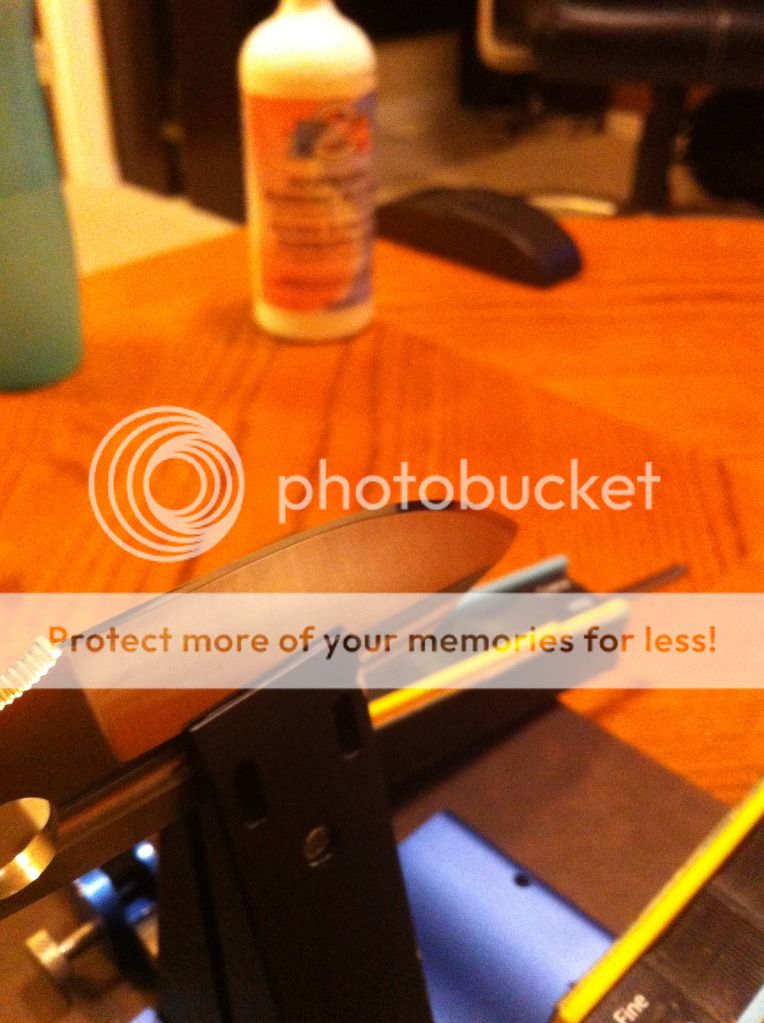

I was able to get a positive clamp on my new Tuff using some foam tape in a fairly wide strip. Bottom holes and B depth.

The tape seems to fill in the fuller and give a tight clamp. Similar to but even more firm than using this technique on full flat ground Spydies.

The blade is very stout at the tip, so I did end up with a pretty wide bevel up there. I guess you could try moving the blade down a bit towards the tip. The factory grind had an even bevel all the way so it must have been very obtuse at the tip because there really isn’t any distal taper. I had to remove a fair amount to get it sharpened at 20 degrees all the way.

I might have been better off at A.5, but the point drops so the clamping was going to get more challenging the closer to the tip I got. A.75 would have been nice, but I would have to mark my depth gauge for that.