Strops or stones ?

Recent › Forums › Main Forum › Welcome Mat › Strops or stones ?

- This topic has 148 replies, 12 voices, and was last updated 01/05/2017 at 6:27 am by

Organic.

Organic.

-

AuthorPosts

-

03/10/2016 at 4:02 pm #31864

Is it OK to use stones instead of strops? After 1000 grit stones Wicked Edge has

Super Fine 1200 / 1600 Grit Ceramic Stones (15/11 micron), then

3 micron Diamond Stone (8,000 grit), then

Micro Fine Ceramic Stones 1.4 micron/.6 micron (13,000/50,000 grit).

Is it possible to get a mirror edge with just stones?

Attachments:

You must be logged in to access attached files.

03/11/2016 at 12:31 am #31867Welcome to the forum. I can only say from personal results thats an edge approaching “true” mirror was difficult with just stones. Even the micro-fine ceramics will leave some visible scratches.

Lapping films in progression are one affordable way to get there or others have done stropping progressions with same results.

As far as stropping I personally try to minimize its use(subject to change) but do feel strops can make for a keener cutting edge and always use strops for a final finishing touch. The difference is noticeably sharper no matter what grit I stopped at.

Half the fun is playing around and finding what works and doesnt. I remember clearly getting to 1000 grit and going “now what?”. Today I could use stones, films, or strops…or a combination of both.

03/11/2016 at 2:06 am #31869

03/11/2016 at 2:06 am #31869Welcome to the forum! I agree with Cliff: playing around is half the fun. Stones and strops do work differently, but surely you can use stones only.

If you want a true mirror edge, my experience is that I get them with 5K/10K Chosera stones. The ceramic stones produce some sort of semi-mirror edge. Also, be a bit cautious when interpreting the grit ratings for the DMT diamond stone and the micro fine ceramics. My experience is that the “rough” micro fine ceramic stone better fits in between the 1000 grit diamond stones and the 1200 ceramics and that the “fine” microfine stone fits in a progression after the 1600 ceramics.

And, as Cliff says: the diamond films work great!

Molecule Polishing: my blog about sharpening with the Wicked Edge

03/11/2016 at 7:10 am #31871You can also use fine grit automotive sandpaper, 2000g and higher to achieve a higher level finish…. attach it to a fine stone or blank with removable double sided scotch tape.

03/11/2016 at 8:07 am #31872Thank you very much for clearing this for me.

Will it be better to avoid any ceramics and use diamond lapping films instead of ceramics? What is better next step after 1000 grit – 1200/1600 ceramic or 12 micron diamond film or else?

Very good to know that grits/microns are different on diamonds, ceramics and strops. Mark76, could you please elaborate again on micro-fine 1.4 micron/.6 micron ceramic stone? I didn’t understand where exactly it fits.

03/11/2016 at 8:20 am #31873Dulledge, it’s very hard, if not impossible, to give a grit rating to this type of ceramic stones. For a bit of background info: moleculepolishing.wordpress.com/2013/08/08/the-mystery-of-the-spyderco-and-the-wicked-edge-ceramic-stones/

The ceramic stones work very well, just a little slower than the diamond stones or films. No need to avoid them.

My usual progression starting from zero is: diamond stones (100-1000) – coarse micro-fine ceramics (“1.4”) – 1200 ceramics – 1600 ceramics – fine micro-fine ceramics (“0.6”).

Hope this helps.

Molecule Polishing: my blog about sharpening with the Wicked Edge

3 users thanked author for this post.

03/11/2016 at 8:52 am #31874Mark76, WOW! Very interesting information! Thank you! Description of WickedEdgeUSA.com for “Micro Fine Ceramic Stone” is pretty misleading then. They should remove ” 1.4 micron/.6 micron” rating and explain how this stone should be used. For now they state that Micro Fine is “one step past our Super Fine Ceramic Stones”, which is not quite exactly like that.

03/11/2016 at 11:11 am #31876You may be right, but everywhere you see people trying to give a grit rating to these stones, since that is their frame of reference. See for example this chart, which also tries to give a grit rating to the Spyderco stones: https://docs.google.com/spreadsheets/d/1VaTf3MXuwuvH-QLwOci4f9B9Zhkbuu1wjoSCZIUsR-o/edit#gid=0

And eventually the progression you prefer is subjective. As Cliff said: half the fun is playing around and finding what works and doesn’t.

(And, to continue on that theme, there are little people who know that the grit rating system used may vary by manufacturer. It’s not just that a different system is used for sandpaper than for whetstones, but even Naniwa and Shapton – maybe the best known suppliers of synthetic Japanese whetstones – use different rating systems.)

Molecule Polishing: my blog about sharpening with the Wicked Edge

03/11/2016 at 12:30 pm #31878Mark76, WOW! Very interesting information! Thank you! Description of WickedEdgeUSA.com for “Micro Fine Ceramic Stone” is pretty misleading then. They should remove ” 1.4 micron/.6 micron” rating and explain how this stone should be used. For now they state that Micro Fine is “one step past our Super Fine Ceramic Stones”, which is not quite exactly like that.

Thank you dulledge for bringing it up (and sending me on a day long investigation!

) Mark is right that there are so many grit scales out there and they don’t all line up well. A lot of smart people have put a lot of time into trying to come up with a unified chart with good, but incomplete success. Of course it would be easiest of everyone would just agree to grade particles by micron and that would work for most things except sintered ceramics like the ones we use. Because of that, the best thing would be for someone to create perfectly polished samples and then run a given grit over it and measure the scratch sizes in an SEM. It would be important to measure the width and the depth of the scratches. At that point, I think we’d have a way to compare all the abrasives out there in an apples-to-apples environment. In the meantime, your comments got me started back up on a project I began a long time ago. In a moment, I’ll post some images from my microscope. In the meantime, the reason I put both of the Superfine stones before the Micro-Fine stones in my progressions (and on our site) is because the Superfine stones are much softer and abrade metal more aggressively than the Micro-Fine stones.

) Mark is right that there are so many grit scales out there and they don’t all line up well. A lot of smart people have put a lot of time into trying to come up with a unified chart with good, but incomplete success. Of course it would be easiest of everyone would just agree to grade particles by micron and that would work for most things except sintered ceramics like the ones we use. Because of that, the best thing would be for someone to create perfectly polished samples and then run a given grit over it and measure the scratch sizes in an SEM. It would be important to measure the width and the depth of the scratches. At that point, I think we’d have a way to compare all the abrasives out there in an apples-to-apples environment. In the meantime, your comments got me started back up on a project I began a long time ago. In a moment, I’ll post some images from my microscope. In the meantime, the reason I put both of the Superfine stones before the Micro-Fine stones in my progressions (and on our site) is because the Superfine stones are much softer and abrade metal more aggressively than the Micro-Fine stones.-Clay

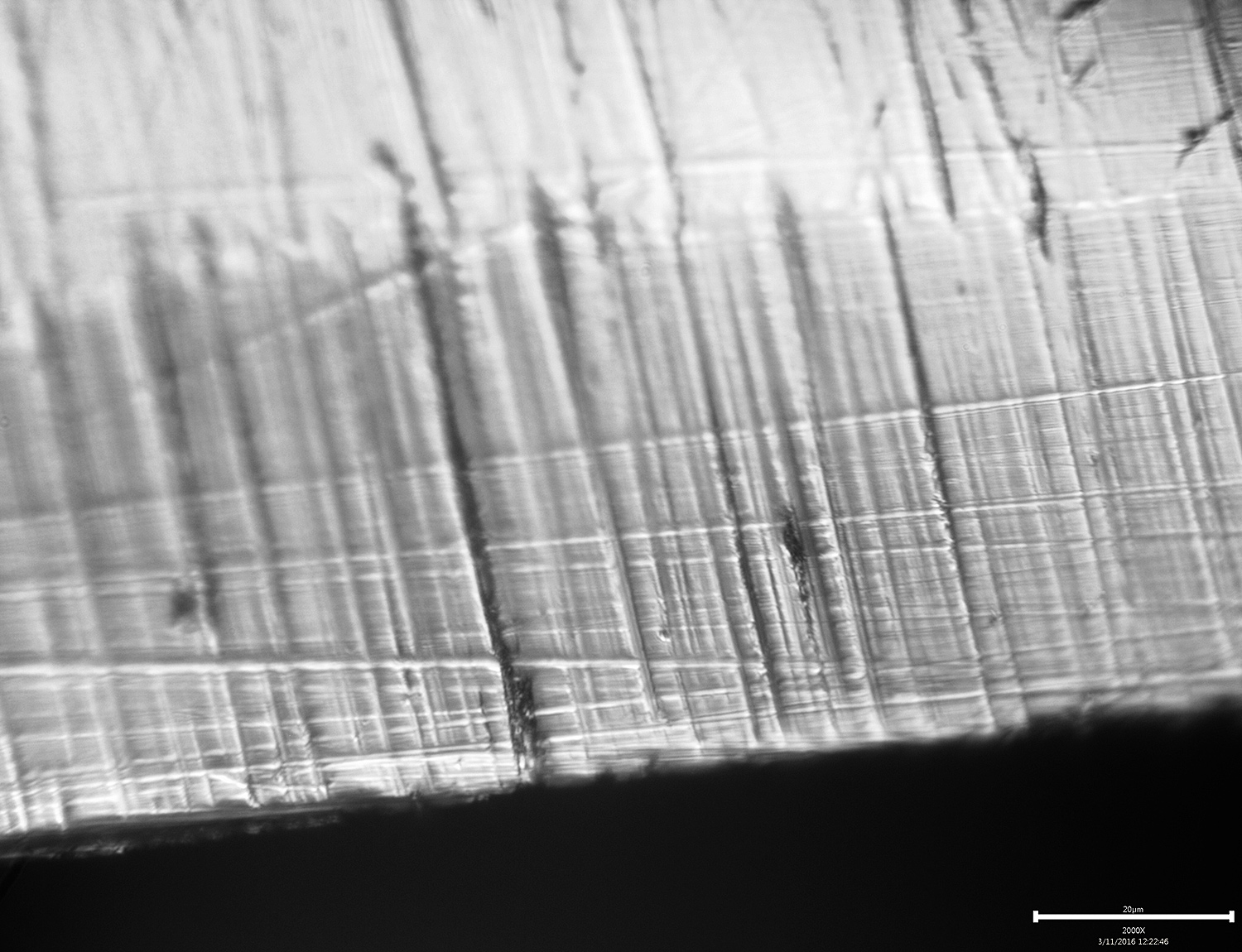

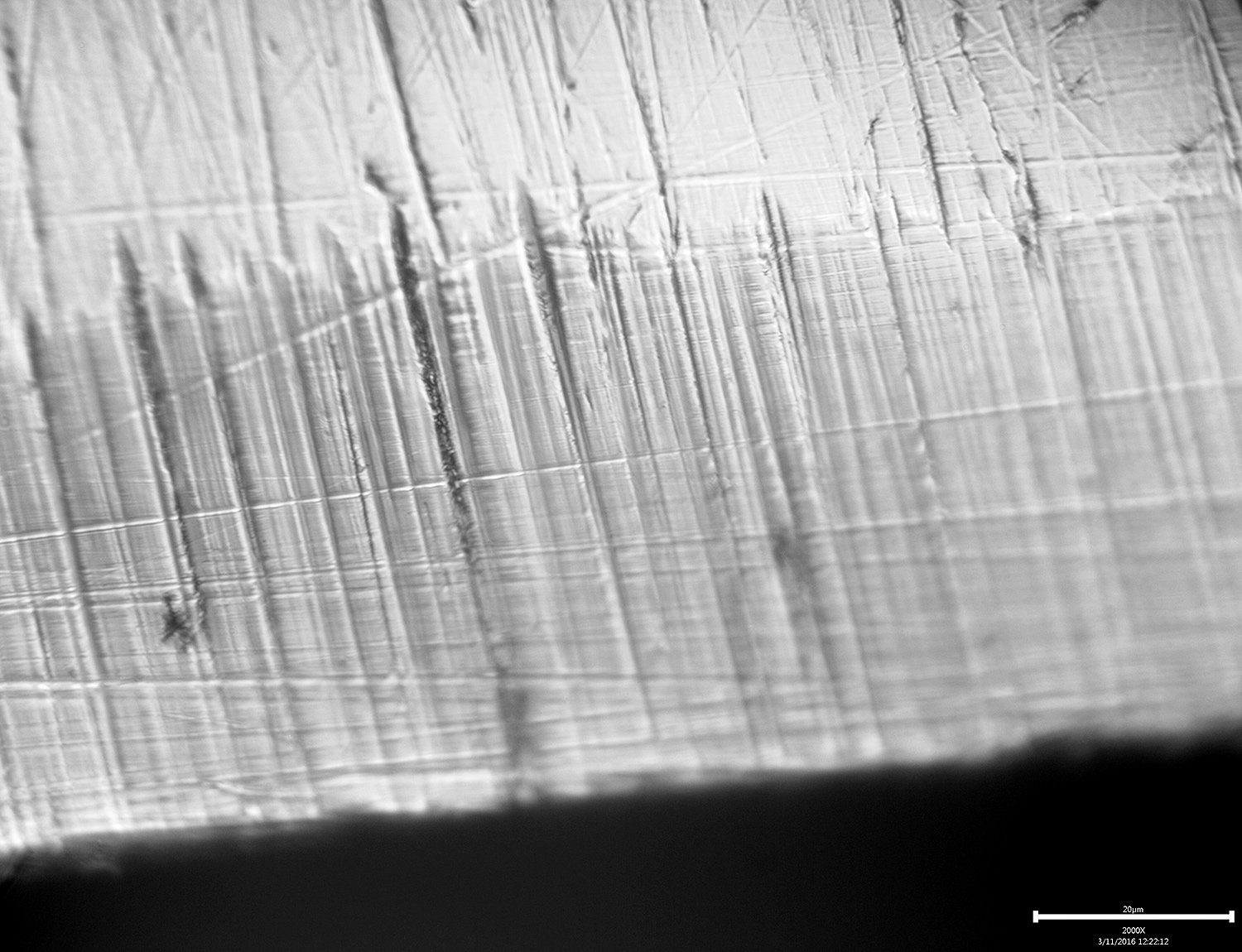

03/11/2016 at 12:40 pm #31879Okay, now the pics… These are at 2000x. I went pretty quickly, so they’re not my best work, but I think they still show the differences in stones pretty well. First I created bevel at 15° and polished it to an acceptable level. It’s messy looking but actually pretty clean. I didn’t have any kangaroo strops in my office to make it perfect, I’ll save that for another day. Then I divided the blade into two sections and created microbevels with both the Micro-Fine Coarse and the Superfine Fine stones at 20°. Here are two images of the microbevel created with the Superfine stones:

The above images have are the same area, one is focused at the edge and the other at the shoulder of the microbevel.

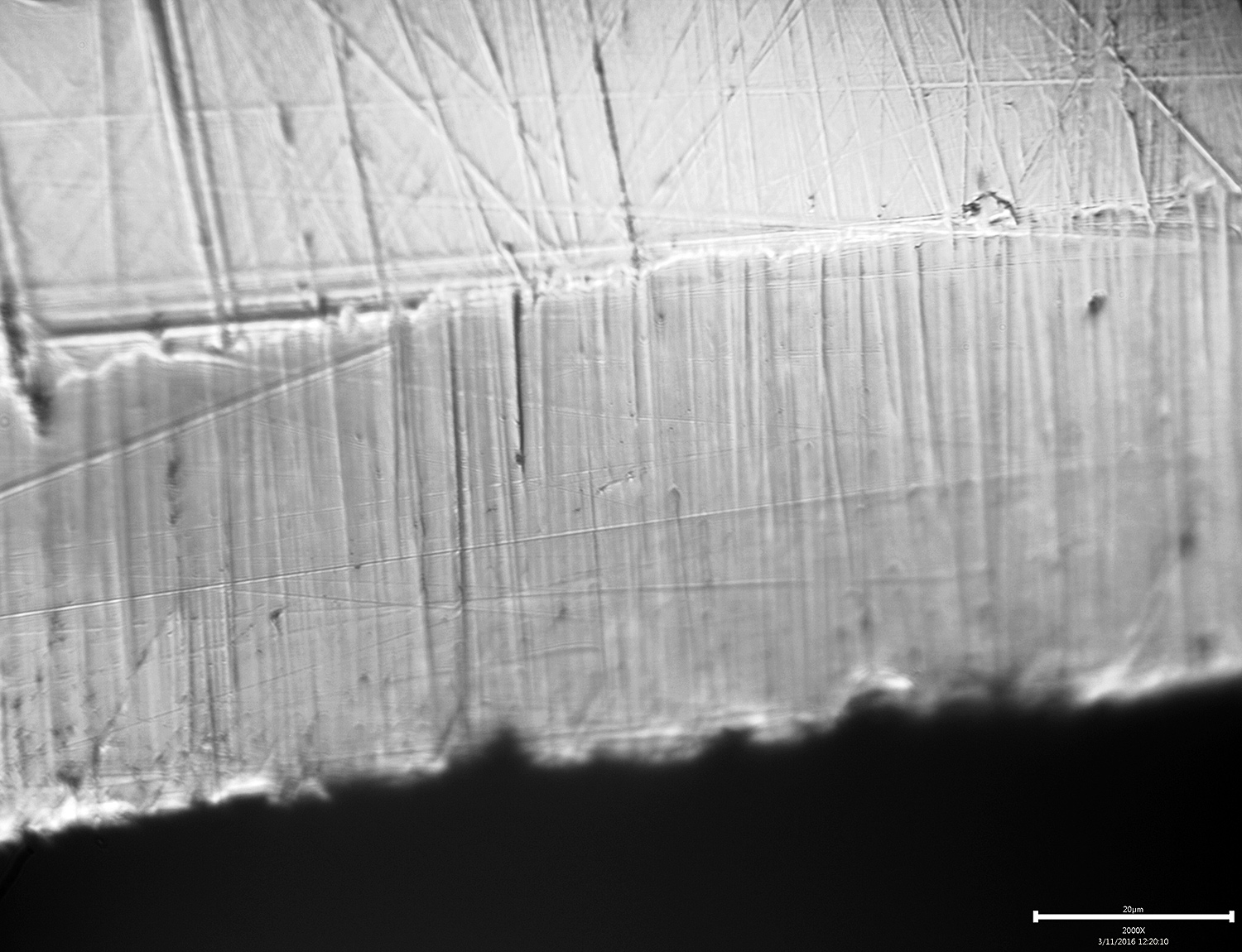

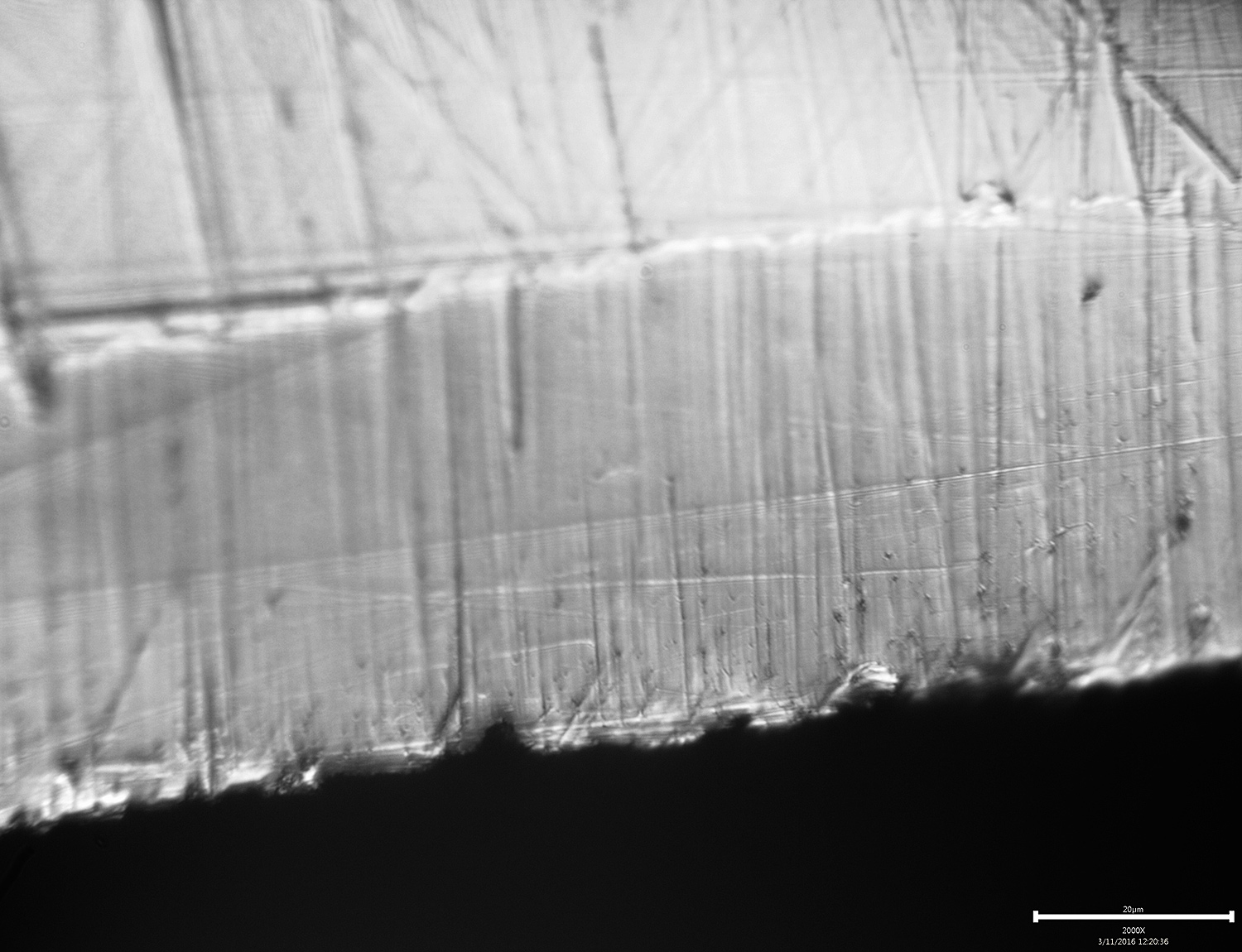

Here is the microbevel created by the Micro-Fine Coarse stones:

It’s interesting to me that the scratch pattern of the Superfine stones is clearly rougher but the edge is cleaner than that of the Micro-Fine Coarse stones. I believe it’s because the Micro-Fine stones are so much harder than the Superfine stones.

-Clay

Attachments:

You must be logged in to access attached files.

03/11/2016 at 1:49 pm #31885Interesting, Clay. I may have to reconsider my opinion on the micro fine ceramics. My “problem” in this is that I still have the old 1200/1600 stones. These are pretty hard. I’ve never experienced the softness (and dust?) some ppl report on the current 1200/ 1600 stones: I have no experience with these latter stones.

Molecule Polishing: my blog about sharpening with the Wicked Edge

03/11/2016 at 2:06 pm #31886Everytime one of these threads comes up, I always have to go experiment a bit. So I sharpened a knife thru the diamonds to 1000g, then I did the right side of the knife with the coarse MicroFine –> 1200g ceramic –> 1600g ceramic –> fine MicroFine. The left side I did with 1200g –> 1600g ceramics then the coarse–> fine MicroFines. To me the right side still comes out more polished. I happened to see a neighbor standing outside so I walked over and asked him if one side looks more shiny than the other. (He doesn’t know anything about the stones). He also picked the right side.

The fine MicroFine is obviously the finest of the bunch, so if you only wanted one set of stones, the MicroFines would probably be the ones to pick.

Another point to consider… not sure it’s been talked about much here, but that is the steel type. This thread on Bladeforums has been talking about stropping wear resistant steels… and the fact that when you get to finer stones and stropping… you pretty much need cbn or diamond to effectively polish the blade. The ceramics will still sharpen and polish to a degree… but the finish will look a bit hazy (my initial finding and not with the WE stones). So some of this may depend on what steel you’re sharpening, and the results you want… especially if you’re going for looks.

Maybe Josh or Clay can chime in on this, since they’ve probably done more variety in this area… especially different steel types? See any difference between ceramics and diamonds in this regard?

4 users thanked author for this post.

03/11/2016 at 3:52 pm #31888Everytime one of these threads comes up, I always have to go experiment a bit. So I sharpened a knife thru the diamonds to 1000g, then I did the right side of the knife with the coarse MicroFine –> 1200g ceramic –> 1600g ceramic –> fine MicroFine. The left side I did with 1200g –> 1600g ceramics then the coarse–> fine MicroFines. To me the right side still comes out more polished. I happened to see a neighbor standing outside so I walked over and asked him if one side looks more shiny than the other. (He doesn’t know anything about the stones). He also picked the right side. The fine MicroFine is obviously the finest of the bunch, so if you only wanted one set of stones, the MicroFines would probably be the ones to pick. Another point to consider… not sure it’s been talked about much here, but that is the steel type. This thread on Bladeforums has been talking about stropping wear resistant steels… and the fact that when you get to finer stones and stropping… you pretty much need cbn or diamond to effectively polish the blade. The ceramics will still sharpen and polish to a degree… but the finish will look a bit hazy (my initial finding and not with the WE stones). So some of this may depend on what steel you’re sharpening, and the results you want… especially if you’re going for looks. Maybe Josh or Clay can chime in on this, since they’ve probably done more variety in this area… especially different steel types? See any difference between ceramics and diamonds in this regard?

I wish I could comment Curtis but I only had the 1200/1600 grit ceramics (guess that’s the super fines now) about 3-4 years ago and did away with them when I went to choseras (no need to have both). Have never went back since! I love diamonds in all capacity as they work very quickly and effectively.

03/11/2016 at 4:20 pm #31889Josh, which choseras do you use between [1000 grit diamonds] and [strops]? When do you start stropping? At which strop size?

03/11/2016 at 5:27 pm #31890Josh, which choseras do you use between [1000 grit diamonds] and [strops]? When do you start stropping? At which strop size?

Well I actually sold my set of choseras in favor of lapping films, hehe, but When I had them I went from 1k diamonds to 800->2k->5k->10k choseras then it doesn’t take much stropping =) you will do just fine w/ the 3.5/5um strops after this type of progression.

But if I were starting out I would do what was recommended above… use automotive sandpaper taped to your ceramic or 1k diamond paddles and progress up… it’s cheap and effective.

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.