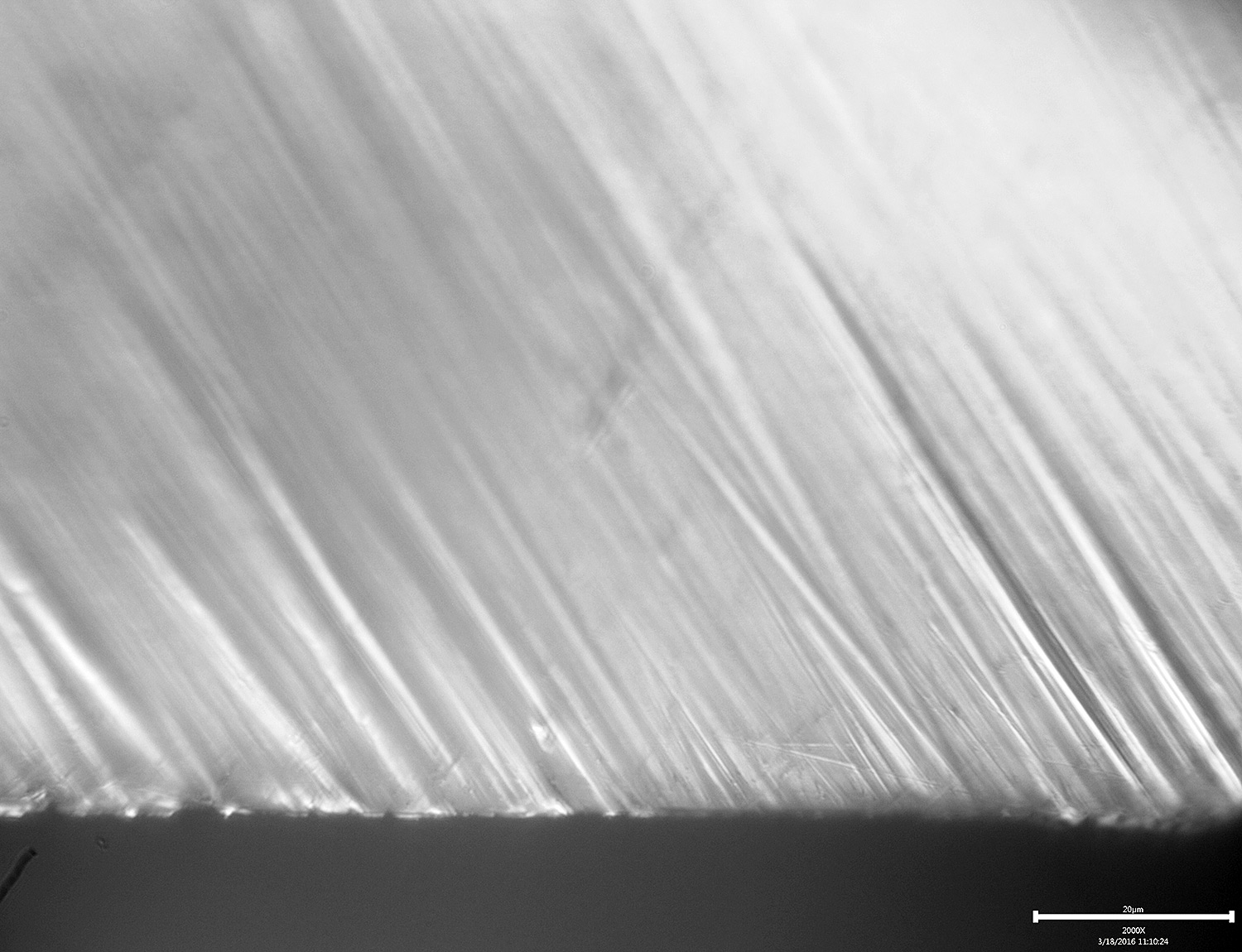

03/18/2016 at 12:52 pm #32185I put the bevel pictures in order so I could compare the scratches.

1000 grit:

SFC:

SFF:

MFC:

MFF:

I *think* this is the preferred order, but I’m still hesitating on some transitions. (Like MFC->MFF. On the other pics I was convinced the MFF were the finest stones, but here there scratches look wider, although maybe a bit shallower, than those of the MFC.) Curious what other people think.

Molecule Polishing: my blog about sharpening with the Wicked Edge

Attachments:

You must be logged in to access attached files.

03/18/2016 at 1:36 pm #32195And here are the final bevels of two progressions to compare:. May we have your votes, please?

1000->MFC->SFC->SFF-MFF:

1000->SFC->SFF->MFC->MFF:

Molecule Polishing: my blog about sharpening with the Wicked Edge

03/18/2016 at 1:39 pm #32197Some of the things about technique that this study reinforced:

- Pressure really matters! Push a little harder and you get deeper scratches which can extend to the very edge and rip out chunks of the edge. This is true for all grits.

- How clean vs. loaded the ceramic stones are really matters. It was taking forever to remove all the scratches from the previous grits until I cleaned my stones with Barkkeeper’s Friend. Before I used that, I did a little cleaning with rubbing alcohol which definitely helped and sped up the scratch removal process.

- I want to compare the number of strokes that are needed to remove the 1000# scratches with the SF, MF and Diamond Lapping Films. I’m guessing that the lapping films are much faster.

- The crosshatch method is very effective for ensuring that you’ve removed the scratches from the previous stones but you really need a good, lighted loupe to take advantage of the technique.

Those are very good tips for everyone, Clay, from beginner to experienced user. Did you also use edge-leading strokes only? (The pics are all have “leading” in their names.)

Maybe you could include one of the diamond stones in the “number of strokes for scratch removal” test (e.g., using 1000 to remove 800 scratches). That way we also get an impression of the efficiency of the diamond stones vs. ceramic stones.

Molecule Polishing: my blog about sharpening with the Wicked Edge

1 user thanked author for this post.

03/18/2016 at 2:06 pm #32199I’ll be honest, my vote now is what I said yesterday… I’m not sure it matters. In looking at the pictures Clay took today, it made me think that what I thought was leftover scratches from the diamond, is actually probably just what the ceramic stone is leaving behind. I’m actually not sure now why I thought the former… when I think about it now, it doesn’t make much sense. Brain going down the wrong track I reckon.

So, thinking of it this way, I guess the real question now, to me anyway, is what works better cleaning up after the ceramics, if your goal is to obtain a (or close to) a true mirror finish? That’s sorta where I was headed yesterday… what happens after the ceramics? If there is a difference in the ceramci progression, how it looks after the next step (after ceramics) is where it might matter more. I think it’s safe to say the ceramics are a good step before the leather strops (or diamond film)… or go the route Josh did, and switch to all diamond stones and strops.

Anyway… that’s my vote.

03/18/2016 at 2:53 pm #32201And here are the final bevels of two progressions to compare:. May we have your votes, please?

1000->MFC->SFC->SFF-MFF:

1000->SFC->SFF->MFC->MFF:

Isn’t it if you make enough strokes, you should get the same results either way? IMHO they do look the same. The question should be – which way is faster to get there? I still would try to evaluate each stone like this https://knife.wickededgeusa.com/forums/topic/strops-or-stones/page/5/#post-32123 . There is a possibility that some stones work the same, so some stone (or two) can be skipped.

-

AuthorPosts

- You must be logged in to reply to this topic.